On-line monitoring system and method for filling body deformation based on fiber Bragg grating sensing

A fiber grating and monitoring system technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as the inability to realize filling body monitoring, achieve the effect of avoiding electromagnetic interference and improving monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

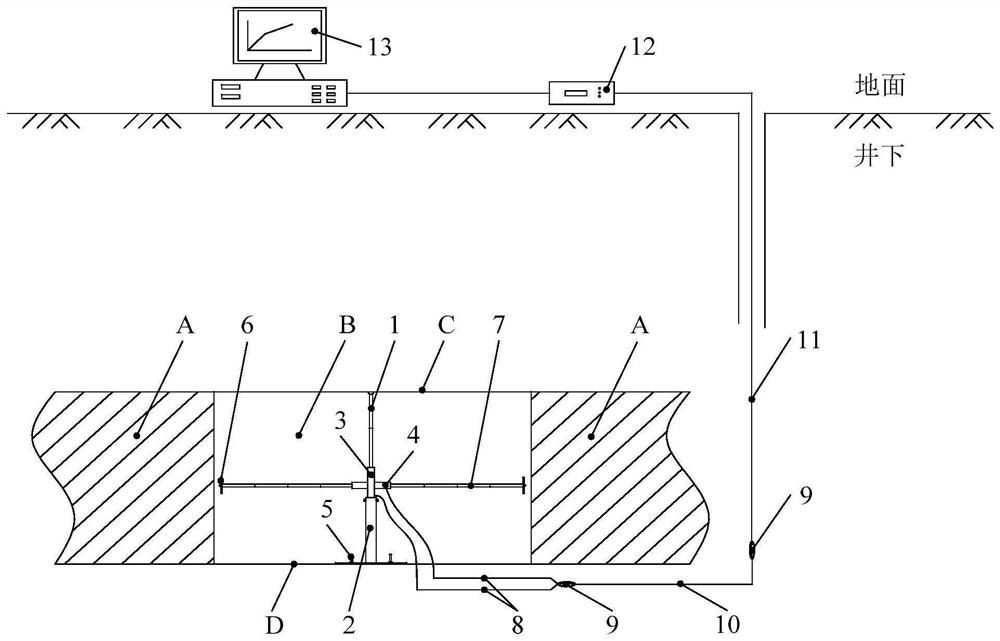

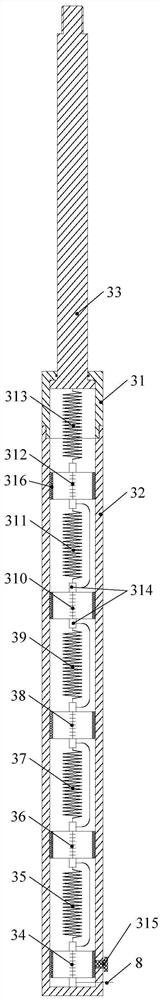

[0047] The present invention proposes an online monitoring system and monitoring method for filling body deformation based on fiber grating sensing. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific embodiments.

[0048] Such as figure 1 As shown, the present invention is an online monitoring system for filling body deformation based on fiber Bragg grating sensing, including an extension part, a fixing device, a filling body lateral displacement measuring device 4 based on fiber Bragg grating sensing, and a filling body vertical displacement measuring device based on fiber Bragg grating sensing. Axial displacement measuring device 3, steel pipe 7, extension wire 14, baffle plate 6, coupler 9, optical fiber 10, optical fiber connector 8, mine optical cable 11, fiber grating demodulator 12 and computer system 13.

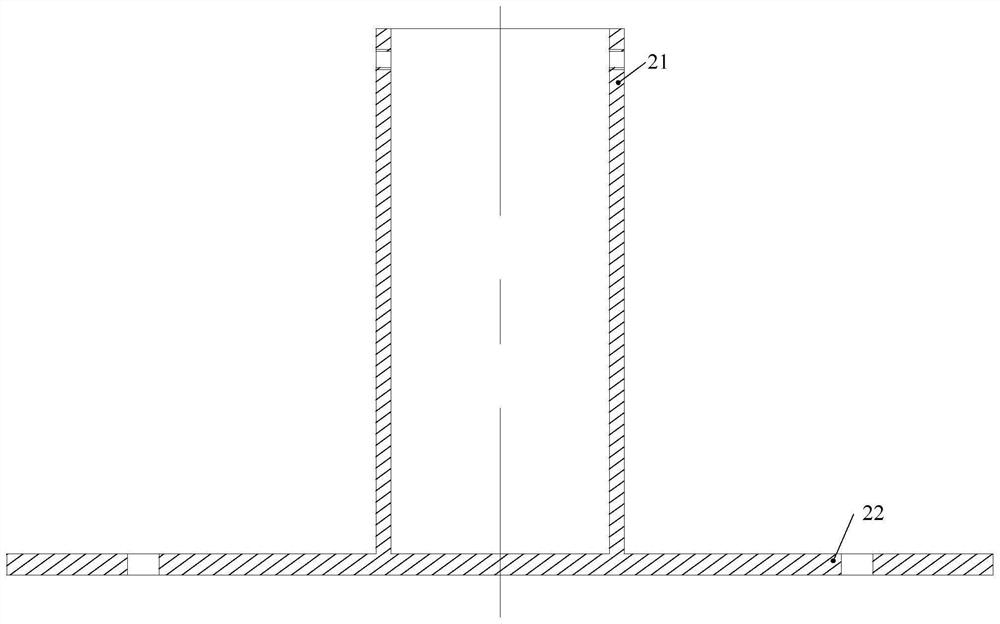

[0049] On both sides of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com