Automatic video inspection device suitable for reactor internal anti-loosening structure

A technology for inspection devices and internal components, applied in measuring devices, photogrammetry/video metrology, instruments, etc., can solve the problem of no automatic inspection tools for underwater video inspections of anti-loose structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment this patent is described in detail:

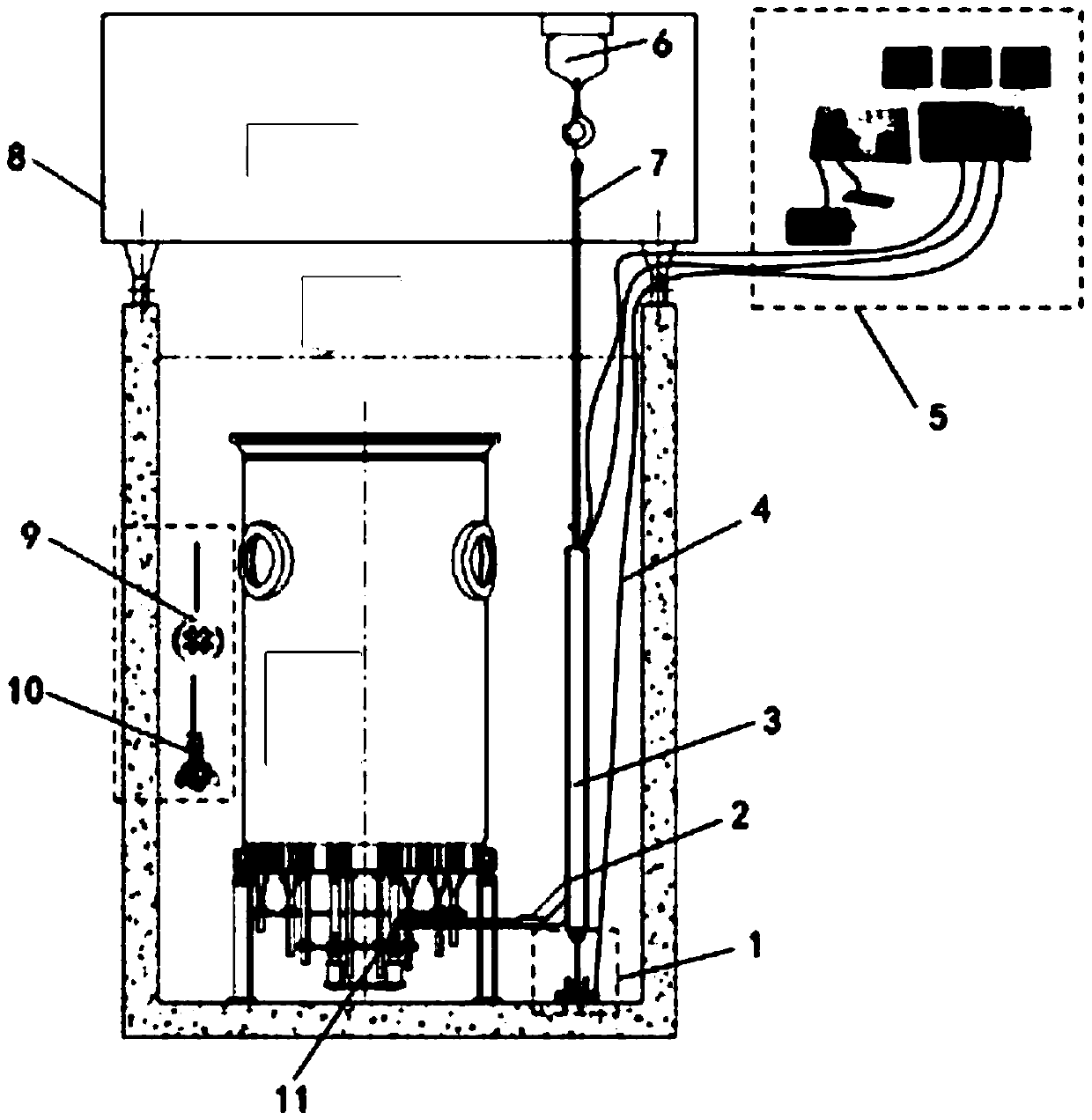

[0017] as attached figure 1 As shown, an automatic video inspection device suitable for the anti-loosening structure of internal components of the present invention mainly includes: an omnidirectional mobile platform 1, an auxiliary camera 2, a chain-type flexible mechanical arm 3, a cable 4, a control system 5, and a refueling machine crane A hook 6, a long rod tool 7, a refueling machine 8, an underwater environment lighting lamp 9, an underwater environment camera 10, and a main video inspection camera 11 are formed.

[0018] In the present invention, the omnidirectional mobile platform 1 is located at the lowermost end of the whole set of tools, and is used to support the chain-type flexible mechanical arm 3 and move it to a suitable position. Under the control of the control system 5 , the omnidirectional mobile platform 1 can move, rotate and fine-tune in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com