Patents

Literature

38results about How to "Reasonable measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

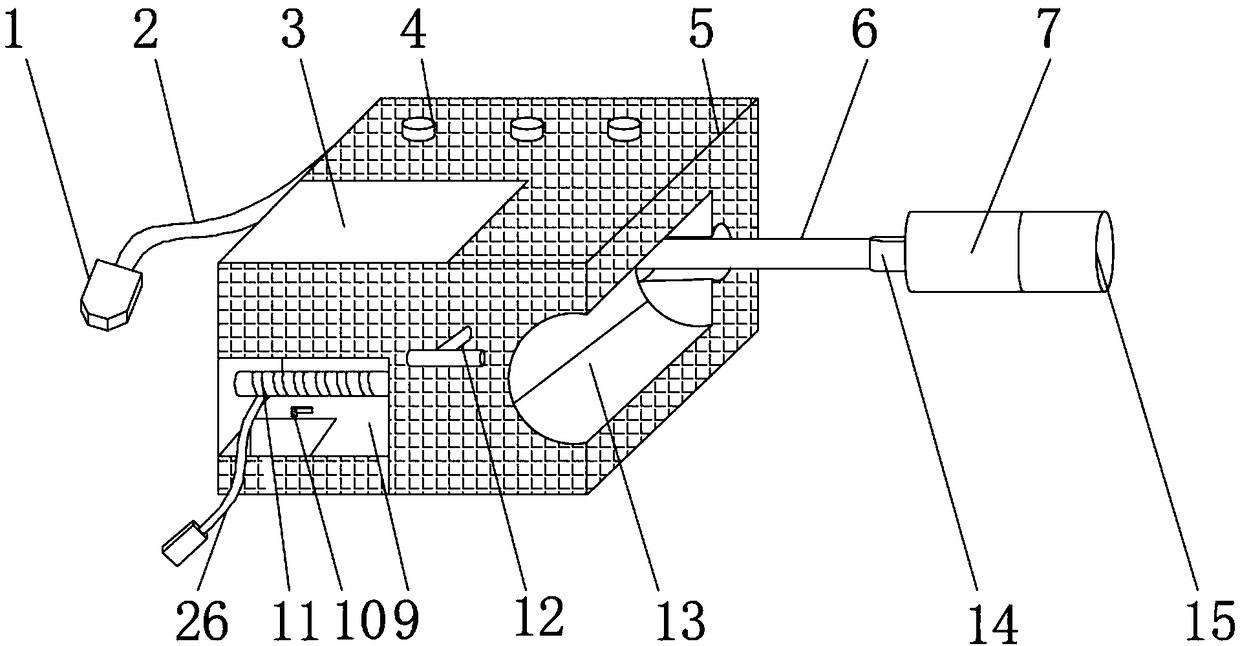

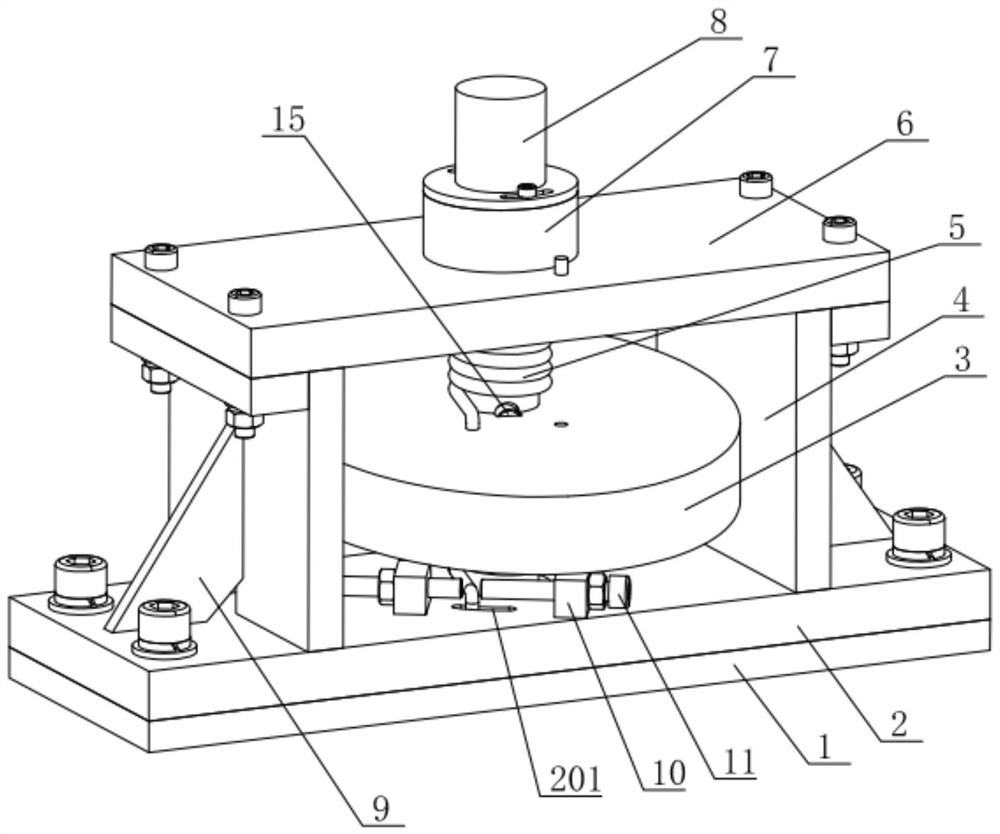

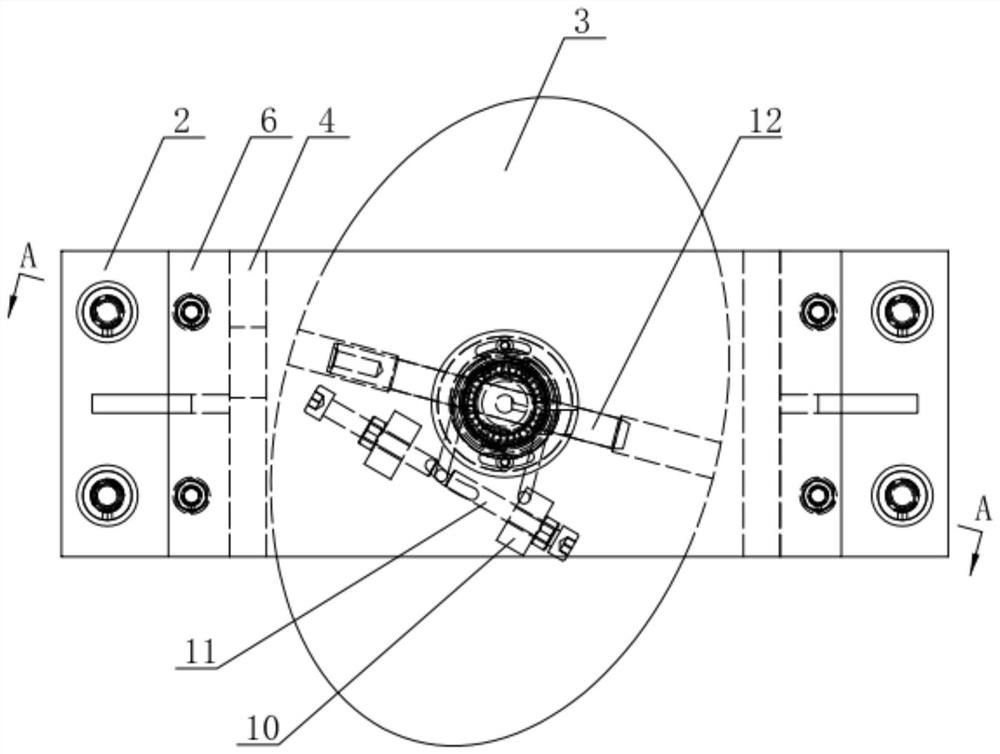

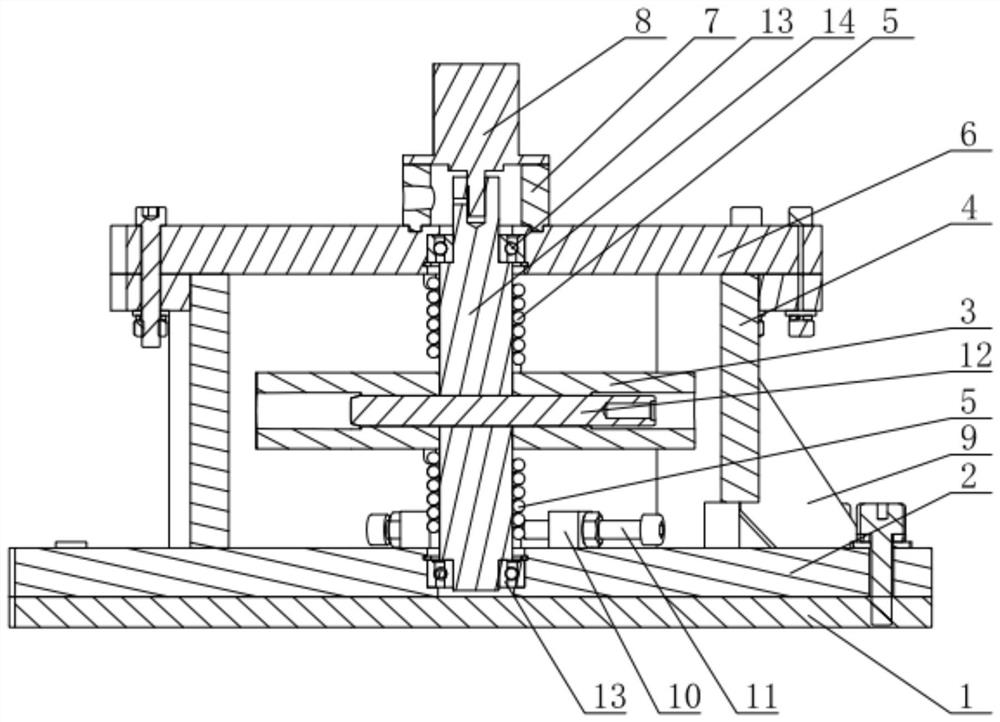

Device used for mechanical property testing of high-temperature superconducting strip and detection method

ActiveCN104965113AVersatileEasy to useCurrent/voltage measurementUsing mechanical meansTest sampleHigh temperature superconducting

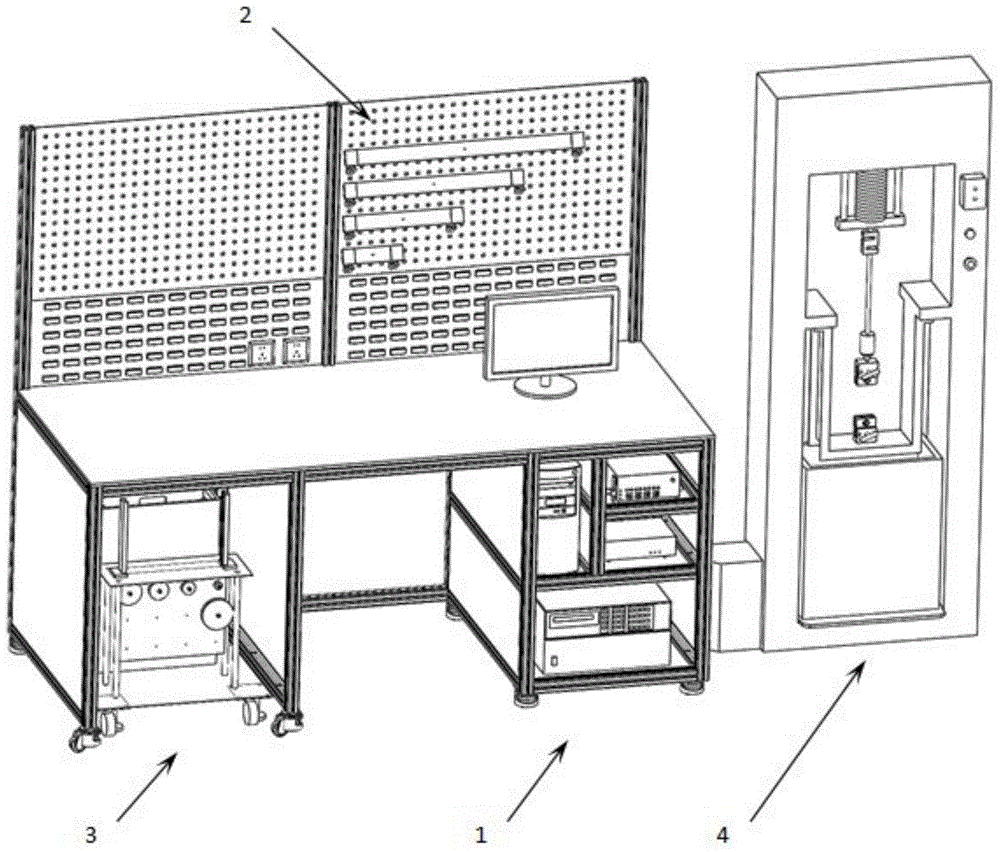

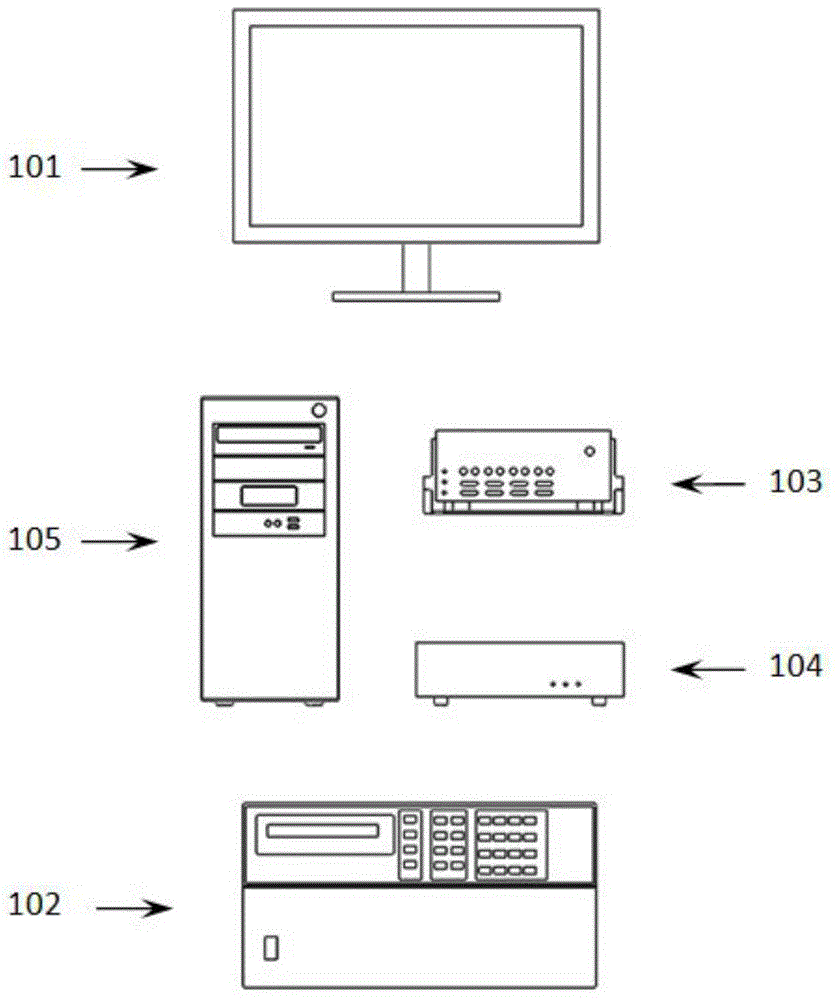

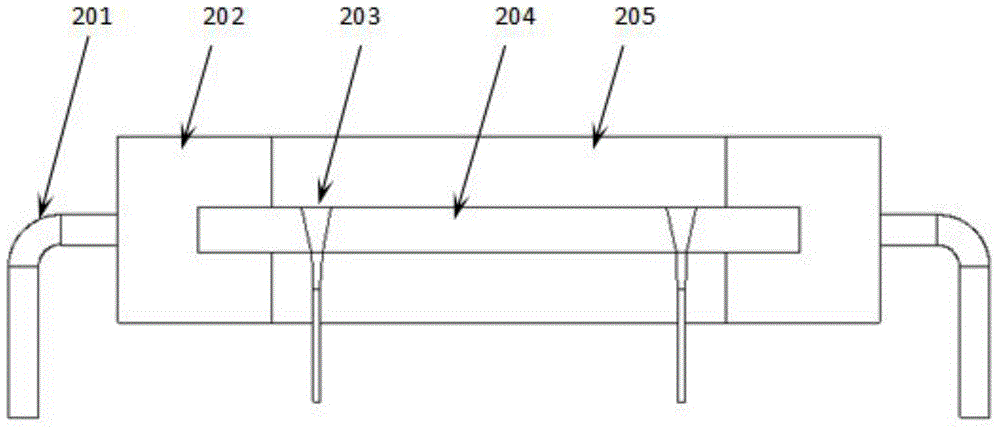

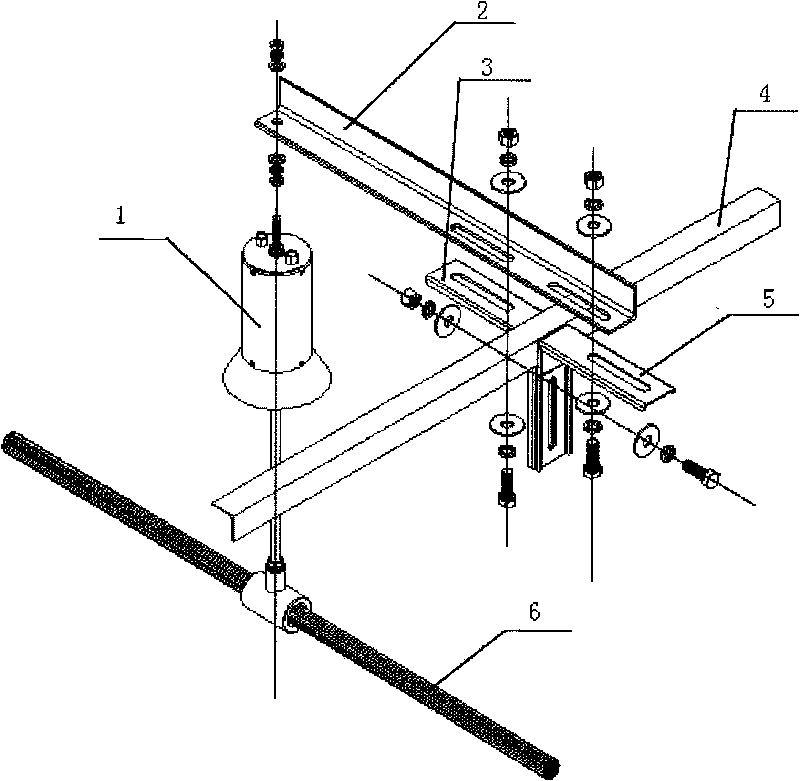

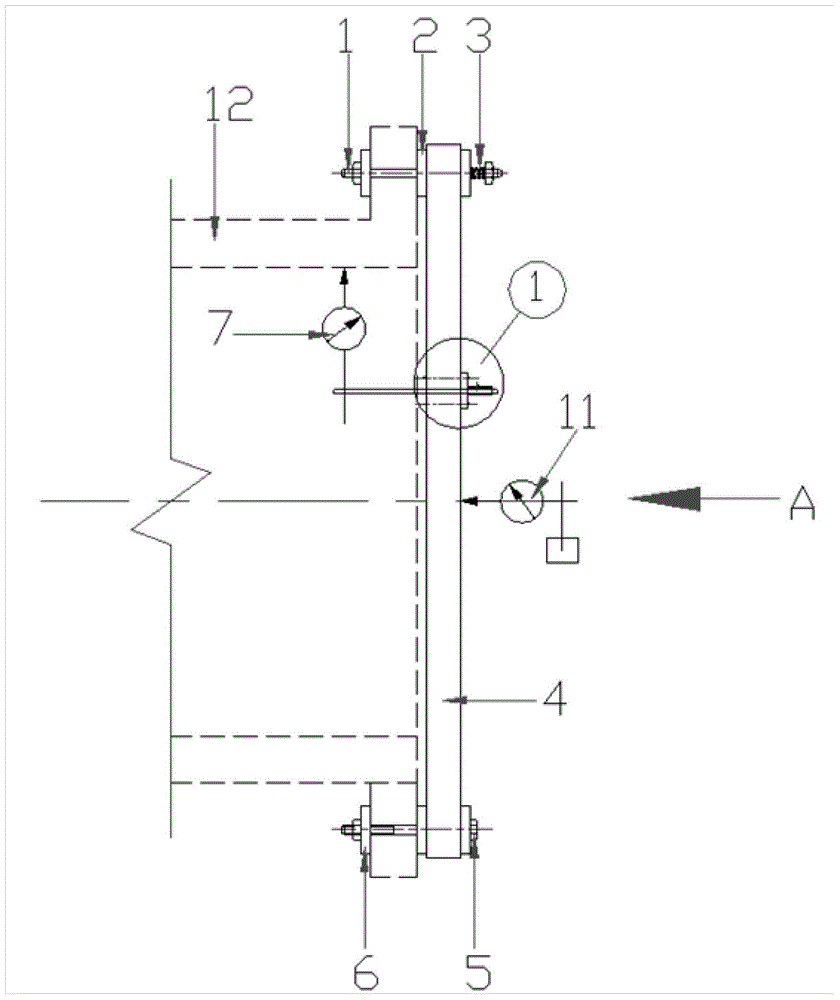

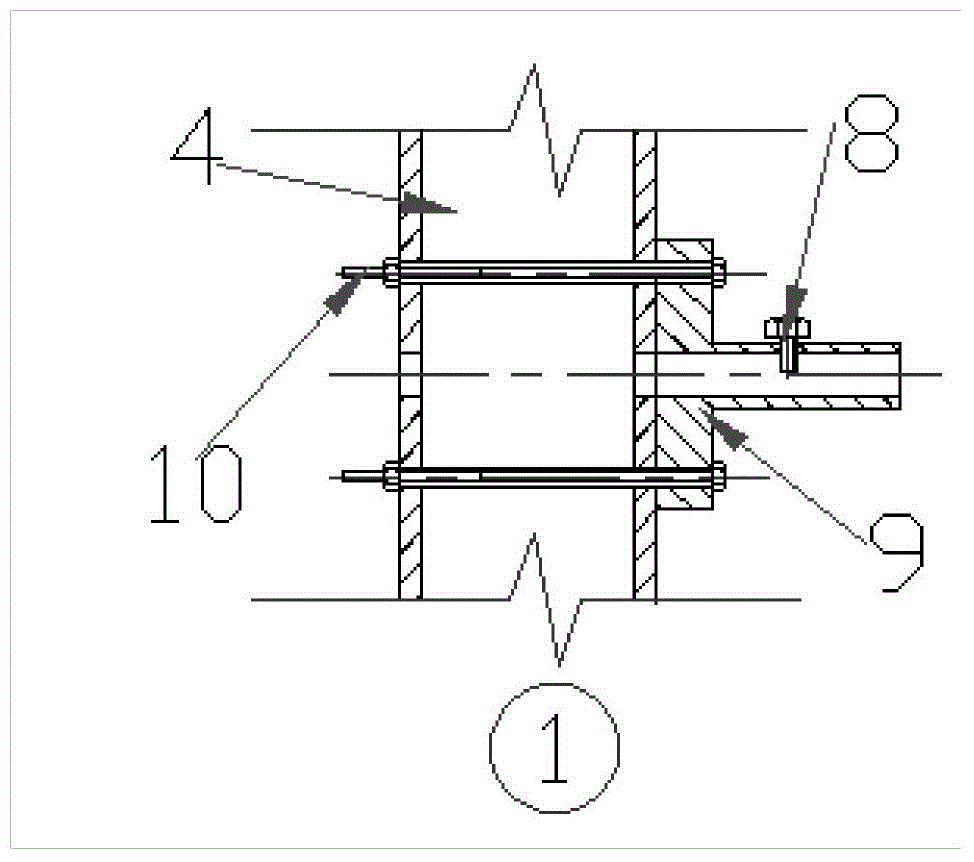

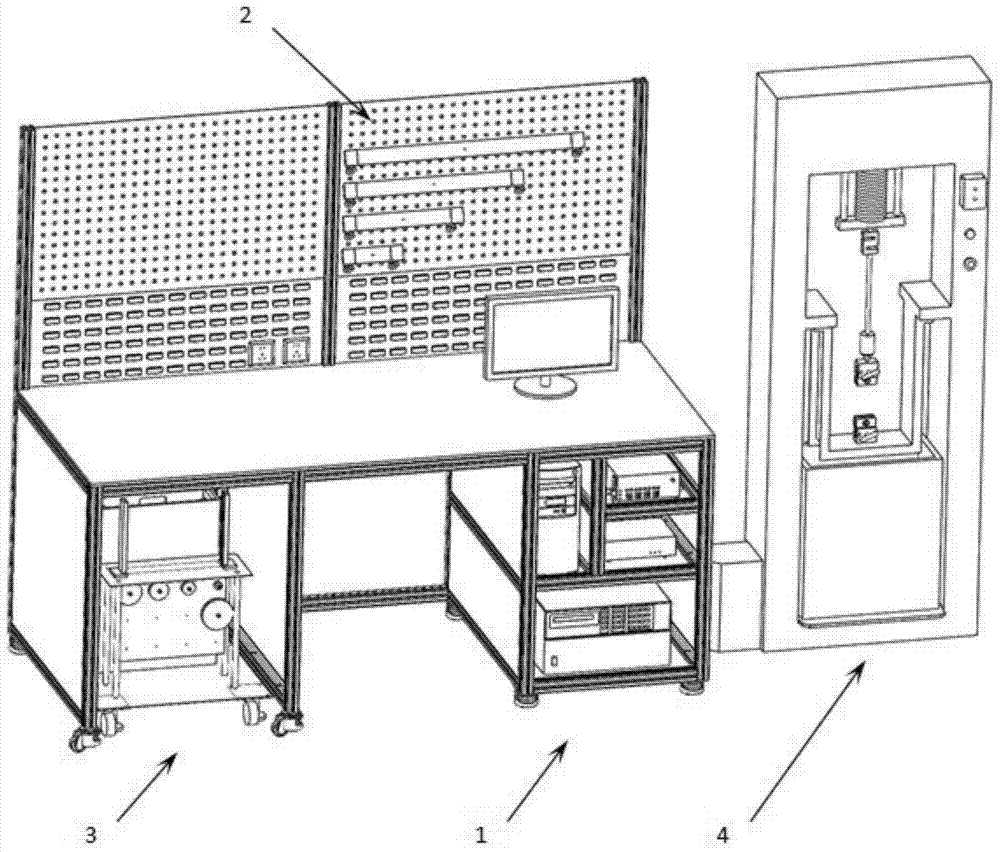

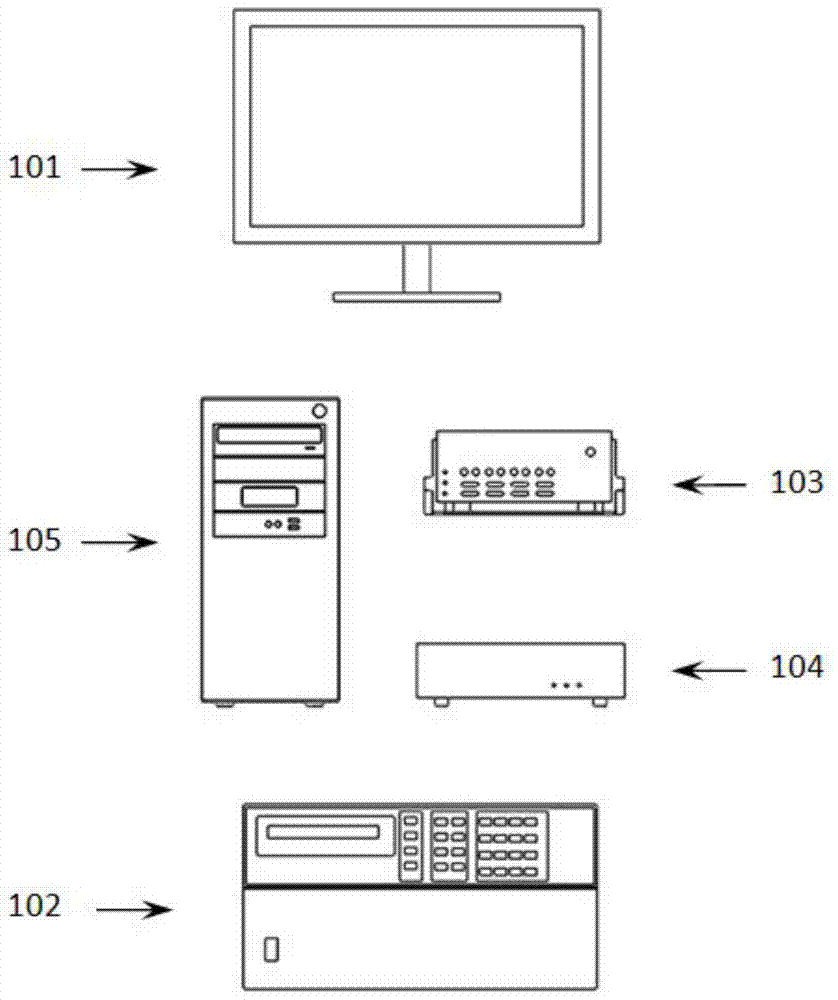

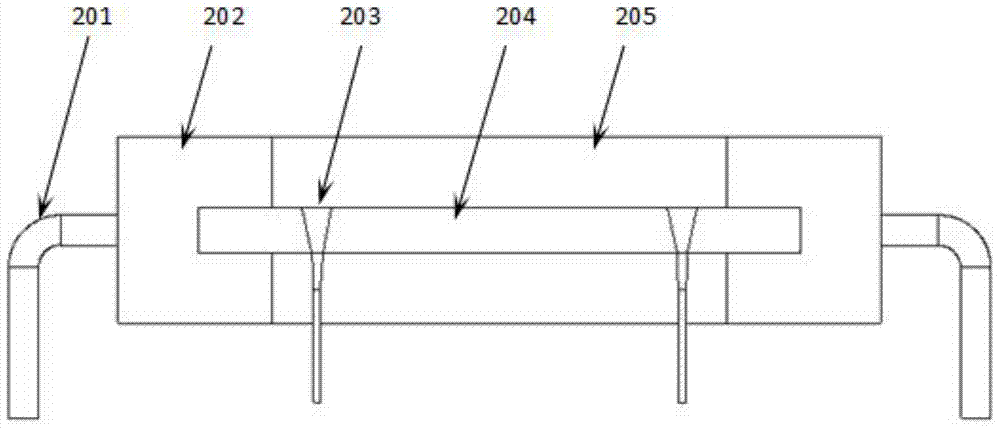

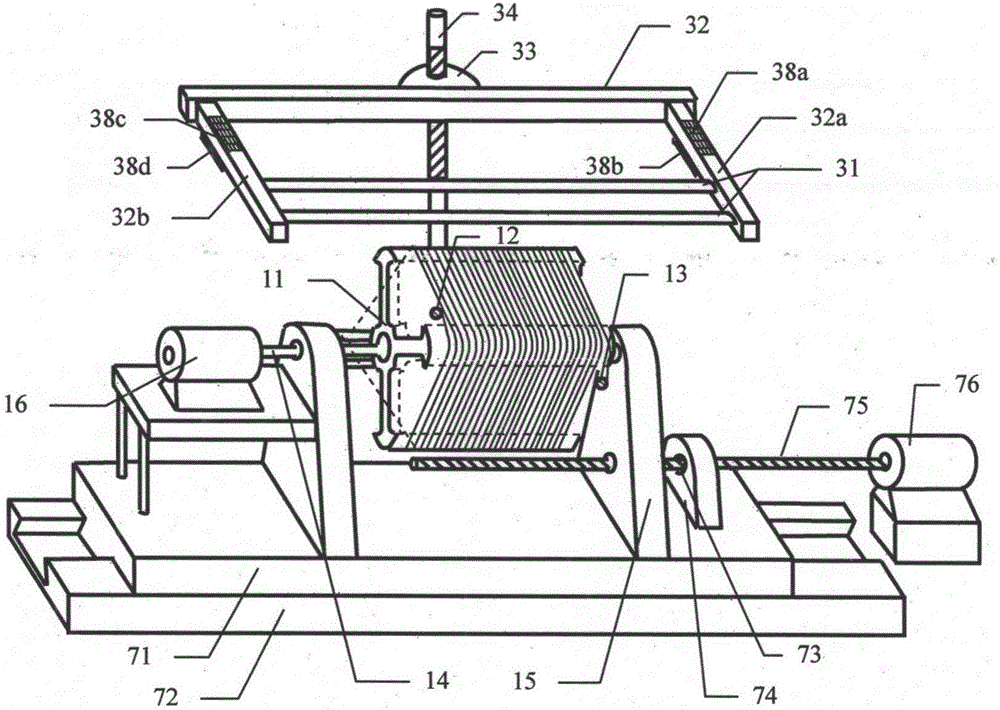

The invention provides a device used for mechanical property testing of a high-temperature superconducting strip, and includes a four-lead control device (1), a strip critical current testing frame (2), a strip turning radius testing frame (3) and a strip stretching stress testing frame (4). The device has the following advantages: 1. through the device, accurate measurement of almost all electrical and mechanical properties of a short sample of a strip can be completed, including a turning radius, stretching stress, delaminating stress and the like, and the device has complete functions and is convenient to use; 2. equipment is complete in design, is practical and humanized, a person can seat on a table surface to carry out processes of welding, testing and the like, and the whole process is easy; 3. a square hole plate mounted on a table top can accommodate various test sample holders, screws, tools and the like, and is convenient and practical; and 4. the test sample holders can reasonably and effectively support measurement of samples.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

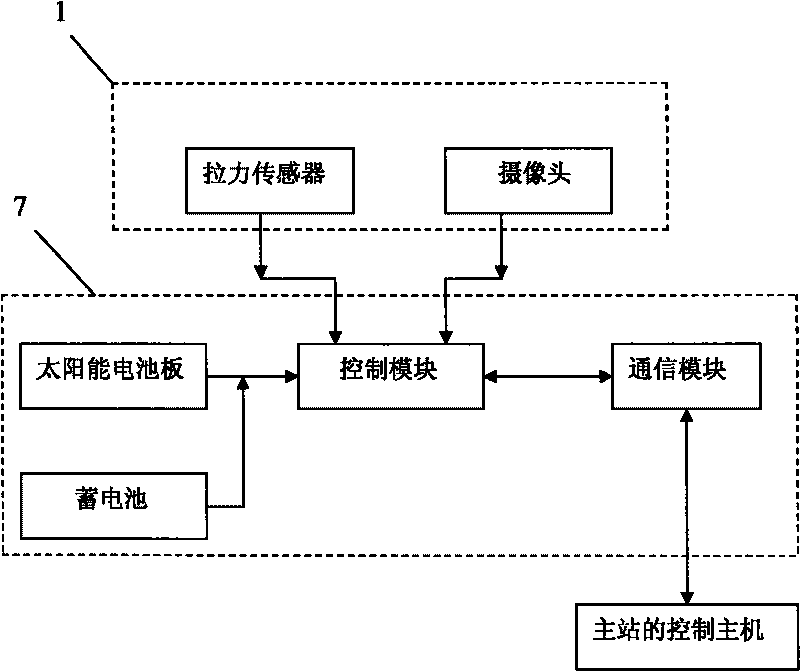

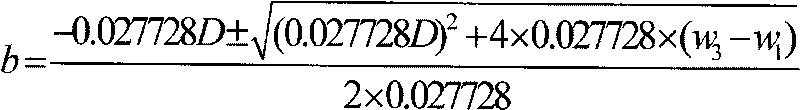

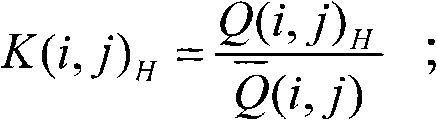

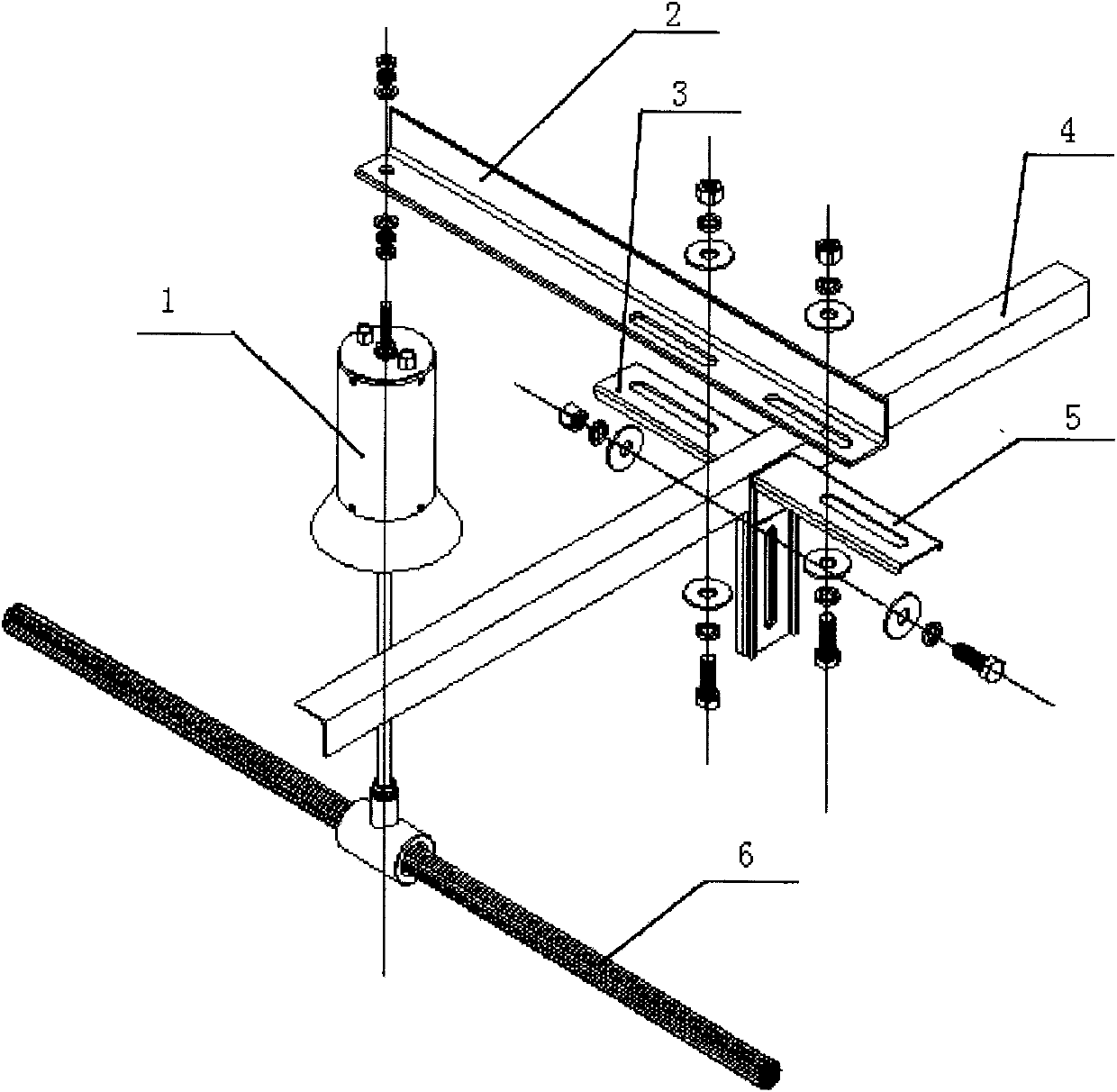

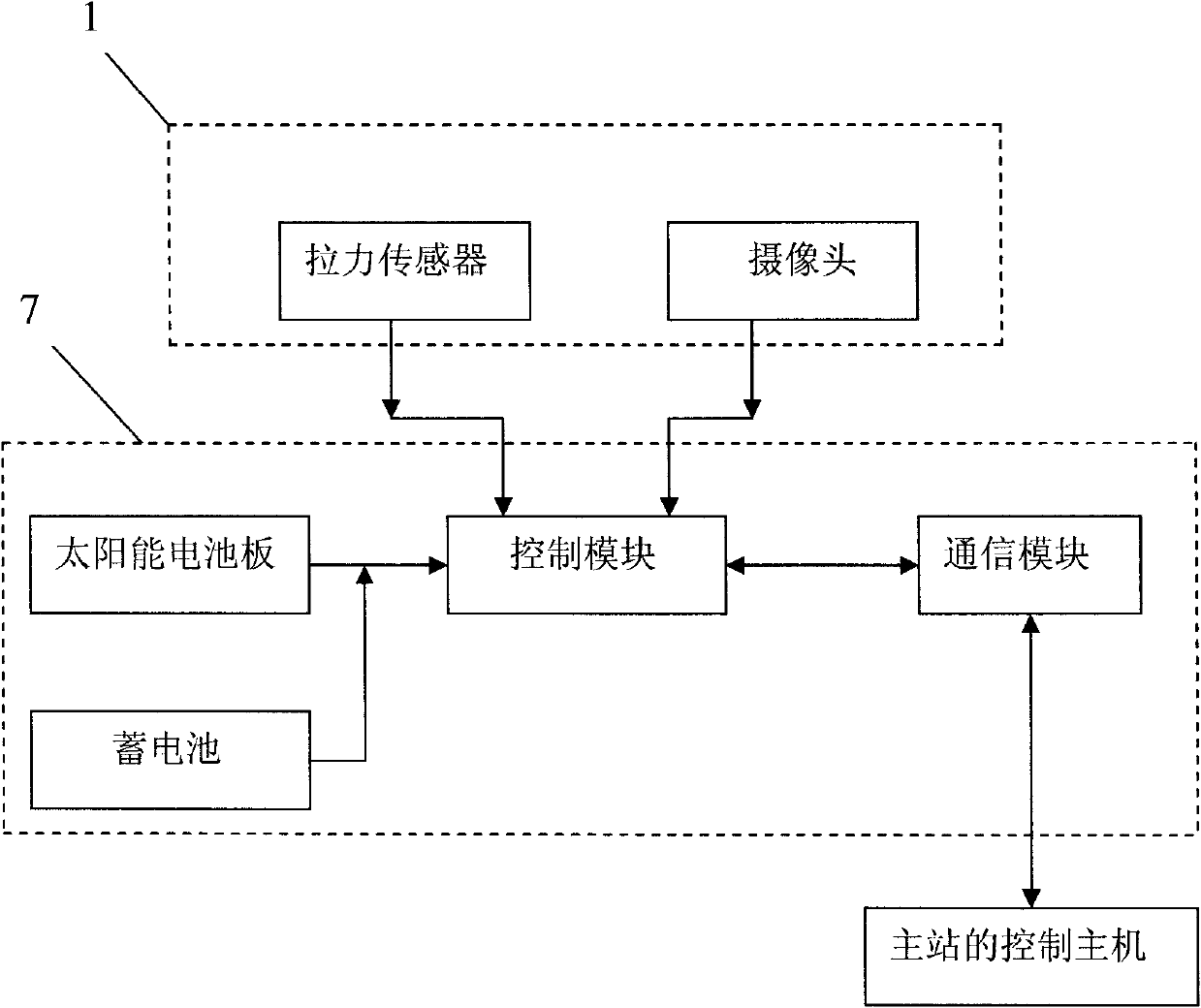

Method and system for real-time monitoring of analog wire coated by ice of overhead power transmission line

InactiveCN101701842AReasonable measurementSimple algorithmTension measurementSpecial purpose weighing apparatusSelf weightEngineering

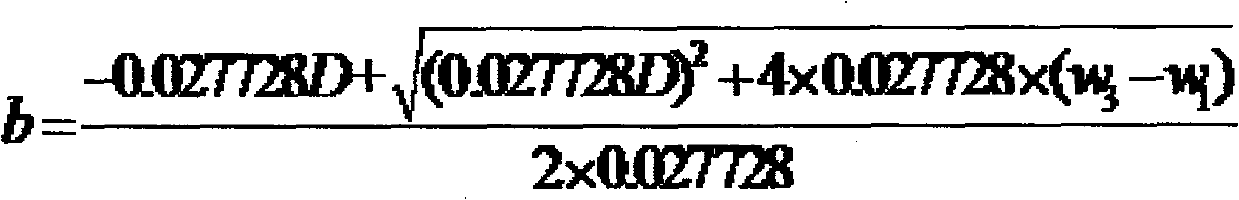

The invention relates to a method and a system for real-time monitoring of an analog wire coated by ice of an overhead power transmission line. The method comprises the following steps of: (1) mounting a section of analog wire having same model and material with the line lead wire on a tower of the overhead power transmission line; (2) arranging a measuring head on the analog wire for measuring weight of the analog wire; (3) ordering that coating ice of various types and with different section shapes is converted to a circular glaze section with density of 0.9g / cm<3>, wherein calculation formula of ice coating thickness b of the analog wire in a unit length is FORMULA, wherein D (mm) is the outer diameter of the analog wire; a known parameter w1 is self-weight load of the analog wire; and a known parameter w3 is vertical total load when the wire is coated by ice and can be measured by the measuring head. The invention has the advantages of reasonable and correct measurement of synthetical load of the line coated by ice and thickness of the coating ice, simple algorithm and accurate result.

Owner:杭州甬能信息技术有限公司 +1

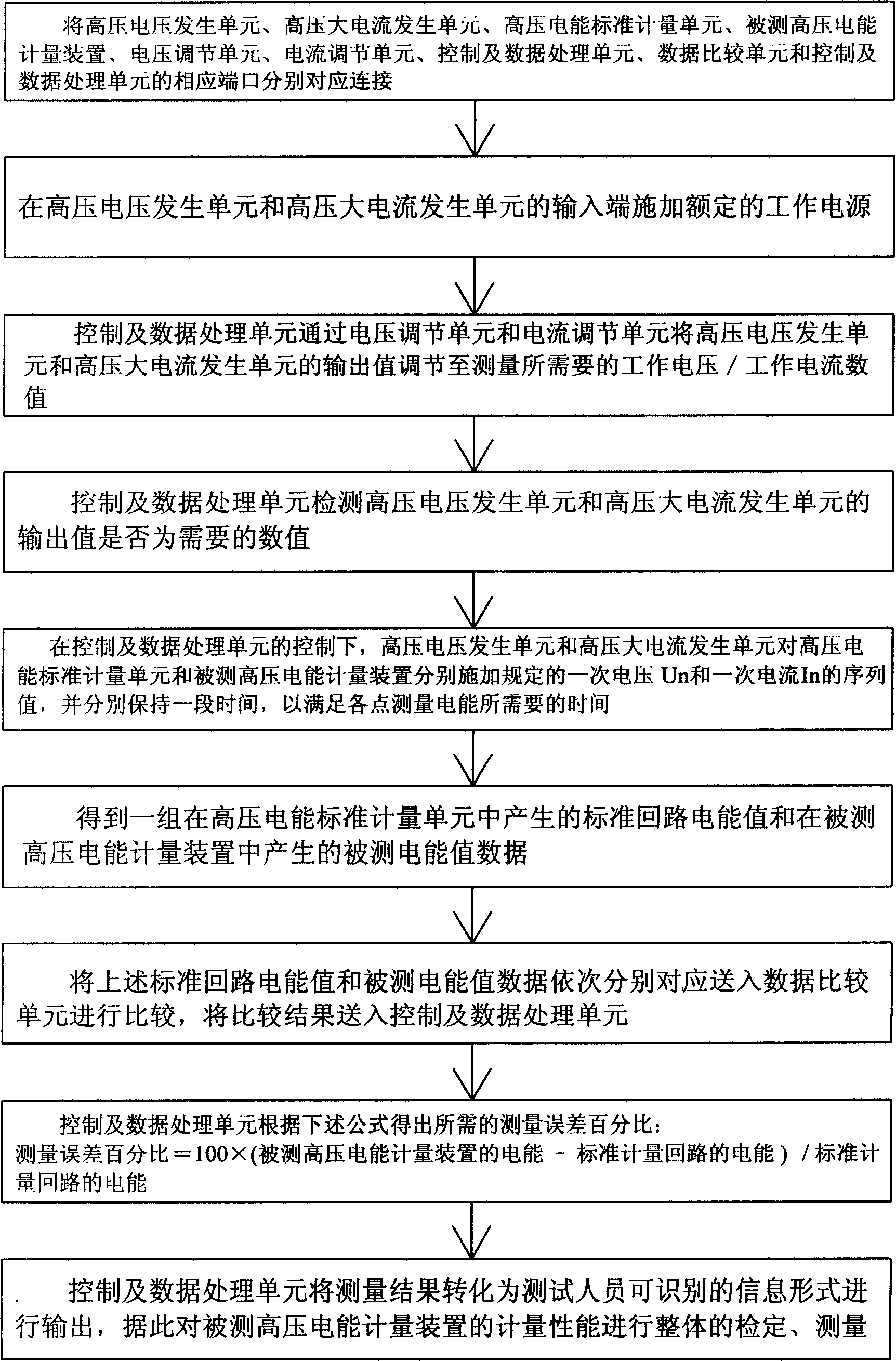

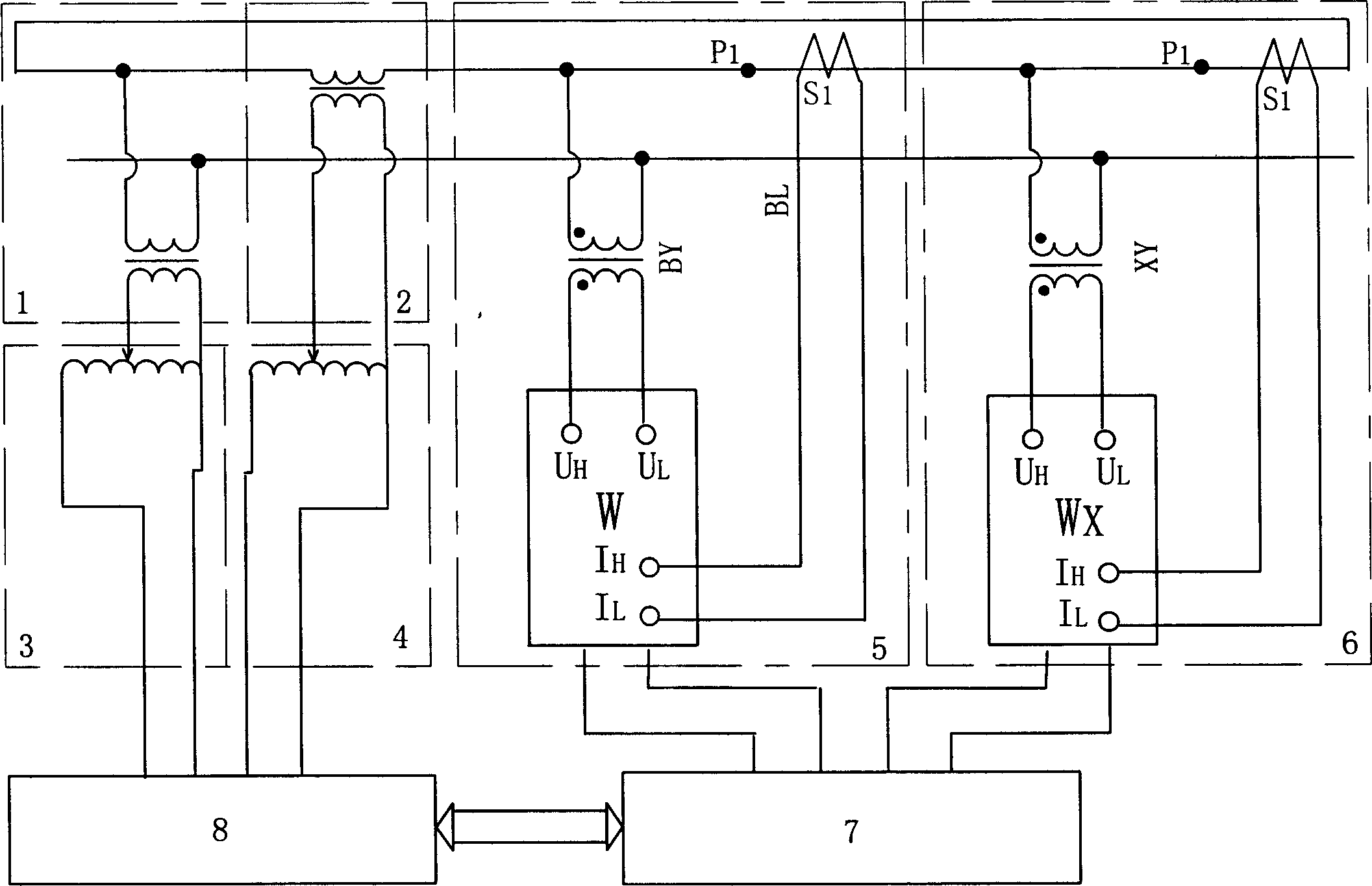

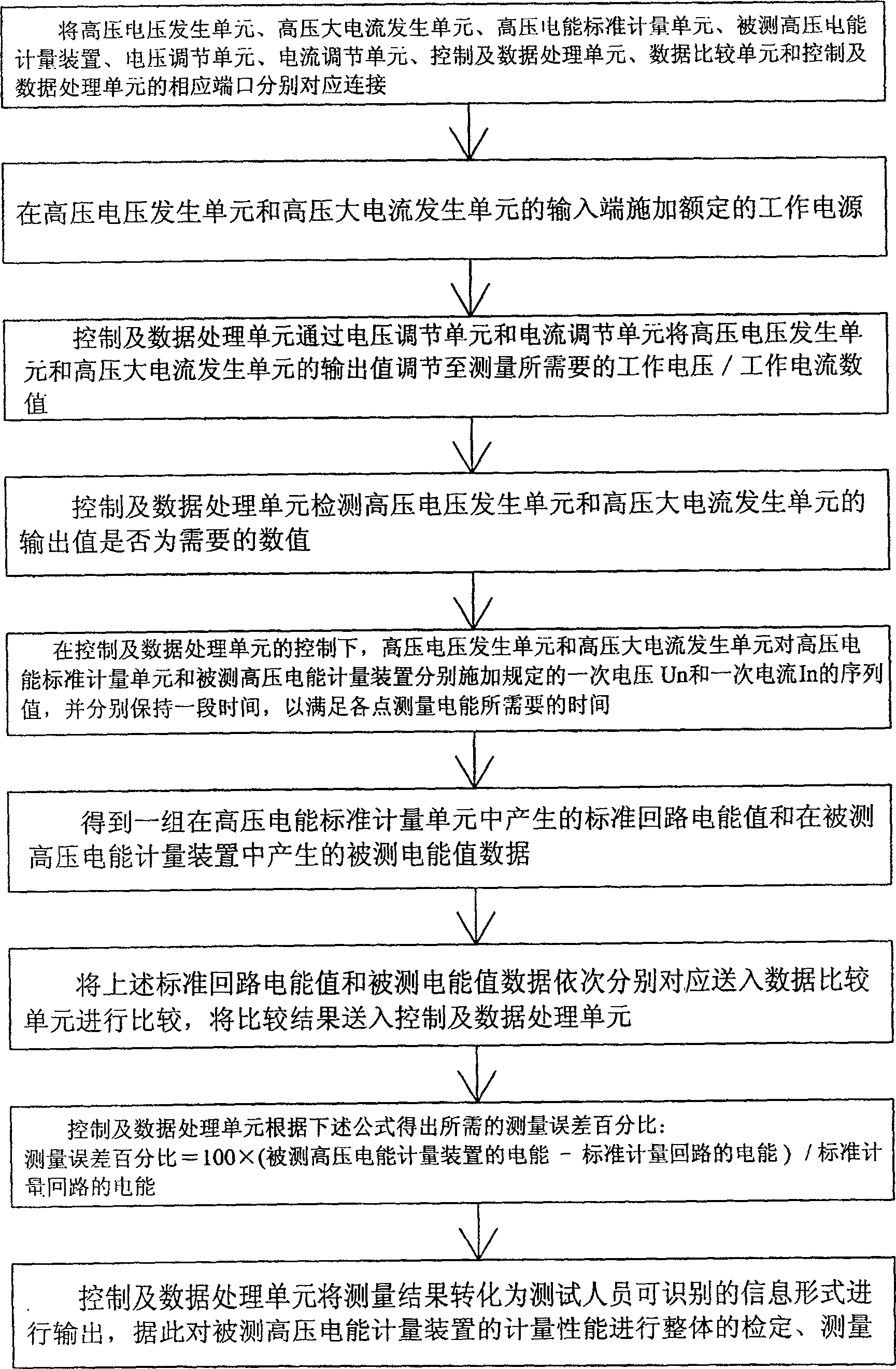

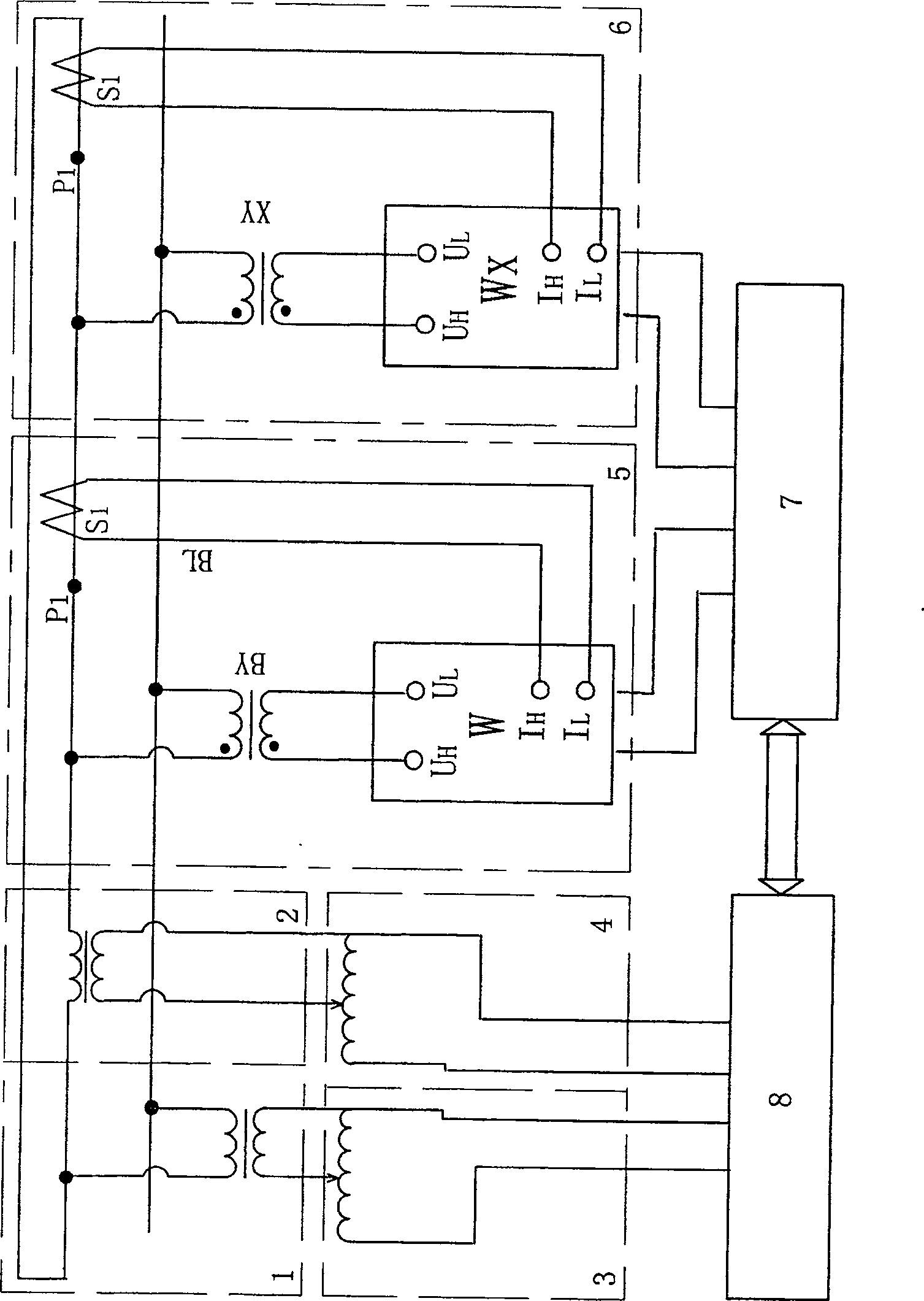

Integrate detecting and measuring method for metering property of high voltage power meter

ActiveCN1782730AAccurate measurementReasonable measurementElectrical measurementsObservational errorElectricity

The integral detection and measurement method of metering performance of high voltage power meter belongs to the field of measurement technology. The method includes connecting high voltage voltage / current generator unit, voltage / current regulating unit, data comparator unit, control and data processing unit, and standard high voltage metering unit with the high voltage power meter to be measured; applying one sequence of voltage and current to the standard high voltage metering unit and the high voltage power meter to be measured to obtain one set of standard power values and one set of measured power values; comparing these two sets of power values in the data comparison unit and feeding the comparison results to the control and data processing unit; calculating the metering error based on the given formula and outputting the measurement results.

Owner:淄博计保互感器研究所(有限公司)

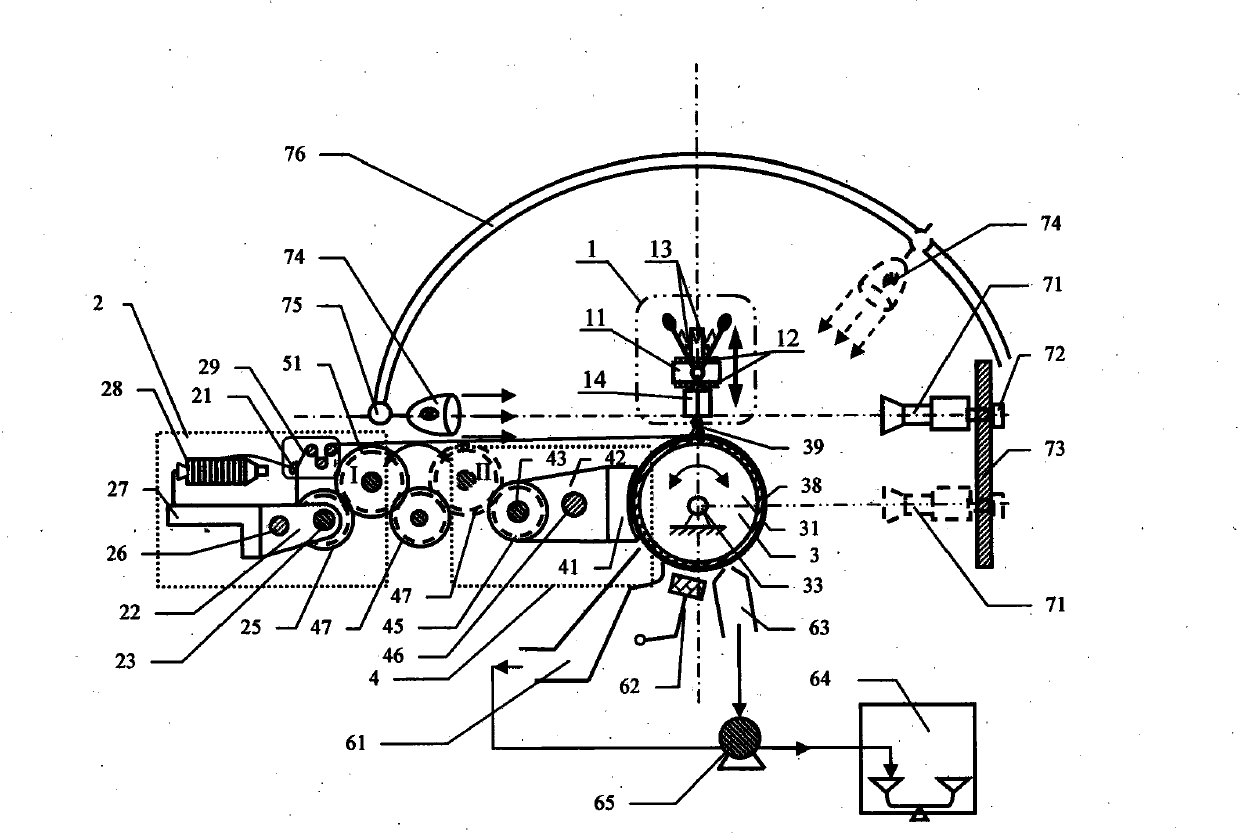

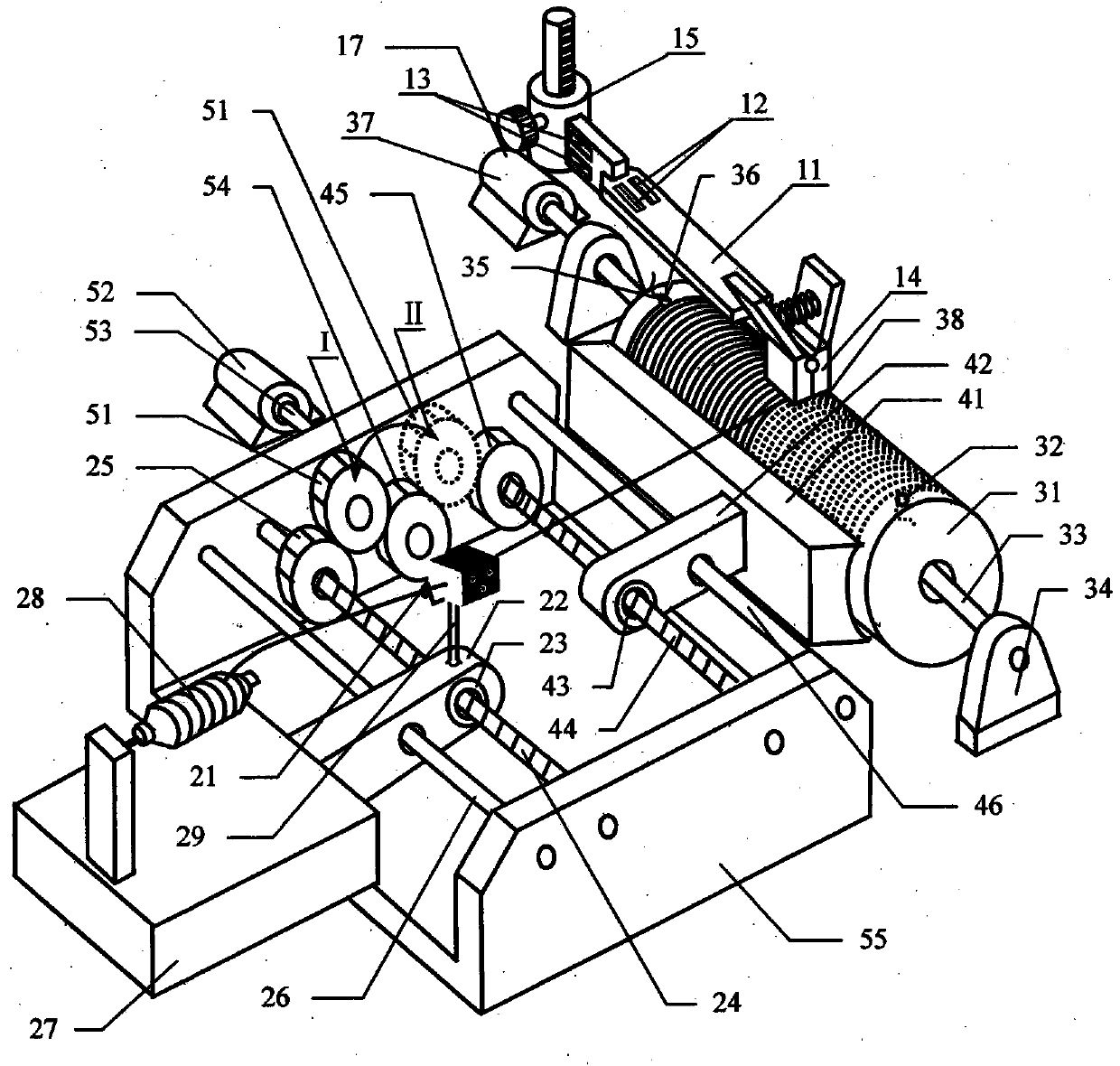

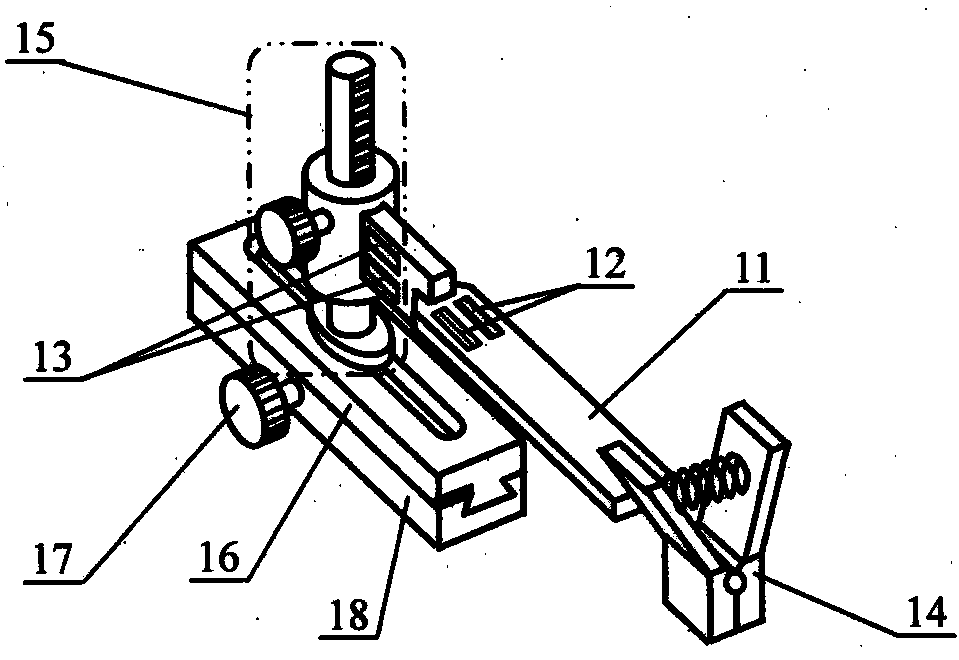

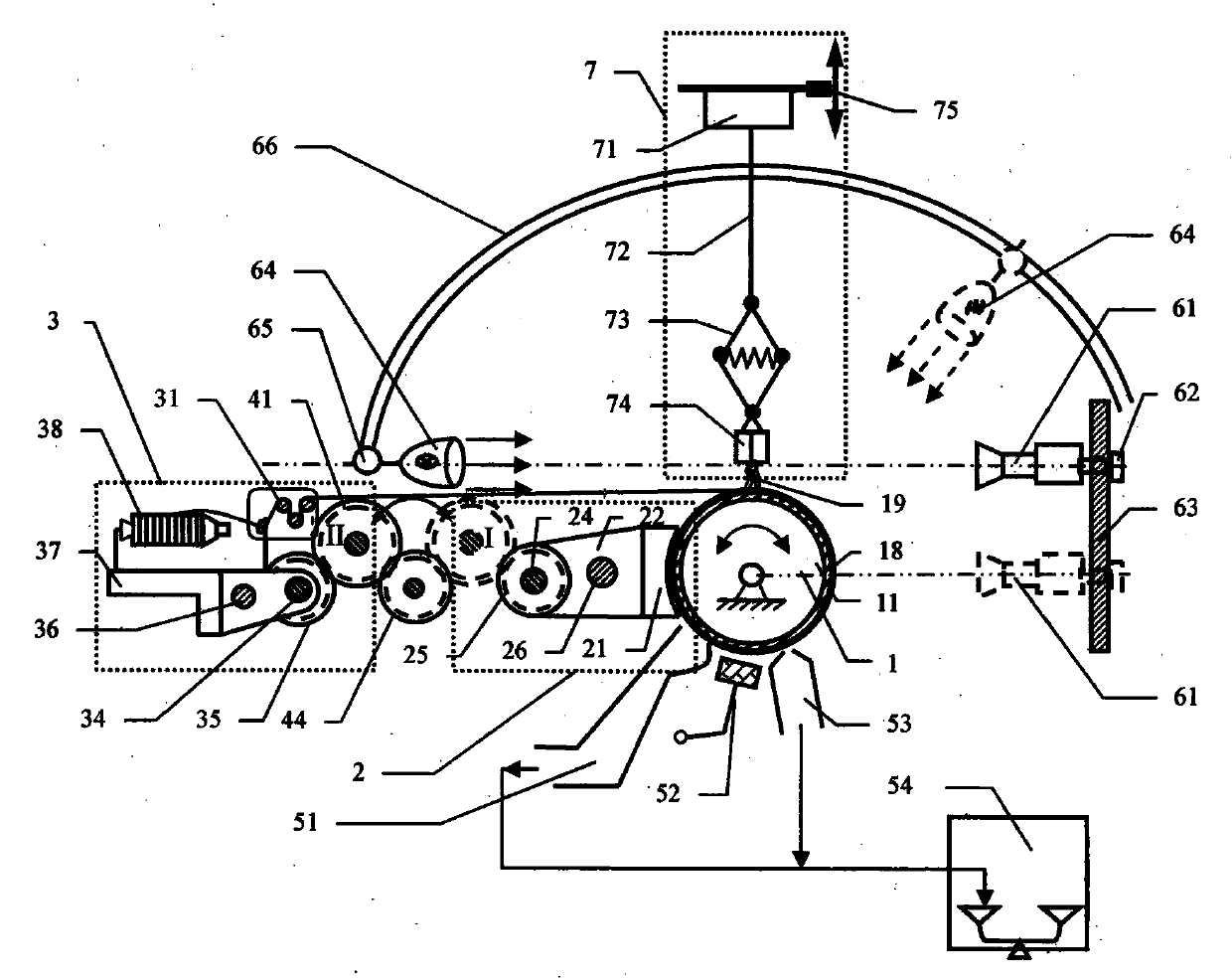

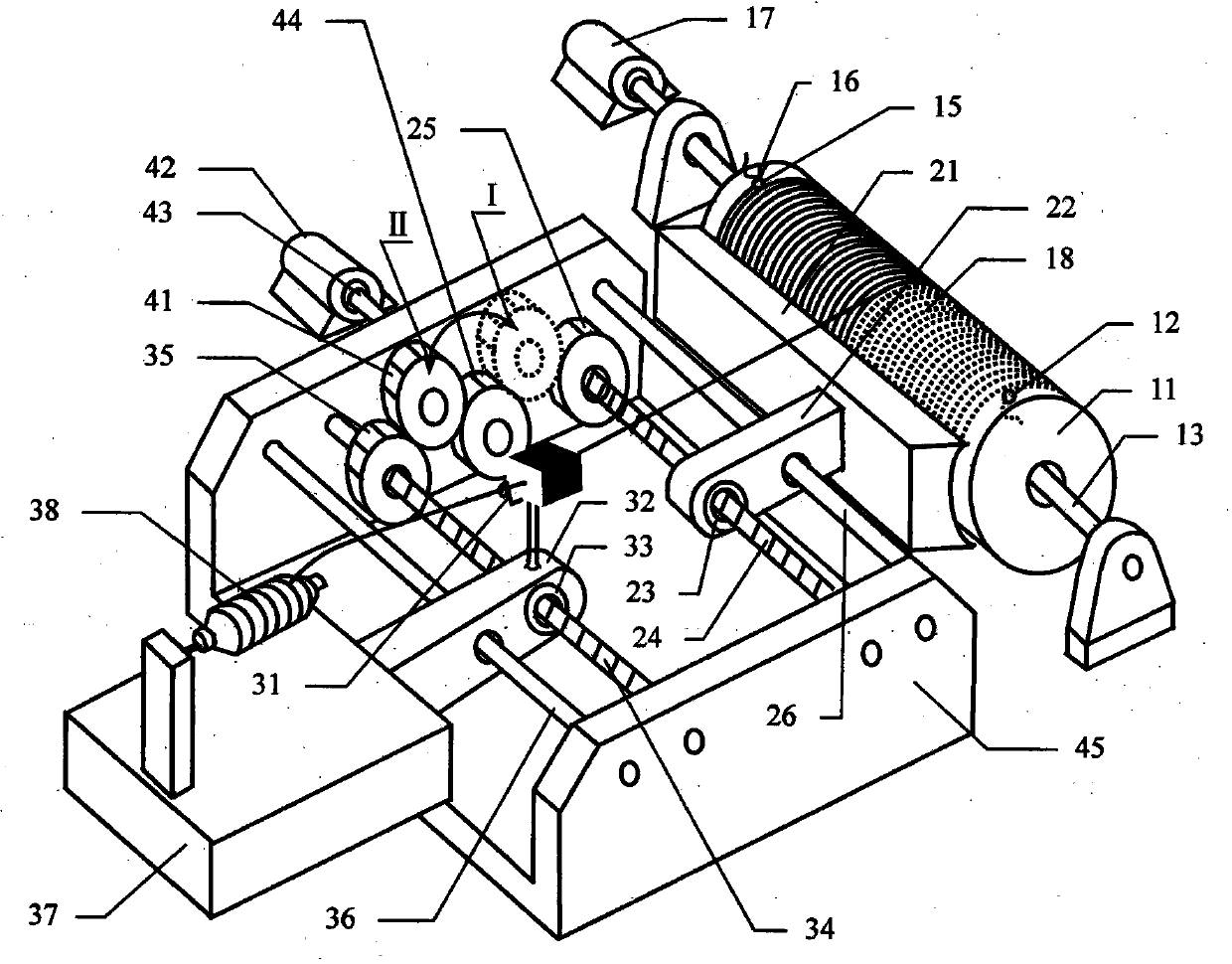

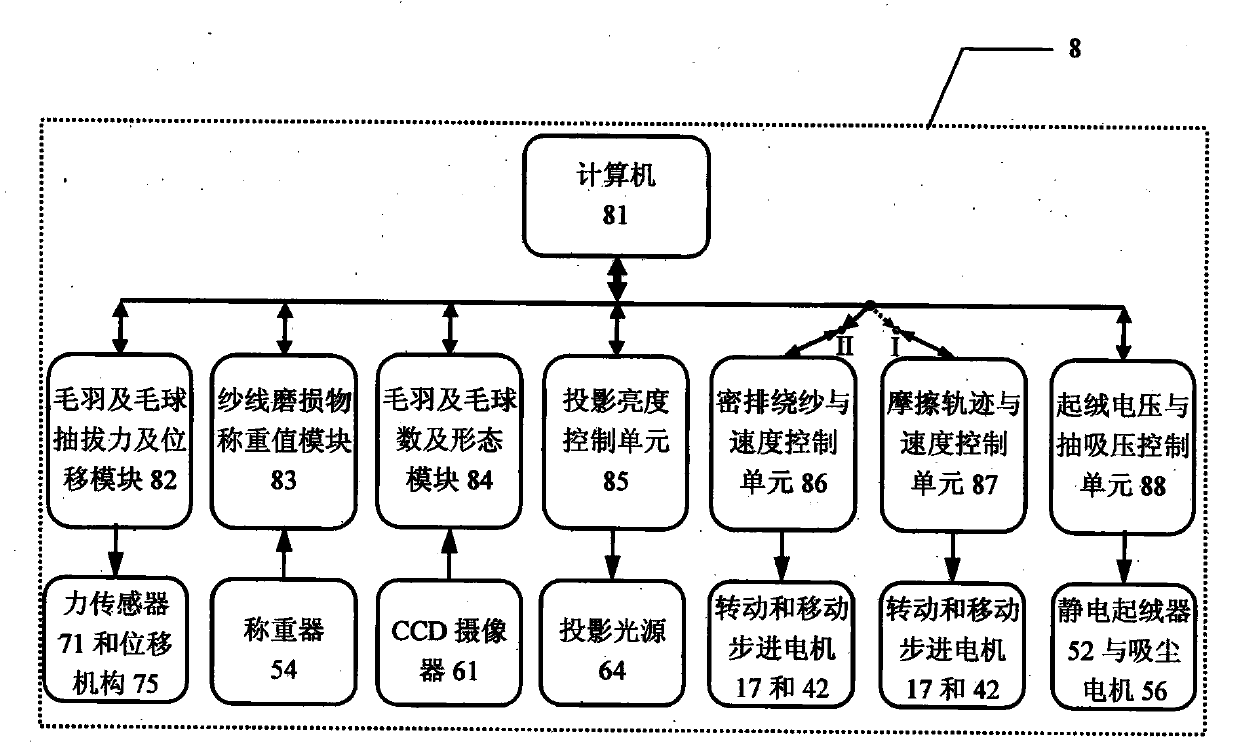

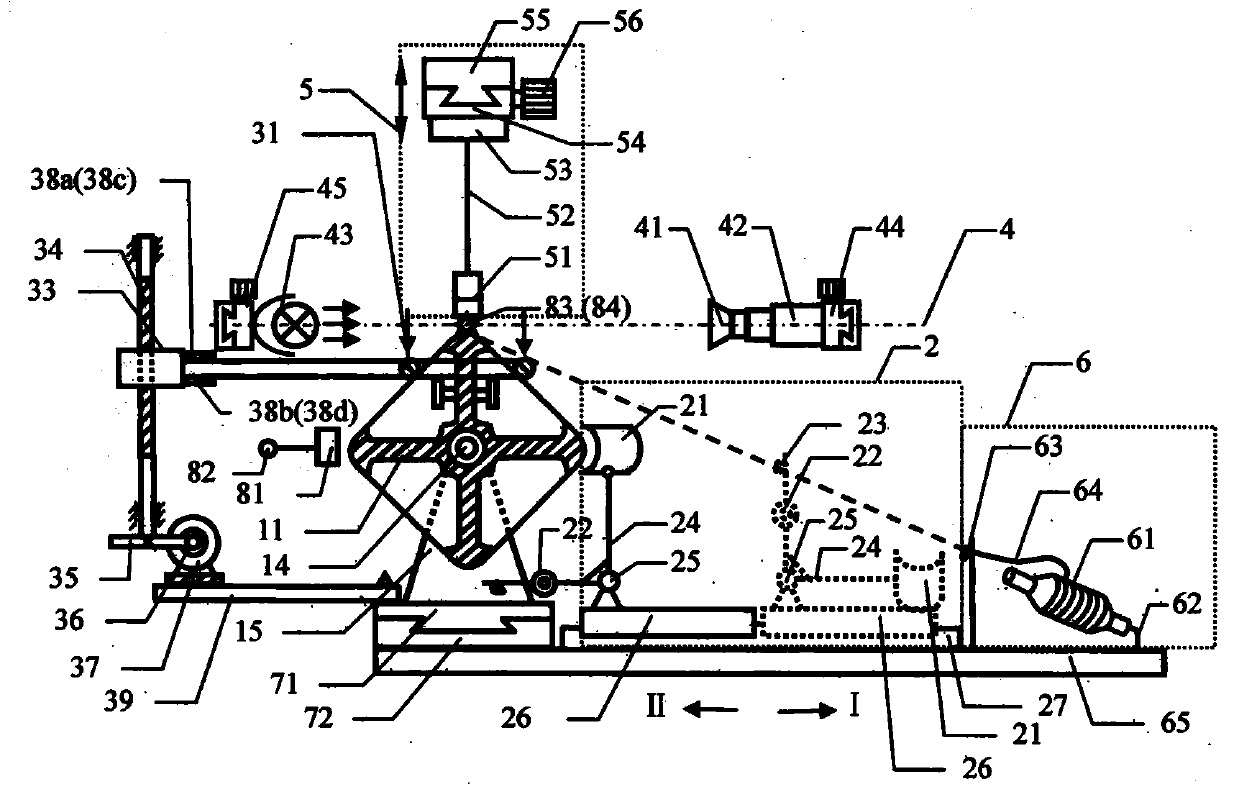

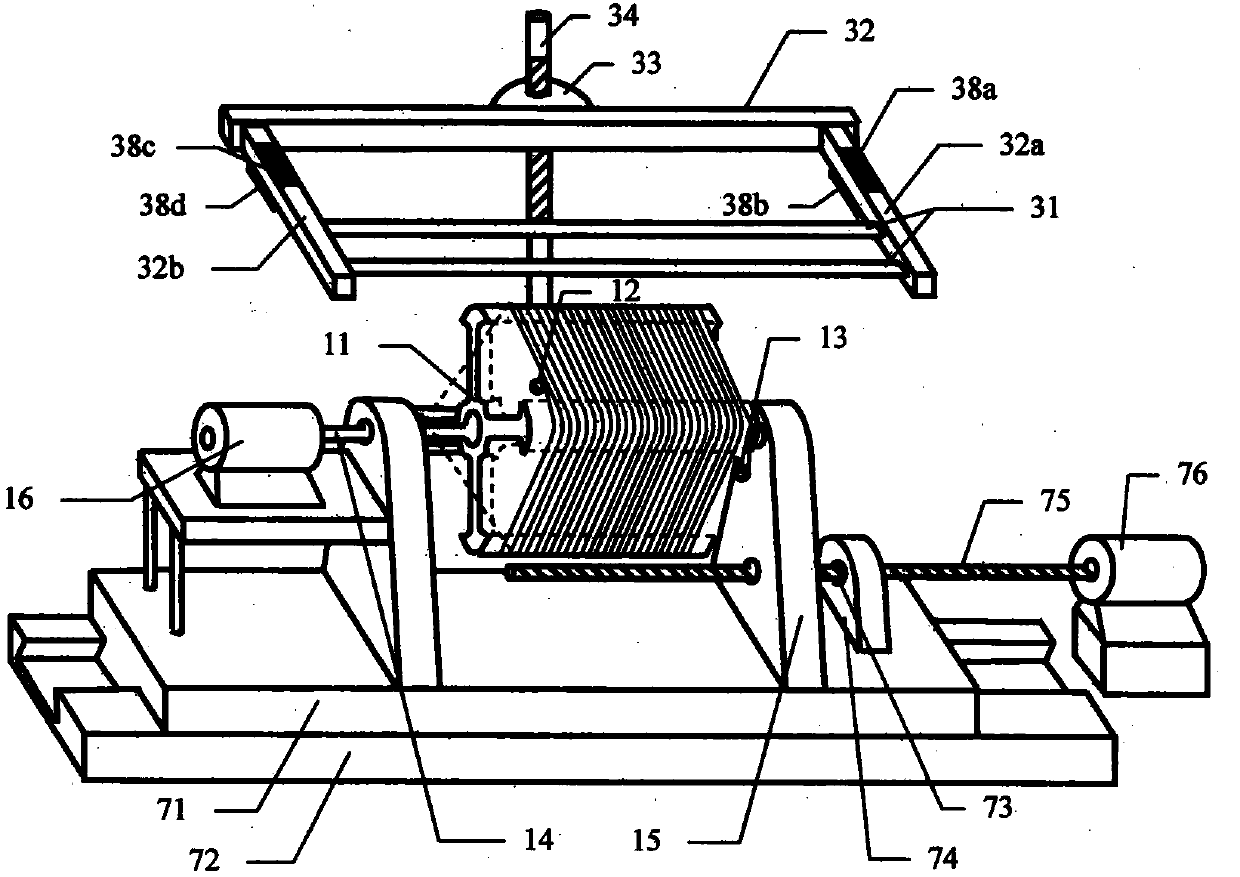

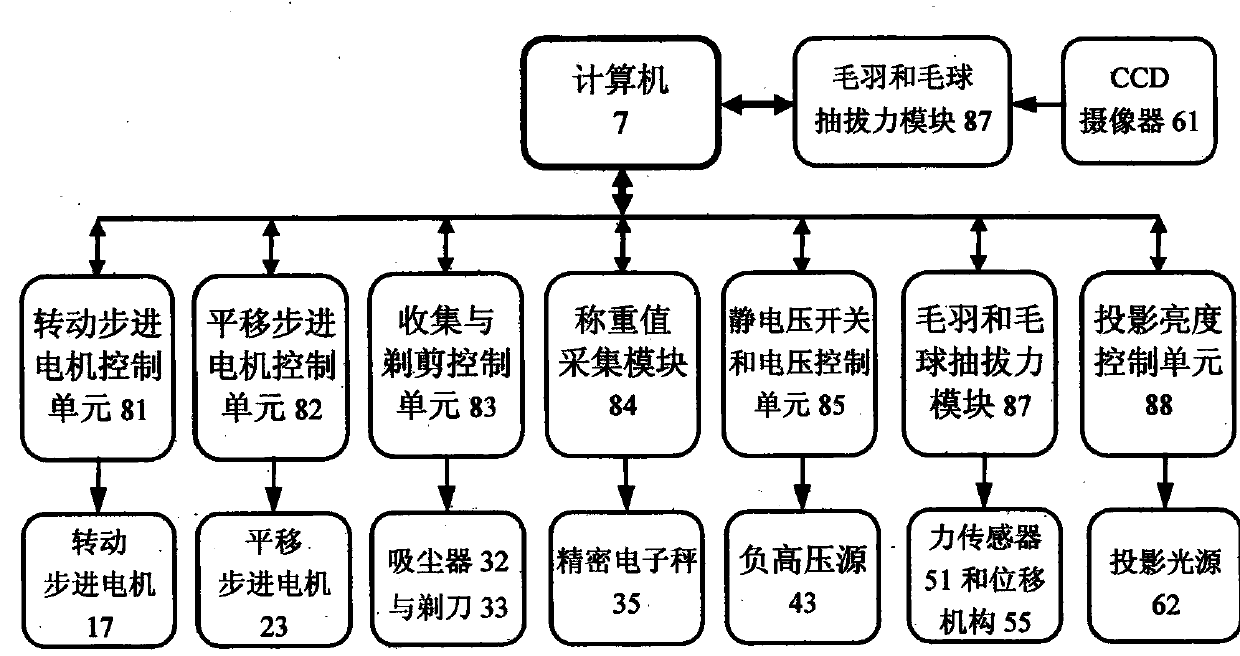

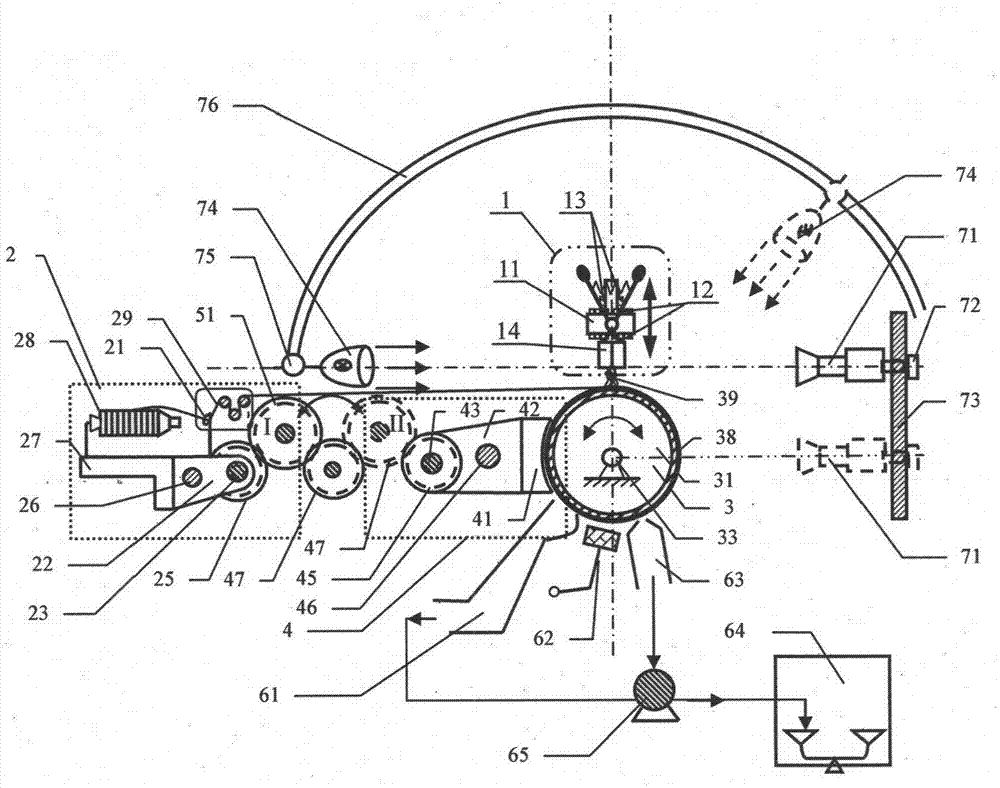

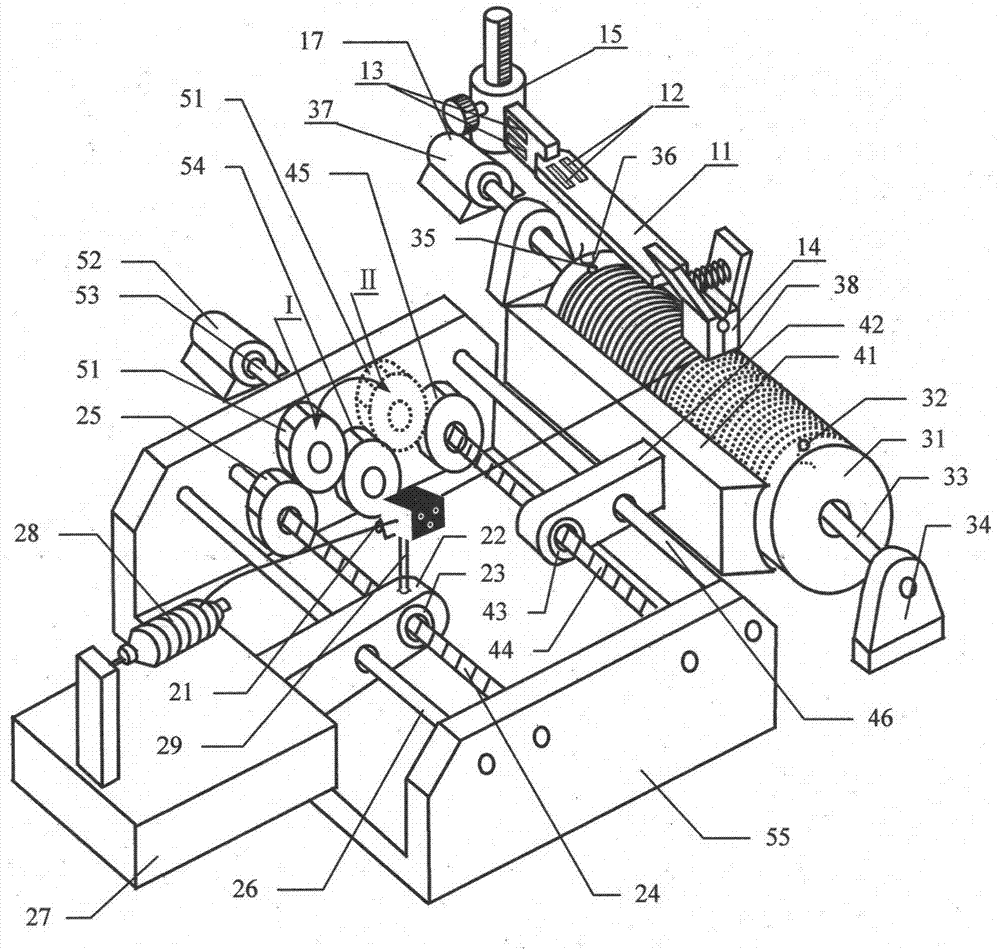

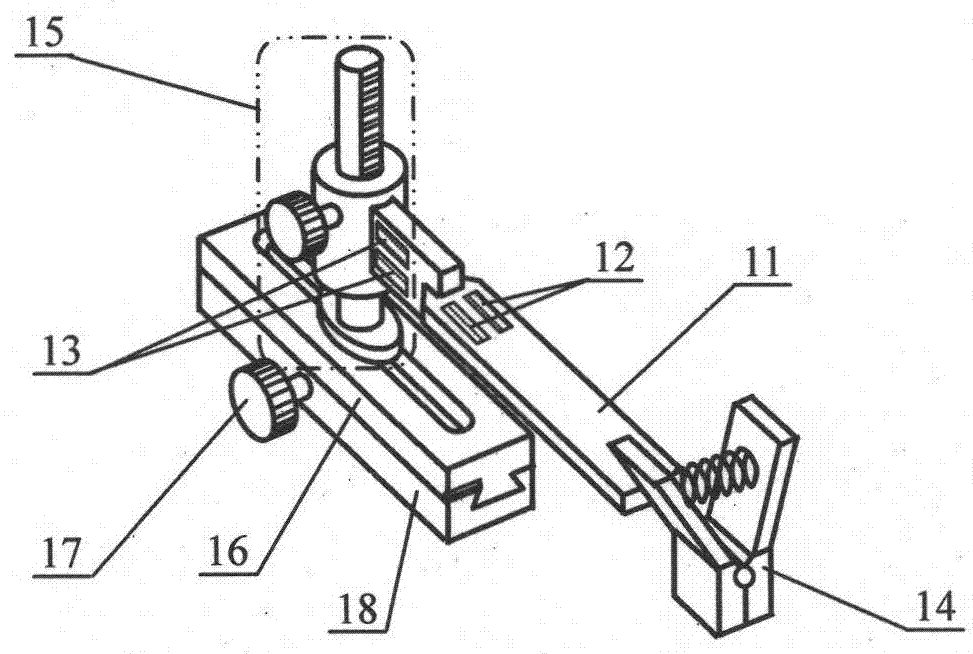

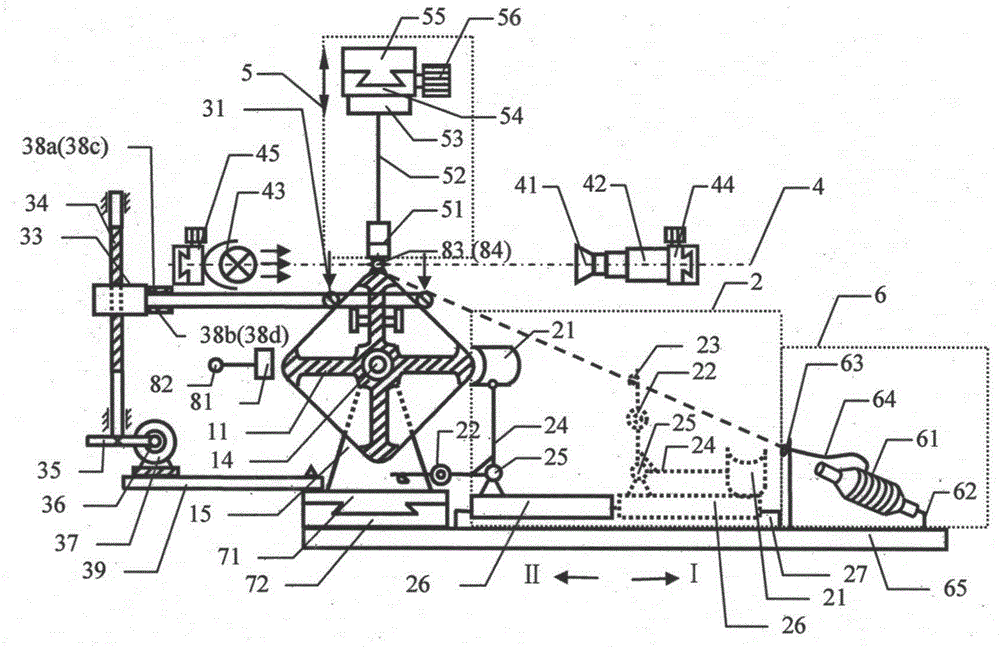

Measuring device and method for fluffing and balling shape as well as hair bulb stripping of yarn

ActiveCN103472210AEasy to measureAccurate collectionTextile testingInvestigating abrasion/wear resistanceYarnEngineering

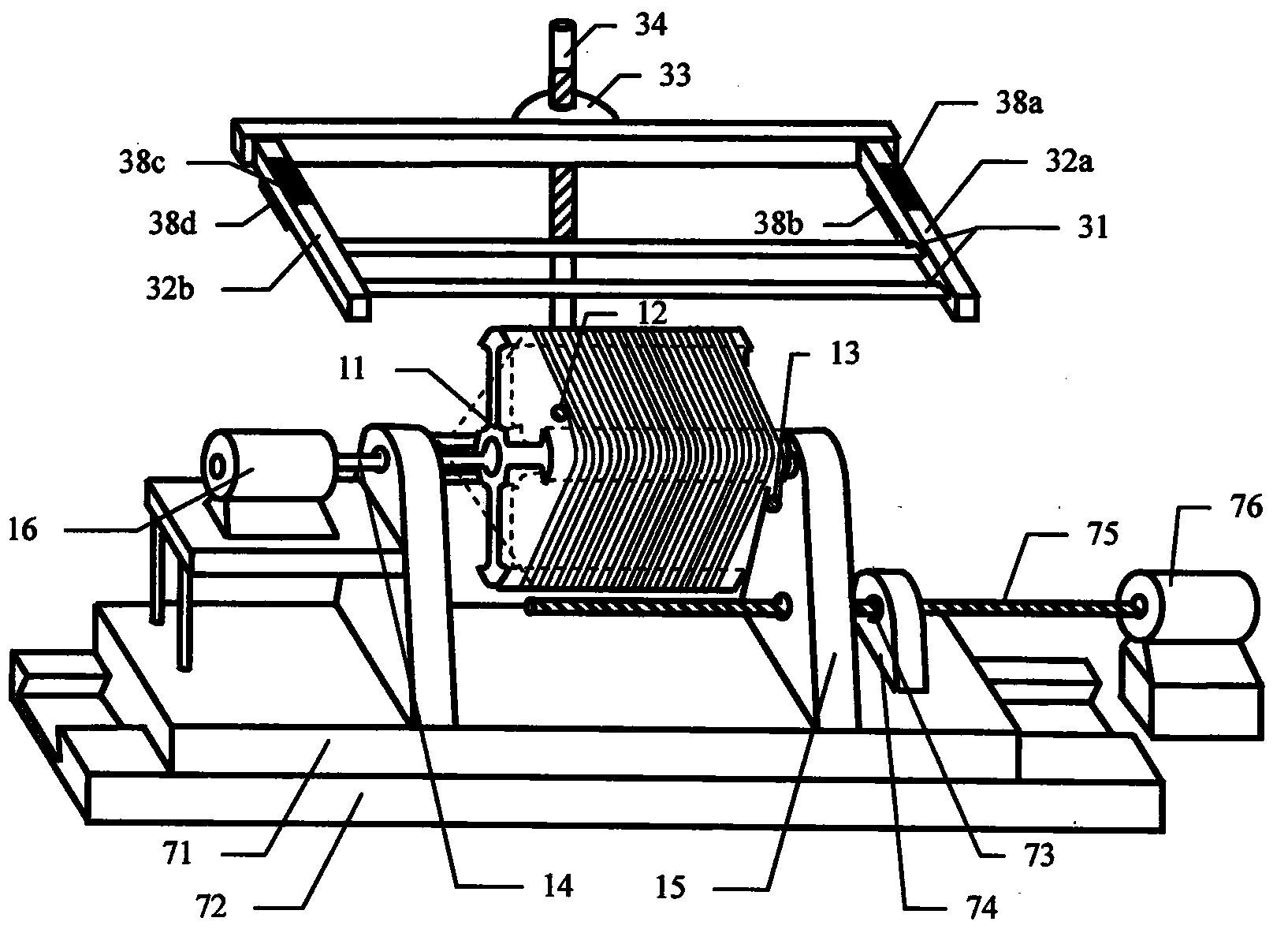

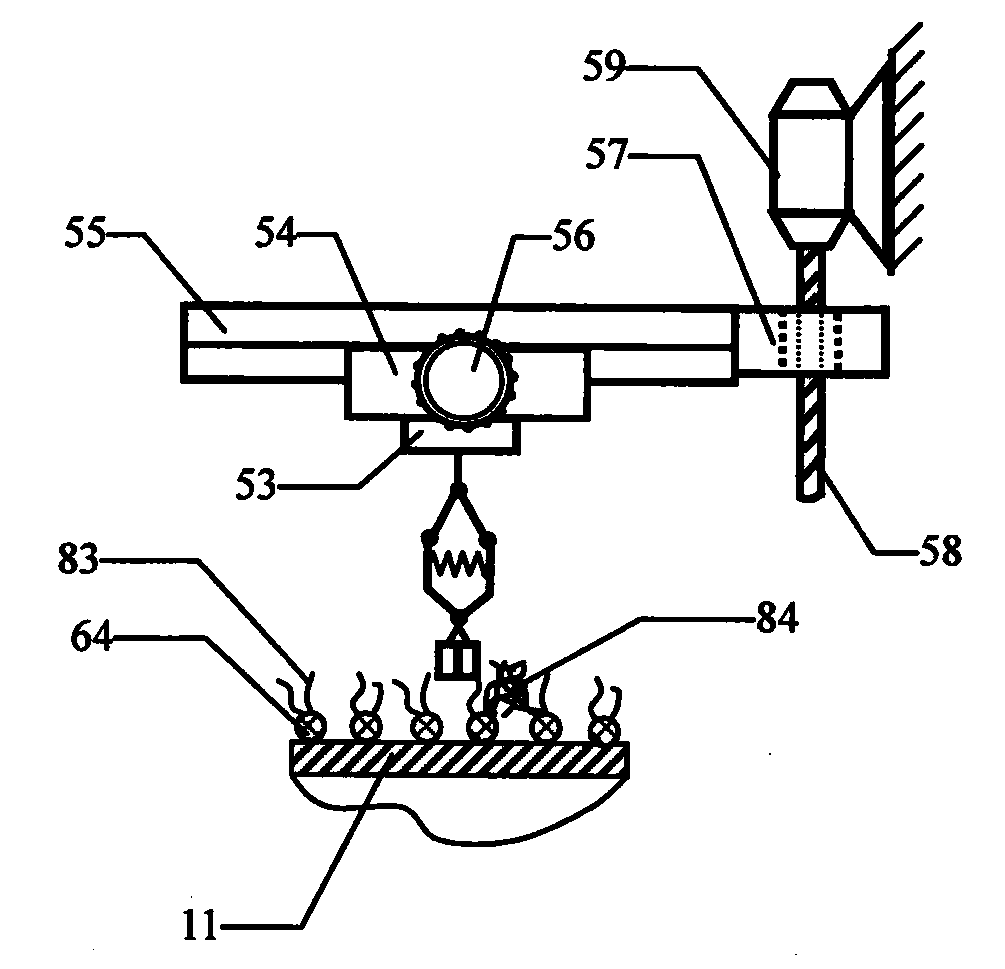

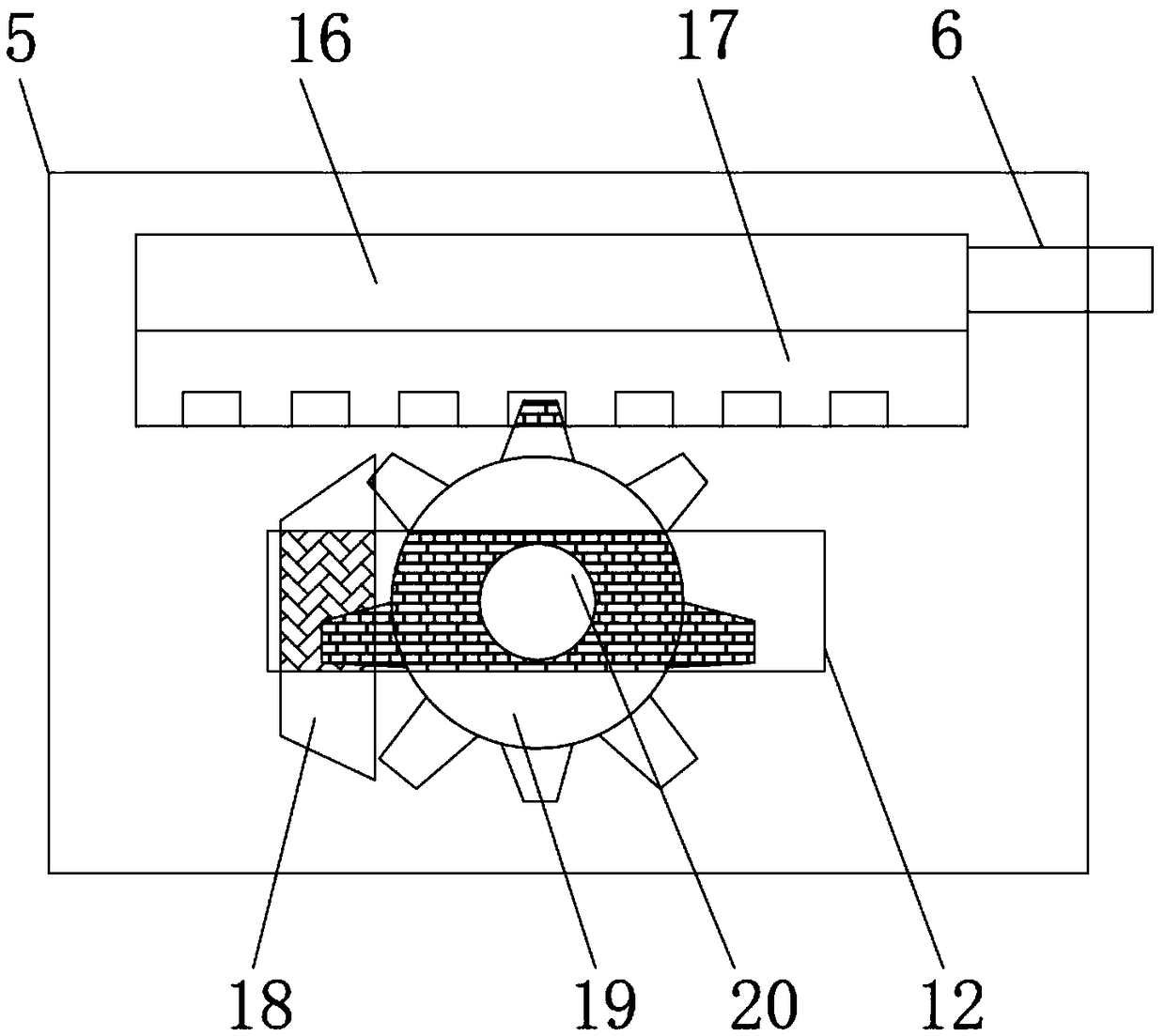

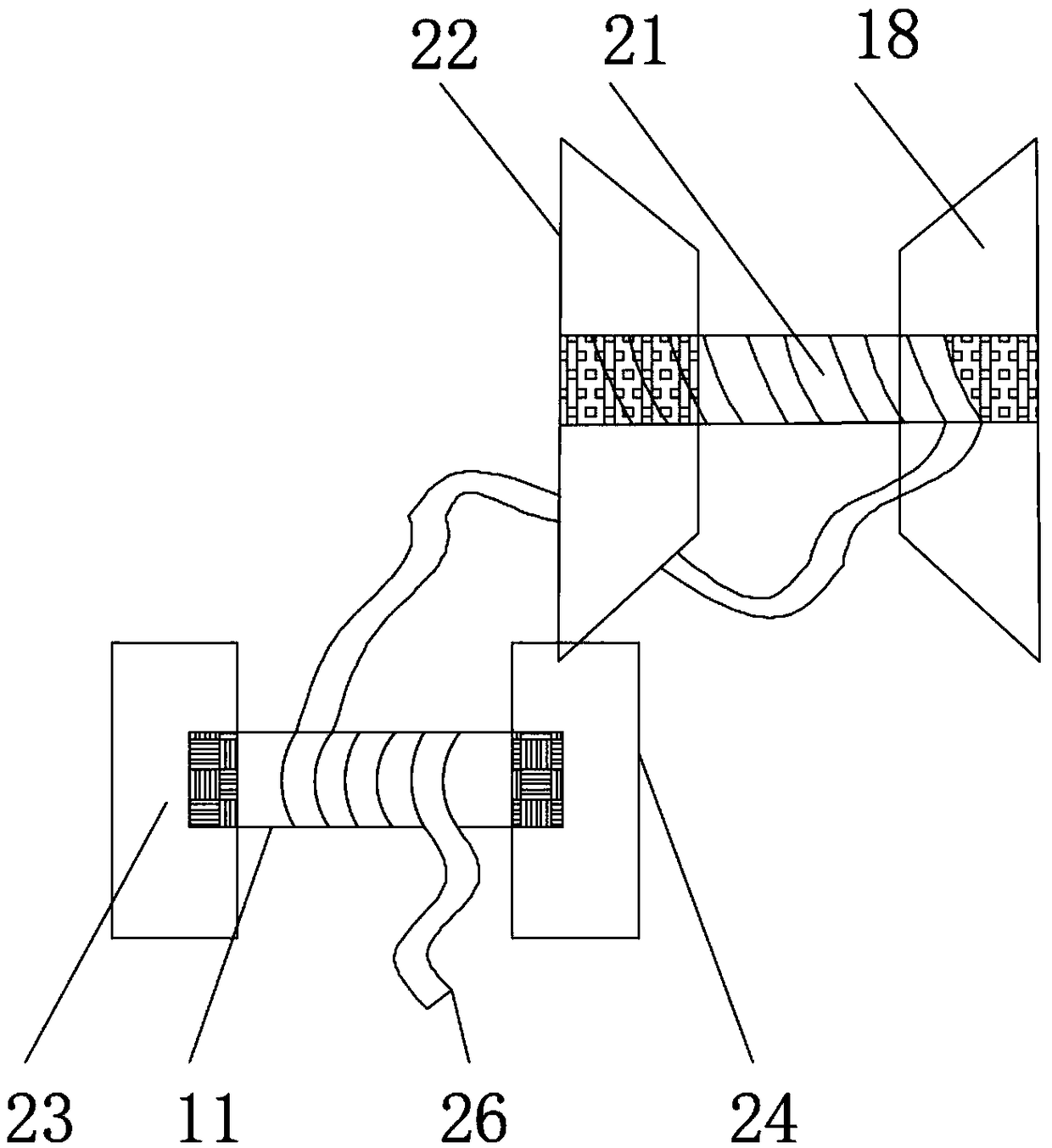

The invention relates to a device and a method for measuring fluffing and balling shape as well as hair bulb stripping of a yarn. The device comprises a mechanism clamping hair bulbs to implement stripping, a yarn delivery mechanism performing equal-tension close packing, a yarn winding mechanism winding the yarn at a constant speed, a yarn grinding mechanism performing friction on the close packed and wound yarn, a translation driving mechanism driving the yarn delivery mechanism and the yarn winding mechanism in a switching manner, an abrasion object collector, a microimaging system and a control and data analysis system. The measuring method comprises the steps that a gap bridge wheel of the translation driving mechanism transposes the yarn delivery mechanism and the yarn grinding mechanism, and is matched with the yarn winding mechanism, so that close packing yarn winding and yarn grinding sampling are achieved; a yarn grinding sample in a yarn grinding process is measured in situ; and comprehensive measuring and evaluation are performed on the yarn grinding sample in a final state. The device is ingenious in structure, practical, precise in measuring, quantitative, and multipurpose, is an in-situ measuring device for measuring multiple indexes, and can be used for measuring of the hair feather and hair bulb quantity, the shape, the abrasion loss and the back-and-forth drag stripping property of the yarn, and for comprehensive evaluation of the fluffing resistance and the balling resistance.

Owner:DONGHUA UNIV

Device and method used for measuring pilling form and pulling force of yarns

ActiveCN103471651AGet the right measurementsAchieve estimatesMaterial analysis by optical meansYarnPull force

The invention relates to a device and method used for measuring the pilling form and pulling force of densely arranged yarns. The device consists of a yarn winding mechanism, a yarn grinding mechanism, a yarn feeding mechanism, a translational driving mechanism, a wearer collector, a microscopic camera system, a clamping and pulling mechanism, and a control and data analysis system. The method comprises the steps of bridging and rotating the yarn feeding mechanism and the yarn grinding mechanism through the translational driving mechanism, kinetically matching with the yarn winding mechanism to achieve the winding of the densely arranged yarns and yarn grinding sample preparation, and carrying out on-line measurement on yarn samples in the process of yarn grinding as well as comprehensive measurement, calculation and evaluation on yarn grinding samples in a final state. The device is ingenious in structure, practical, and precise and quantitative in measurement, and the device and the method are an in-situ measuring device and an in-situ measuring method which are multi-purpose and multi-index in one measurement. The device and the method can be used for the measurement of the pilling quantity, form and wear quantity of the yarns and pulling forces of hairiness and hair bulbs as well as the comprehensive evaluation of the pilling resistance.

Owner:DONGHUA UNIV

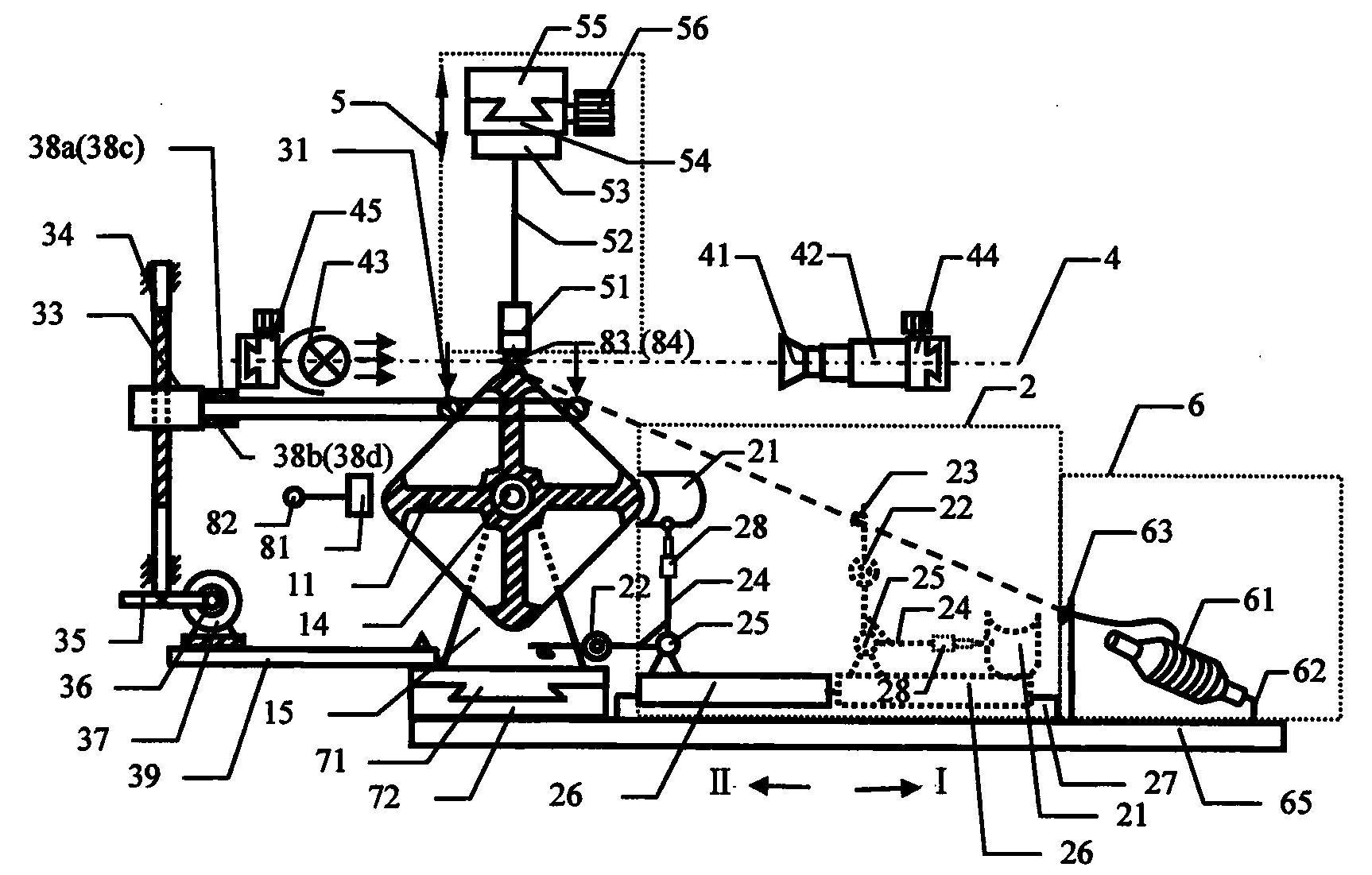

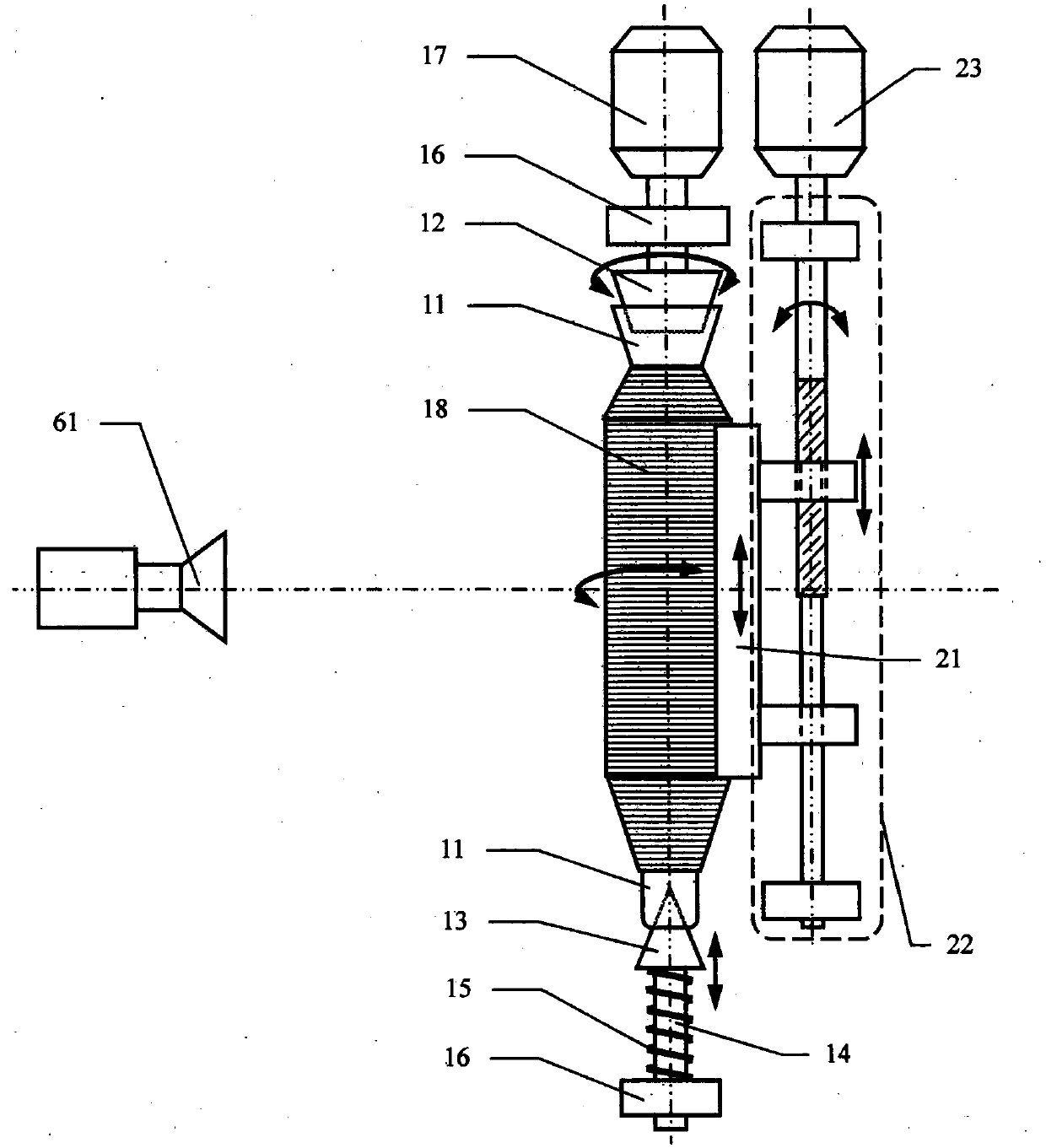

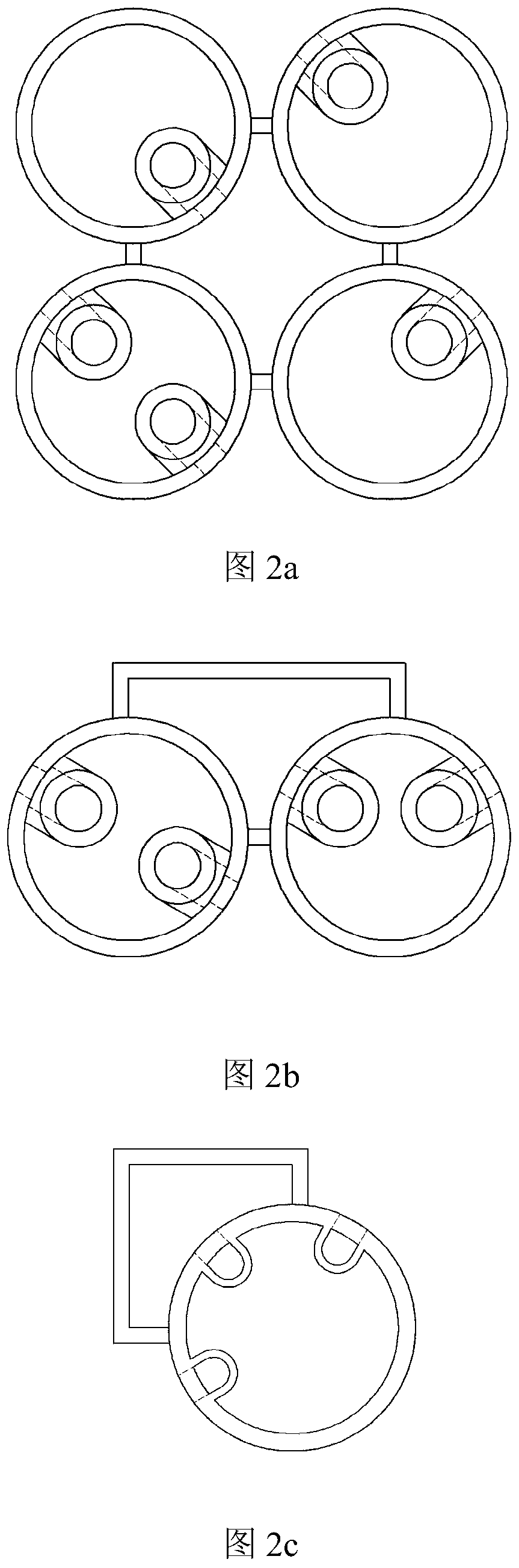

Polygonal-barrel tension-controllable fuzzing and pilling form and pulling measurement device and method

ActiveCN103898730APredicting Pilling ResistanceSample preparation results are stableInspecting textilesMeasurement deviceYarn

The invention relates to a polygonal-barrel tension-controllable fuzzing and pilling form and pulling measurement device and method. The device comprises a polygonal barrel, a friction mechanism, a tension mechanism, a microscopy photographing mechanism, a pulling mechanism, a creel, a static raising device and a control and data collection analysis system. The method includes the steps that after yarns are arranged and wound, by means of the polygonal barrel rotating angle by angle clockwise, raising, form observation and fuzzing and pilling sample preparation are carried out synchronously angle by angle on original yarn, ground yarn is obtained, raising and form observation are carried out synchronously angle by angle on the ground yarn until friction sample preparation and form measurement of all angles are finished, and then a microscopy form value and a pull force curve of yarn hairness and hair balls pulled from the ultimate ground yarn which pre-tension is exerted on are measured angle by angle. The measurement device and method are quick, easy and convenient to use, practical and accurate, can be used for fuzzing and pilling sample preparation of the yarn, measurement of fuzzing and pilling yarn hairness, hair ball quantity and form and the pulling curve and comprehensive evaluation of anti-pilling performance of the yarn.

Owner:DONGHUA UNIV

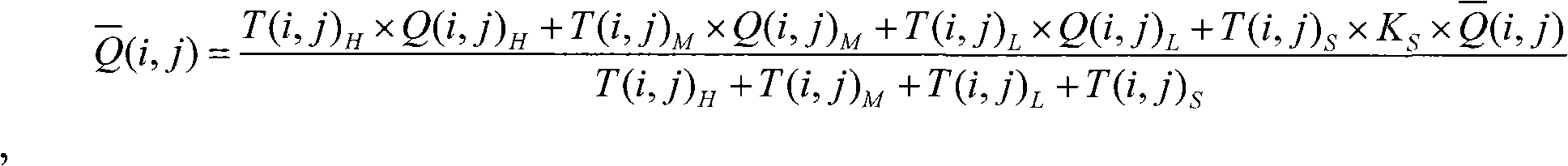

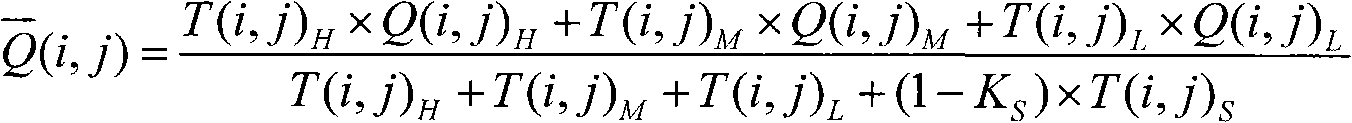

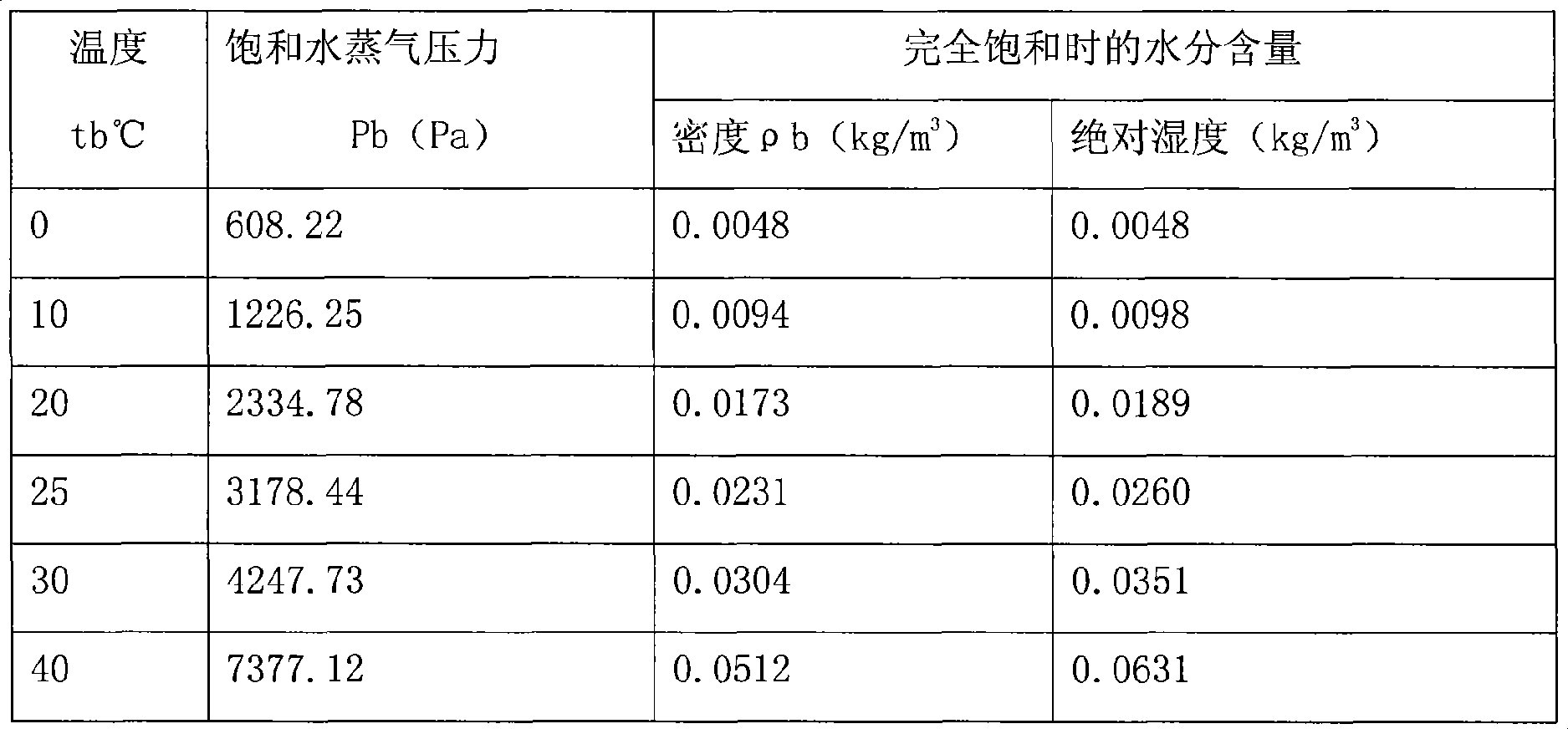

Cold and heat metering isenthalpic difference calibration weighting method for central air-conditioning fan coil

InactiveCN101995264AEasy to measureSolve the problem of fairness in heat cost sharingTariff metering apparatusCalorimeterEngineeringWind speed

The invention relates to a cold and heat metering isenthalpic difference calibration weighting method for a central air-conditioning fan coil, comprising the following steps of: calibrating the weighted values of the fan coil at various air speeds on site; determining the thermal equivalents of the fan coil at various air speeds according to the weighted values; determining the heating cost of the fan coil according to the thermal equivalents at various air speeds, wherein the calibration of the weighted values comprises the following steps of: inputting the total heat corresponding to the high air speed, the medium air speed and the low air speed through looking up a product specification of the fan coil into a metering temperature controller; imbedding the weighted value of the fan coil under the fan stop status into the metering temperature controller; embedding the time of starting the calibration and the time of stopping the calibration into the metering temperature controller; controlling temperature by the metering temperature controller through automatically regulating the air speed of the coil fan; and after the calibration is ended, automatically generating the weighted values of the fan coil corresponding to the high air speed, the medium air speed and the high air speed through the metering temperature controller. The invention makes the fan coil metering simple and easy to implement, can realize the same comfort level and the same cost and can restrain the waste phenomenon of windowing and the like.

Owner:张帆

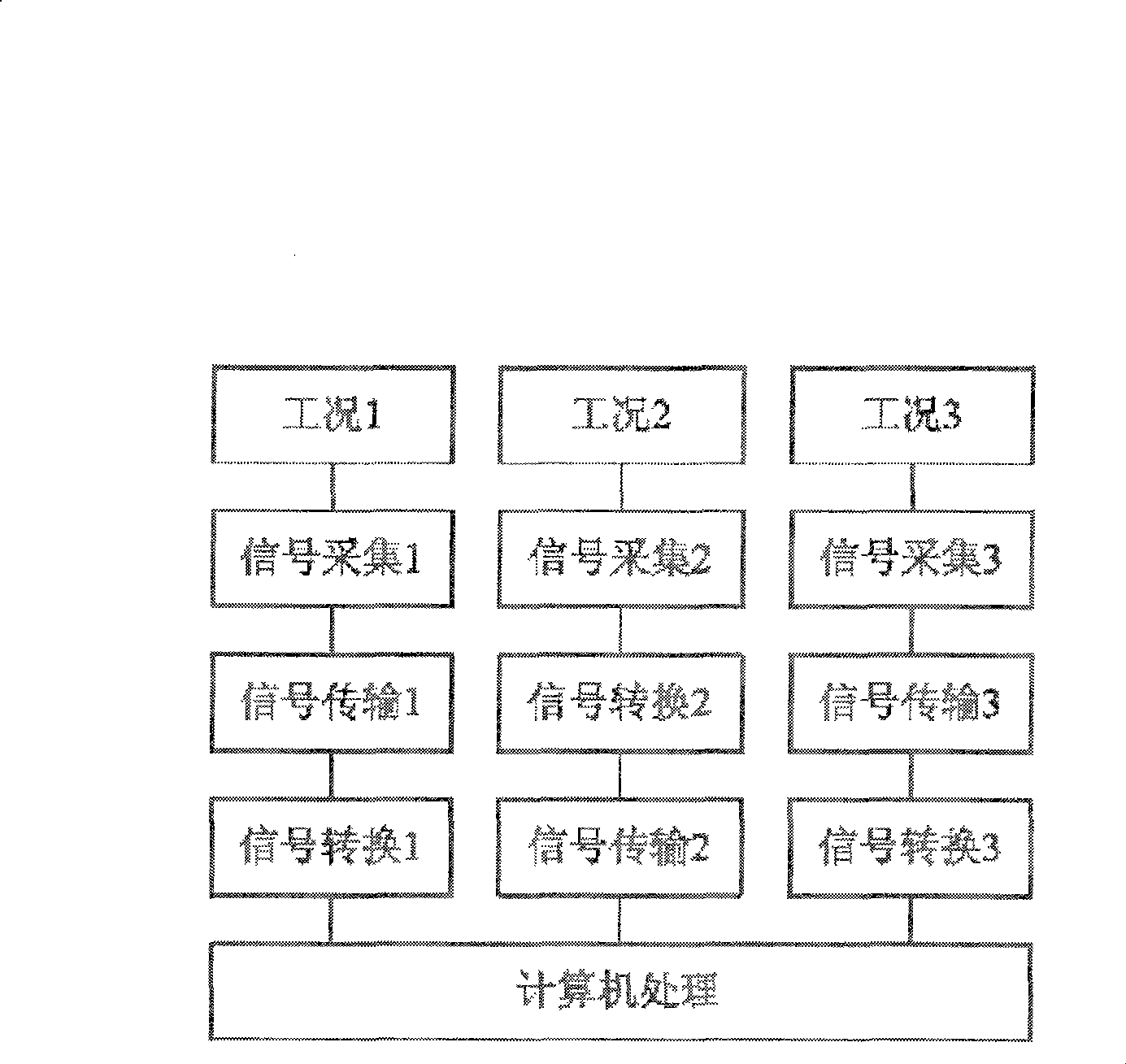

Measuring method for mixed gas under complex working condition

InactiveCN101382448AImprove stabilityImprove reliabilityVolume variation compensation/correction apparatusIndirect mass flowmetersMathematical modelProduct gas

The invention relates to a measuring method of gas energy resources of industrial enterprises, in particular to the measuring method of mixed gas under complex working condition. The technical proposal is that: under the condition of mixing blast furnace gas and coke oven gas, density compensation is carried out by applying computer software to compensate a mathematical model according to a thermal value and taking the thermal value as one of the parameters on the basis of the original temperature and pressure compensation, thus obtaining the accurate measuring value of the mixed gas; the adoption of the co-existence of a plurality of communication ways, and the application of computer process control technology and thread parallel technology can effectively improve the stability and reliability of system operation. The method can cause the measurement of the mixed gas to be more scientific and close to the true value, solves the problem of the accurate measurement of mixed gas medium which is greatly influenced by the thermal value under the condition of complex working condition, and can be widely applied to heavy industry enterprises using the mixed gas, thus causing the measurement and the operation of the mixed gas to be more reasonable and effectively guiding the production.

Owner:承德新新钒钛股份有限公司

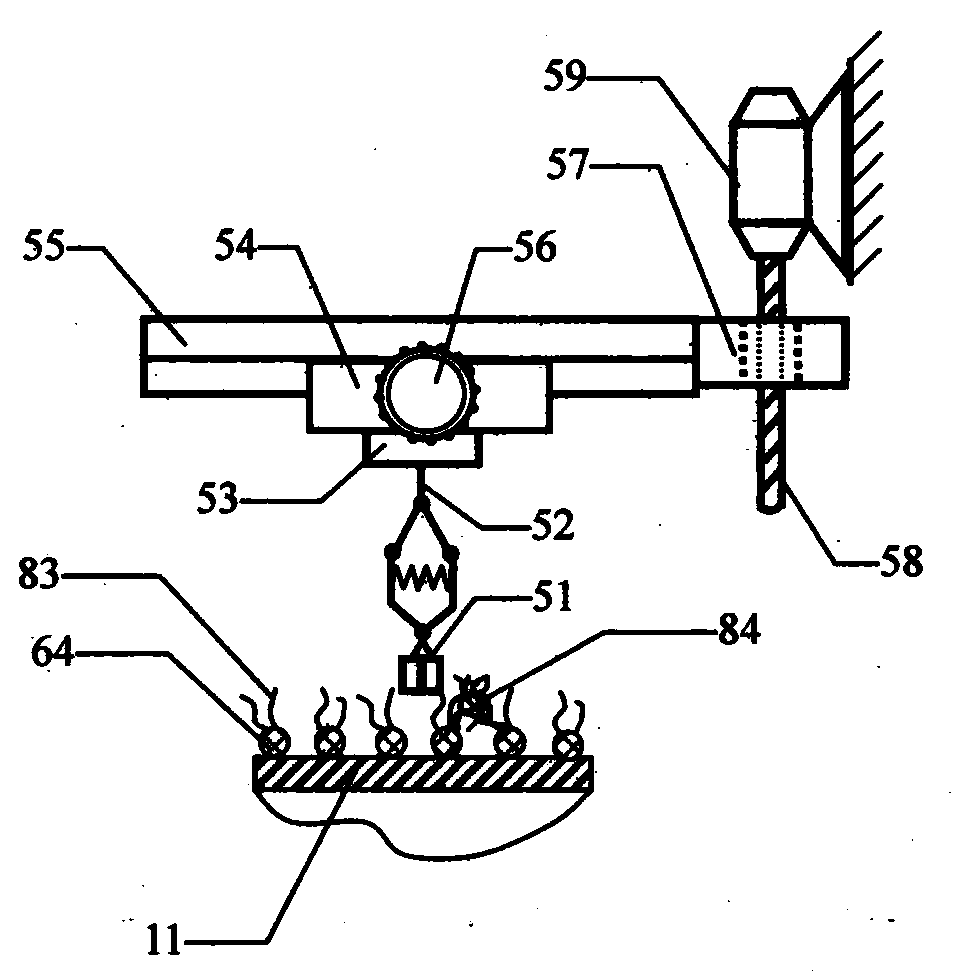

Polygonal cylinder type yarn grinding hairness and hair bulb tension holding pull measuring device and method

ActiveCN103469533APredicting Pilling ResistanceThe results of the extraction measurement are accurateInspecting textilesUsing mechanical meansYarnPull force

The invention relates to a polygonal cylinder type yarn grinding hairness and hair bulb tension holding pull measuring device and method. The device comprises a polygonal cylinder with 3-6 angles, a friction mechanism, a yarn layer tension mechanism, a microscopy camera mechanism, a pull mechanism, a yarn frame, a static raising device and a control and data collection analyzing system. The method includes: when dense yarn winding is completed, performing Lissajous curve friction on yarn on the polygonal cylinder angle by angle to obtain yarn grinding samples, pressurizing the yarn grinding samples turning to the top angle by angle, holding yarn layers, clamping ground hairness or hair bulbs for pull force measurement and hairness or hair bulb formation observation until pull measurement of each angle is completed so as to obtain hairness and hair bulb microscopy formation values and pull force curves under tension holding. The device and the method are fast, simple, practical, accurate, applicable to hairness and hair bulb sampling of yarn. measurement of hairness and hair bulb pull curves and formation, and comprehensive evaluation of anti-hairness and anti-hair-bulb performance of yarn.

Owner:DONGHUA UNIV

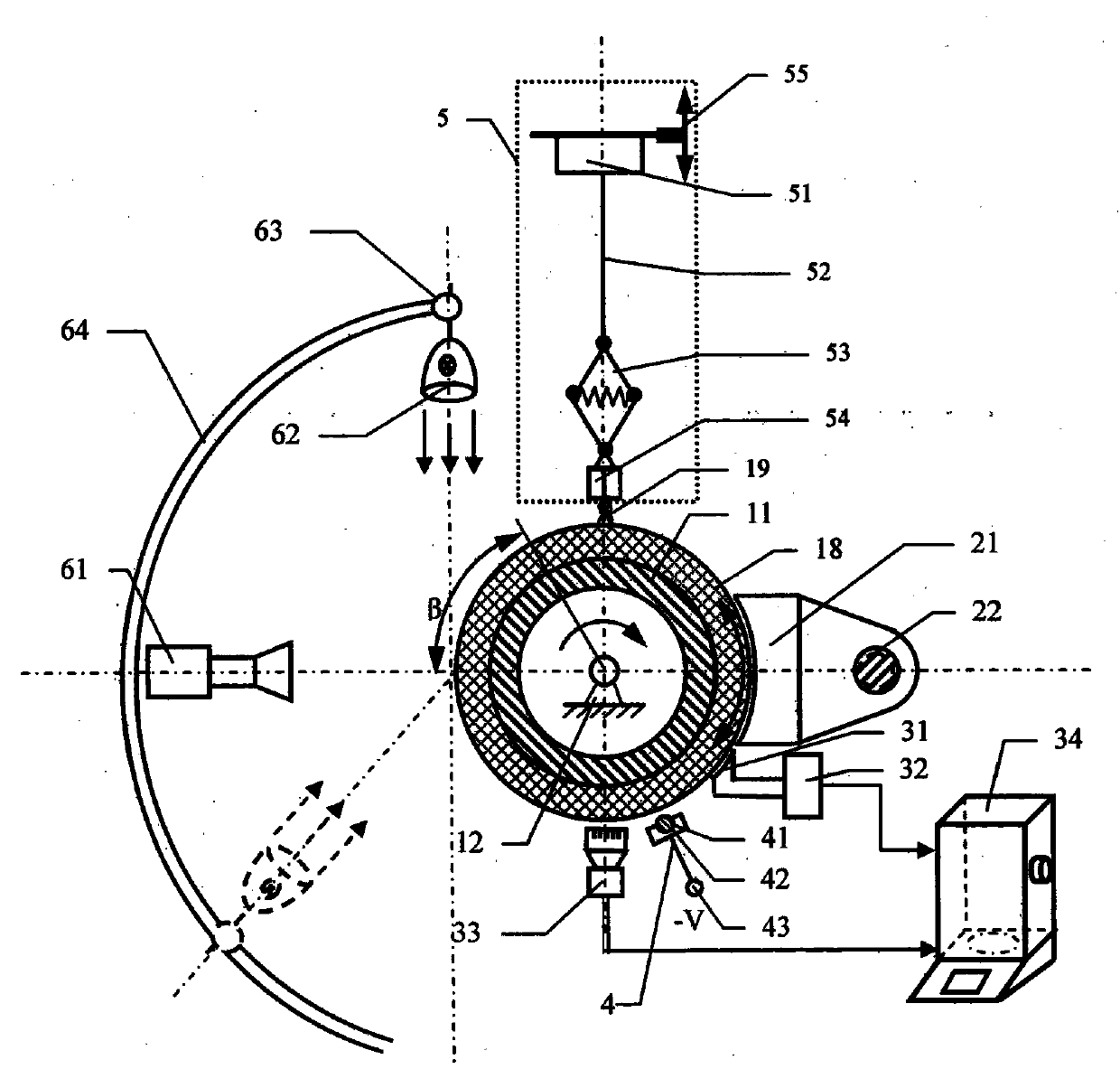

Device and method for measuring friction fuzzing and pilling forms and pulling-out force of bobbin yarns

ActiveCN103471650AEliminate the winding processSimple sample preparationMaterial analysis by optical meansYarnEngineering

The invention relates to a device and method for measuring friction fuzzing and pilling forms and a pulling-out force of bobbin yarns. The device comprises a cop creel for clamping cops to rotate, a friction mechanism for fuzzing and pilling bobbin yarns, a collecting mechanism for collecting shaving and shearing filoplumes and fuzzy balls, a static raising device for helping filoplumes to stand, a pulling-out mechanism used for measuring the pulling-out force of the filoplumes and fuzzy balls, an imaging system for observing the filoplumes and fuzzy balls of the bobbin yarns, a computer and a data acquiring and controlling system. The method comprises the steps of: measuring the prominence of the filoplumes and the number, the form size and distribution of the fuzzy balls after coaxially jacking and clamping the cops, carrying out friction for fuzzing and pilling and synchronously measuring the prominence of the filoplumes, the number of the fuzzy balls, the abrasion loss and retention of the filoplumes and fuzzy balls, and the pulling-out force of the filoplumes and fuzzy balls of the process and a final friction sample. The device and method are exquisite, practical, accurate and quantitative, and can be used for measuring the fuzzing and pilling forms of the bobbin yarns and comprehensively evaluating the fuzzing and pilling resistance. In situ measurement of multiple functions in one machine and multiple indexes in one-time measurement is adopted in the device and method.

Owner:DONGHUA UNIV

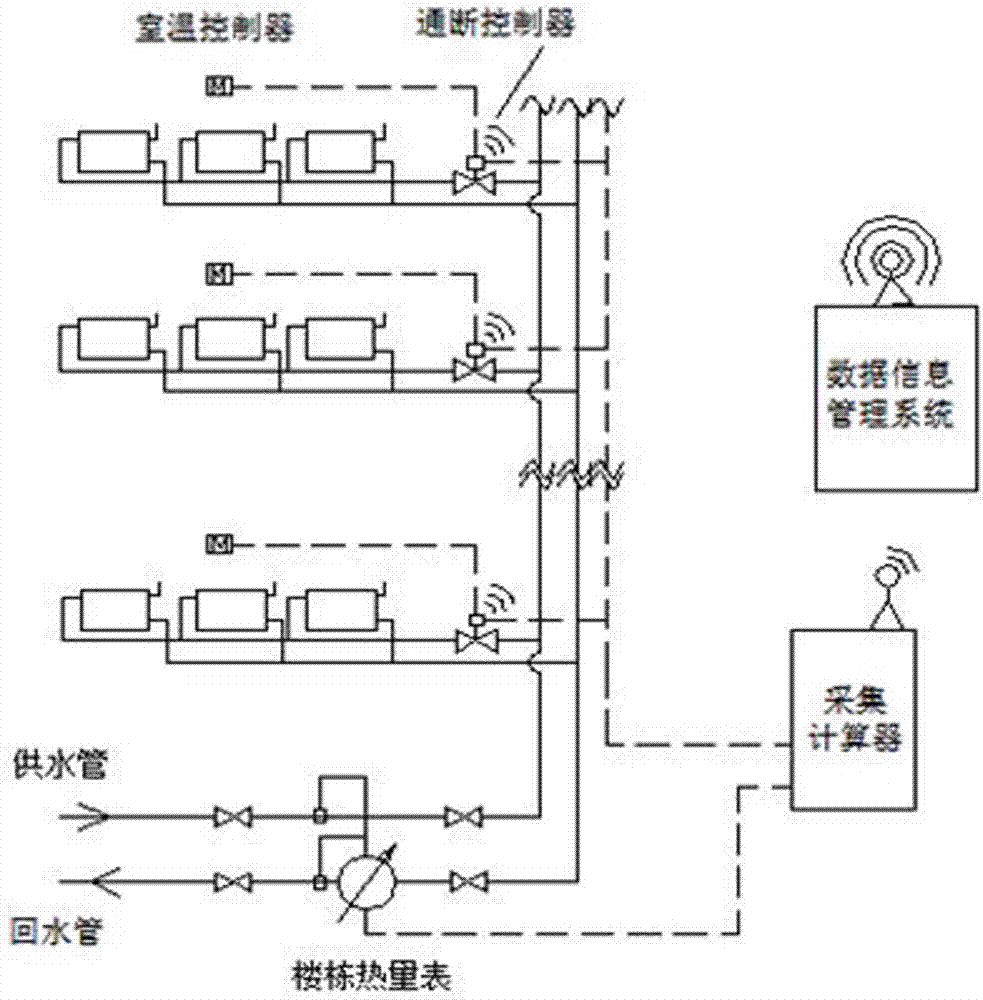

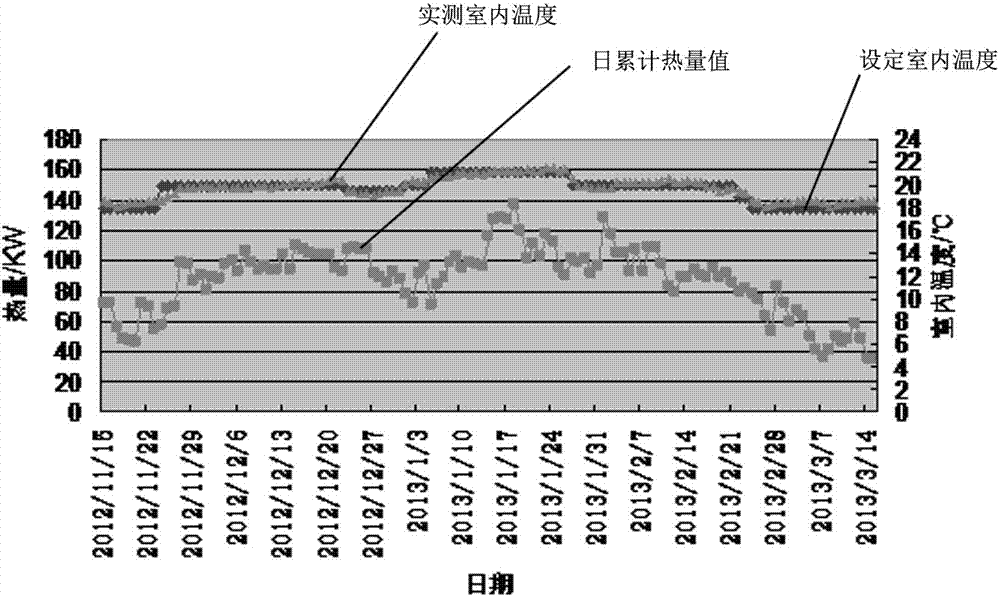

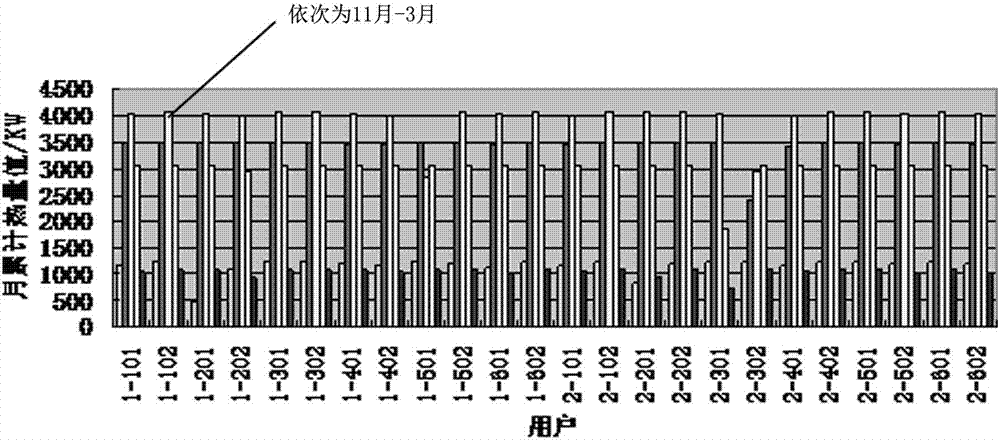

On-off time area apportioning method based on climate compensation and on-off type heat metering device based on climate compensation

InactiveCN107166506ARealize separate adjustmentReasonable measurementLighting and heating apparatusSpace heating and ventilation detailsThermodynamicsEngineering

The invention discloses an on-off time area method heat apportioning method based on climate compensation and an on-off type heat metering device based on climate compensation. Existing heating metering methods are compared and analyzed, the problems and the defects of the on-off time area method are summarized when the method is better than other heat metering methods, a relatively perfect method is put forward on the basis of theoretical research and experimental verification so as to solve the problems, according to adjusting periods of climate compensation, a novel heat apportioning scheme for a heat apportioning mode is determined, and the on-off time area method heat metering device based on climate compensation is developed and researched. The novel heat apportioning technology based on climate compensation is adopted, heat apportioned to various users are basically consistent with the user heat consumption, that is, the outdoor temperature change, the problem of heat apportioning difference in the same period within the same on-off time is solved, heat apportioning is fair and reasonable, and the principle that the same heat fee is paid under the condition of the same comfort level for the users having the same area is met.

Owner:石家庄华浩能源科技有限公司

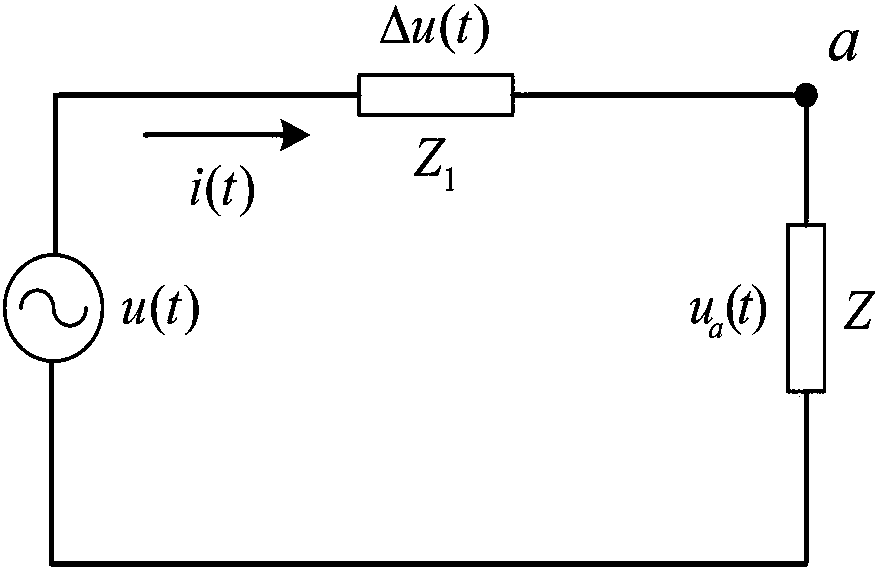

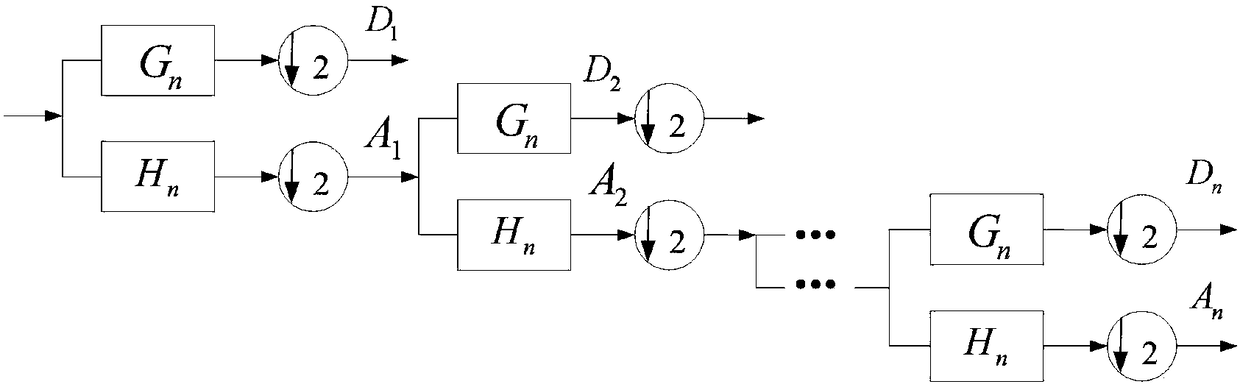

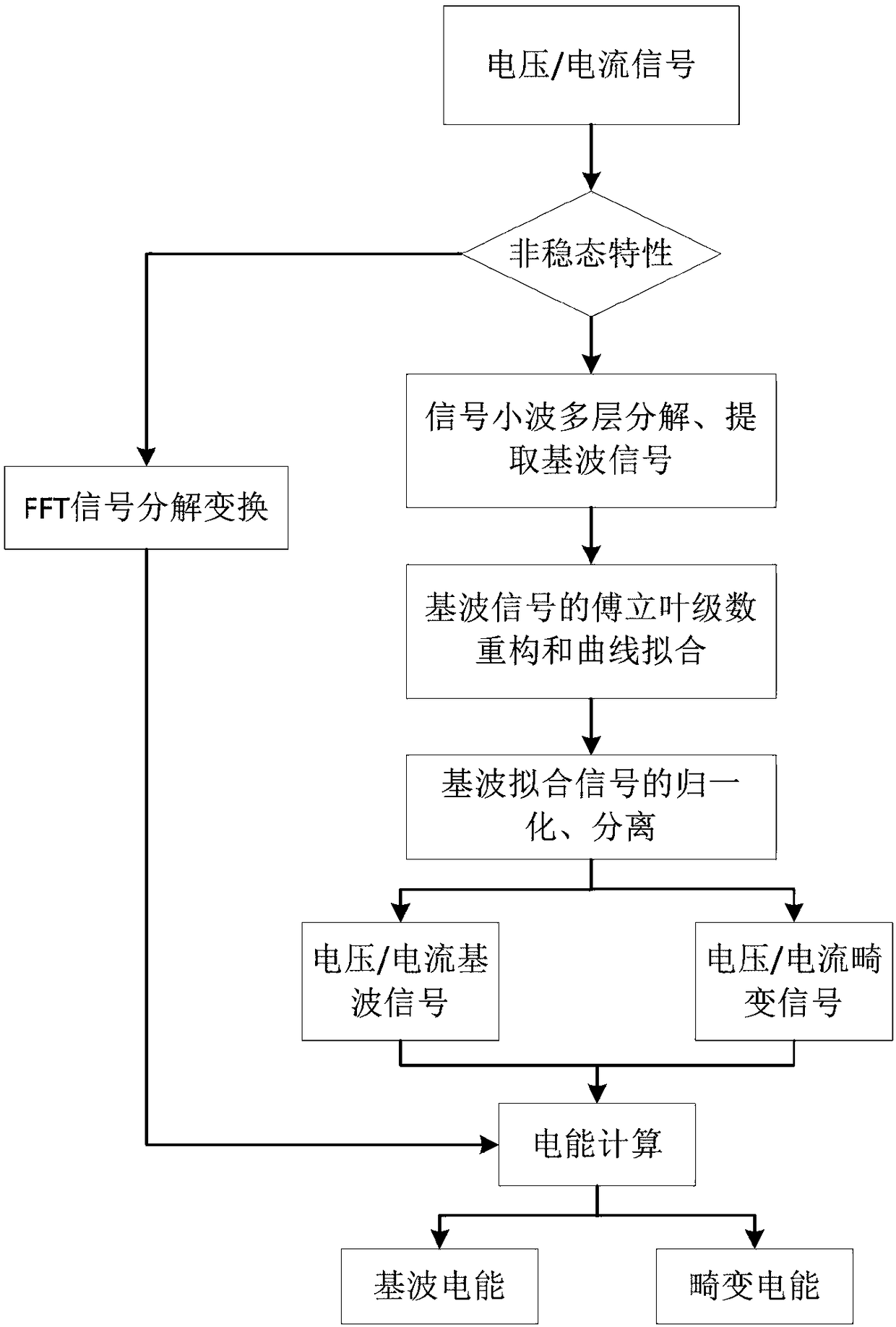

Electric energy metering method under distorted signal condition based on wavelet transform and curve fitting

InactiveCN108169553AAccurate and reasonable measurementReasonable measurementElectrical measurementsElectric power systemPower grid

The invention belongs to the electric power system field and discloses an electric energy metering method under a distorted signal condition based on wavelet transform and curve fitting. The method ischaracterized by firstly using wavelet transform to decompose and reconstruct power grid distortion voltage and current signals and acquiring a fundamental wave signal; then, using Fourier series tocarry out curve fitting on a fundamental wave reconstruction signal, and after normalization, acquiring the measured values of a power grid fundamental wave voltage and a current; and finally, subtracting the measured fundamental wave signal from an original signal and acquiring the power grid distortion voltage and current signals, and through the data processing module of an electric energy metering device, accurately calculating the values of a fundamental wave and distortion electric energy.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Tool for detecting hydraulic pipe on forklift

InactiveCN109141326AEasy to controlAccurate measurement dataMeasurement devicesHollow article cleaningForeign matterEngineering

The invention discloses a tool for detecting the hydraulic pipe on a forklift, and the tool comprises a main body. The external surface of the upper end of the main body is fixedly provided with a display screen, and one side of the display screen is provided with a power switch. The external surface of one side of the main body is fixedly connected with a first wire, and one end, far from the main body, of the external surface of one end of the first wire is fixedly connected with a plug. The external surface of the front end of the main body is provided with an accommodation groove, and theexternal surface of the upper end of the accommodation groove is fixedly provided with a fixed platform. The external surface of the upper end of the fixed platform is fixedly provided with a spring column. The tool provided by the invention can detect the type of foreign matters in the hydraulic pipe and clear the foreign matters, can achieve the functions simultaneously through simple control, and is more convenient and reasonable for the measurement of the basic data of the hydraulic pipe. The accommodation of a flow sensor is more reasonable, and the wire connected with the flow sensor canbe conveniently arranged.

Owner:安徽双兴机械有限公司

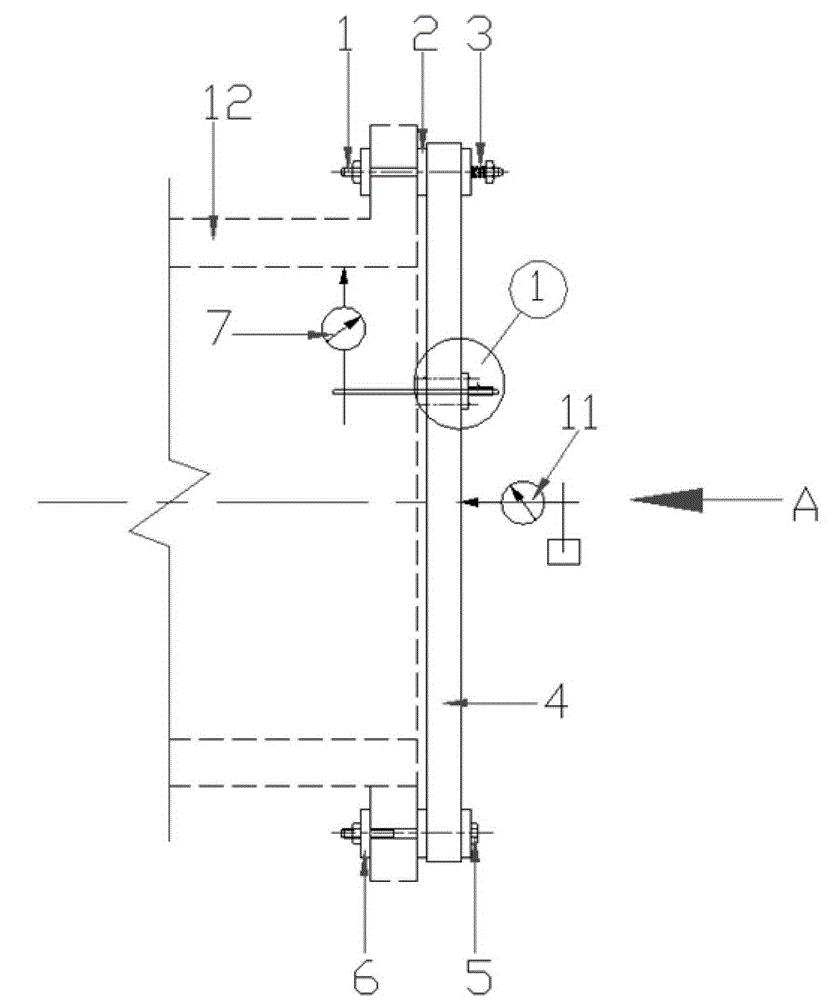

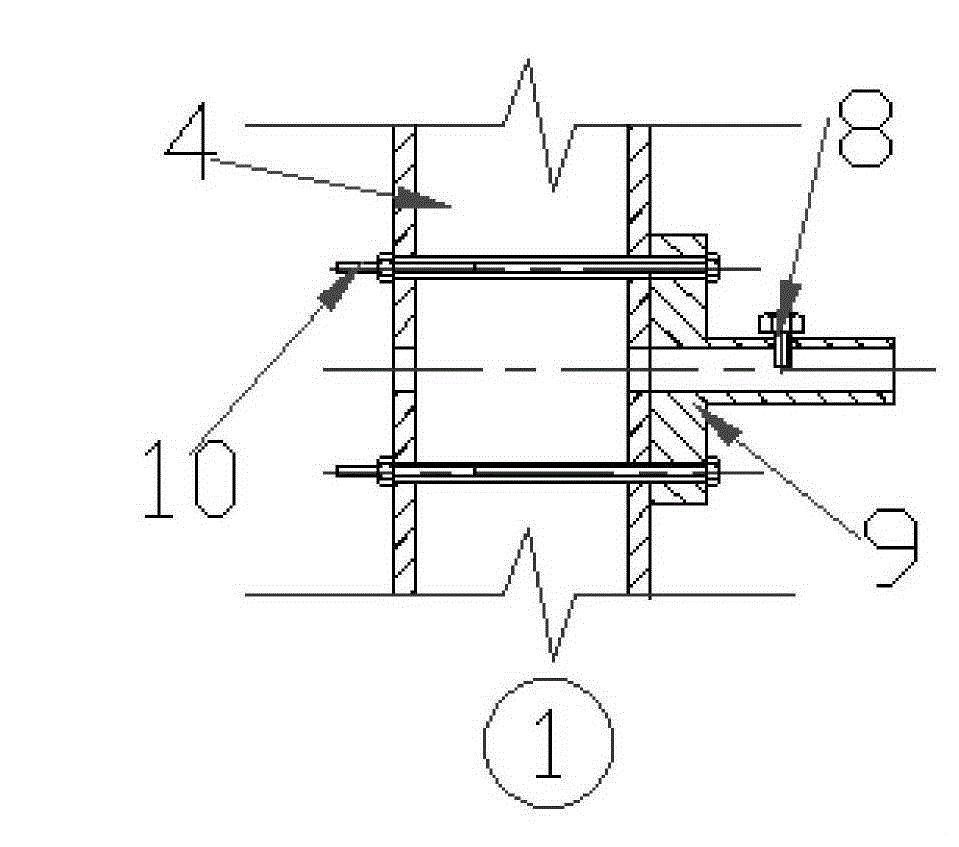

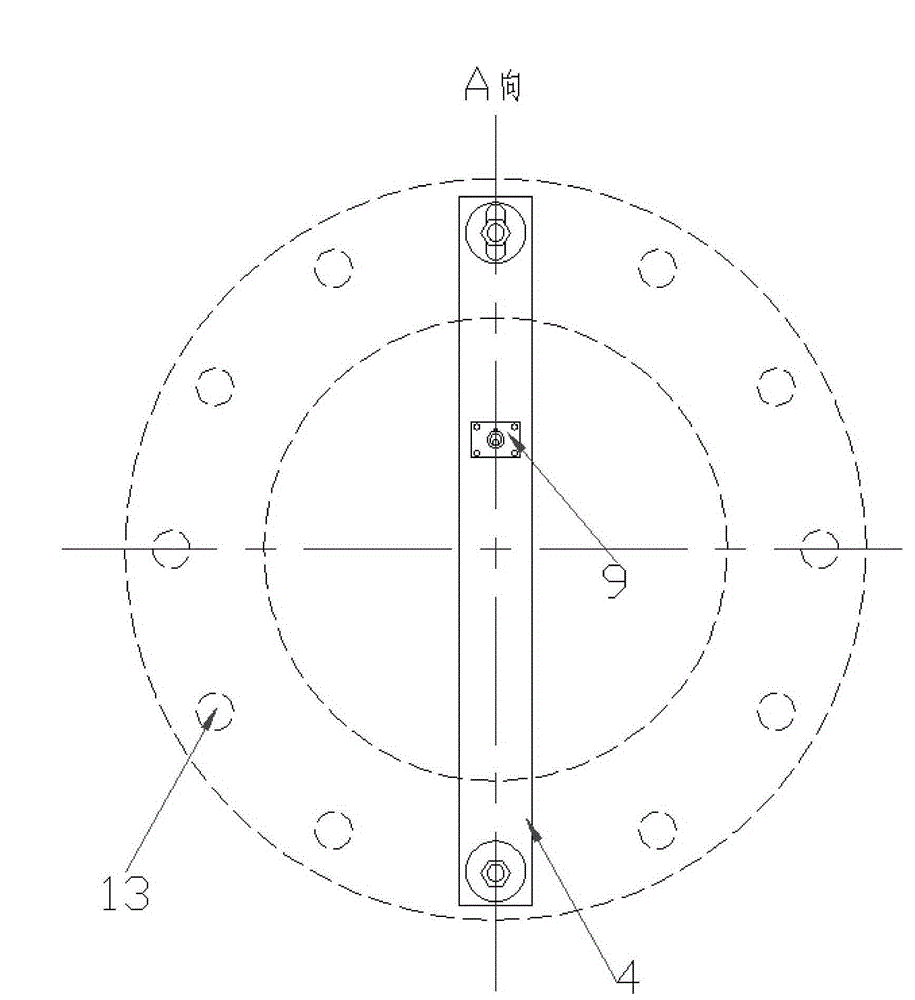

Light stop block for axial movement measurement of large cylindrical rotating equipment and installation method

ActiveCN103604334AReasonable measurementHigh precisionMechanical measuring arrangementsMovement measurementEngineering

Provided is a light stop block for axial movement measurement of large cylindrical rotating equipment. A stop block body is a hollow plate, the two ends of the stop block are respectively provided with a bolt hole, one end is a movable end, a double-end bolt penetrating through the bolt hole in the movable end is provided with an adjusting spring, the other end is a fixed end, and a bolt penetrates through the bolt hole in the fixed end; the stop block and a base frame are fixedly arranged in an integrated mode, a dial gauge is fixed on the base frame, and an axial movement measurement dial gauge is erected above the center of the equipment. The stop block is light in weight, can guarantee stability when axial movement measurement of the large cylindrical rotating equipment is conducted, and therefore effectively guarantee measurement accuracy.

Owner:MCC TIANGONG GROUP

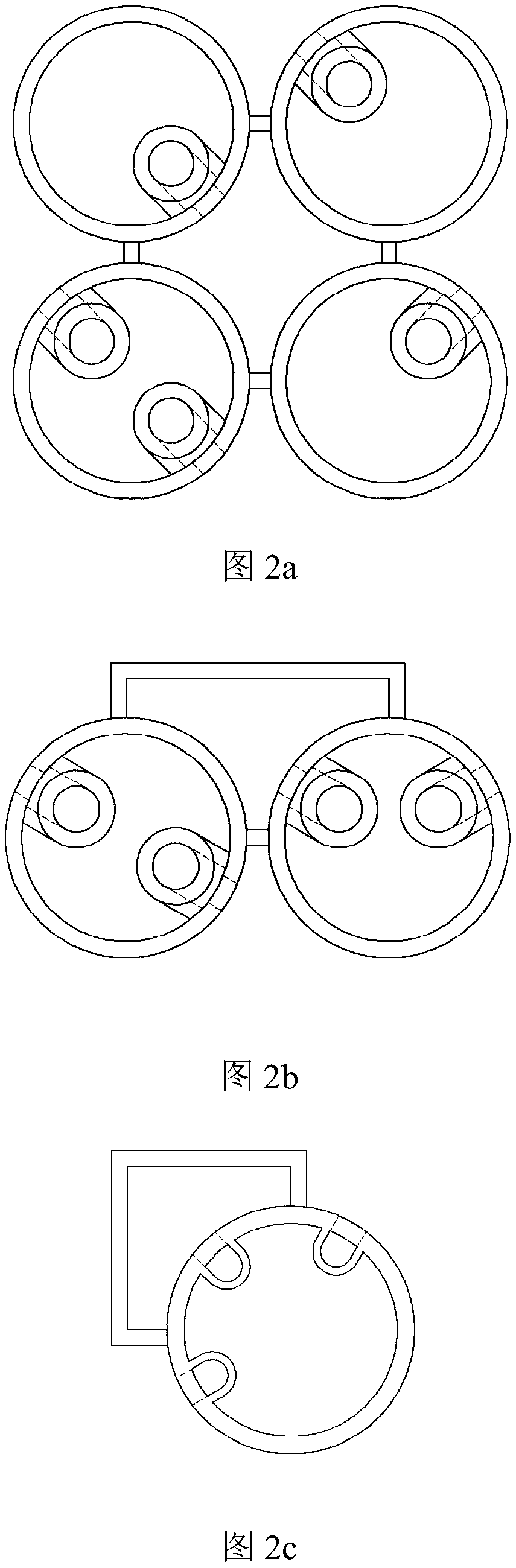

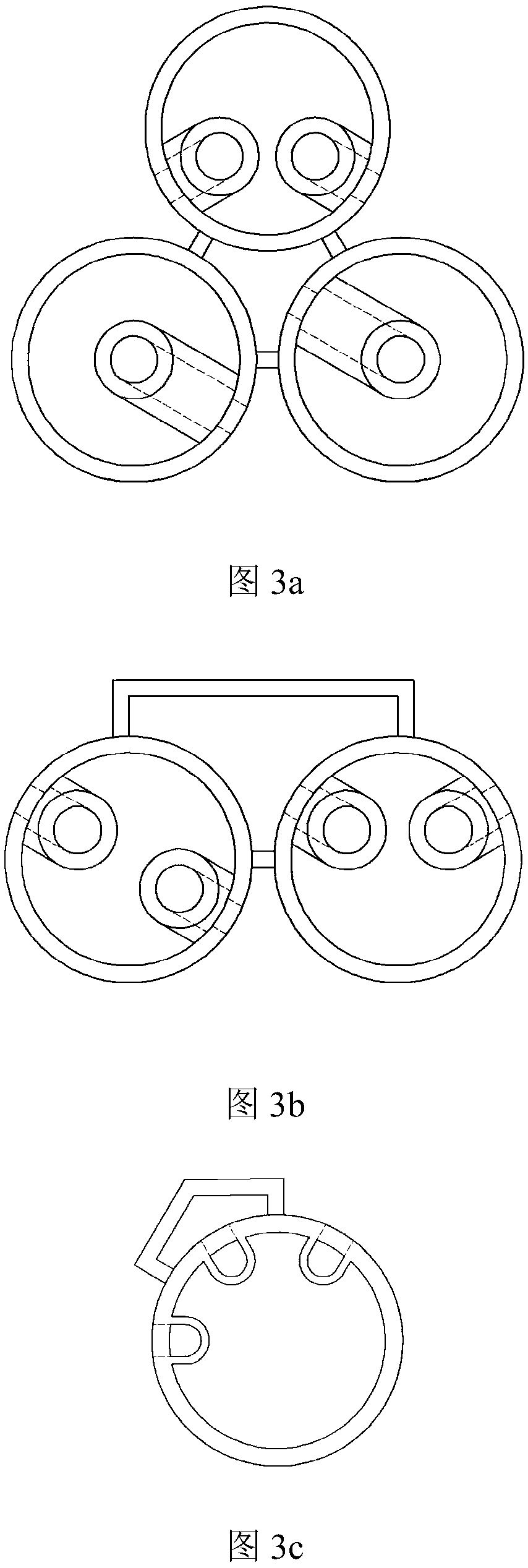

Sub-channel flow sampling device and method

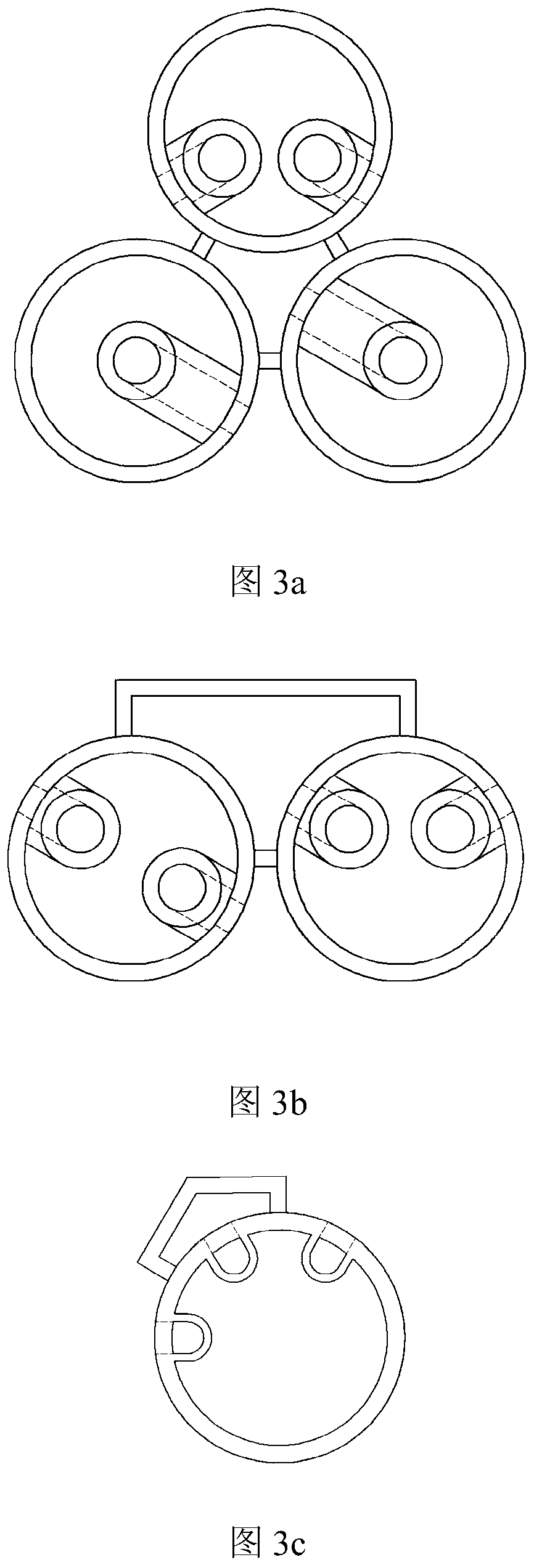

Provided is a sub-channel flow sampling device. The device comprises an e-press, a sampling passageway upper sealing cover, a sampling section outlet connecting pipe, a round section sampling passageway, a flexible corrugated pipe, an upper chamber, an upper chamber outlet connecting pipe, a sampling passageway lower sealing cover, a sampling probe, a visible pipe section and an adjusting device,wherein the e-press is welded to a hole in the lower end side face of the sampling probe, the sampling probe is used for measuring the static pressure of an internal sub-channel and an adjacent sub-channel, the round section sampling passageway penetrates through the top of the upper chamber and is connected with the upper chamber through the flexible corrugated pipe. The lower end of the upper chamber is connected with the visible pipe section for observing and calibrating the position of the sampling probe. The adjusting device can adjust the position of the sampling probe. The sampling device is connected with a rod cluster test section through the visible section and connected with a test pipeline system through the sampling section outlet connecting pipe and the upper chamber outlet connecting pipe. The sampling device is simple in overall structure and easy to machine, and a flow sampling scheme is provided for the research on the rod cluster sub-channel flowing characteristic. The invention further provides a use method of the sampling device.

Owner:XI AN JIAOTONG UNIV

Detection device for road and bridge concrete structure and detection method thereof

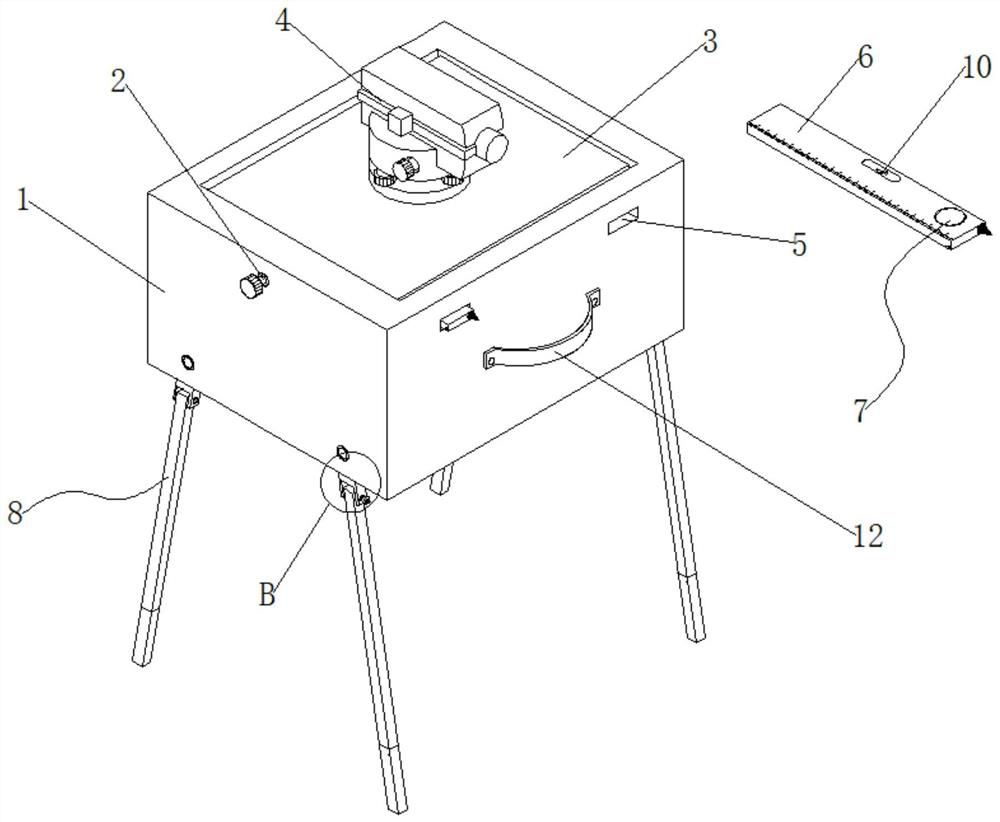

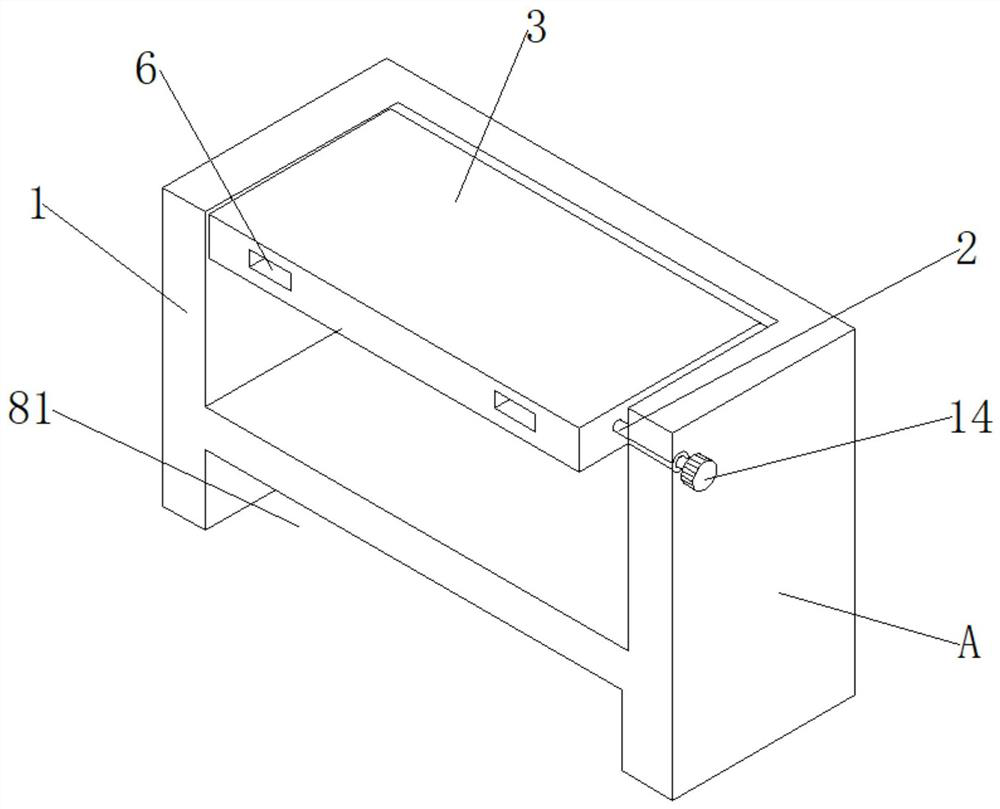

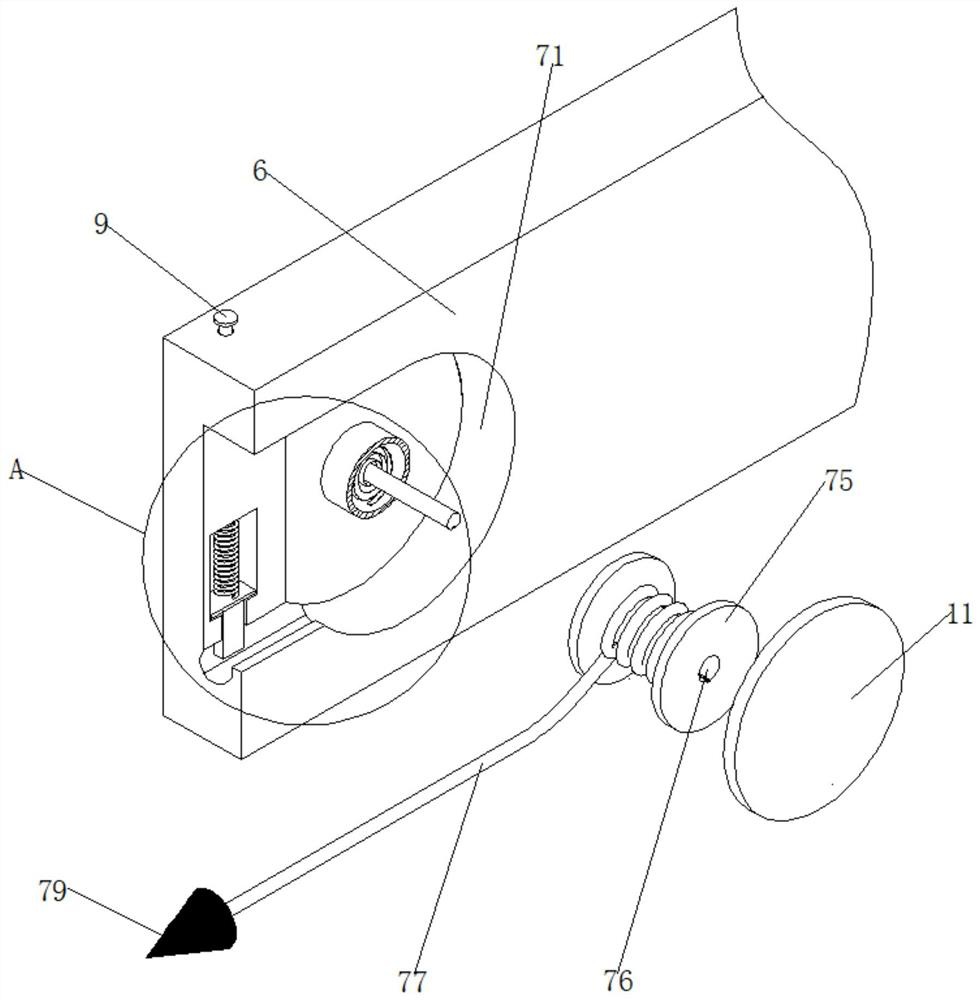

PendingCN112595217AEasy to set upEasy to useAngles/taper measurementsIncline measurementTape measureStraightedge

The invention discloses a detection device for a road and bridge concrete structure and a detection method thereof. The detection device comprises an installation box, a rotating shaft, an installation plate, an engineering measurement instrument, an insertion hole, a clamping straight ruler, a measuring tape measurement assembly, a folding support frame assembly and a hand wheel, wherein the inner wall of the top end of the installation box is rotatably connected with the installation plate through the rotating shaft; a hand wheel is fixedly connected to the end, penetrating through the exterior of the mounting box, of the rotating shaft, an engineering measurement instrument is mounted on the outer wall of the top end of the installation plate through bolts, insertion holes are correspondingly formed in the installation plate and the outer wall of one side of the installation box in a penetrating mode, clamping straight rulers are inserted into the insertion holes, and the measuringtape measurement assembly is arranged on the inner wall of one end of the clamping straight ruler. According to the detection device, the whole detection device can be transferred and moved, the measurement instrument can be stored after being used, and the problem that traditional equipment is prone to being corroded by dust is solved; the arrangement of the measuring tape measurement assembly onthe clamping straight ruler is beneficial to auxiliary measurement in the detection process of the bridge concrete structure.

Owner:MCC NORTHEAST CONSTR SHENYANG ENGTECH CO LTD

Integrated detecting and measuring method for metering property of high voltage power meter

ActiveCN100520437CAccurate measurementReasonable measurementElectrical measurementsObservational errorElectricity

The invention relates to an overall verification and measurement method for the measurement performance of a high-voltage electric energy metering device, which belongs to the field of measurement. It connects the high-voltage voltage / current generation unit, voltage / current adjustment unit, data comparison unit, control and data processing unit with the high-voltage electric energy standard metering unit and the measured high-voltage electric energy metering device; the high-voltage electric energy standard metering unit and the measured The high-voltage electric energy metering device respectively applies the sequence values of primary voltage Un and primary current In to obtain a set of standard circuit electric energy value and measured electric energy value data; the above data are respectively sent to the data comparison unit for comparison, and the comparison results are sent to the control and a data processing unit; the required measurement error percentage γ is obtained according to the following formula: γ (%)=((the electric energy of the measured high-voltage electric energy metering device-the electric energy of the standard metering circuit) / the electric energy of the standard metering circuit)×100 ; The control and data processing unit converts the measurement results into identifiable information and outputs them, based on which the overall measurement performance of the measured high-voltage electric energy metering device is verified and measured. It is suitable for the field of verification and measurement of high-voltage electric energy metering devices.

Owner:淄博计保互感器研究所(有限公司)

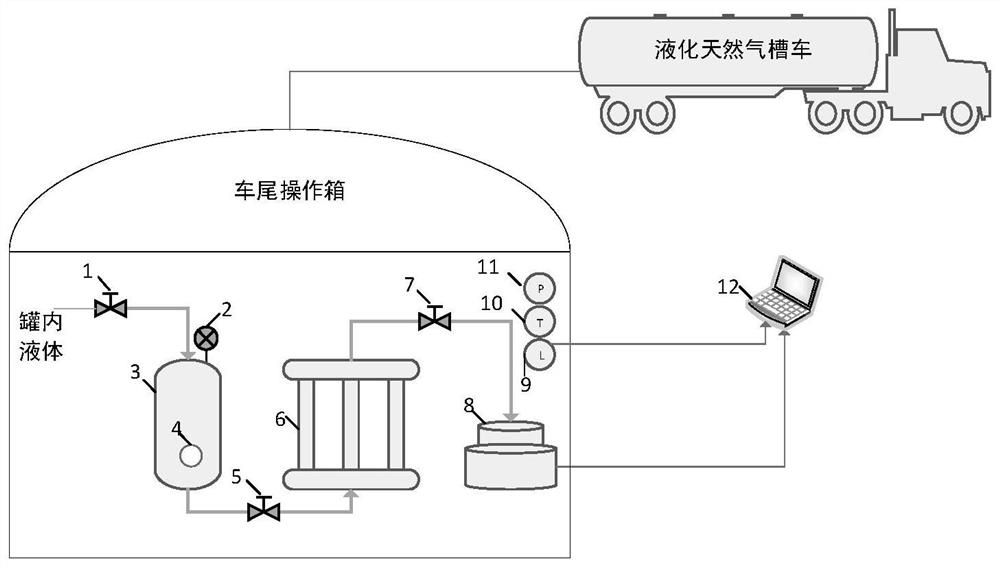

Multifunctional fair metering system and metering method based on LNG tank car

PendingCN114777011AEliminate dependenciesMeet the requirements of refined managementGas handling applicationsFluid handledEnergy meteringLiquid storage tank

The invention discloses a multifunctional fair metering system and metering method based on an LNG tank car, and belongs to the technical field of metering. The system comprises a first valve, a liquid storage tank pressure gauge, a liquid storage tank, a liquid storage tank liquid level meter, a second valve, a gasifier, a third valve, an online chromatographic analyzer, an in-tank liquid level meter, a temperature transmitter, a pressure transmitter and a flow computer. According to the invention, multiple metering modes of volume metering, mass metering and energy metering can be realized, accurate metering can be ensured, trade disputes are reduced, the working efficiency is improved, and the device can be widely applied to the fields of trade handover of liquid natural gas (LNG), liquefied petroleum gas (LPG), ethane (C2) and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for measuring yarn pilling shape and pilling peeling

ActiveCN103472210BEasy to measureAccurate collectionTextile testingInvestigating abrasion/wear resistanceYarnEngineering

The invention relates to a device and a method for measuring fluffing and balling shape as well as hair bulb stripping of a yarn. The device comprises a mechanism clamping hair bulbs to implement stripping, a yarn delivery mechanism performing equal-tension close packing, a yarn winding mechanism winding the yarn at a constant speed, a yarn grinding mechanism performing friction on the close packed and wound yarn, a translation driving mechanism driving the yarn delivery mechanism and the yarn winding mechanism in a switching manner, an abrasion object collector, a microimaging system and a control and data analysis system. The measuring method comprises the steps that a gap bridge wheel of the translation driving mechanism transposes the yarn delivery mechanism and the yarn grinding mechanism, and is matched with the yarn winding mechanism, so that close packing yarn winding and yarn grinding sampling are achieved; a yarn grinding sample in a yarn grinding process is measured in situ; and comprehensive measuring and evaluation are performed on the yarn grinding sample in a final state. The device is ingenious in structure, practical, precise in measuring, quantitative, and multipurpose, is an in-situ measuring device for measuring multiple indexes, and can be used for measuring of the hair feather and hair bulb quantity, the shape, the abrasion loss and the back-and-forth drag stripping property of the yarn, and for comprehensive evaluation of the fluffing resistance and the balling resistance.

Owner:DONGHUA UNIV

Method and system for real-time monitoring of analog wire coated by ice of overhead power transmission line

InactiveCN101701842BRealize monitoringReasonable measurementOverhead installationTension measurementEngineeringTower

The invention relates to a method and a system for real-time monitoring of an analog wire coated by ice of an overhead power transmission line. The method comprises the following steps of: (1) mounting a section of analog wire having same model and material with the line lead wire on a tower of the overhead power transmission line; (2) arranging a measuring head on the analog wire for measuring weight of the analog wire; (3) ordering that coating ice of various types and with different section shapes is converted to a circular glaze section with density of 0.9g / cm<3>, wherein calculation formula of ice coating thickness b of the analog wire in a unit length is FORMULA, wherein D (mm) is the outer diameter of the analog wire; a known parameter w1 is self-weight load of the analog wire; anda known parameter w3 is vertical total load when the wire is coated by ice and can be measured by the measuring head. The invention has the advantages of reasonable and correct measurement of synthetical load of the line coated by ice and thickness of the coating ice, simple algorithm and accurate result.

Owner:杭州甬能信息技术有限公司 +1

Device for testing mechanical properties of high-temperature superconducting strips and its testing method

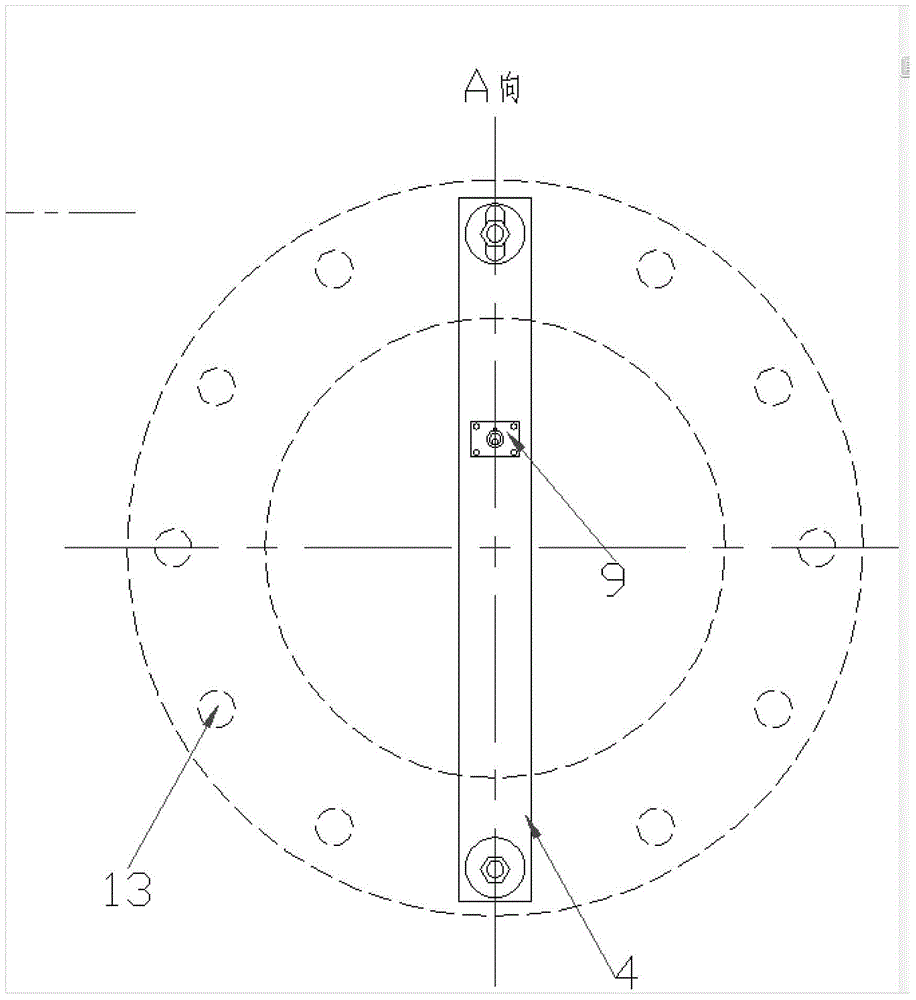

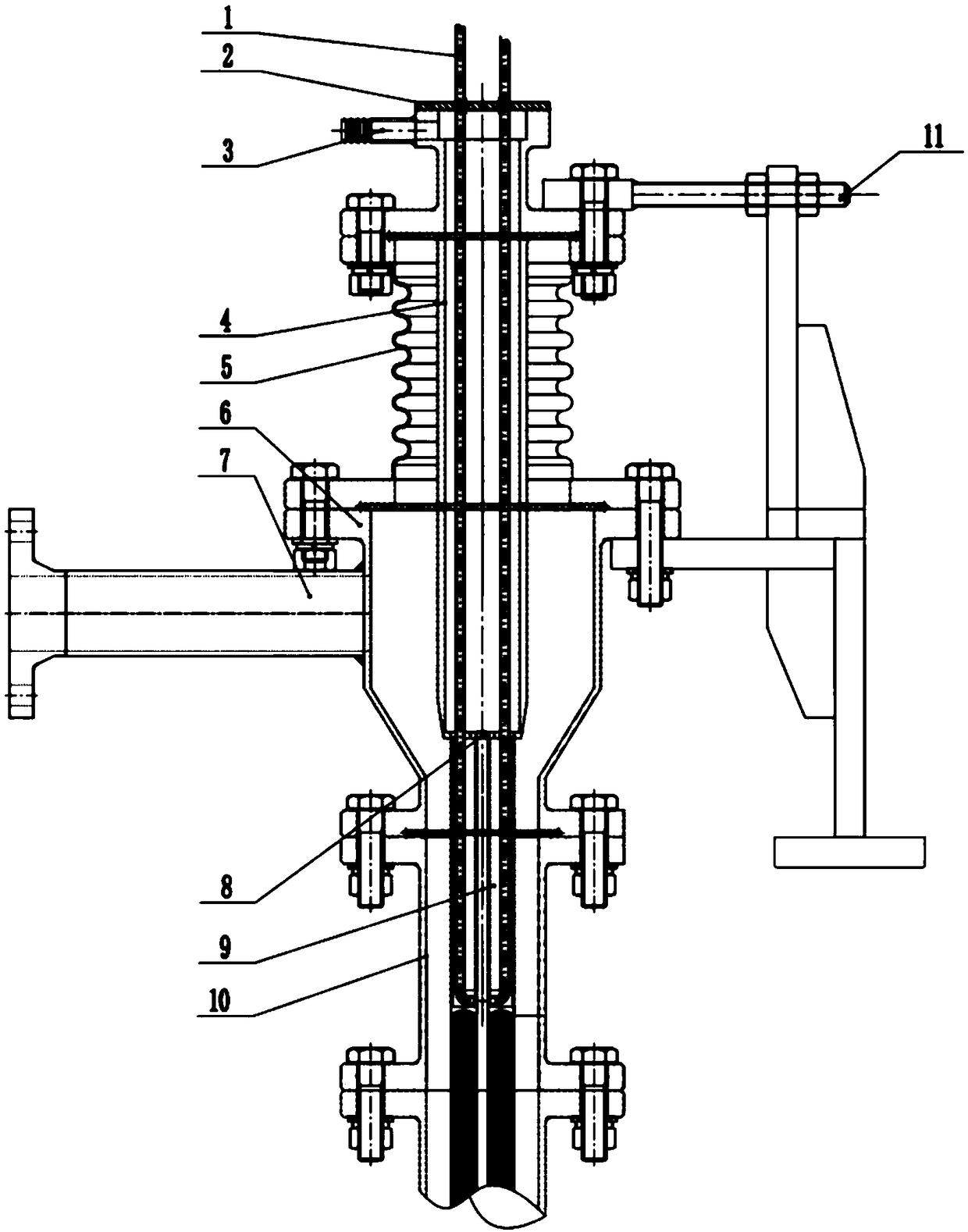

ActiveCN104965113BVersatileEasy to useMaterial analysis by electric/magnetic meansUsing mechanical meansTest sampleHigh temperature superconducting

The invention provides a device for testing the mechanical properties of high-temperature superconducting strips, which includes a four-lead control device (1), a strip critical current test stand (2), a strip turning radius test stand (3), a strip material tensile stress test frame (4). The advantages of the present invention are: 1. The device of the present invention can complete the precise measurement of almost all the electrical and mechanical properties of the strip short sample, including the turning radius, tensile stress, delamination stress, etc., with complete functions and convenient use; 2. Equipment The design is complete, practical and humanized, people can sit on the table for welding, testing and other processes, the whole process is relatively easy. 3. The square hole plate installed on the desktop can accommodate various test sample racks, screws, tools, etc., which is convenient and practical; 4. The test sample racks can reasonably and effectively support the measurement of samples.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

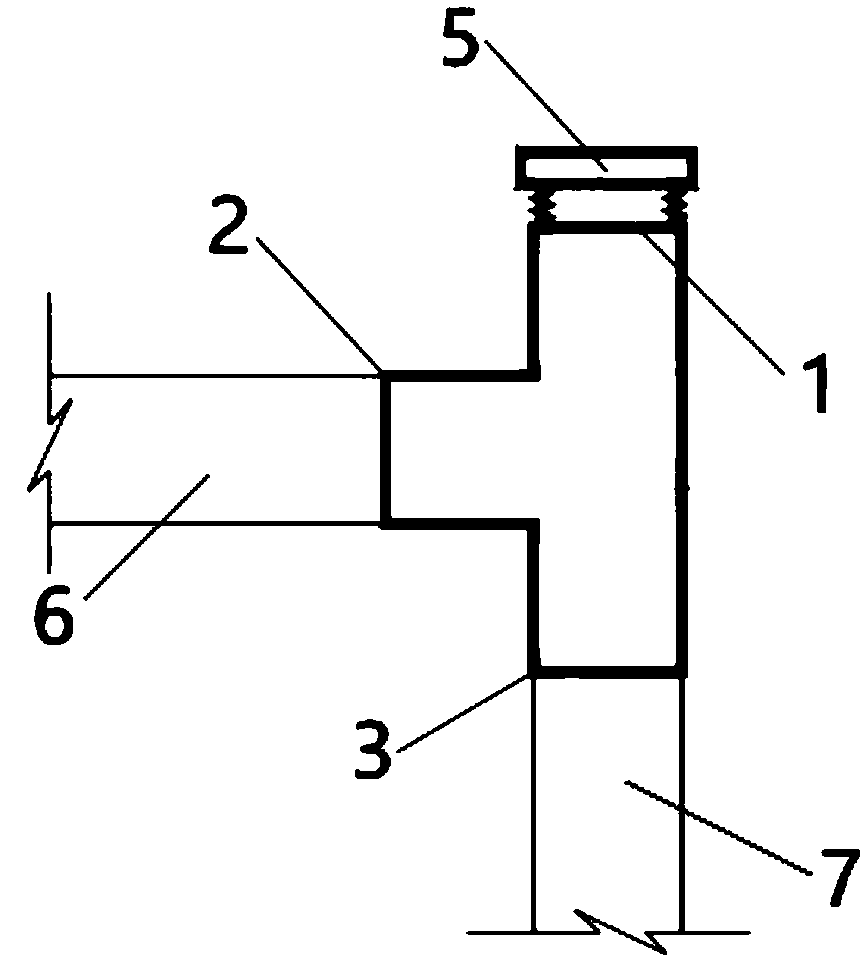

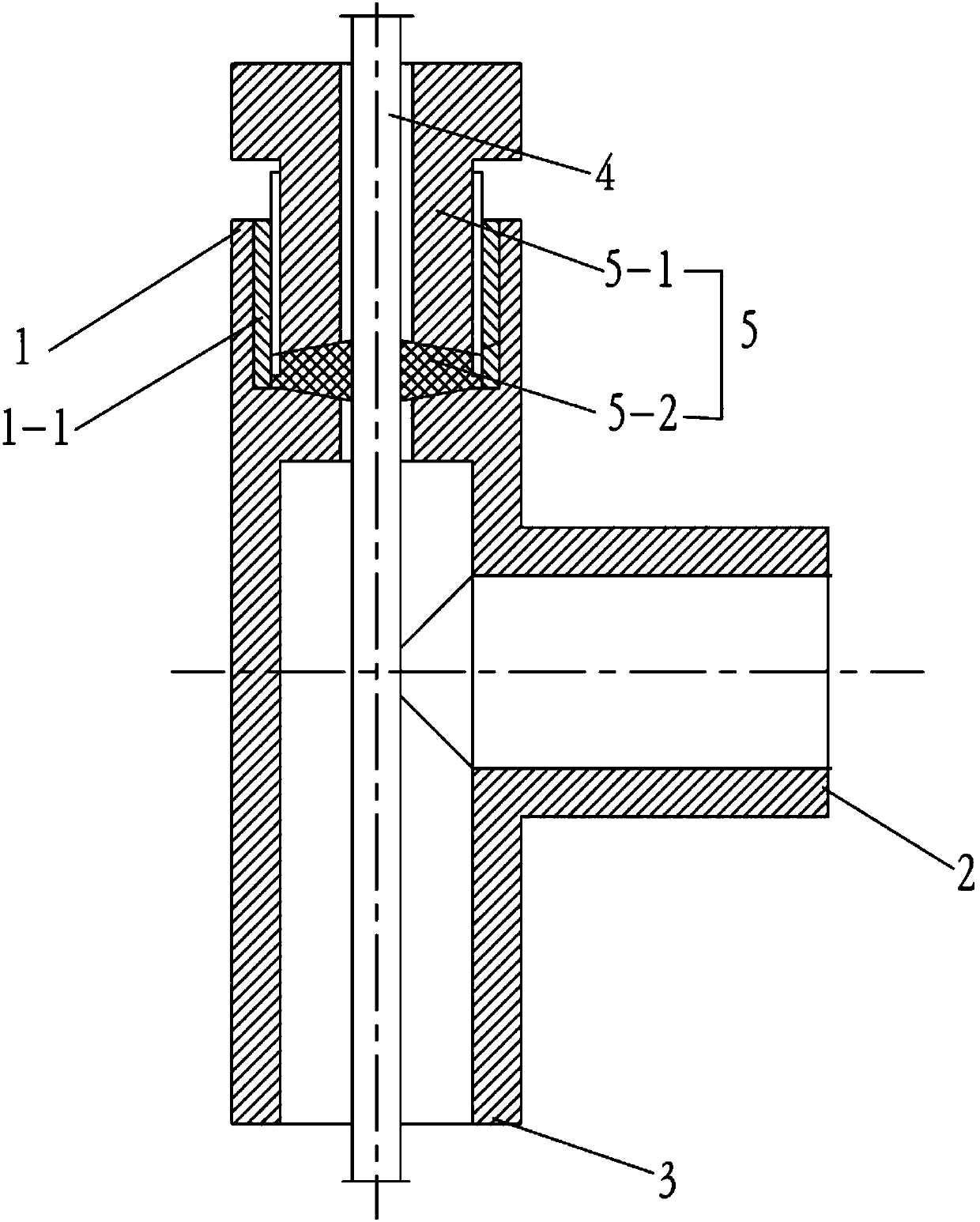

Special joint for ground-source heat pump system and ground-source heat pump system

ActiveCN107726670AGuaranteed uptimeReasonable designHeat pumpsGeothermal energy generationMeasurement deviceGeothermal heat pump

The invention relates to the technical field of ground-source heat pumps, in particular to a special joint for a ground-source heat pump system and the ground-source heat pump system. The special joint for the ground-source heat pump system comprises joint body; the joint body is arranged vertically, is hollow inside and comprises a main joint body; the main joint body comprises a first connectingport, a second connecting port and a third connecting port; the first connecting port is arranged at the upper end of the main joint body; the second connecting port is arranged on one side surface of the main joint body; the third connecting port is arranged at the lower end of the main joint body; a tip detachably connected with the first connecting port is arranged at the first connecting portand is provided with a wire hole communicating with an inner cavity of the joint body; a cable of a measuring device penetrates through the wire hole; the second connecting port is connected with a buried pipe horizontal header; and the third connecting port is connected with a buried hole heat exchanger. By the aid of the special joint, characteristic data of a fluid inside a buried pipe can bemeasured conveniently and accurately, design of the buried hole heat exchanger and stable operation of the ground-source heat pump system are effectively guaranteed, and the joint is simple in structure and simple and convenient to mount.

Owner:BEIJING TALENT NEW ENERGY TECH DEV CO LTD

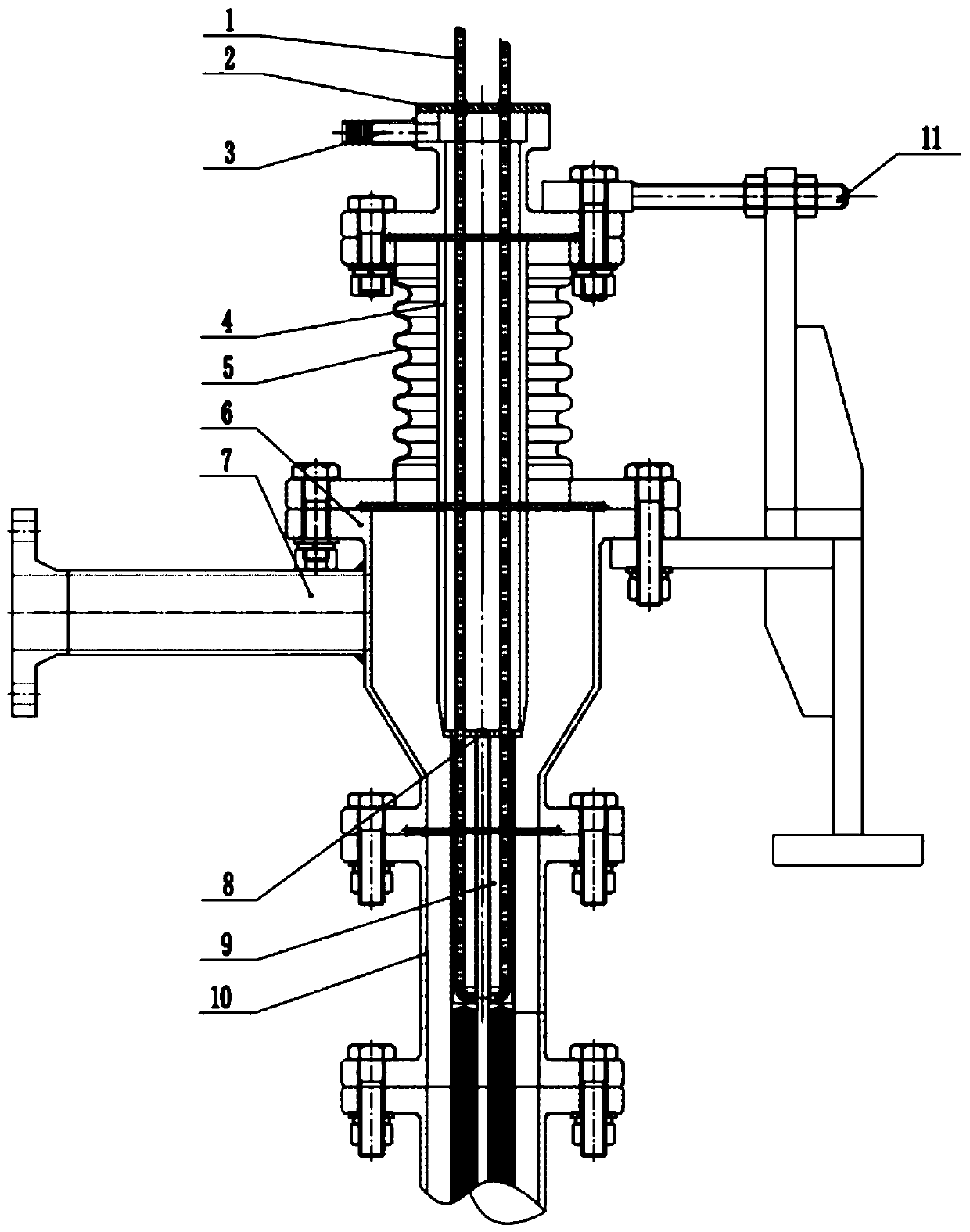

A sub-channel flow sampling device and method

ActiveCN108955796BReasonable measurementSimple structureVolume meteringHydrologyMechanical engineering

Provided is a sub-channel flow sampling device. The device comprises an e-press, a sampling passageway upper sealing cover, a sampling section outlet connecting pipe, a round section sampling passageway, a flexible corrugated pipe, an upper chamber, an upper chamber outlet connecting pipe, a sampling passageway lower sealing cover, a sampling probe, a visible pipe section and an adjusting device,wherein the e-press is welded to a hole in the lower end side face of the sampling probe, the sampling probe is used for measuring the static pressure of an internal sub-channel and an adjacent sub-channel, the round section sampling passageway penetrates through the top of the upper chamber and is connected with the upper chamber through the flexible corrugated pipe. The lower end of the upper chamber is connected with the visible pipe section for observing and calibrating the position of the sampling probe. The adjusting device can adjust the position of the sampling probe. The sampling device is connected with a rod cluster test section through the visible section and connected with a test pipeline system through the sampling section outlet connecting pipe and the upper chamber outlet connecting pipe. The sampling device is simple in overall structure and easy to machine, and a flow sampling scheme is provided for the research on the rod cluster sub-channel flowing characteristic. The invention further provides a use method of the sampling device.

Owner:XI AN JIAOTONG UNIV

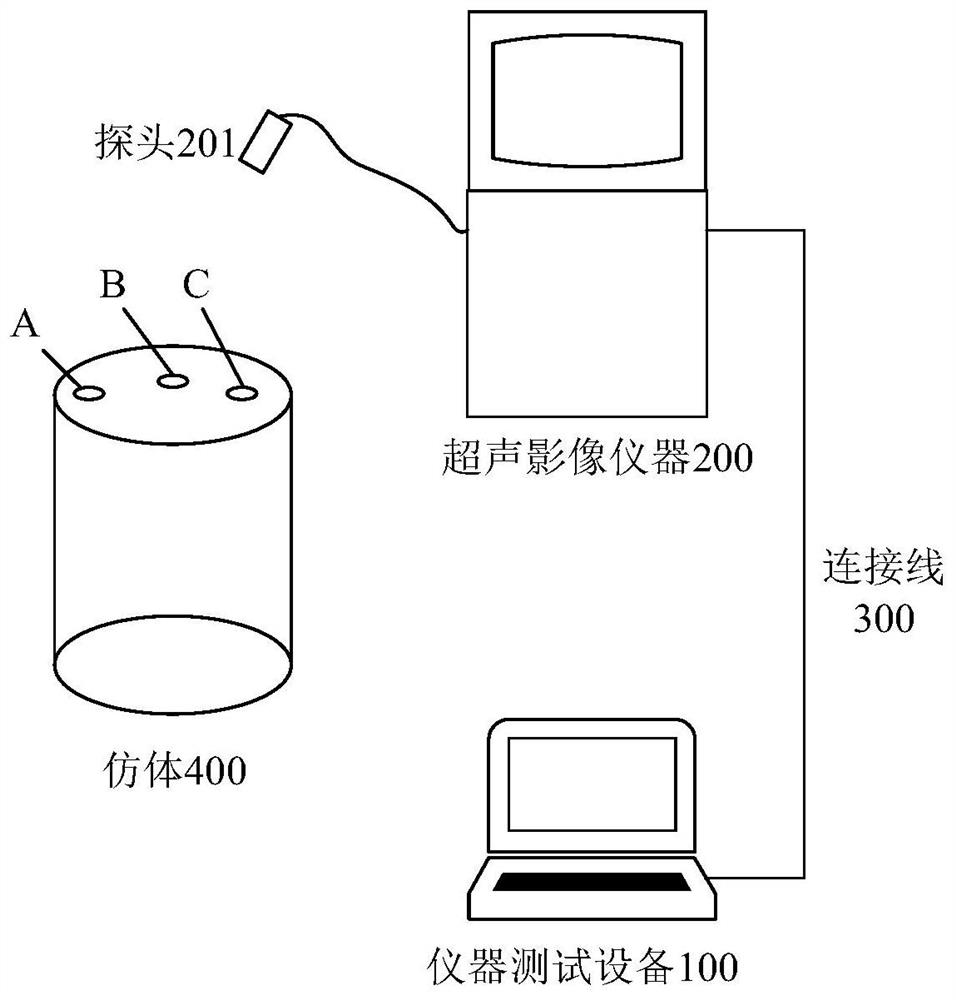

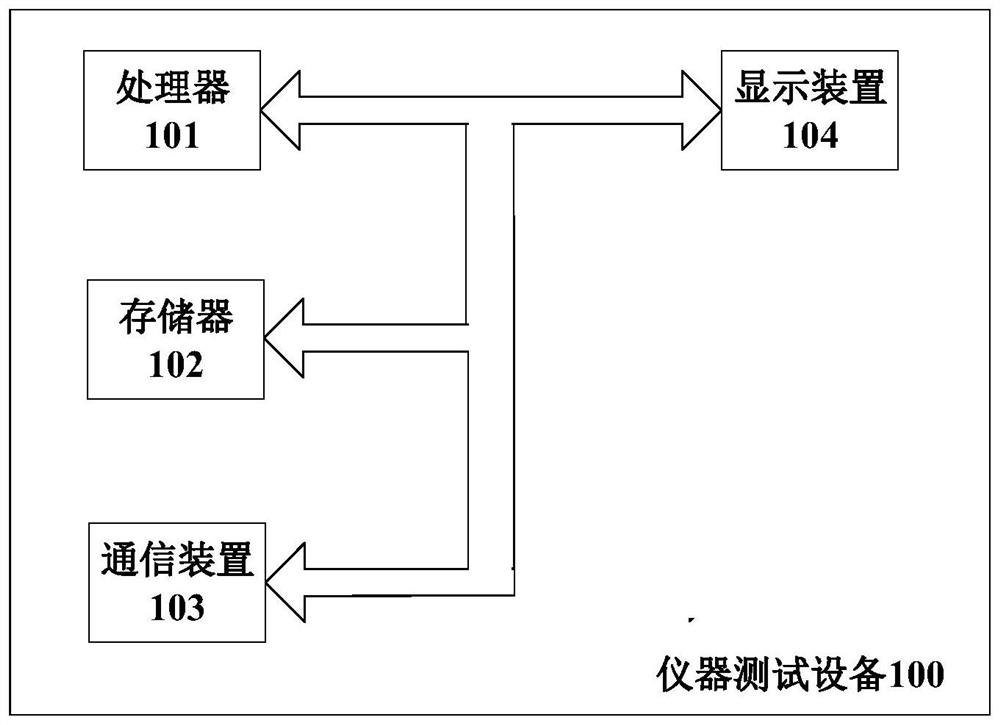

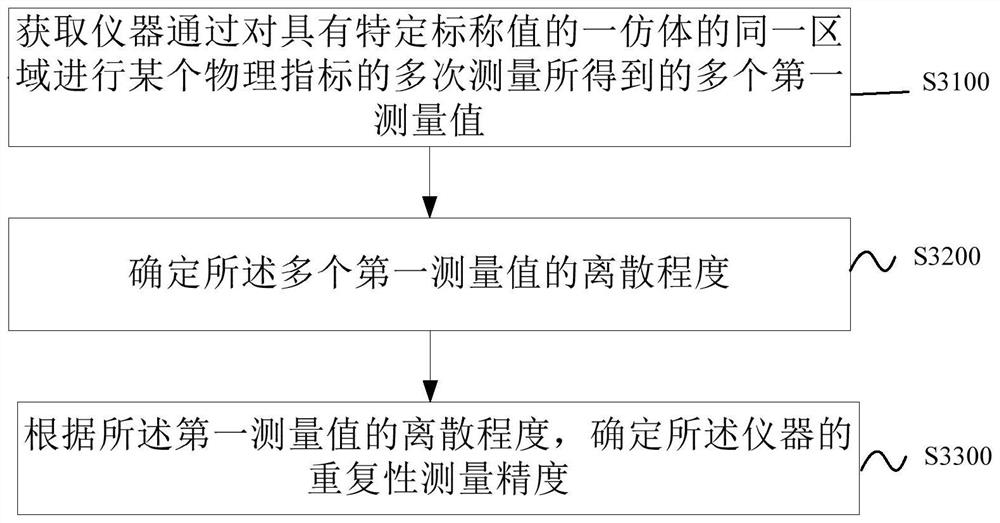

A kind of instrument test method, device and equipment

ActiveCN111743569BEliminate the effects ofReasonable measurementInfrasonic diagnosticsSonic diagnosticsEngineeringTissue phantom

The invention provides an instrument testing method, an instrument testing device and an instrument testing device. The method includes: obtaining a plurality of first measurement values obtained by the instrument through multiple measurements of a certain physical index on the same area of a tissue-mimicking phantom with a specific nominal value; determining the plurality of first measurement values The degree of dispersion of the measured values; according to the degree of dispersion of the first measured value, the repeatability measurement accuracy of the instrument is determined.

Owner:SMEDA MEDICAL CO LTD

Eccentric wheel type horizontal shock spectrum measuring device and its installation and measuring method

The invention relates to an eccentric wheel type horizontal impact spectrum measuring device and a mounting and measuring method thereof. The eccentric wheel type horizontal impact spectrum measuringdevice comprises a base and a top plate which are horizontally arranged up and down at intervals, wherein the space between the base and the top plate is supported by vertical plates on the two sides;a vertical shaft is jointly mounted by the base and the top plate, the two ends of the shaft are connected with the base and the top plate through bearings respectively, and the upper end of the shaft extends out of the top plate and an angle sensor is mounted at the end; an eccentric wheel with an oval structure is horizontally and fixedly arranged on the shaft between the base and the top plate; and torsion springs are fixedly arranged between the eccentric wheel and the top plate and between the eccentric wheel and the base respectively; when a test is carried out, the angle sensor is connected with a controller, the eccentric wheel is rotated under the action of an external impact load, the angle sensor transmits rotation angle information to the controller, and the eccentric wheel isreset under the action of an upper torsion spring and a lower torsion spring after the external load is removed; and the impact spectrum displacement is obtained according to the measured rotation angle information, and then the measurement of the horizontal impact spectrum is realized. The device is simple and compact and reliable in structure and convenient to operate and use, and the obtaineddata is reliable and effective.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Measuring device and method for tension gripping and pulling out of multi-angle cylinder type brushed feather badminton

ActiveCN103469533BPredicting Pilling ResistanceThe results of the extraction measurement are accurateInspecting textilesUsing mechanical meansPull forceData acquisition

The invention relates to a tension gripping and drawing measuring device and method for a polygonal cylinder type grinding yarn feather badminton. , creel, electrostatic piler and control and data acquisition and analysis system. The method is to rub the yarns on the polygonal tube corner by corner in a Lisharu curve after the close-packed winding is completed, and then apply pressure to the grinded yarn samples turned to the top to hold the yarn layer corner by corner, and then Clamp the ground hair feathers or balls to measure the pulling force and observe the shape of the tested hair feathers or balls until the drawing measurement of each corner is completed, and the microscopic shape of the hair feathers and balls pulled out under tension is obtained. value and extraction force curve. It is a fast, simple, practical and accurate measuring device and method, which can be used for the pilling sample preparation of yarn, the measurement of pilling hairiness and pilling curve and shape, and the pilling resistance of yarn comprehensive evaluation.

Owner:DONGHUA UNIV

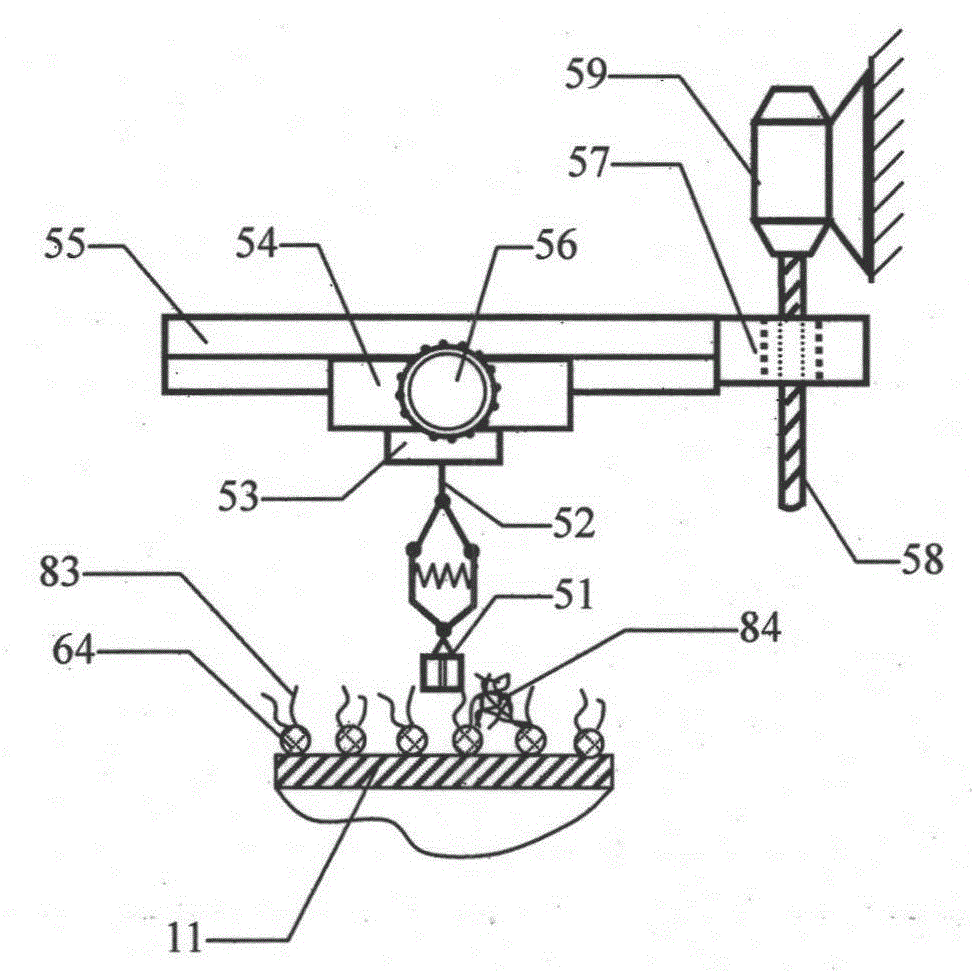

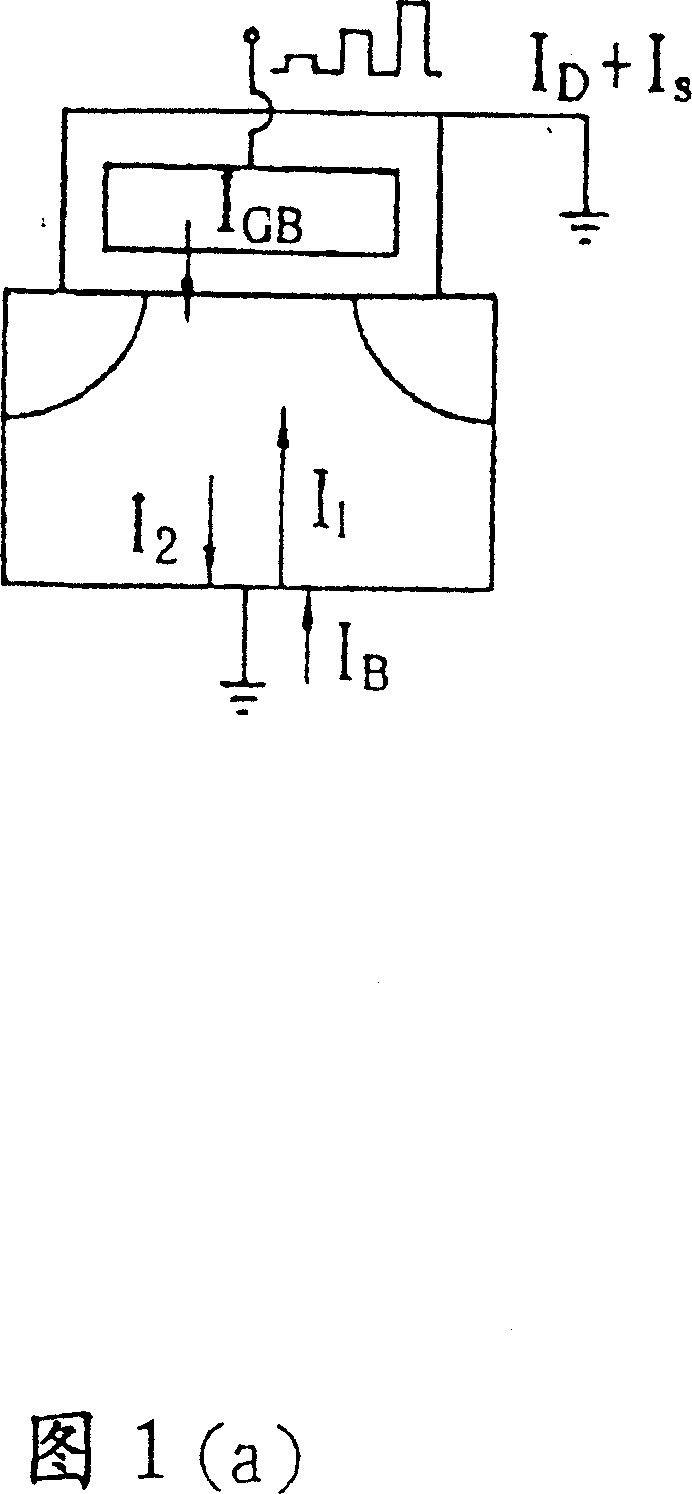

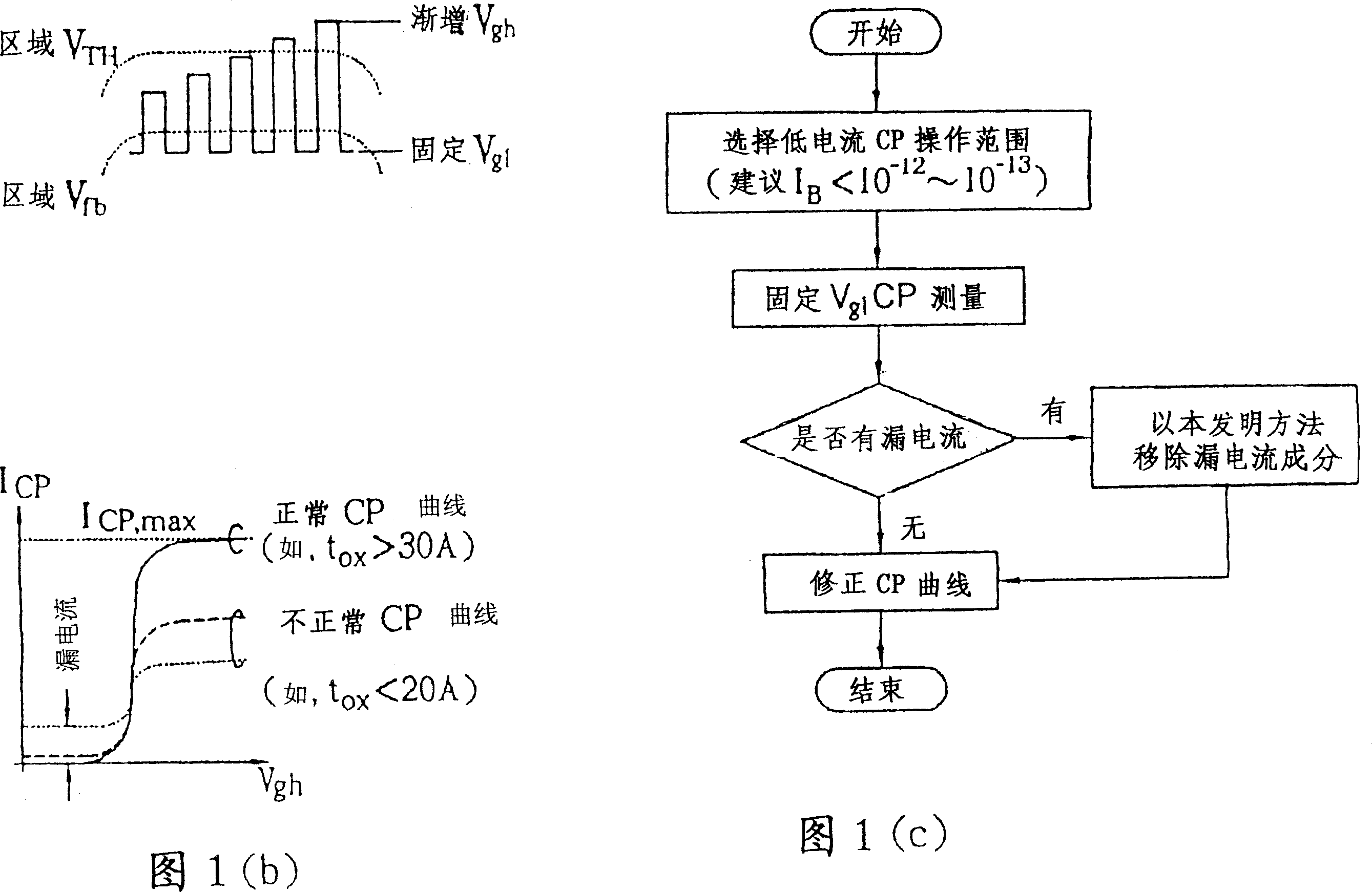

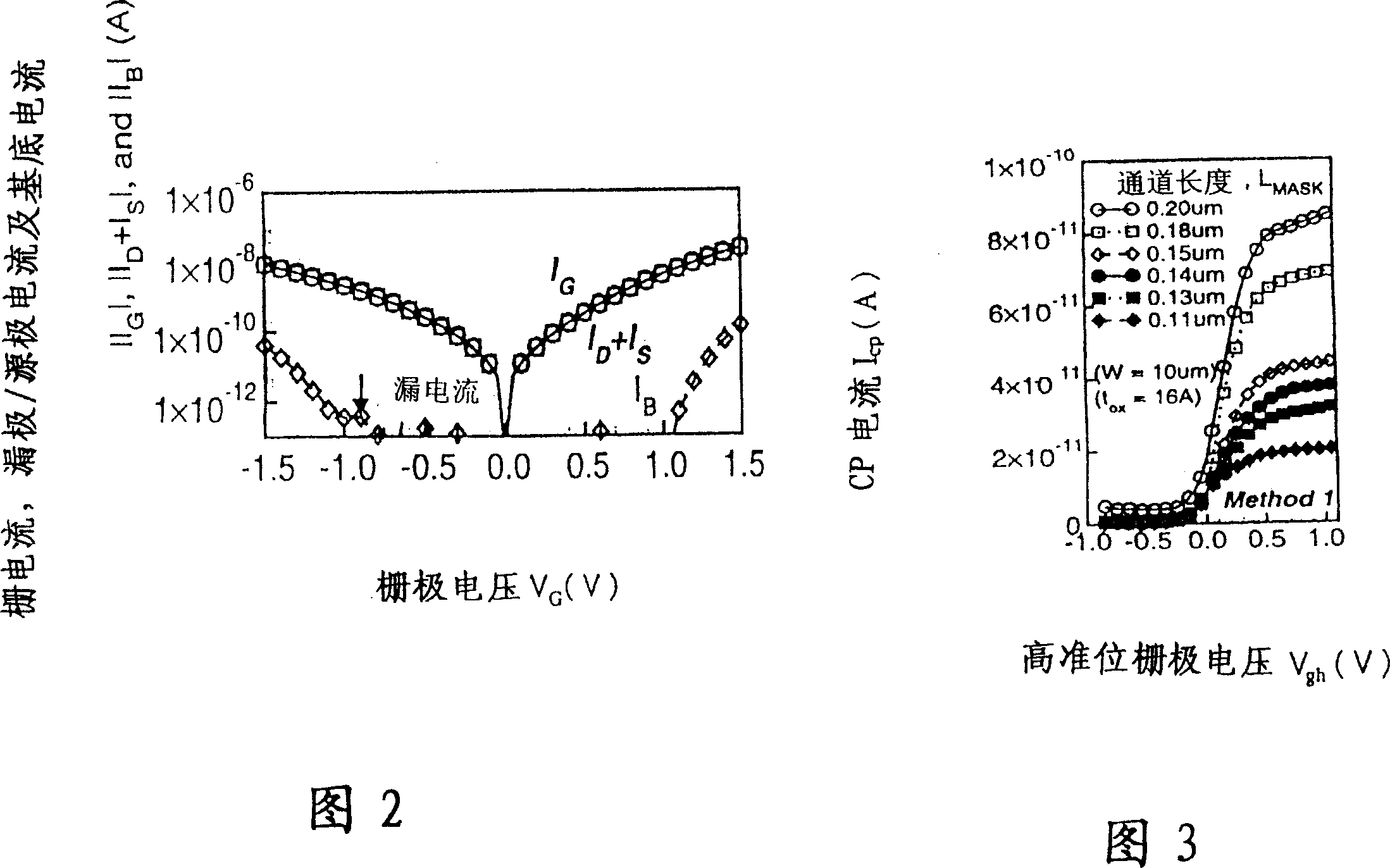

Direct calculation method of interface trap in MOS semiconductor field-effect rransistor

InactiveCN100377328CReasonable measurementAccurate measurementSemiconductor/solid-state device testing/measurementElectronic circuit testingCMOSHalf field

A method which is used for directly calculating the defect amount of the metal-oxide half field-effect transistor which mainly comprises the following procedures: (1) constructing a measuring interval suitable for the low electric leakage to find out a given interval which can be suitable for the bias voltage (Vgl and Vgh) of the grid impulse (gate pulse); (2) eliminating the parasitical tunneling drain current with a low drain current CP method, and a high-low frequency measuring method or frequency adding CP measuring method can be adopted; the present invention uses the low electric leakage CP method to eliminate the considerable parasitic drain current and can be accurately applied for calculating the interface defect of the grid oxidizing layer and effectively evaluating the grid oxidizing layer growing quality / oxidizing layer technique; the experiment data shows that the analysis relative to the interface defect of the grid oxidizing layer, such as the generation of the grid interface defect, the monitoring to the grid oxidizing layer thin film and the evaluating to the reliability of the microminiature CMOS element, the invention can calculate the number of the interface defect (Nit) quickly and simply and the satisfactory result can be obtained.

Owner:UNITED MICROELECTRONICS CORP

A light-duty stopper and installation method for axial movement measurement of large-scale cylindrical rotating equipment

ActiveCN103604334BReasonable measurementHigh precisionMechanical measuring arrangementsMovement measurementEngineering

Provided is a light stop block for axial movement measurement of large cylindrical rotating equipment. A stop block body is a hollow plate, the two ends of the stop block are respectively provided with a bolt hole, one end is a movable end, a double-end bolt penetrating through the bolt hole in the movable end is provided with an adjusting spring, the other end is a fixed end, and a bolt penetrates through the bolt hole in the fixed end; the stop block and a base frame are fixedly arranged in an integrated mode, a dial gauge is fixed on the base frame, and an axial movement measurement dial gauge is erected above the center of the equipment. The stop block is light in weight, can guarantee stability when axial movement measurement of the large cylindrical rotating equipment is conducted, and therefore effectively guarantee measurement accuracy.

Owner:MCC TIANGONG GROUP

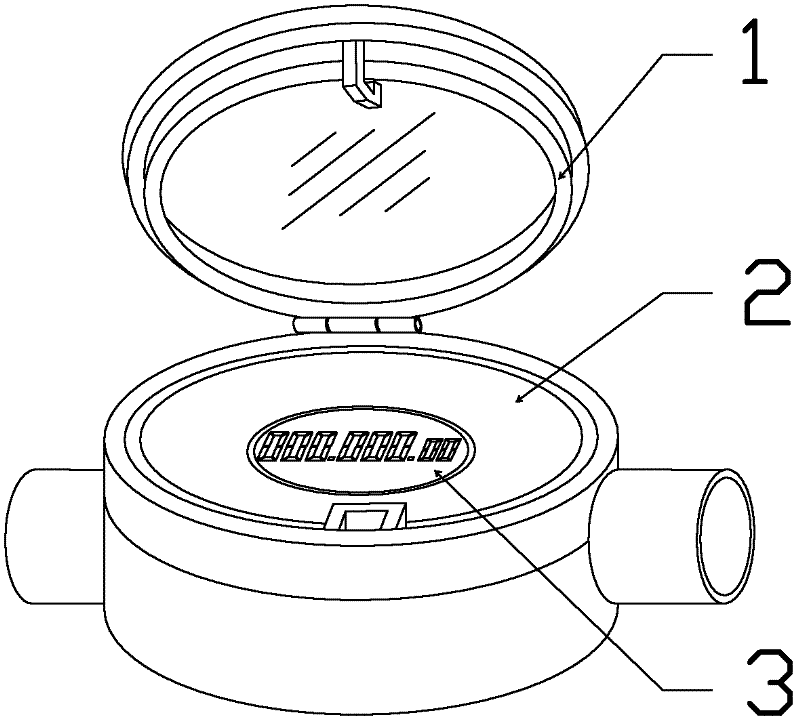

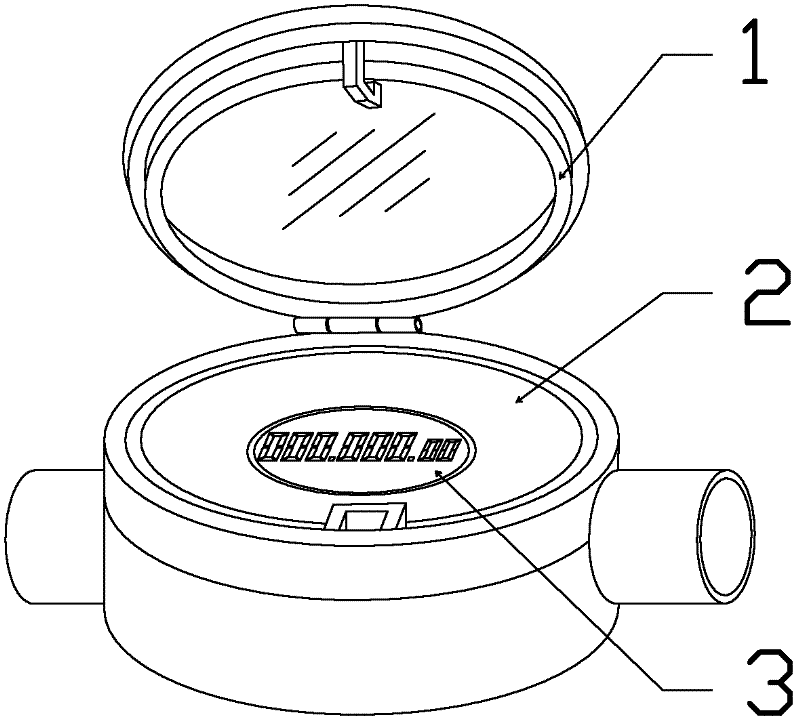

Digital type water meter

InactiveCN102346061AAccurate measurementReasonable measurementVolume indication and recording devicesElectricityDisplay device

The invention discloses a digital type water meter, belonging to a tap water flow metering instrument and mainly solving the problem that the traditional water meter is inconvenient to read. The digital type water meter structurally comprises a meter shell, a meter core and a digital display, wherein the meter shell is internally provided with the meter core for water metering and the digital display for displaying the water consumption amount; and the digital display is electrically connected with the meter core. Since the digital display is electrically connected with the meter core, the meter core is based on the flow metering principle and displays the accumulated consumed water amount on the digital display, so that the observation is more intuitive, the reading can be clear at a glance, the error caused when the traditional water meter is read is reduced, and further the metering of the water amount is more accurate and reasonable and is convenient to recognize.

Owner:许方超

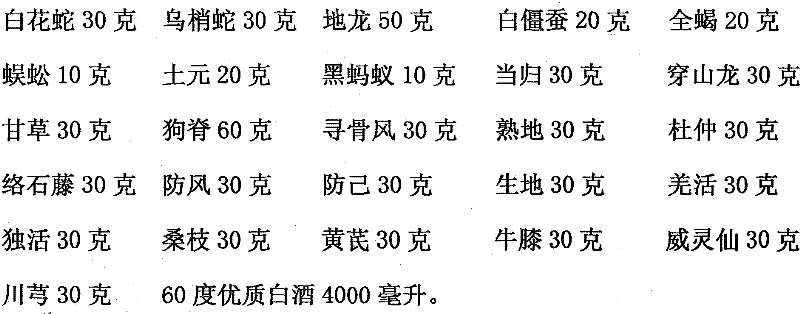

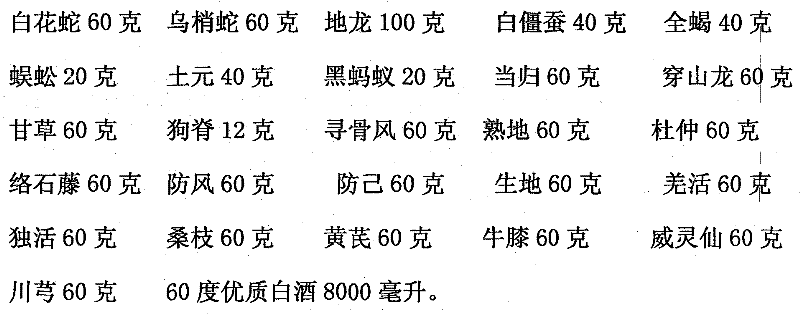

Wind-dispelling and damp-clearing wine

InactiveCN101972383BEasy to takeAccurate medicationAnthropod material medical ingredientsAntipyreticStephaniaRhizome

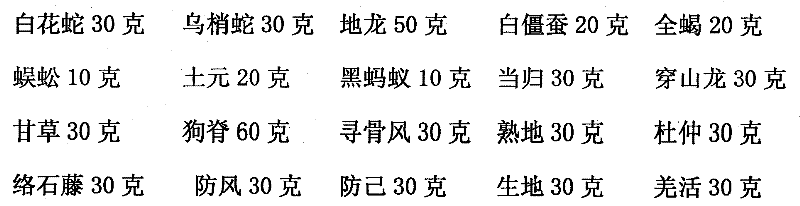

The invention relates to a wind-dispelling and damp-clearing wine comprising 30g of long-nodded pit viper, 30g of ophidian black snake, 50g of earthworm, 20g of white silkworm, 20g of scorpio, 10g of chilopod, 20g of ground beetle, 10g of black ant, 30g of Chinese angelica, 30g of yam, 30g of liquorice, 60g of rhizome cibotii, 30g of aristolochina mollissima, 30g of rehmannia glutinosa, 30g of eucommia ulmoides, 30g of Chinese starjasmine stem, 30g of radices sileris, 30g of fourstamen stephania root, 30g of radix rehmanniae recens, 30g of notopterygium root, 30g of doubleteeth pubescent angelica root, 30g of mulberry twig, 30g of radix astragali, 30g of the root of bidentate achyranthes, 30g of clematis root, 30g of rhizoma chuanxiong, and 4000ml of high-quality white spirit with 60 degrees. The wind-dispelling and damp-clearing wine takes the high-quality white spirit as a carrier and makes the traditional medical effective disease treating elements fully solve in the carrier to specially treat rheumatism with exact medicine usage, proper dosage and strong pertinence; and the patient takes the medicine conveniently with small dosage and fast curative effect.

Owner:王存银

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com