Online monitoring system and method of transverse deformation of filling body

A technology of lateral deformation and monitoring system, applied in the direction of measuring devices, instruments, etc., can solve the problem of inability to monitor the filling body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

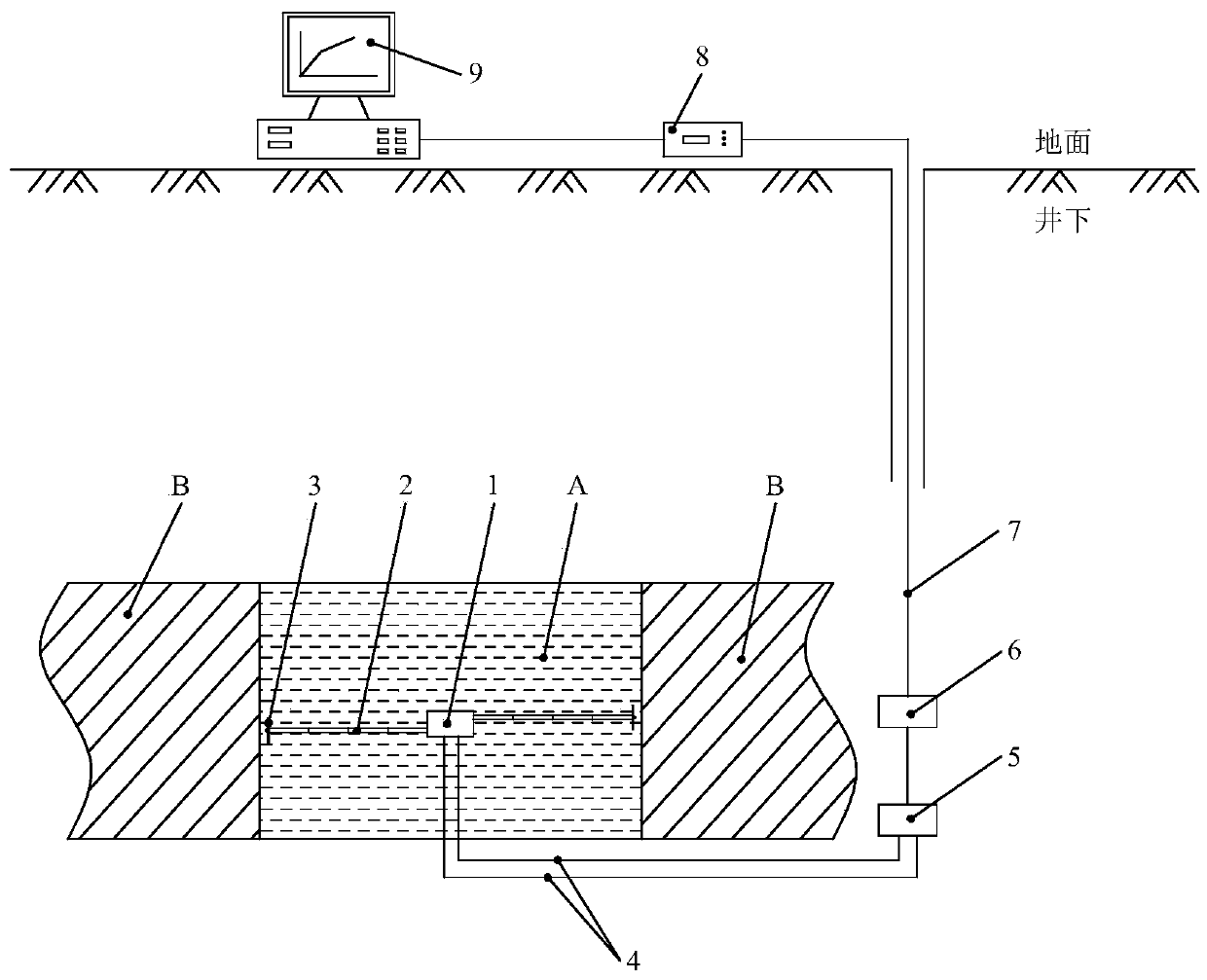

[0052] An online monitoring system for lateral deformation of a filling body, comprising a two-way displacement measuring device 1, a fixed plate 3, a data transmission line 4, a communication substation 5, a communication master station 6, a telephone line (Ethernet) 7, a ground data acquisition instrument 8 and a computer system9.

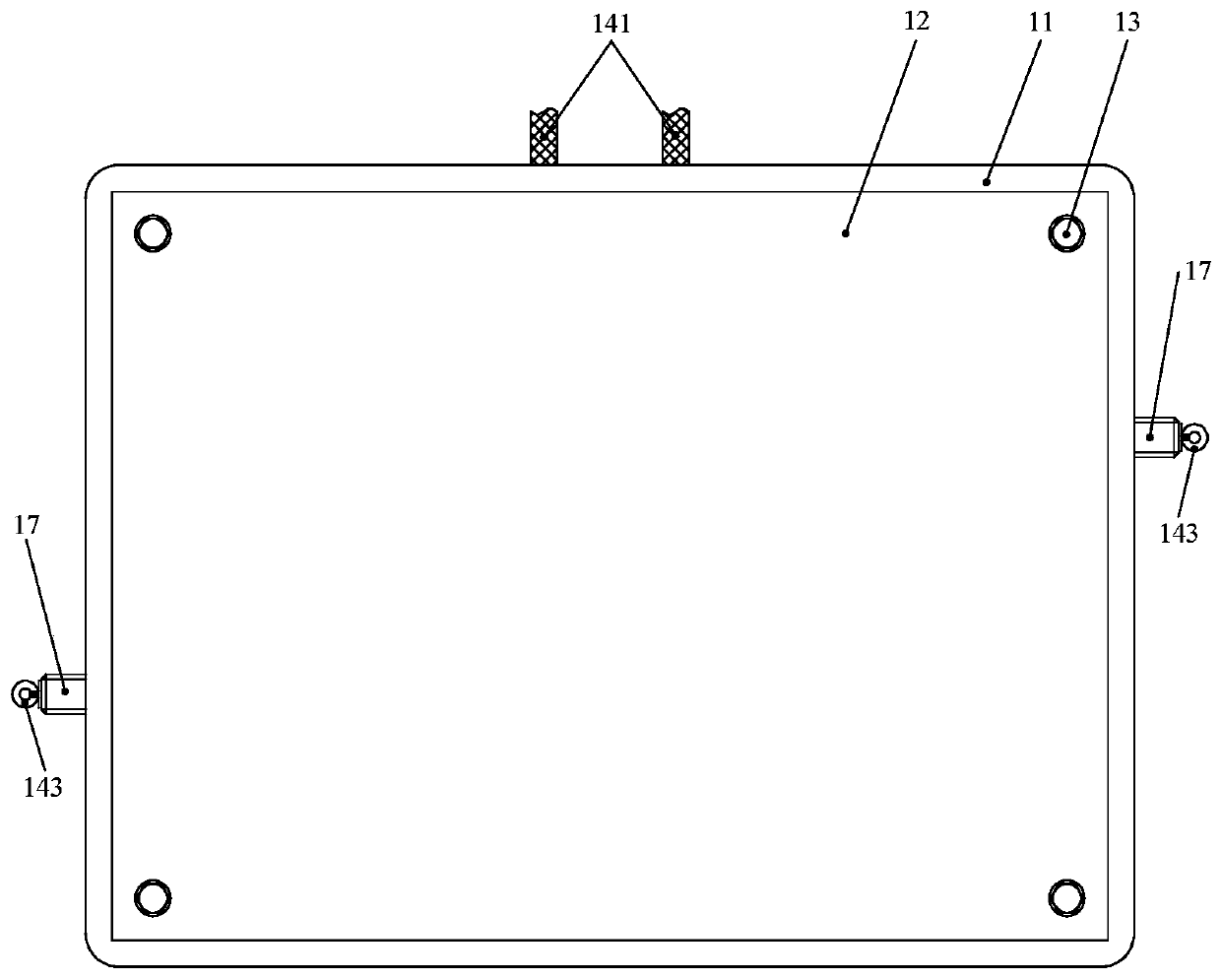

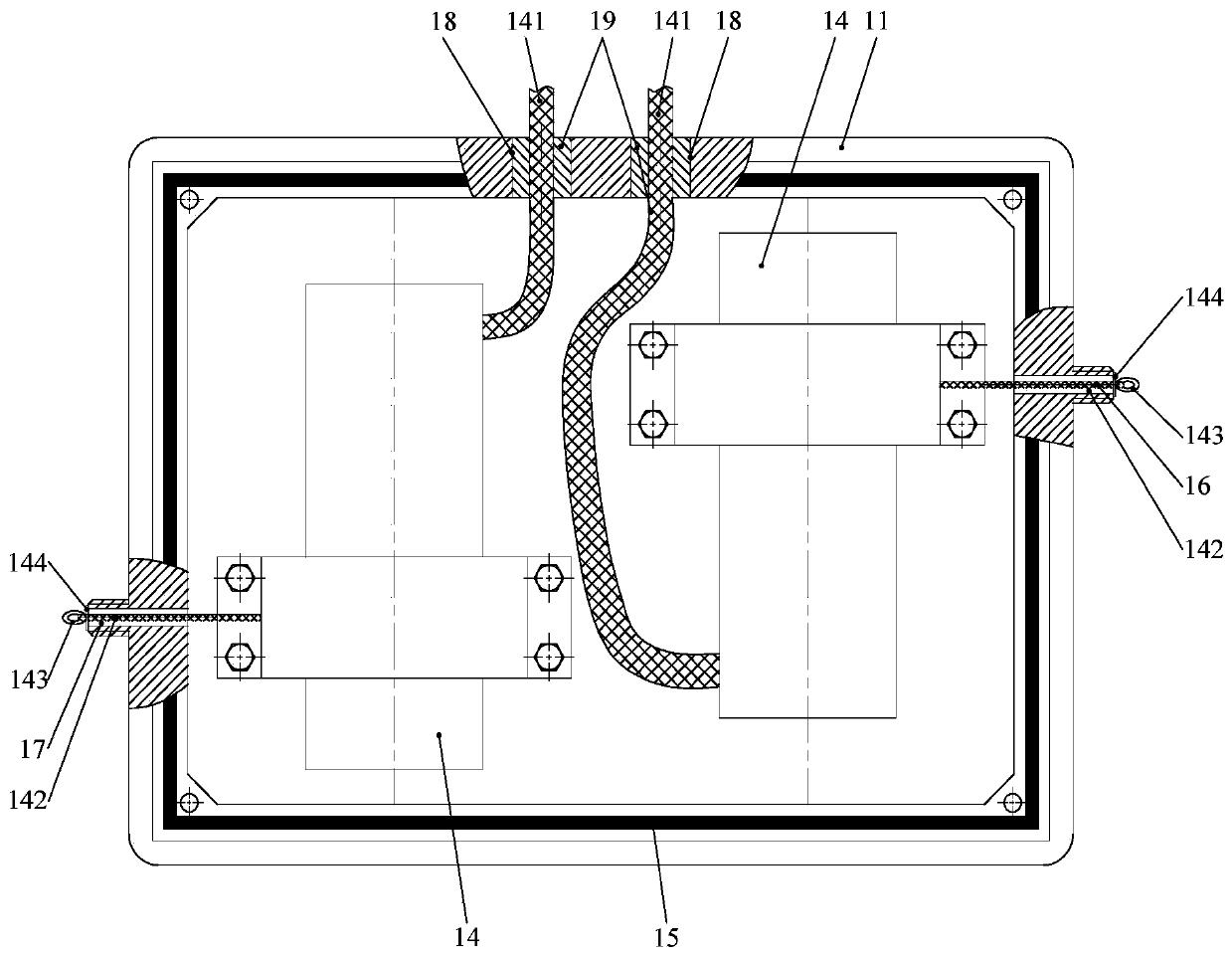

[0053] The above-mentioned two-way displacement measuring device 1 includes a measuring body, a steel pipe, an extension wire and two pull-cord displacement sensors 14 , and the measuring body includes a housing 11 and an upper cover 12 .

[0054] The above-mentioned housing 11 is a hollow cuboid structure without a cover, and a sealing ring 15 is arranged at the upper opening position, and the pull rope displacement sensor 14 is fixed in the housing 11 by screws; the housing 11 and the upper cover 12 are connected by bolts 13; The shell 11 and the upper cover 12 are preferably made of high-strength stainless steel; the left and right sides of th...

Embodiment 2

[0071] Embodiment 1 The installation and use method of the online monitoring system for lateral deformation of the filling body is as follows:

[0072] Step 1: According to the specific measurement purpose, cut off the extension line of appropriate length, select a certain number of steel pipes, connect the shell with the steel pipe, extension line and fixed plate, and install the connected two-way displacement measuring device on a suitable Location;

[0073] Step 2: Connect the connection line of the two-way displacement measuring device with the data transmission line through a junction box, connect the data transmission line with the communication substation, connect the communication substation with the communication master station, and connect the communication substation The station is connected with the underground telephone line (Ethernet or optical fiber), the underground telephone line (Ethernet or optical fiber) is connected with the ground data acquisition instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com