Discharging device for iron sheet bending

A technology of blanking and iron sheet, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high safety risk, energy consumption, etc., and achieve safe use of equipment, faster bending speed, safe and convenient use of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

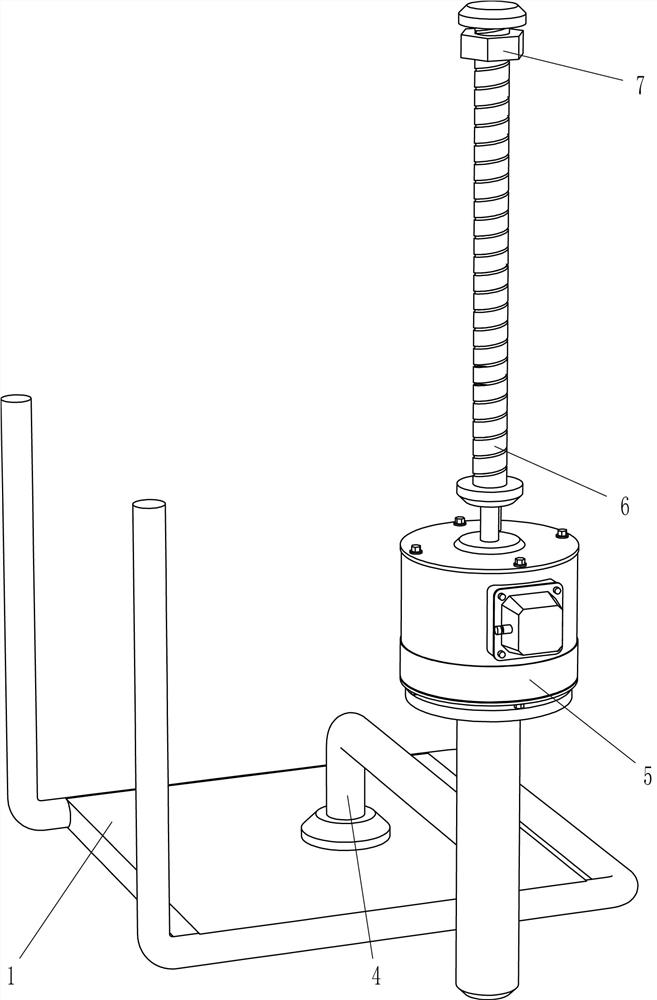

[0021] A blanking device for bending iron sheets, such as Figure 1-4 As shown, it includes a frame 1, a material discharging assembly, a lifting assembly and a pushing assembly. The top of the left side of the frame 1 is provided with a material discharging assembly for discharging by lifting, and the front side of the top of the frame 1 is equipped with a The working lifting component is provided with a pushing component between the lifting component and the discharging component through lifting.

[0022] like figure 1 and 2 As shown, the discharging assembly includes a guide rail 2 and a blanking frame 3, the top left side of the frame 1 is fixed with the guide rail 2 by bolts, and the top right side of the guide rail 2 is fixed with the blanking frame 3 by bolts.

[0023] like figure 1 and 3 As shown, the lifting assembly includes a support rod 4, a reduction motor 5, a screw rod 6 and a nut 7, the front middle part of the frame 1 is connected with a support rod 4 by a...

Embodiment 2

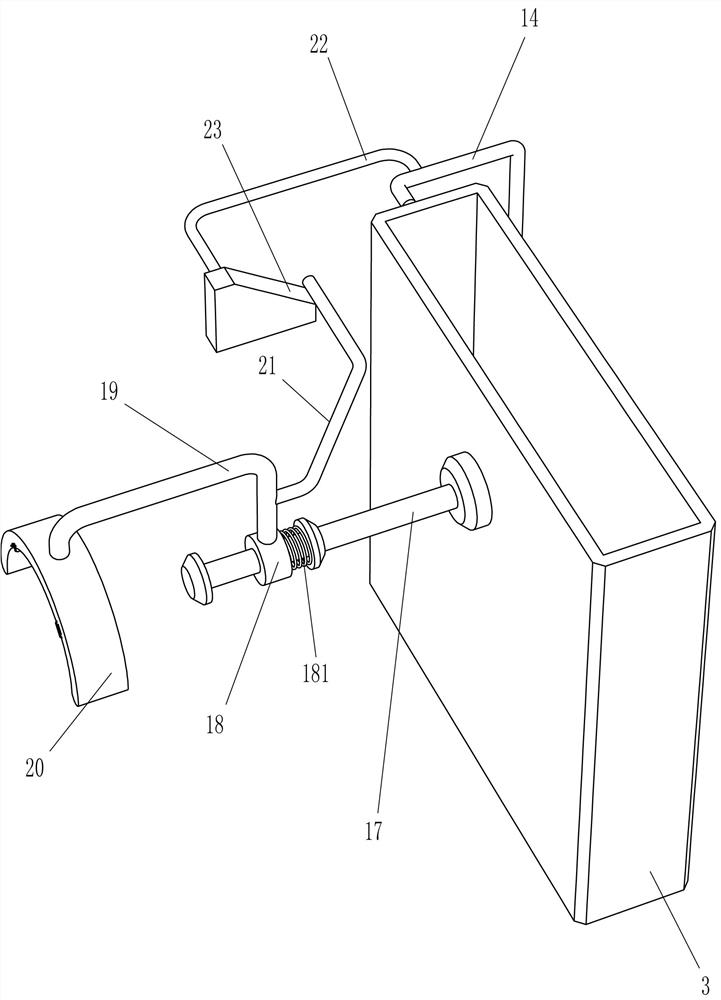

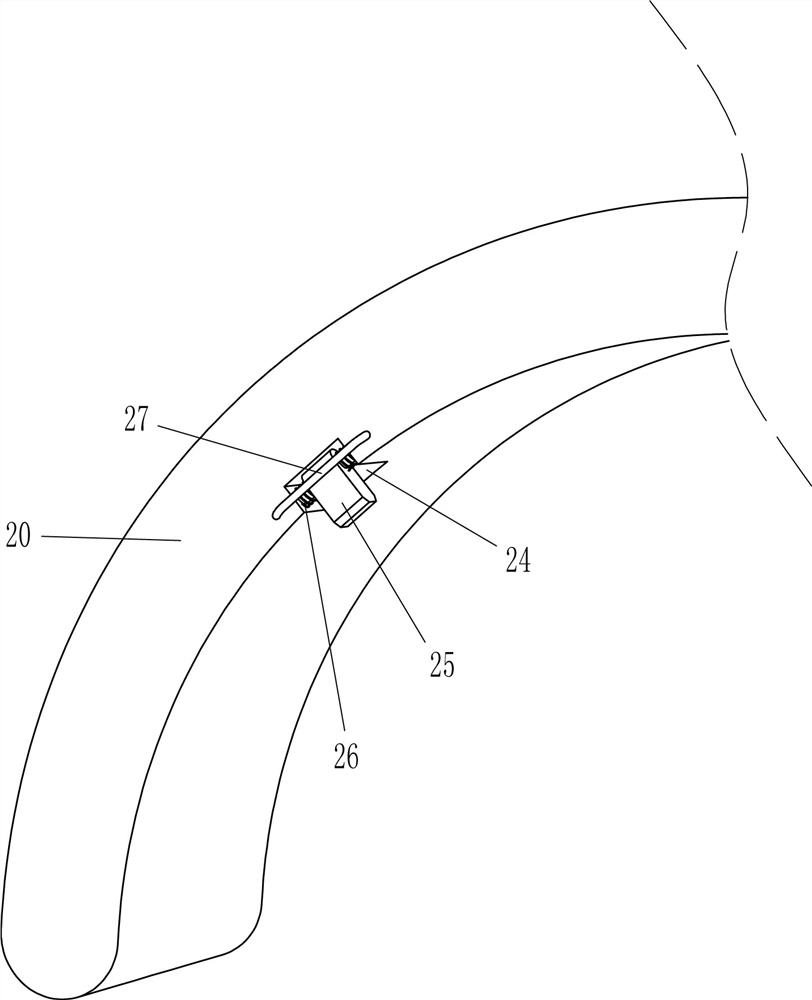

[0030] On the basis of Example 1, such as figure 1 , 5 Shown in and 6, also include fixed rod 17, sliding sleeve 18, second spring 181, second special-shaped rod 19, arc plate 20, pull bar 21, U-shaped bar 22, wedge block 23, block 25, torsion spring 26 and retaining bar 27, blanking frame 3 left side tops are welded with fixed bar 17, and fixed bar 17 left part sliding type is provided with sliding sleeve 18, is connected with second spring 181 between the fixed bar 17 middle part and sliding sleeve 18 right sides , the top of the sliding sleeve 18 is welded with a second special-shaped rod 19, the left end of the second special-shaped rod 19 is welded with an arc-shaped plate 20, the right part of the second special-shaped rod 19 is welded with a tie rod 21, and the upper part of the first special-shaped rod 14 on the rear side is welded with a U Type bar 22, U-shaped bar 22 front ends are welded with wedge-shaped block 23, and wedge-shaped block 23 cooperates with pull bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com