Measuring method for mixed gas under complex working condition

A technology of mixed gas and complex working conditions, applied in indirect mass flow meters, mass flow measurement devices, volume change compensation/correction devices, etc. Insufficient stability and other problems, to achieve the effect of reasonable measurement and operation, improve stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

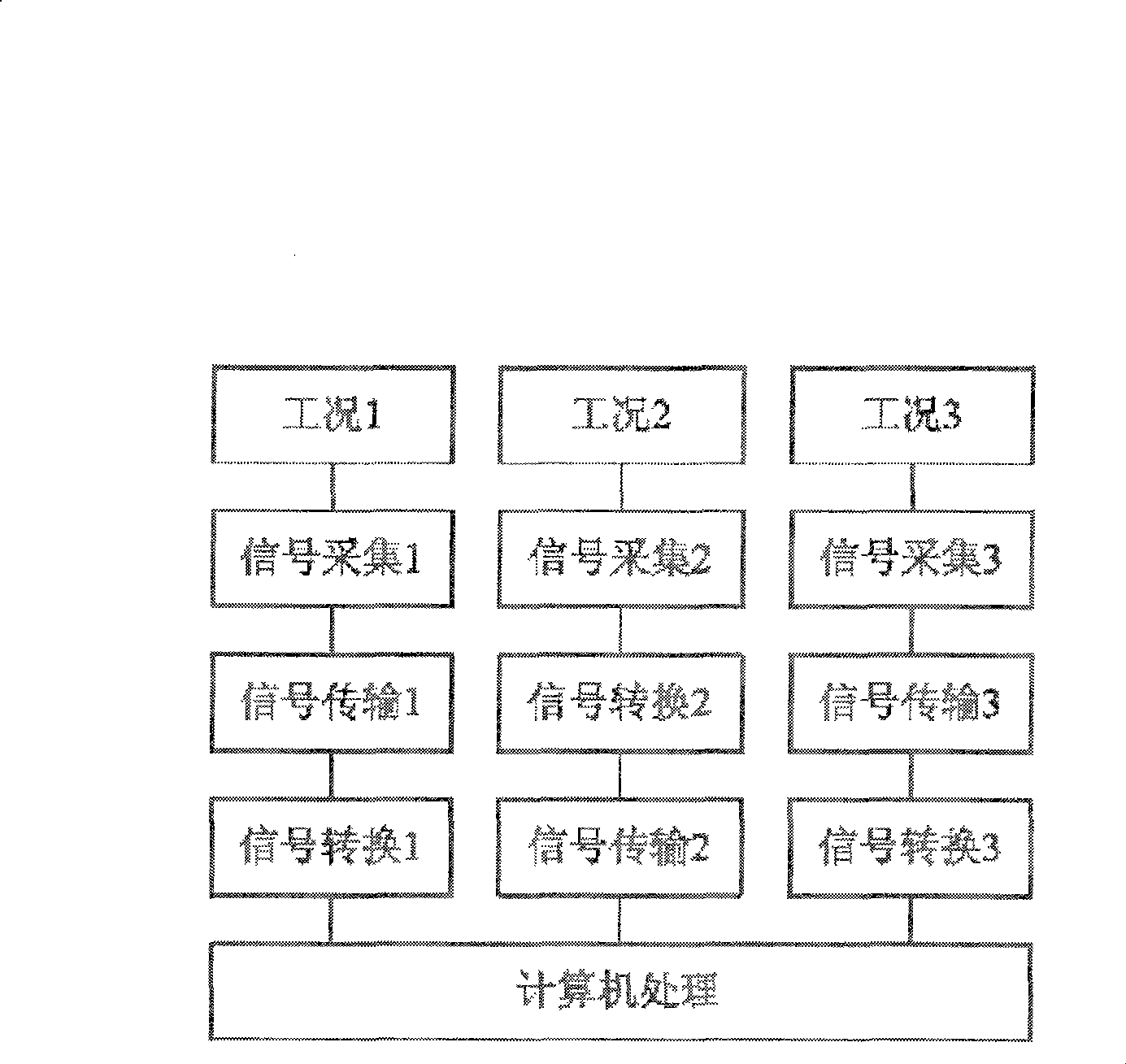

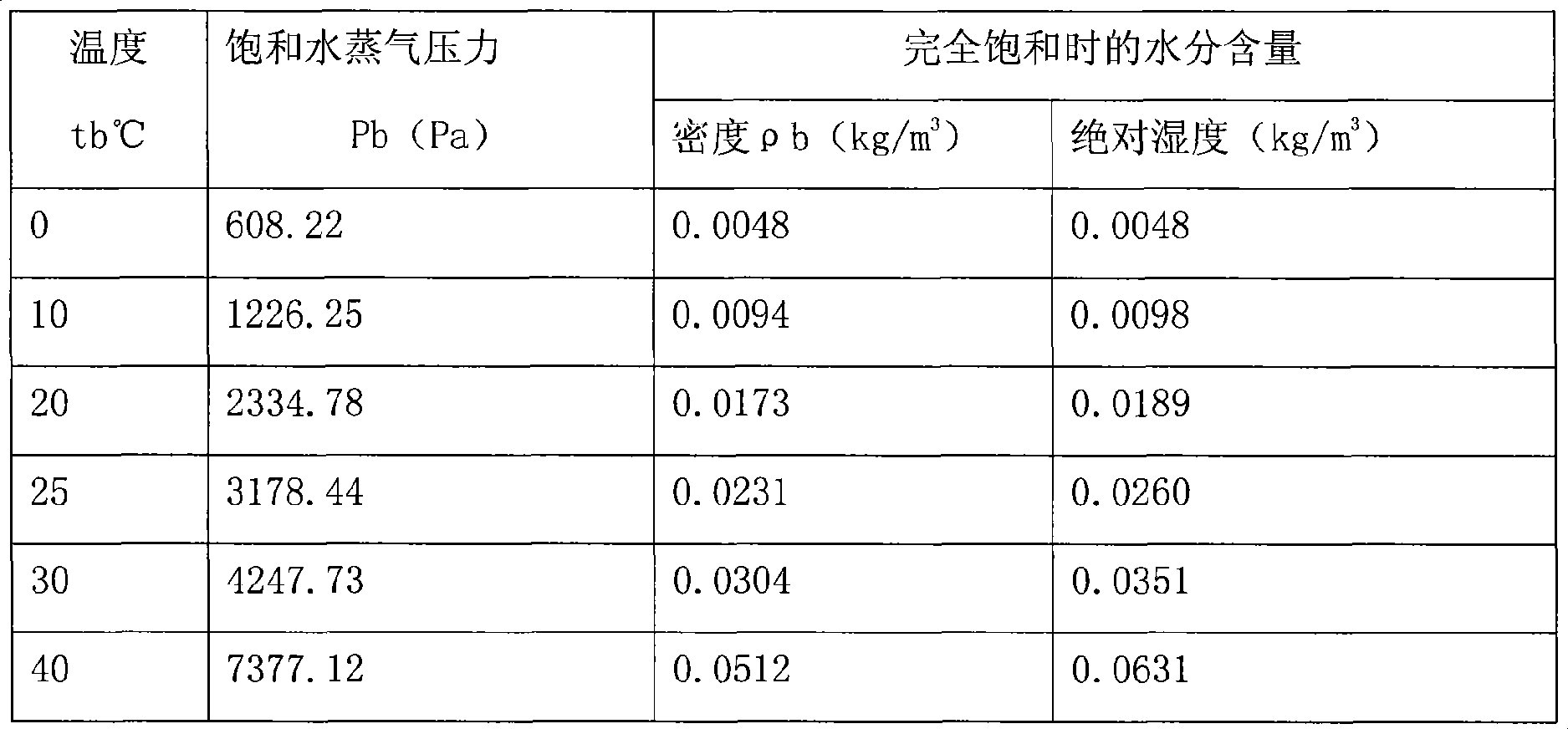

[0016] In the embodiment, for the mixed gas (blending of blast furnace gas and coke oven gas) medium under the condition that the medium of blast furnace gas and coke oven gas has no effective metering due to working conditions, computer software is used to compensate the mathematical model according to the calorific value, in the original On the basis of temperature and pressure compensation, the calorific value is used as one of the parameters for density compensation to obtain accurate measurement values of mixed gas; use computers to complete data collection, storage and transmission of various mixed gas media; receive on-site mixed gas temperature , pressure, differential pressure and calorific value of the standard instrument signal, using a combination of wired and wireless communication, computer program application process control and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com