Threshing roller having adjustable diameter

A threshing drum and adjustable technology, applied in the field of agricultural machinery, can solve the problems of fixed drum diameter, affecting threshing quality, and grain loss, etc., to achieve the effects of simple and convenient adjustment operation, good threshing quality and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

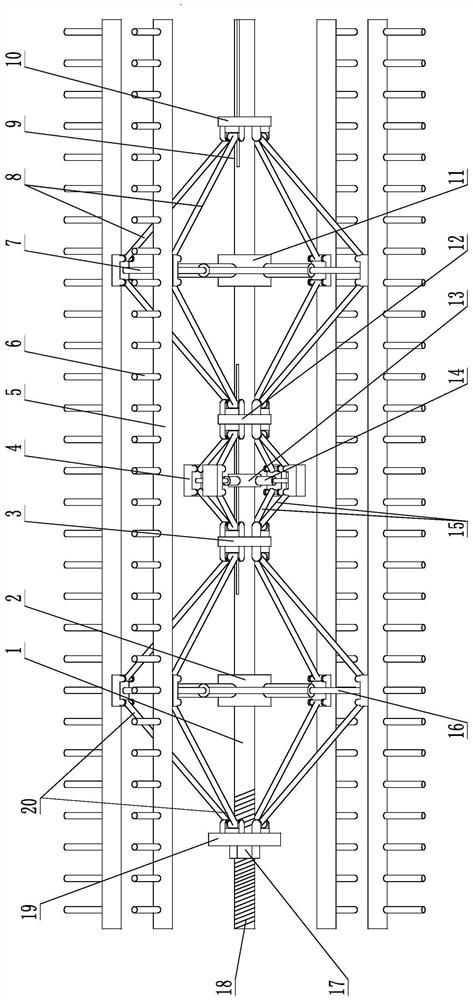

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A diameter-adjustable threshing drum, including a tooth seat plate 5, on which a threshing nail tooth 6 is fixed, and a screw thread 18 and an axial slideway groove 9 are respectively arranged on the left end and the right end of the drum shaft 1, On the drum shaft 1, the adjusting nut 17, the adjusting drive plate 19, the left supporting seat 2, the left sliding seat 3, the transition connection supporting seat 13, the right sliding seat 12, the right supporting seat 11 and the To adjust the follower plate 10, the adjusting nut 17 is rotatably matched with the screw thread 18, the adjusting nut 17 is locked radially and axially with the adjusting driving plate 19, and is connected rotatably in the circumferential direction, the adjusting driving plate 19, the left sliding seat 3. The right sliding seat 12 and the adjusting follower plate 10 are locked r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com