Device special for detecting radial runout of long-axis workpiece and using method thereof

A radial runout and workpiece technology, applied in the direction of measuring devices, adopting mechanical devices, mechanical measuring devices, etc., to achieve the effect of avoiding lost rotation and ensuring relative motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

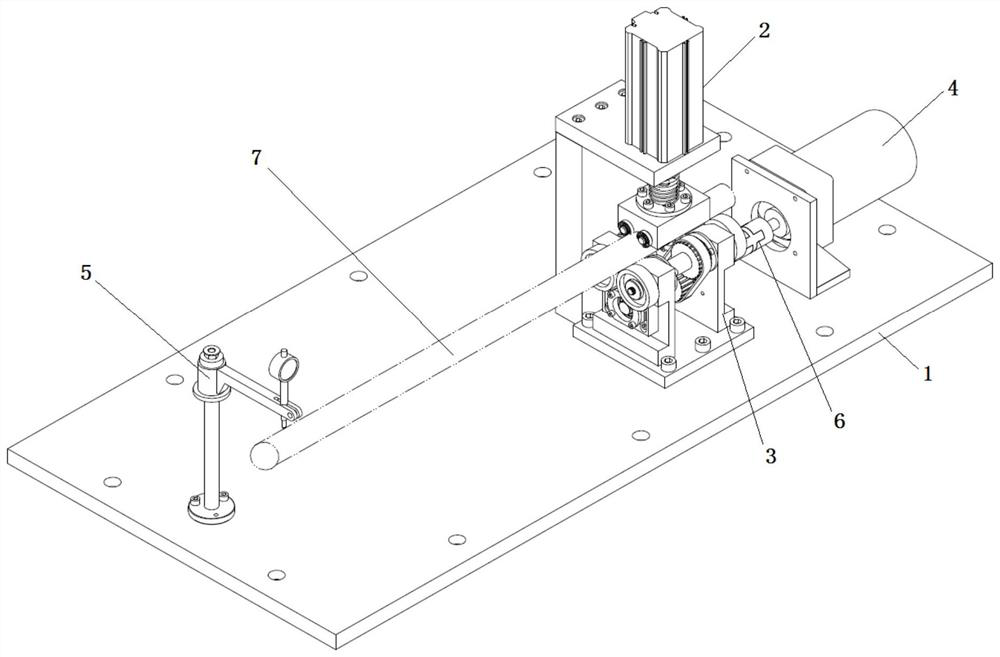

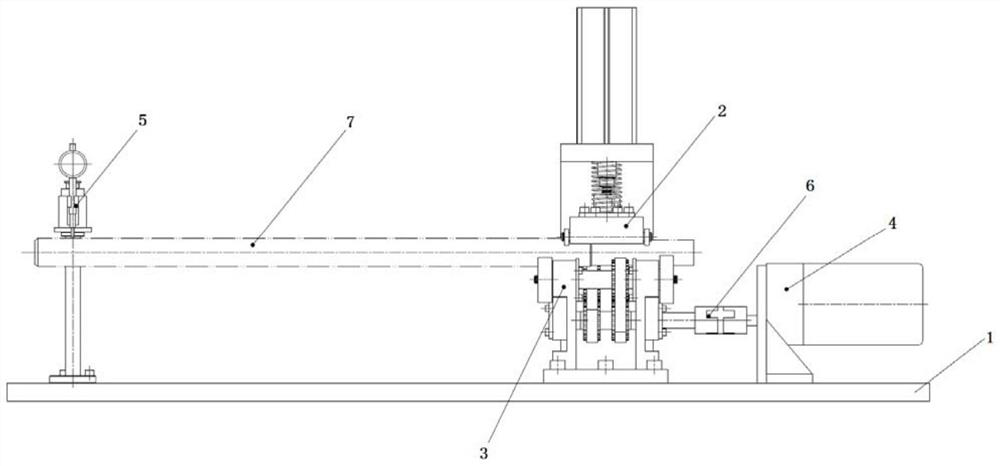

[0056] A device dedicated to detecting radial runout of long-axis workpieces, including a worktable, a measuring mechanism, a pressing mechanism, a roller drive transmission mechanism, and a driving mechanism;

[0057] The top surface of the worktable is a horizontal plane; the measuring mechanism is arranged on the left side of the top surface of the workbench for detecting the radial runout of the workpiece; the roller drive transmission mechanism is arranged on the top surface of the workbench On the right side, it is used for the bearing and rotary drive of the workpiece; the pressing mechanism is arranged in cooperation with the roller drive transmission mechanism, and is used to apply radial pressing force to the workpiece and its pressing part can follow the workpiece; The driving mechanism is connected with the roller driving transmission mechanism, and is used for providing driving force to the roller driving transmission mechanism.

[0058] The invention provides a d...

Embodiment 2

[0060] On the basis of the first embodiment above, as a preference, the measuring mechanism includes a vertical support rod vertically arranged on the workbench, a horizontal support rod with one end rotatably connected to the top end of the vertical support rod, and a horizontal support rod arranged on the The measuring instrument at the other end of the horizontal support rod is used to detect the radial runout of the workpiece.

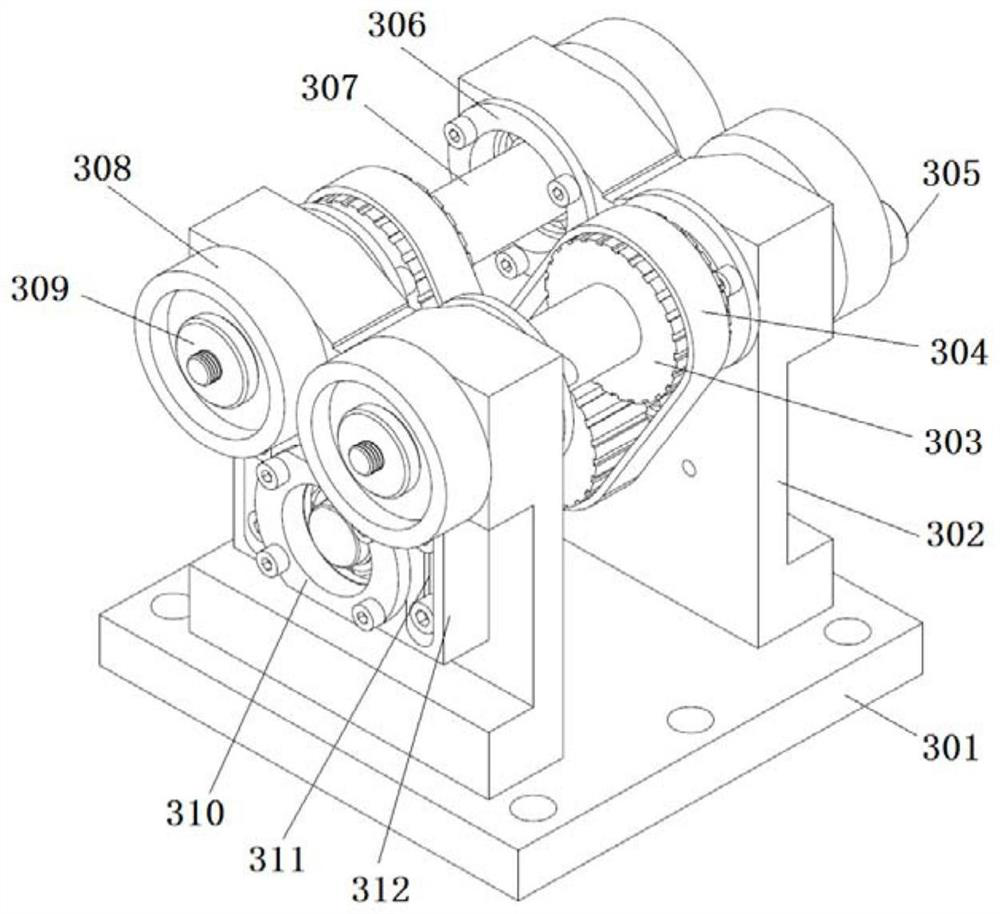

[0061] As a preference, the pressing mechanism includes a support frame, a cylinder, a connecting rod, a compression spring, a connecting sleeve, a pressing block and a pressing wheel; the supporting frame is used to support the whole mechanism, and the upper end is provided with a The extended convex edge and the upper and lower end surfaces are horizontal planes parallel to each other, the cylinder is vertically arranged on the convex edge, the connecting rod is vertically arranged, and its top is detachably connected with the bottom end of the cy...

Embodiment 3

[0067] On the basis of the second embodiment above, as a preference, in the pressing mechanism: the difference between the support frame is that it includes a vertical plate and a cylinder seat plate, the vertical plate is vertically arranged, and the bottom surface and the top surface parallel to each other, and the bottom surface and the top surface are provided with connecting screw holes; the cylinder seat plate is used to carry the cylinder, and is horizontally arranged on the top surface of the vertical plate, and one end of the top surface of the cylinder seat plate is close to the edge A through hole for passing through the cylinder rod is opened.

[0068] Preferably, the connecting rod is a threaded rod, and one end connected to the cylinder is locked by a nut for axial limitation.

[0069] Preferably, the pressing force of the compression spring is changed according to the different wire diameters of the compression spring.

[0070] Preferably, the connecting rod is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com