Development method for realizing advanced water injection and early water injection by utilizing horizontal well

A technology for horizontal wells and operation methods, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as water injection difficulties, and achieve the effects of overcoming water injection difficulties, delaying decline rate, and improving development benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

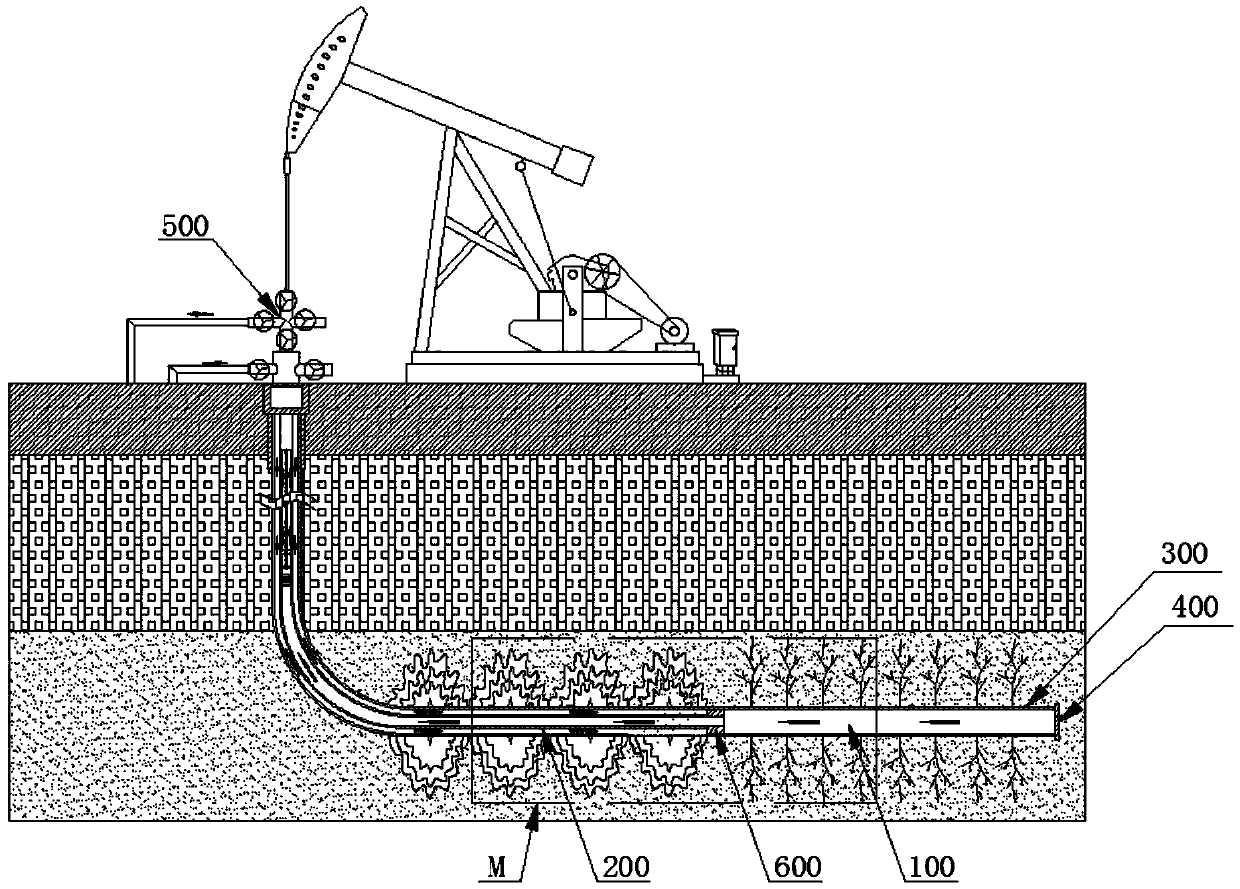

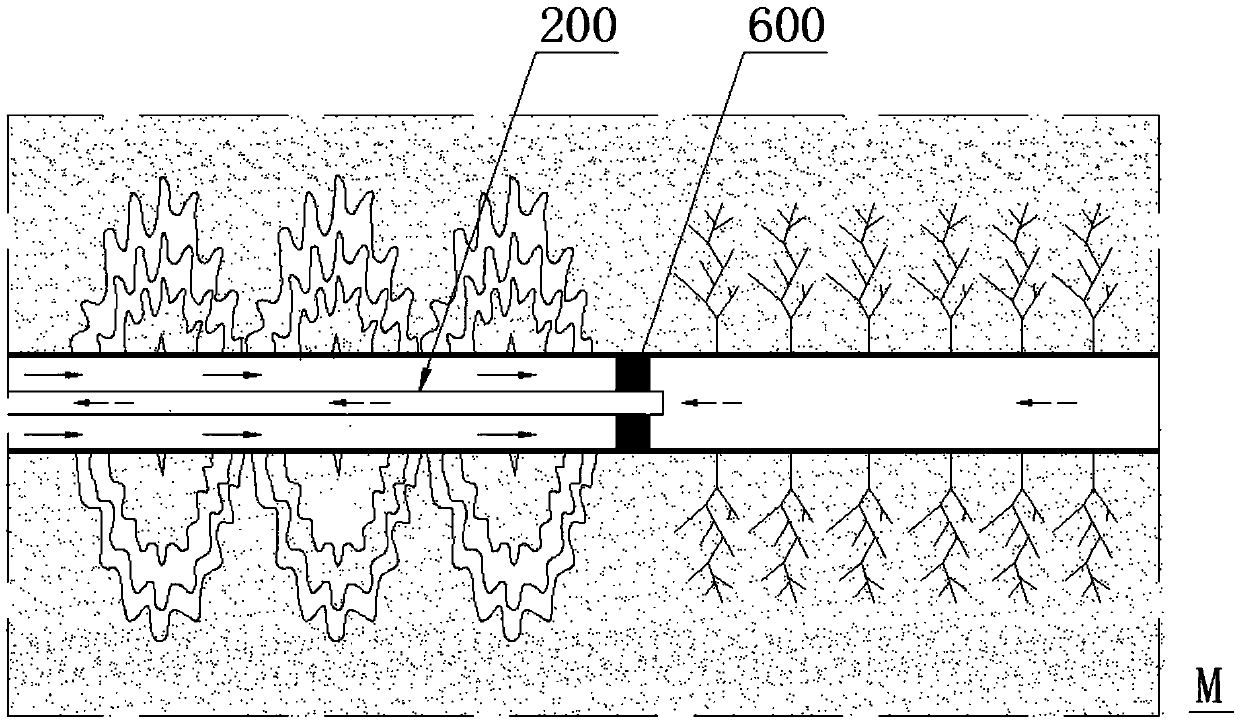

[0054] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, below in conjunction with the accompanying drawings and specific embodiments, further elaborate how the present invention is implemented.

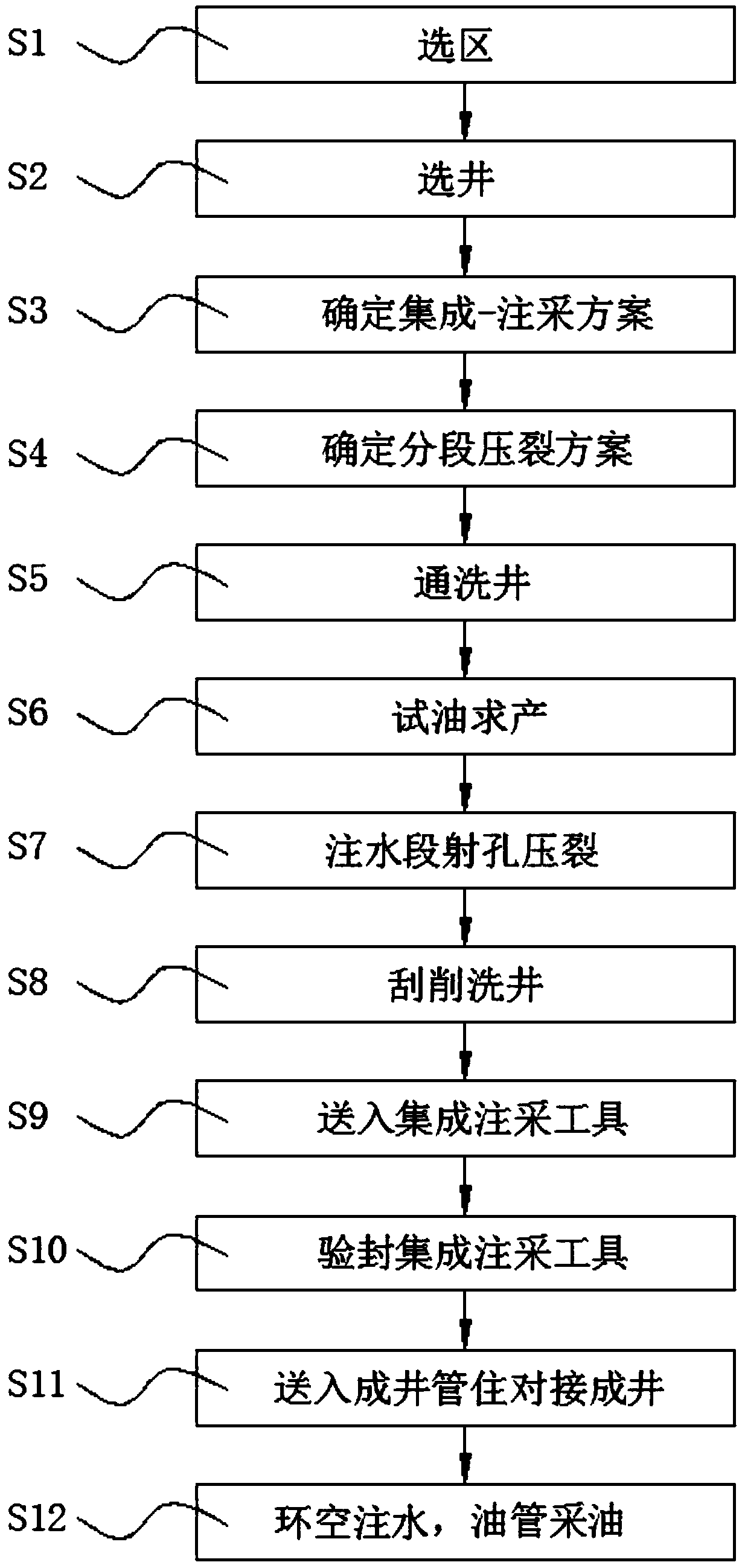

[0055] refer to figure 1 As shown, a kind of development method utilizing horizontal well to realize advanced water injection and early water injection provided by the present invention, it specifically comprises the following steps:

[0056] S1. Constituent area: select the restricted area for water injection construction;

[0057] S2, well selection: in the selection area of step S1, select a horizontal well with a horizontal section length ≥ 800m;

[0058] S3. Determine the integration-injection-production scheme: According to the area selected in step S1 and the well pattern characteristics of the horizontal wells selected in step S2, the integration-injection-production scheme is determined. The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com