A light-duty stopper and installation method for axial movement measurement of large-scale cylindrical rotating equipment

A technology of rotating equipment and axial movement, applied in measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of low measurement efficiency, heavy components, complicated installation, etc., to achieve high accuracy, reasonable measurement, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

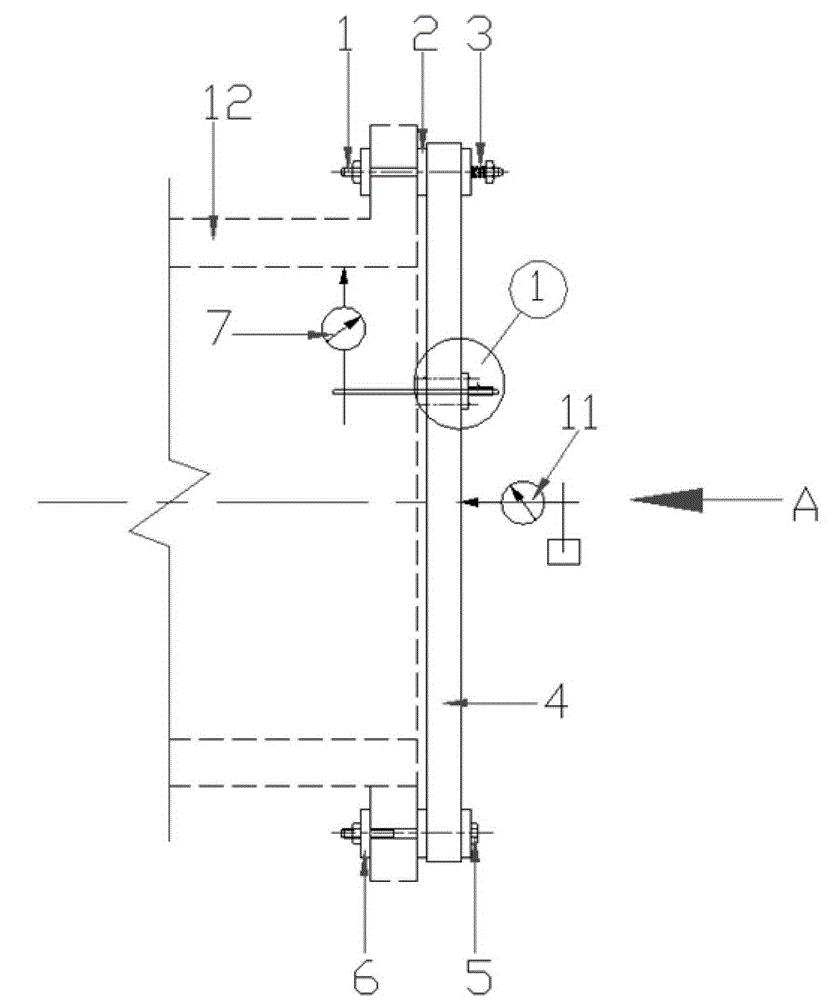

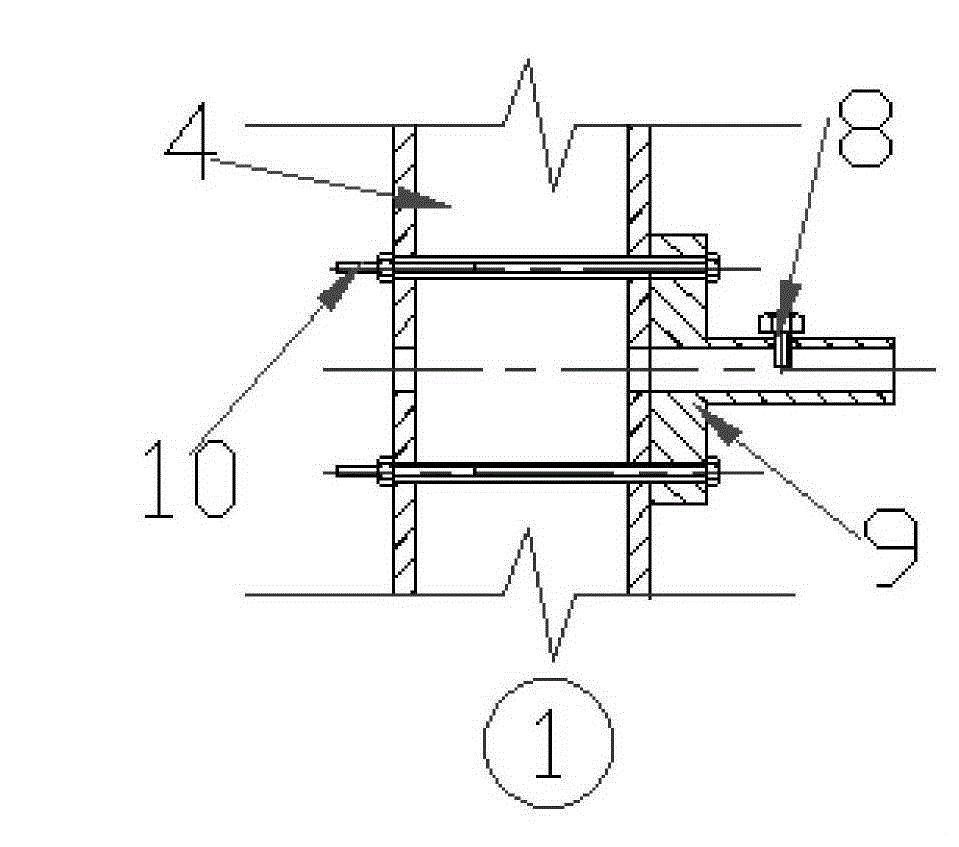

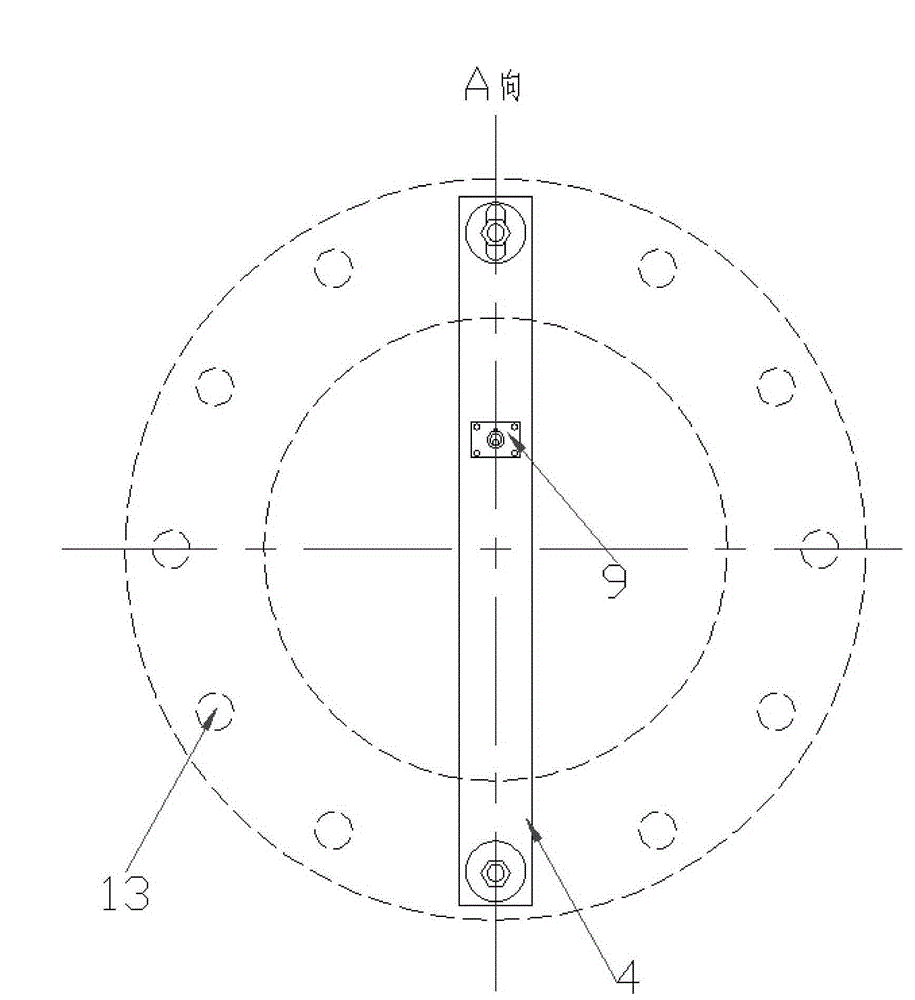

[0017] The utility model relates to a light-duty stopper for axial movement measurement of large-scale cylindrical rotating equipment, the stopper body 4 is a hollow aluminum alloy plate, and its weight is very light. There is a bolt hole at both ends of the block, and the bolt hole at one end is a long hole, and the stud bolt 1 passing through it has an adjustment spring 3, which is called the movable end, and the bolt hole at the other end is a round hole pierced with a bolt 5. The belt spring is called the fixed end; 2 and 6 are washers, and the dial indicator 7 is fixed on the seat frame 9 by the locking bolt 8, which is used to check whether the installation of the stopper 4 is qualified; the seat frame 9 is fixed with the seat frame fixing bolt 10 and The stoppers are integrated, and the dial indicator 11 is a dial indicator installed on the center of the equipment for axial movement measurement.

[0018] The installation method of the stopper of the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com