A cylindrical heating rod test section with a chamber and its parameter measurement method

A test section and cylindrical technology, applied in the field of cylindrical heating rod test section and its parameter measurement, can solve the problems of complex structure, affecting the flow of heating fluid and heat distribution, difficulty in measuring test parameters, etc. Certainty, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

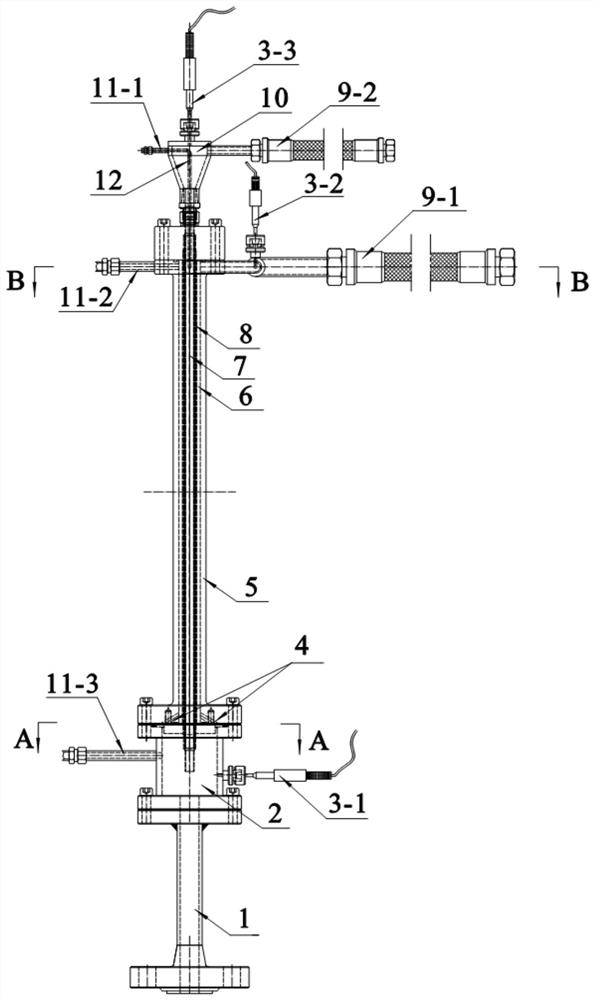

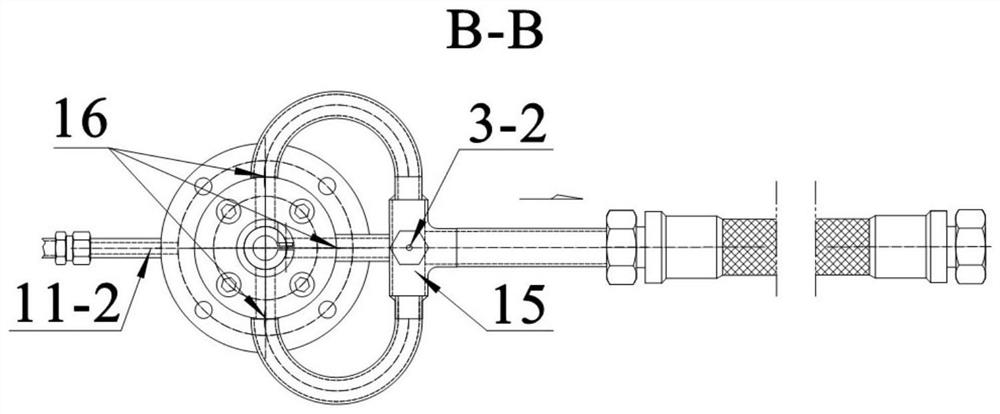

[0021] Such as figure 1 As shown, a cylindrical heating rod test section with a chamber, including a fully developed tube 1, a lower chamber 2, a test section outer casing 5 and an upper chamber 10 connected by flanges from bottom to top, is arranged in the test section. Cylindrical heating rod 8 in segment outer casing 5. The central circular channel of the cylindrical heating rod 8 is the inner channel 7 , and the annular channel between the outer casing 5 of the test section and the cylindrical heating rod 8 is the outer channel 6 .

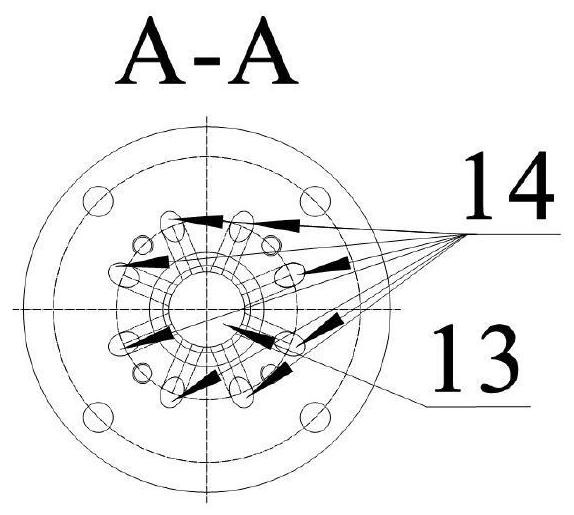

[0022] Such as figure 2 As shown, the lower chamber 2 is provided with a lower chamber pressure-taking channel 11-3 and a lower chamber thermal resistance 3-1, the lower end is connected to the fully developed tube 1, and the center of the upper end is provided with an inner hole 13 connected to the entrance of the inner passage 7, A numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com