Method and device for measuring linear shrinkage rate and thermal stress of metal solidification process

A technology of metal solidification and linear shrinkage, which is applied in the investigation stage/state change, etc., can solve problems such as difficult testing and uneven temperature, and achieve accurate and reasonable solidification shrinkage characteristics, low axial temperature gradient, linear shrinkage and thermal The effect of accurate stress value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

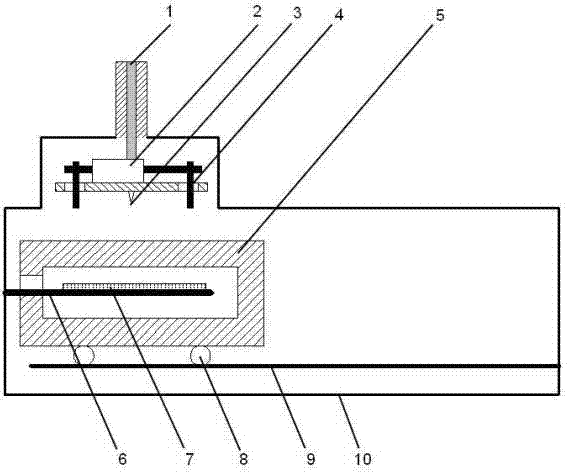

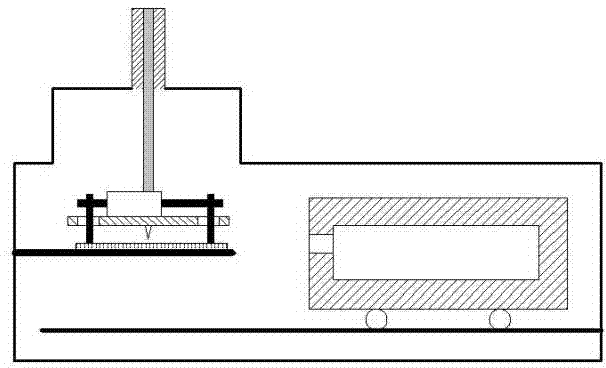

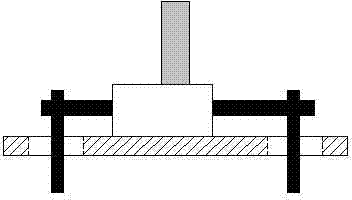

[0030] refer to Figure 1~Figure 6 , the linear shrinkage rate and thermal stress measurement method during the metal solidification process. Put the metal material in the crucible, fix the crucible on the horizontal support, put the crucible in the heating furnace under the protection of vacuum or set atmosphere to heat; after the metal reaches the preset melting temperature and keep warm, remove the heating furnace, measure the line The shrinkage rate and thermal stress sensors are in full contact with the molten metal through the transmission mechanism, and measure the linear shrinkage rate and thermal stress of the metal under different cooling rates. It is characterized by:

[0031] 1) The samples (13, 14) are solidified after in-situ melting in the crucible (7), which can realize solidification under different cooling conditions;

[0032] 2) During the cooling process, the sample is uniformly solidified, the axial temperature gradient is low, and the measured linear sh...

Embodiment 2

[0035] refer to Figure 1~Figure 6 , the measuring device for shrinkage rate and thermal stress during the metal solidification process mainly includes heating and atmosphere protection system, temperature control and temperature acquisition system, linear shrinkage rate and thermal stress acquisition system, transmission system, data display and processing system, etc. system. Using this device to measure the shrinkage rate and thermal stress during the metal solidification process is as follows:

[0036] 1. Make a block of the metal sample to be tested into a suitable size, and put it in the thermal stress sample crucible (13) and the shrinkage sample crucible (14). The size of the two sample crucibles is 200mm long and 10mm wide , 20mm high. The two sample crucibles (13, 14) prevent the formation of a crucible (7) on the crucible insulation layer base (15), and the crucible (7) is fixed on the horizontally fixed crucible support (6). The whole crucible is initially place...

Embodiment 3

[0043] refer to Figure 1~Figure 6 , the measuring device for shrinkage rate and thermal stress in the metal solidification process is applied to the above method for measurement, including heating and atmosphere protection system, crucible (7), temperature control and temperature acquisition system, linear shrinkage rate and thermal stress acquisition system, The transmission system, data display and processing system are characterized as follows:

[0044]1) The heating and atmosphere protection system: the main body of the system is a silicon-molybdenum rod box-type atmosphere protection resistance furnace (5); the heating curve can be set arbitrarily within the tolerance range of the heating body; the resistance furnace (5) passes through the pulley (8) Installed on the guide rail (9), driven by the transmission system, to realize horizontal movement, so that the crucible (7) fixedly installed on the crucible support (6) moves in and out from the furnace mouth of the resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com