Heat dissipation system of power distribution cabinet and control method thereof

A heat dissipation system and control method technology, applied in the cooling/ventilation of substation/switchgear, electrical components, panel/switch station circuit device, etc., can solve the problems of high cost, inability to adjust in real time, poor heat dissipation effect, etc., to achieve Effects of controlling equipment cost, ensuring control accuracy and real-time operation, and simplifying simulation complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

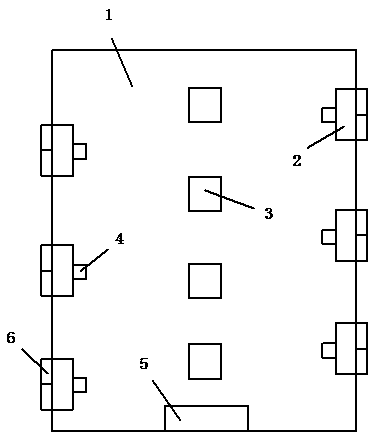

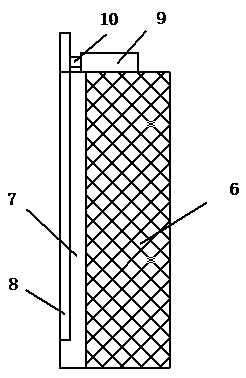

[0026] refer to Figure 1-2 , a specific embodiment of the present invention includes a cabinet body 1, several reversing fans 2 are installed on the cabinet body 1, a first temperature sensor 3 is installed on the inner side of each reversing fan 2, and several reversing fans 2 are arranged in the cabinet body 1 The second temperature sensor 4, the ratio of the maximum value to the minimum value of the distance between any two second temperature sensors 4 is not more than 3:1, a controller 5 is arranged in the cabinet body 1, and the input terminal of the controller 5 is connected to the first temperature sensor 3 is in communication connection with the second temperature sensor 4, and the output end of the controller 5 is in communication connection with the control end of the reversing fan 2. Two side-by-side filters 6 are installed on the outside of the reversing fan 2, a chute 7 is arranged on the inside of the filter 6, a valve plate 8 is slidably inserted in the chute 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com