Integrate detecting and measuring method for metering property of high voltage power meter

A technology of high-voltage electric energy and metering devices, which is applied in the field of measurement, can solve the problems of inconvenient management, large difference in measurement values, and unmeasurable, etc., and achieve accurate detection/test work, accurate high-voltage electric energy measurement, and reduce uncertain factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

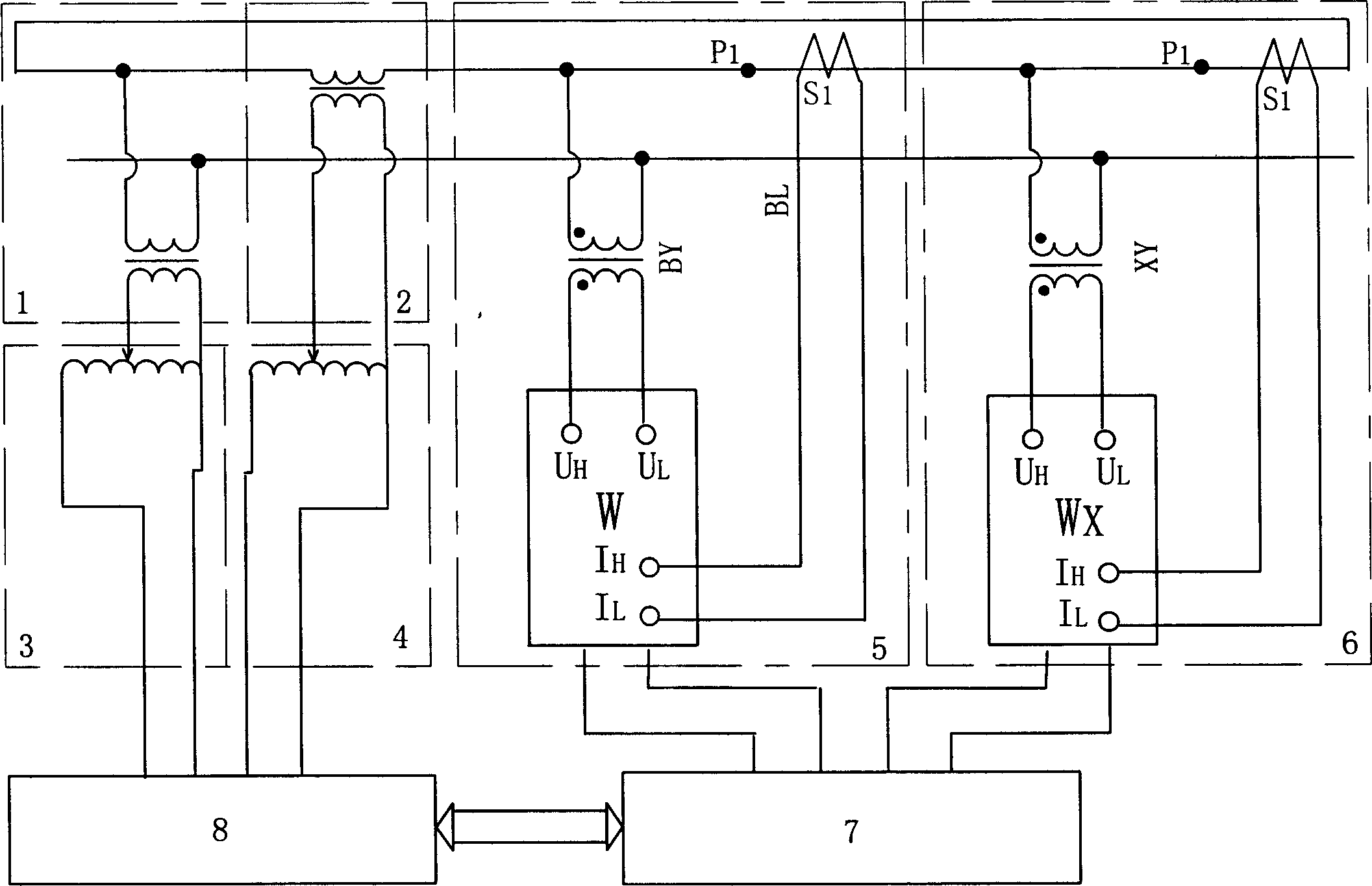

[0092] Detection / testing of single-phase high-voltage electric energy metering devices:

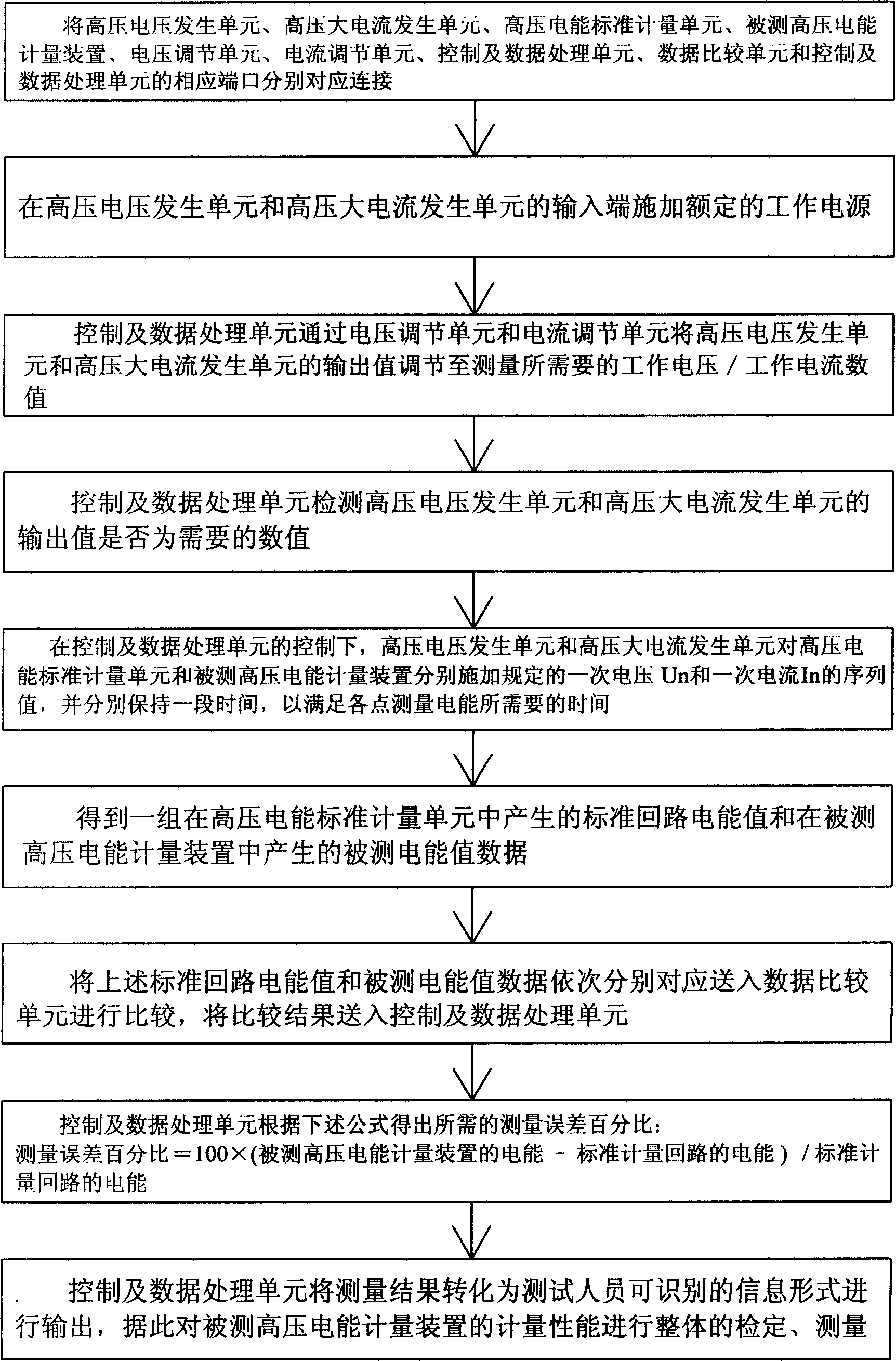

[0093] use figure 1 The test method and process of the test, the schematic diagram of the connection wiring of the specific device is as follows image 3 shown.

[0094] Wherein, the reference numerals in the figure all adopt the standard marking method in the field, which is easily understood and realized by those skilled in the art.

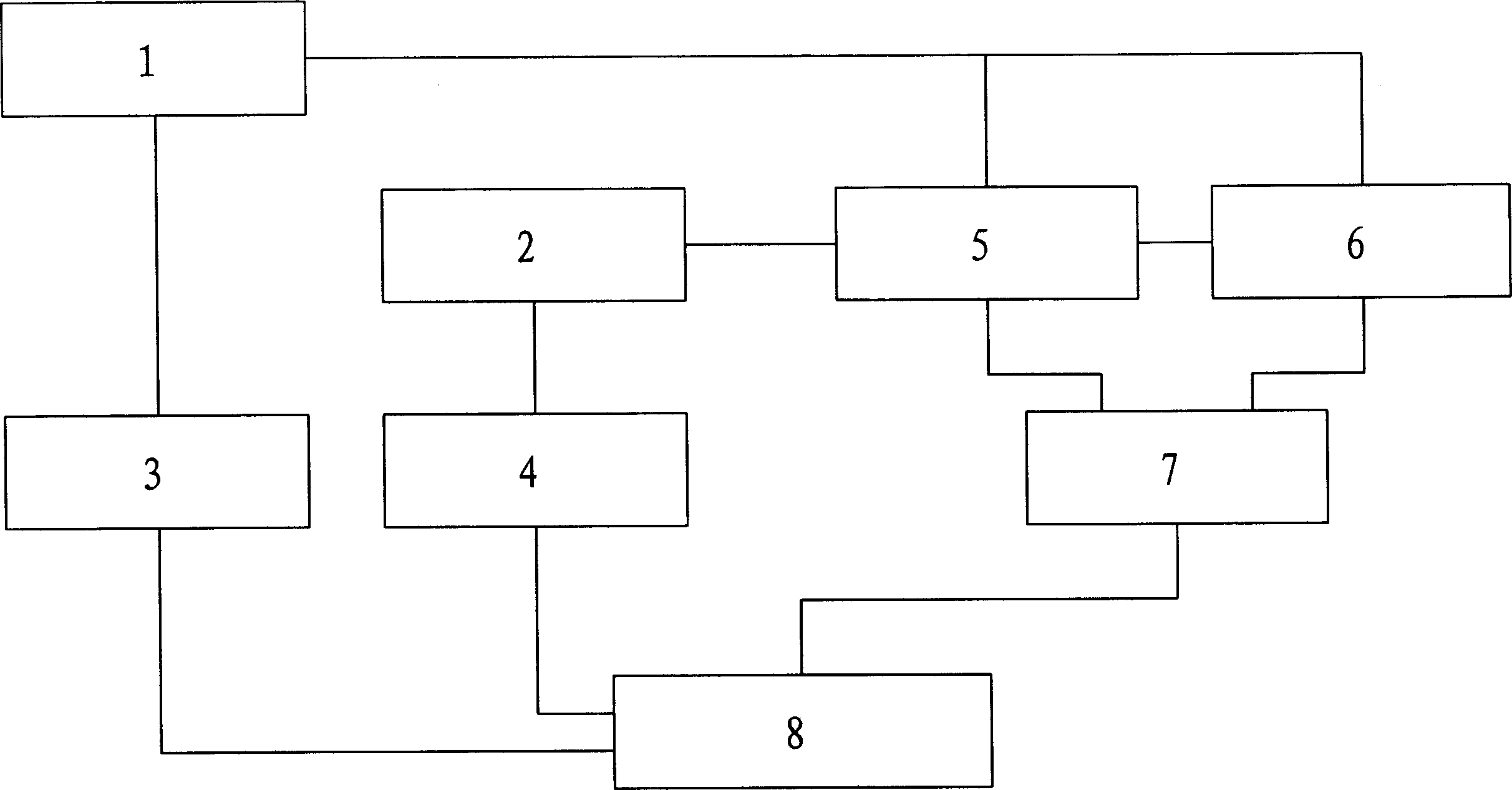

[0095] The specific functions of each unit are as follows:

[0096] A. High-voltage voltage generator, high-voltage and high-current generating unit: convert the low voltage and current provided by the regulating unit into the sequence values of high-voltage voltage Un and high-voltage and large current In required for measurement, and connect the voltage in parallel to the standard high-voltage electric energy metering circuit and The high-voltage terminal of the measured high-voltage electric energy metering device provides power for the overall det...

Embodiment 2

[0113] Detection / testing of three-phase three-wire high-voltage electric energy metering device:

[0114] use figure 1 The test method and process of the test, the schematic diagram of the connection wiring of the specific device is as follows Figure 4 shown.

[0115] This embodiment is for detection / testing of a three-phase three-wire system high-voltage electric energy metering device. The difference from the first embodiment lies in the wiring method, and the rest are the same as the first embodiment.

Embodiment 3

[0117] Detection / testing of three-phase four-wire high-voltage electric energy metering device:

[0118] use figure 1 The test method and process of the test, the schematic diagram of the connection wiring of the specific device is as follows Figure 5 shown.

[0119] This embodiment is for detection / testing of a three-phase four-wire system high-voltage electric energy metering device. The difference from Embodiment 1 or Embodiment 2 lies in the wiring method, and the rest is the same as Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com