Variable-diameter threshing cylinder

A technology of threshing drum and variable diameter, applied in the field of agricultural machinery, can solve the problems of complex structure and high manufacturing and processing cost, and achieve the effects of good effect, low manufacturing cost and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

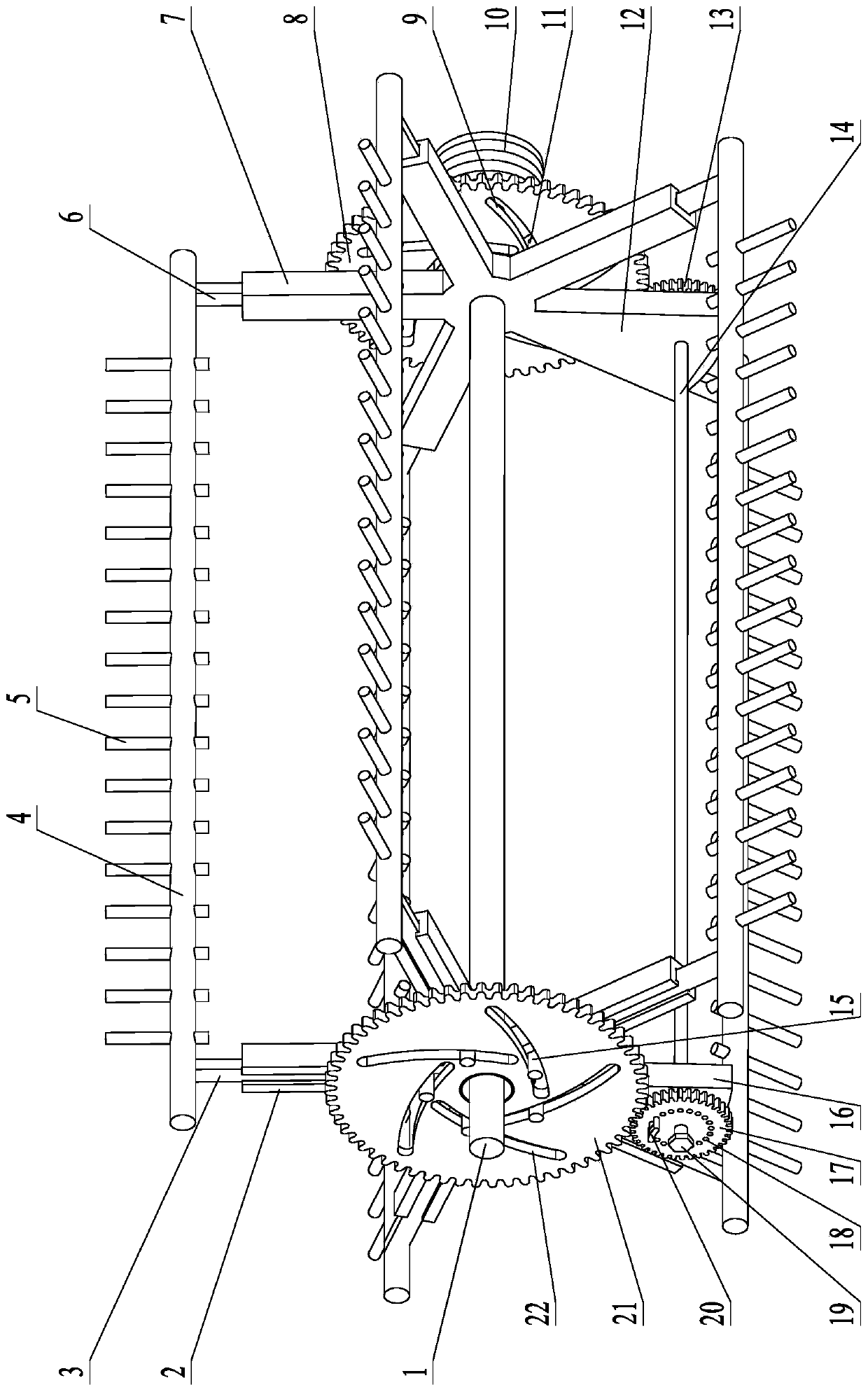

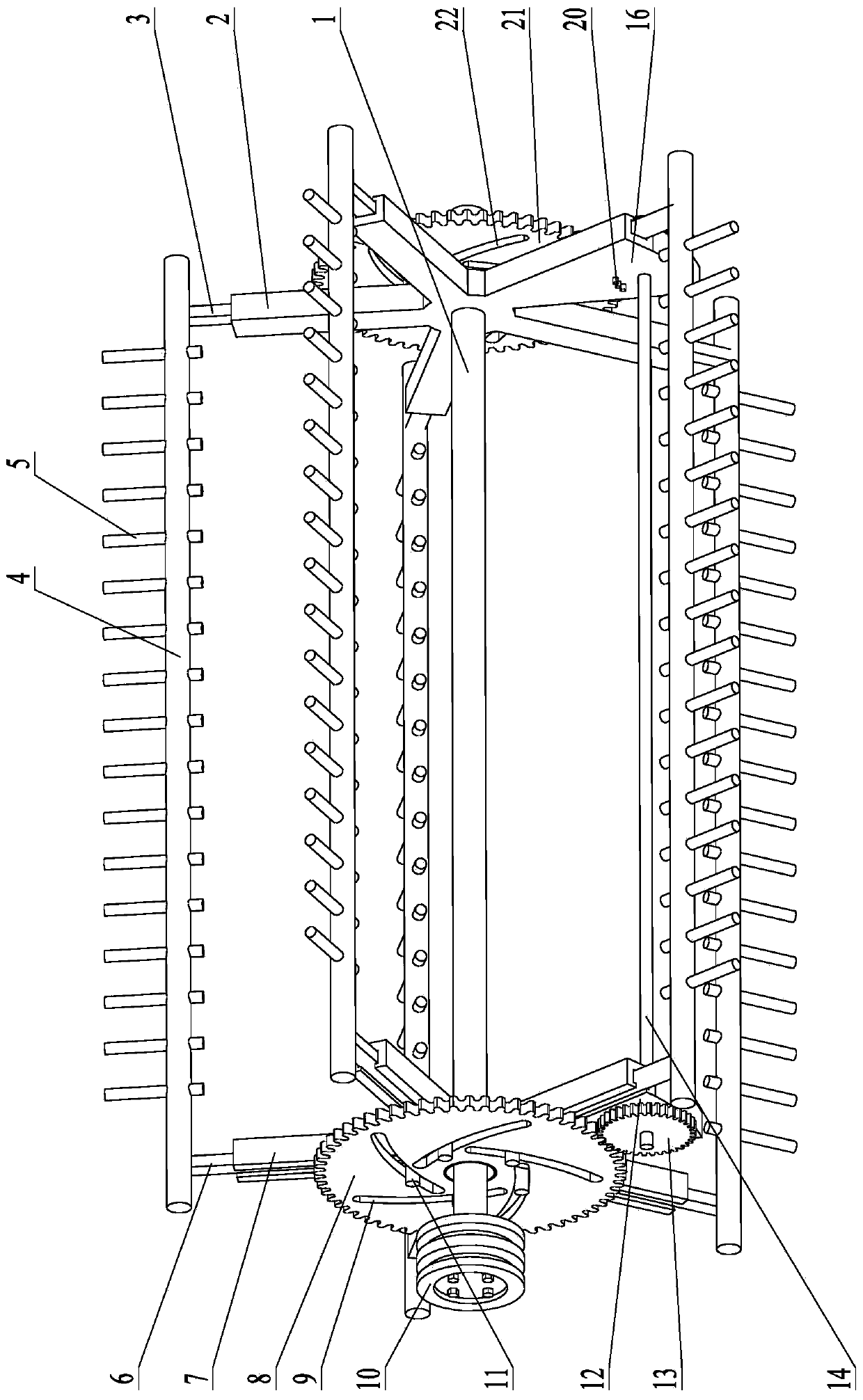

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A variable-diameter threshing drum, including a drum main shaft 1 and a nail seat plate 4 with threshing spikes 5 fixedly mounted on the left and right sides of the drum main shaft 1 symmetrically to each other. Frame 7, on the left star frame 2 and right star frame 7, the left strut 3 and the right strut 6 are reciprocally movable in the radial direction, and the left strut 3 and the right strut 6 are mated respectively, and the sliding post A15 and the sliding post B11 are fixed Installed on the side of the left pole 3 and the right pole 6, the nail seat plate 4 with the threshing nail teeth 5 is fixedly supported on the outer ends of the left pole 3 and the right pole 6; On the left and right sides of the roller main shaft 1, at the outer parts of the left star frame 2 and the right star frame 7, the axial and radial positioning are symmetrical to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com