Apparatus and method for cleaning painting machine and recycling paint

A paint recycling and coating technology, which is applied in the device, coating, cleaning device and other directions of coating liquid on the surface, which can solve the problems of obstruction and imperfect paint recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

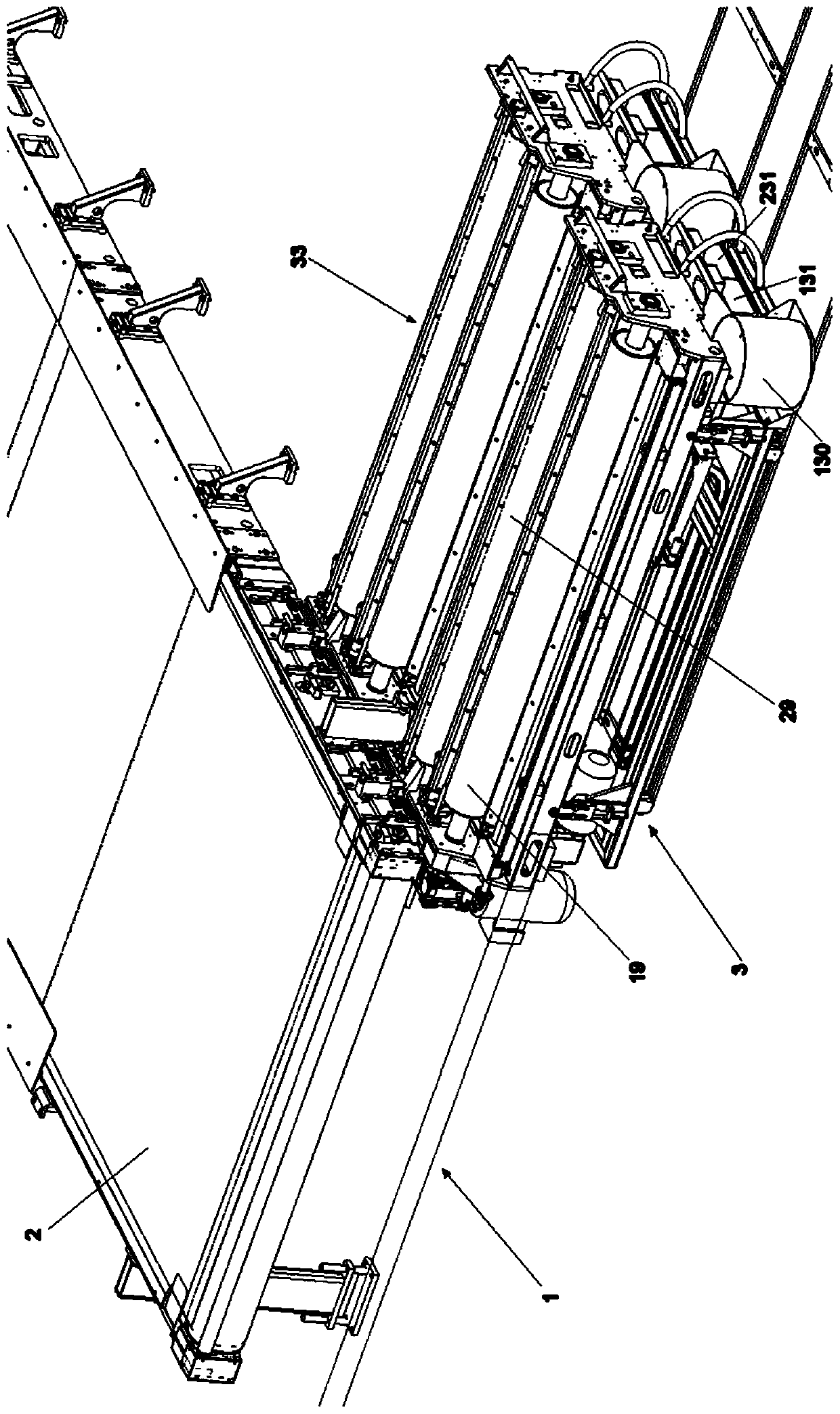

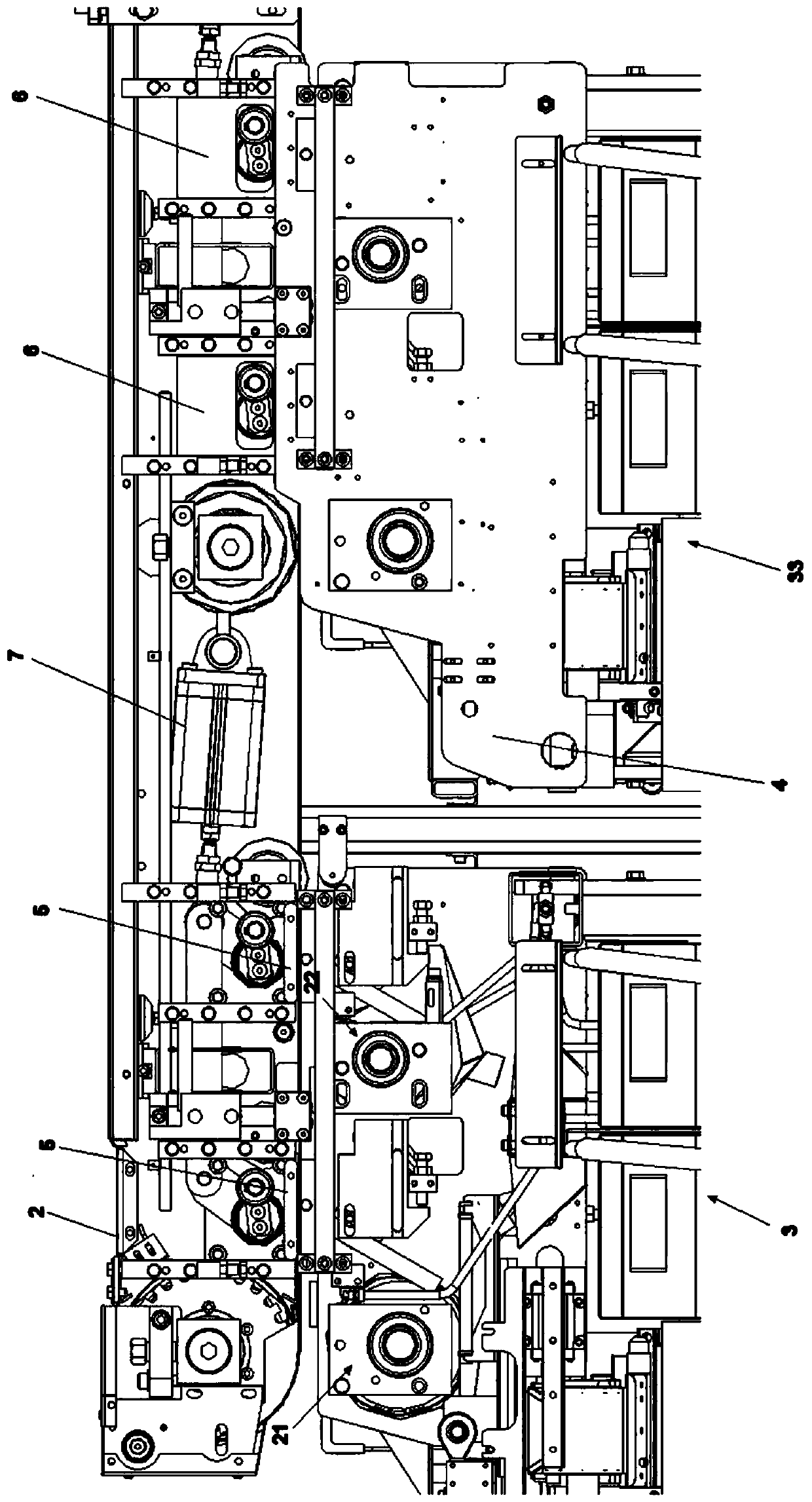

[0031] figure 1 A preferred embodiment is shown in which, according to the invention, a device 1 for applying paint, comprising a conveyor belt 2 for the parts to be painted (not shown), is provided with two paint recovery and cleaning trolleys 3, 33 . exist figure 1 The trolleys 3, 33 are shown in the sideways withdrawn position, and for paint recovery and cleaning, the trolleys 3, 33 have to be shifted under the conveyor belt 2 until they are perfectly aligned with the conveyor belt itself.

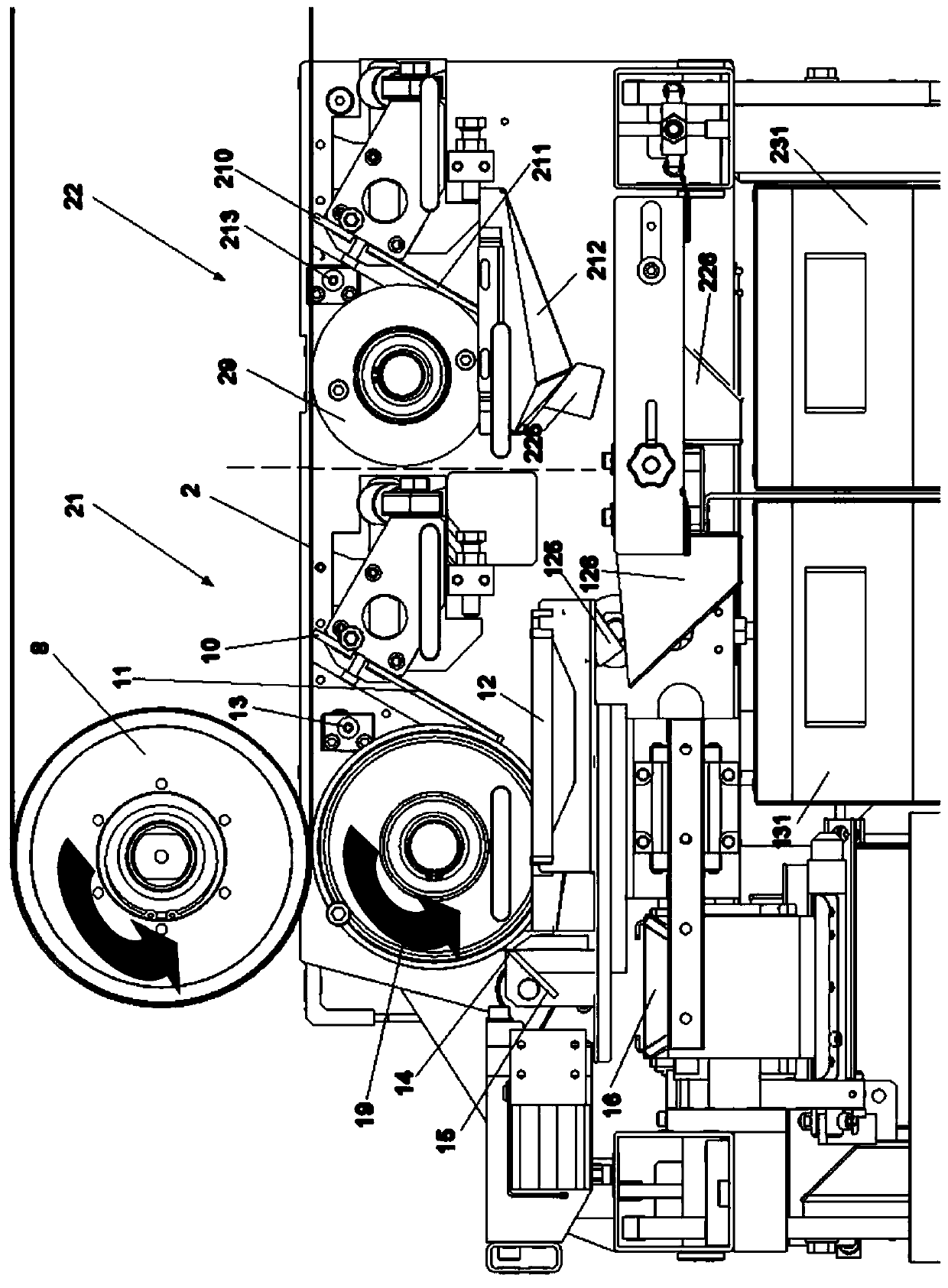

[0032] The conveyor belt 2 of the parts to be painted is usually a closed belt moved by two rollers, one of which is powered (not shown) and the other is an idler roller 8 (visible in figure 2 and image 3 middle). Said solution is well known in the art and provides an upper outward part of the belt on which the piece to be painted is located, and a lower return part (see figure 2 and image 3 middle).

[0033] In use, paint is applied to the parts to be painted, which undesira...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap