Patents

Literature

50results about How to "Fast bending speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

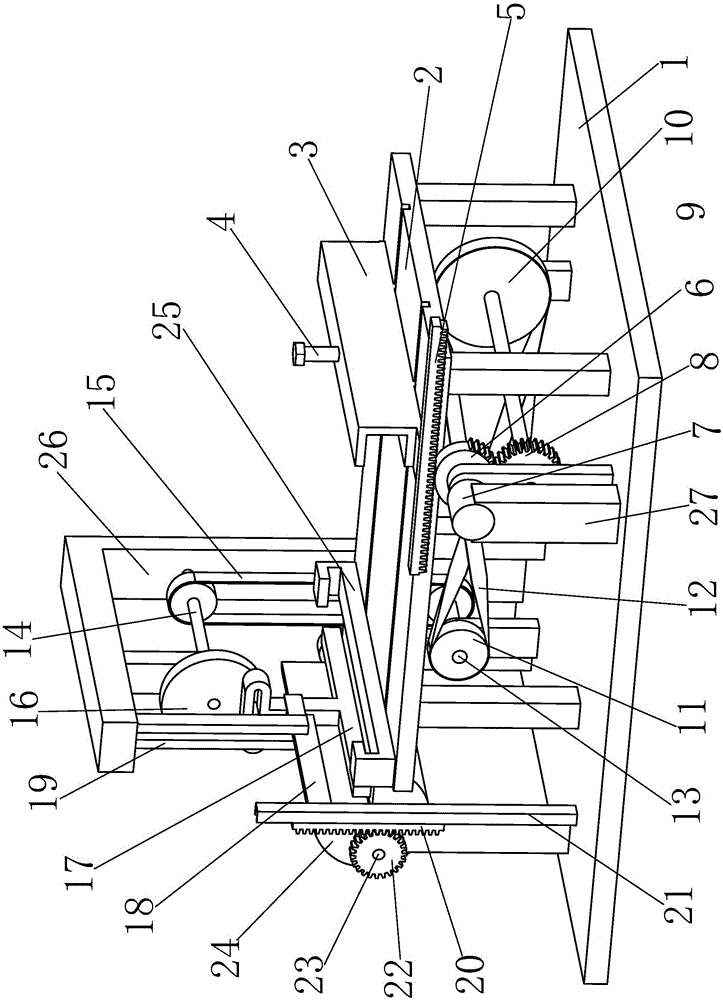

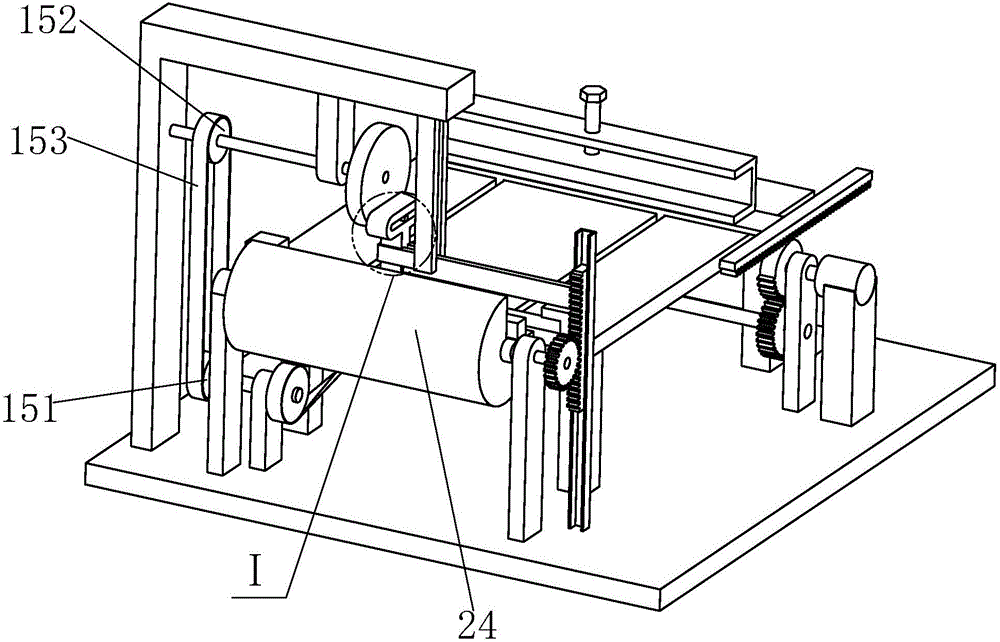

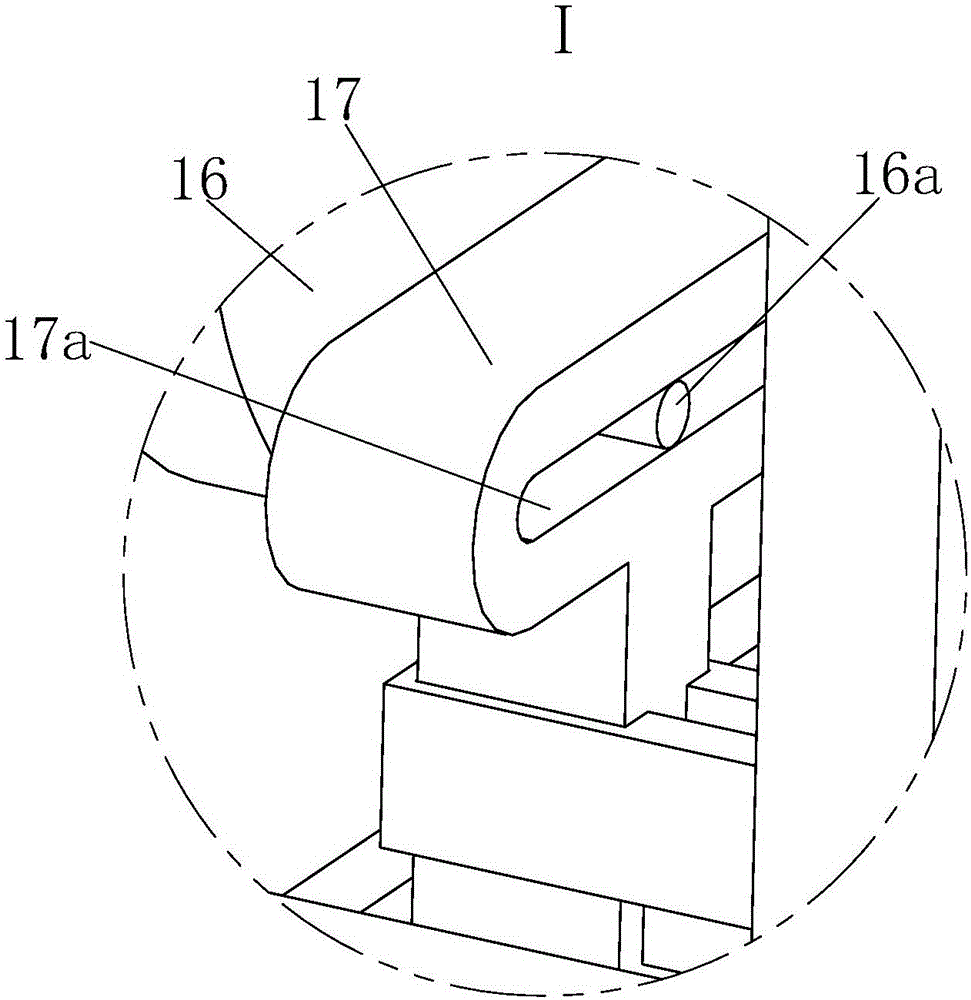

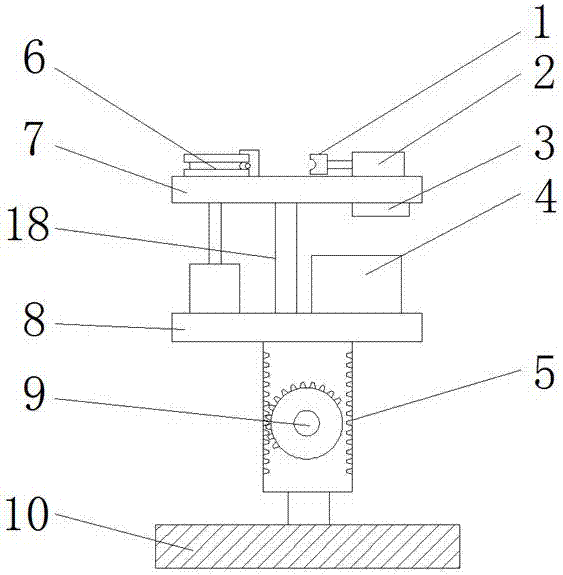

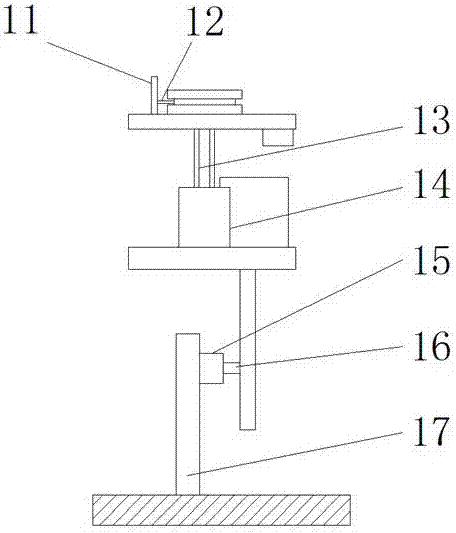

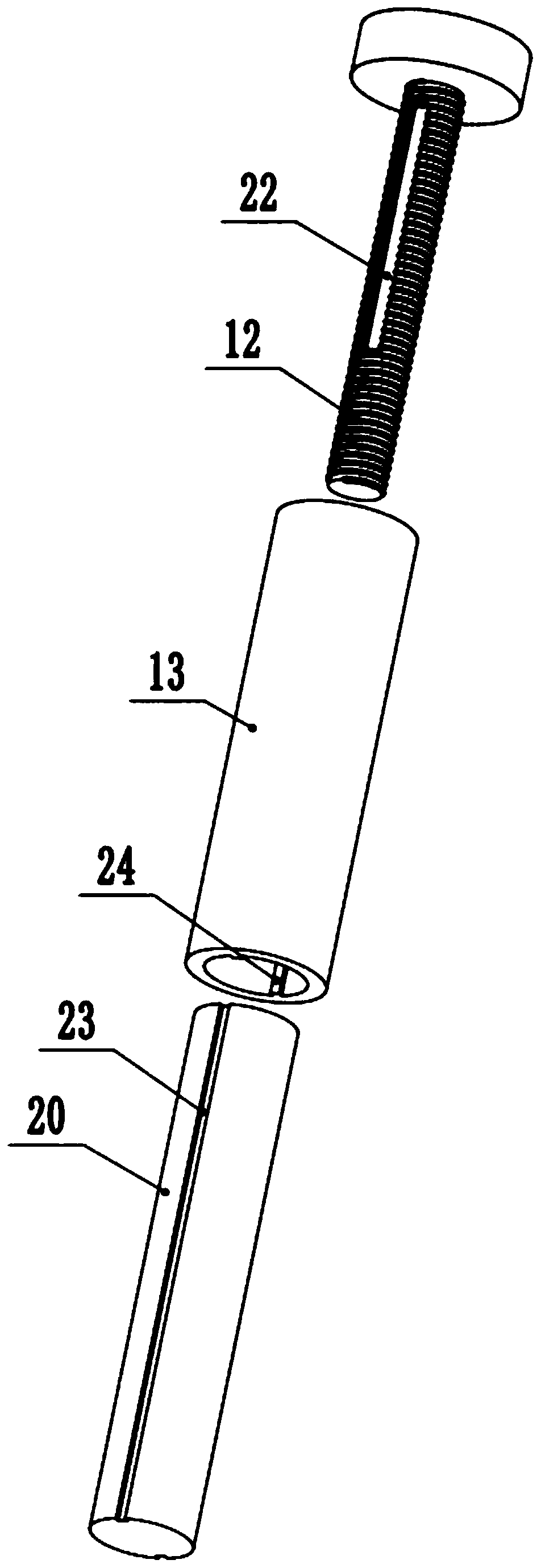

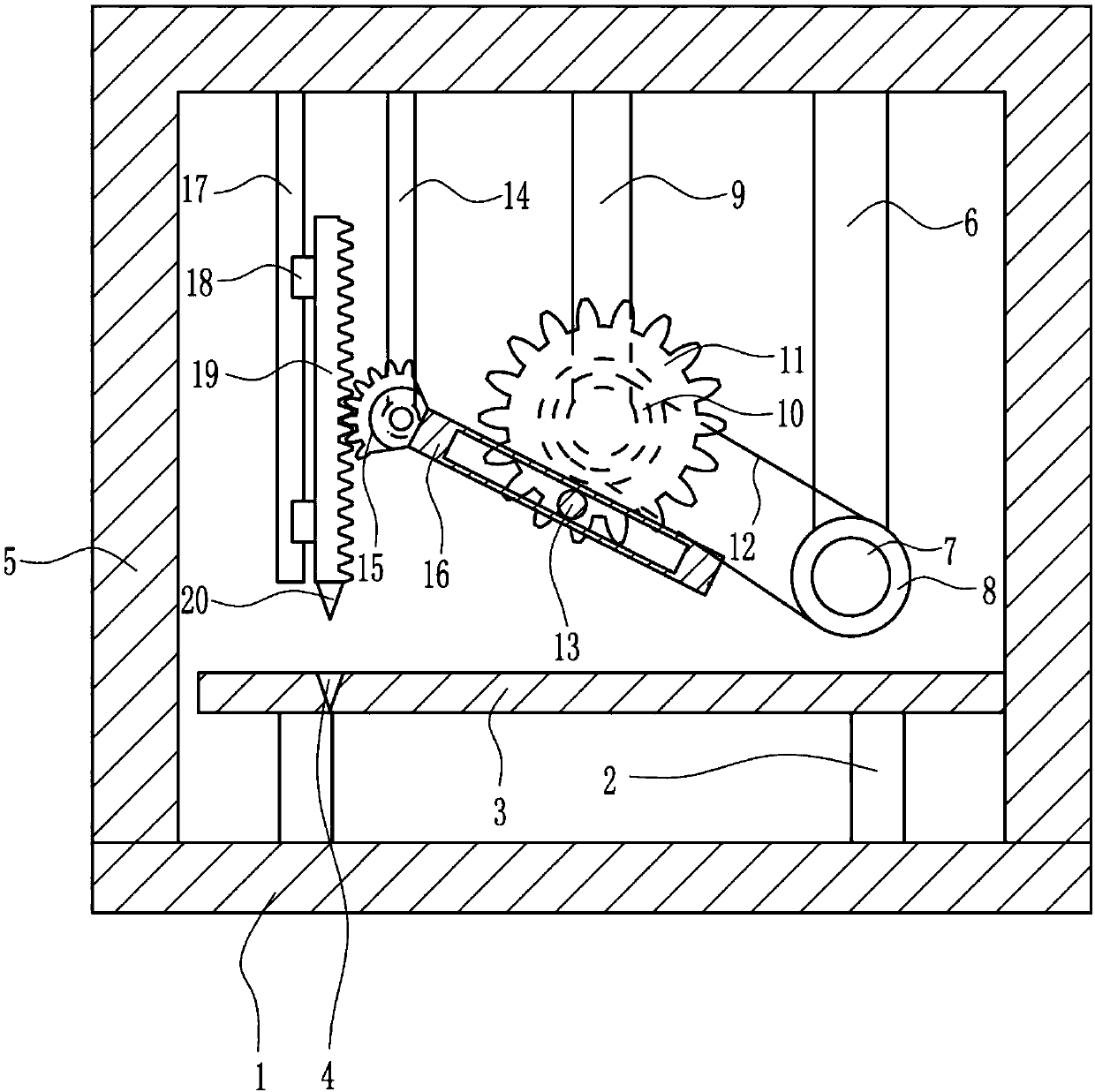

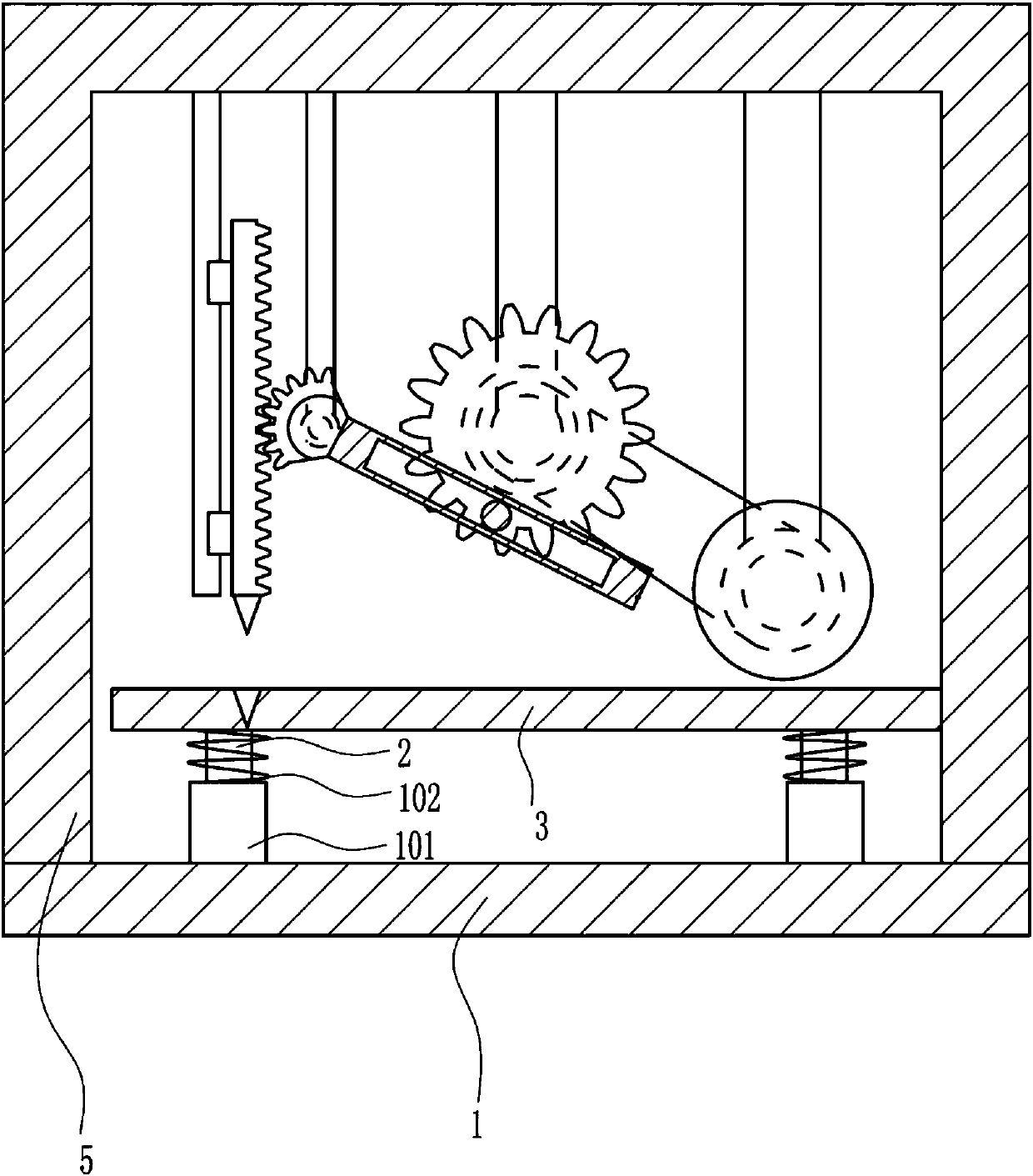

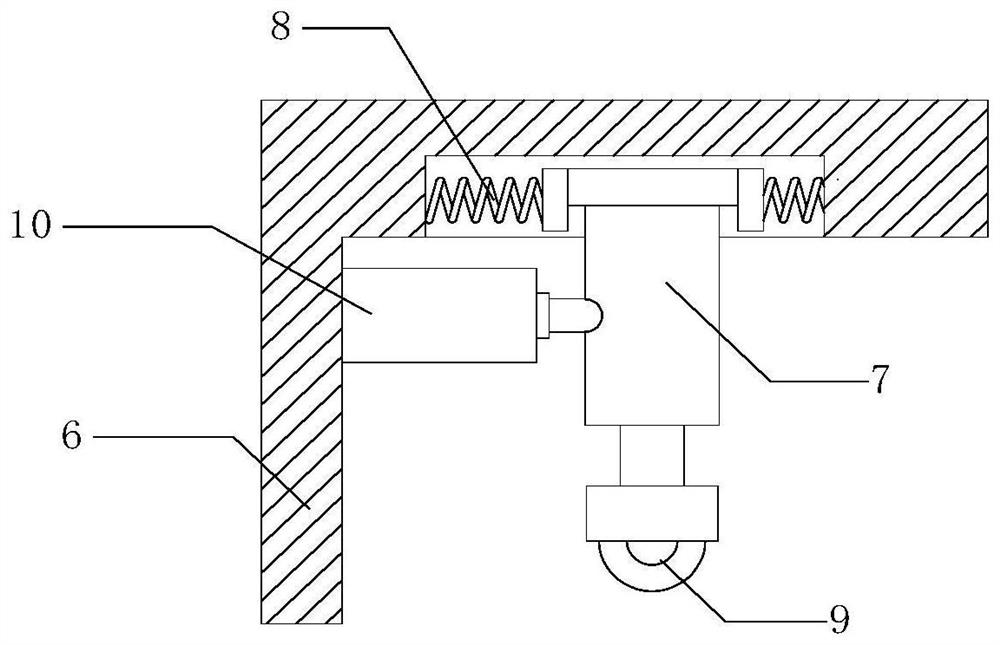

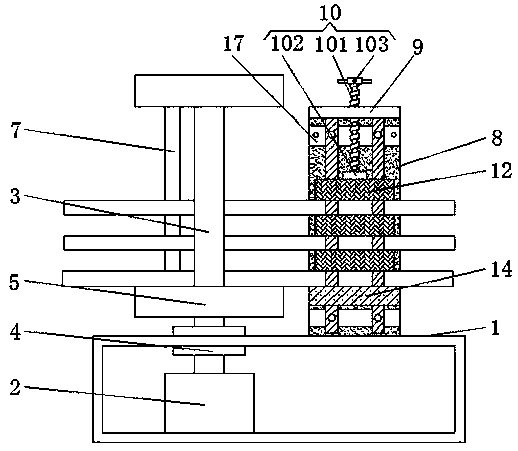

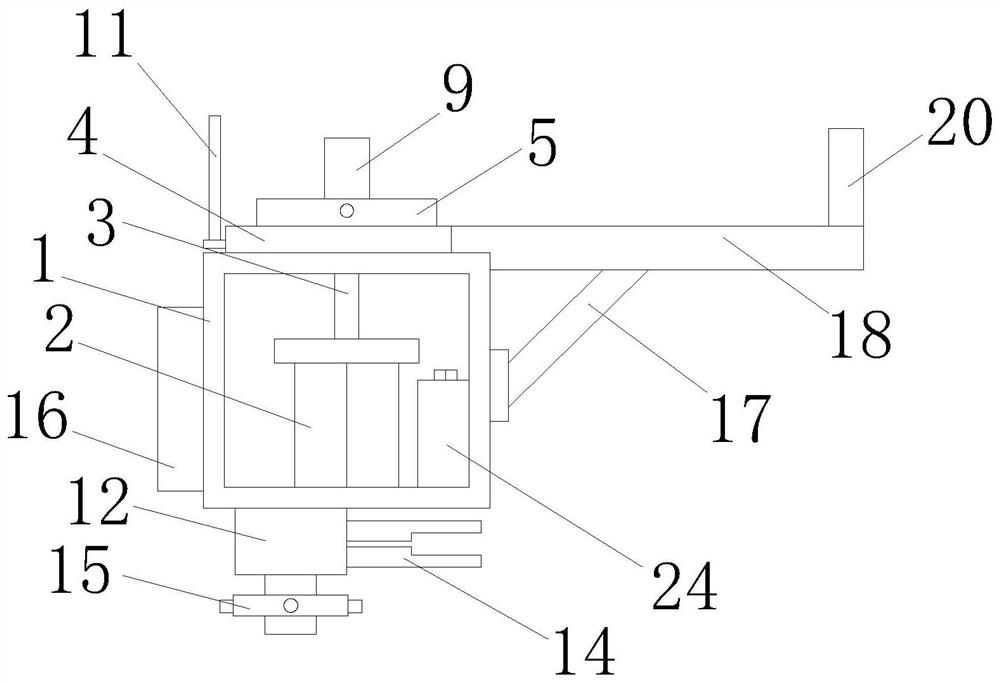

Sheet metal part bending machine

ActiveCN106799413AHigh bending strengthFast bending speedMetal-working feeding devicesPositioning devicesEngineeringRack and pinion

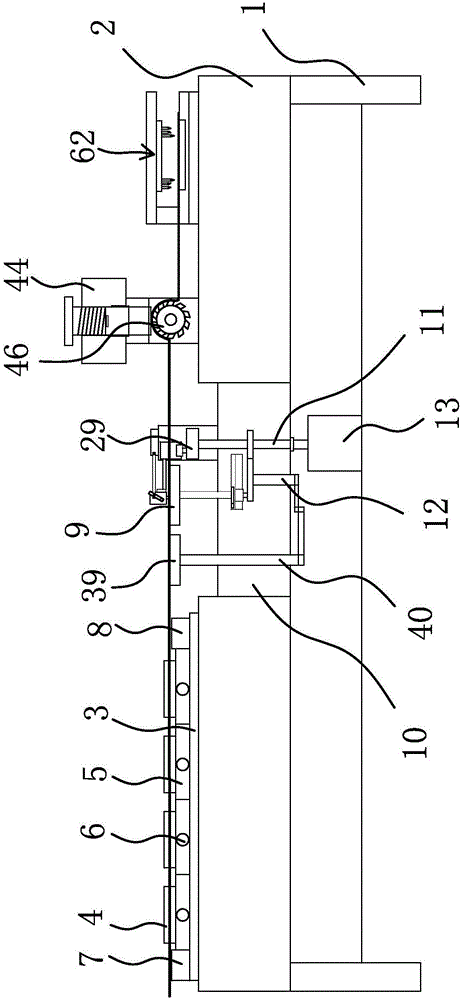

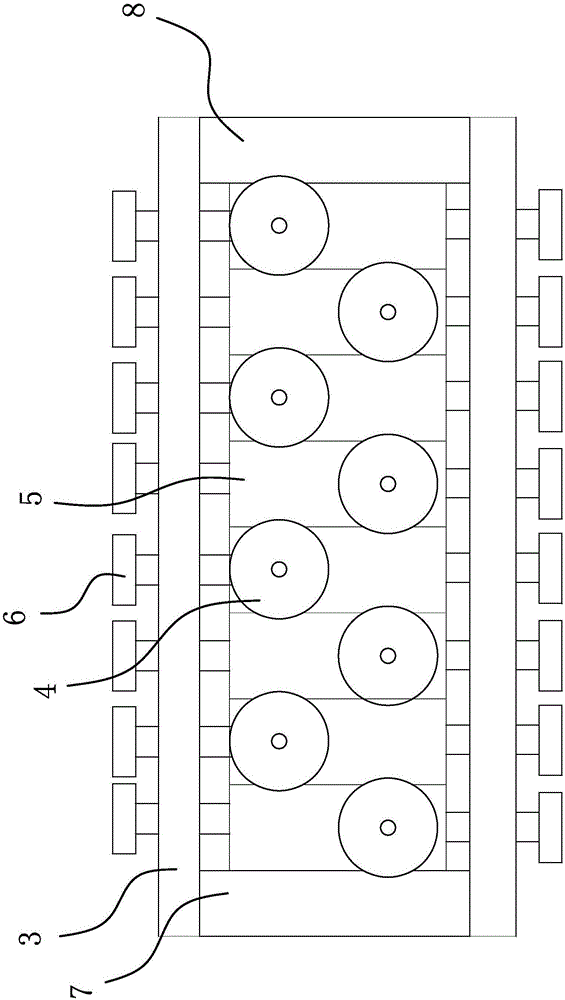

The invention relates to a sheet metal part bending machine which comprises a bottom plate and a workbench. A clamp opening frame is mounted on the workbench in a sliding manner and provided with a fastening bolt. A first gear rack is welded to the clamp opening frame. An incomplete gear is arranged at the lower end of the first gear rack and connected with a motor. A transmission gear is arranged below the incomplete gear and connected with a transmission shaft. The transmission shaft is connected with a right belt wheel. A left belt wheel is arranged right at the left portion of the right belt wheel. A flat rope belt is arranged between the left belt wheel and the right belt wheel. The left belt wheel is connected with a countershaft. An upper shaft is arranged over the countershaft. A parallel belt transmission mechanism is arranged between the countershaft and the upper shaft. According to the sheet metal part bending machine, by means of alternate meshing of the incomplete gear, the gear rack and the transmission gear, sheet metal parts can be slid leftwards at equal distance, a lifting bending frame and a drive rotating disc cooperate to alternately bend the sheet metal parts by 90 degrees, and then the sheet metal parts can be automatically and fast bent by 90 degrees many times; and the beneficial effects of large bending strength and high bending speed are achieved.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

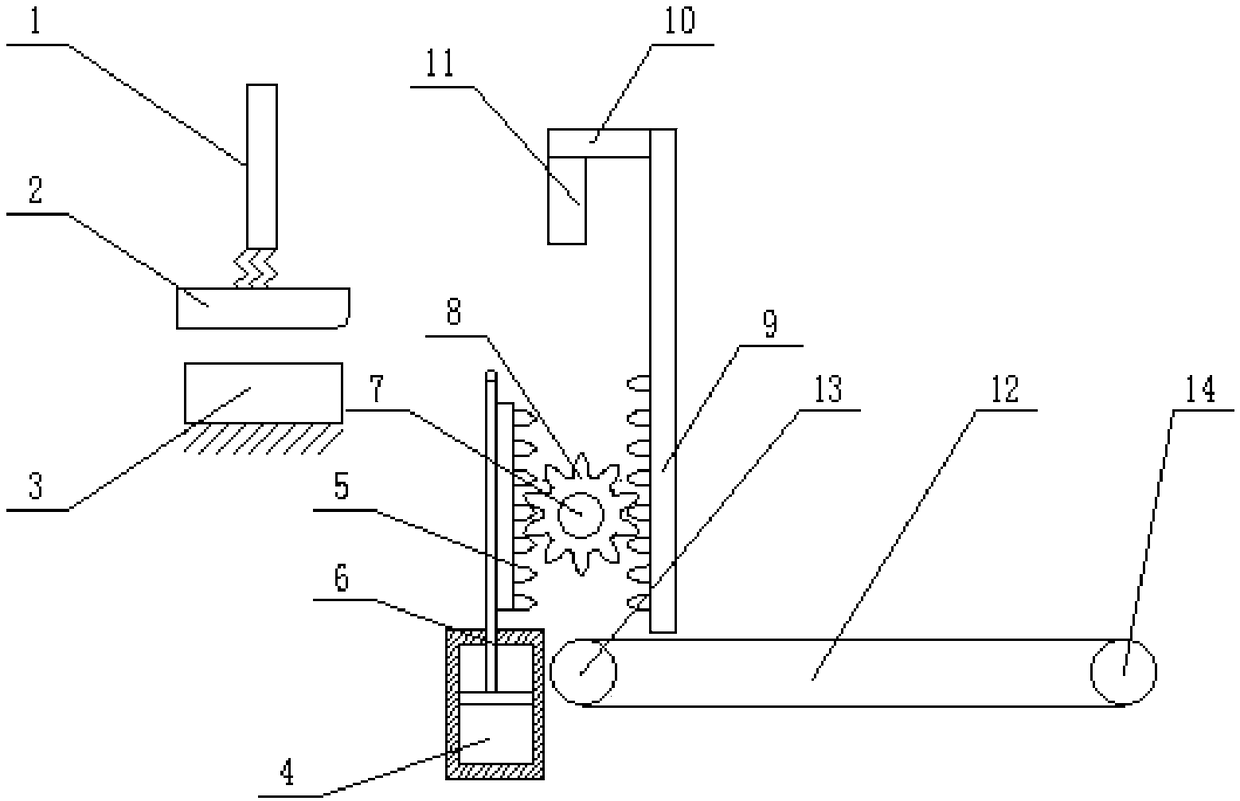

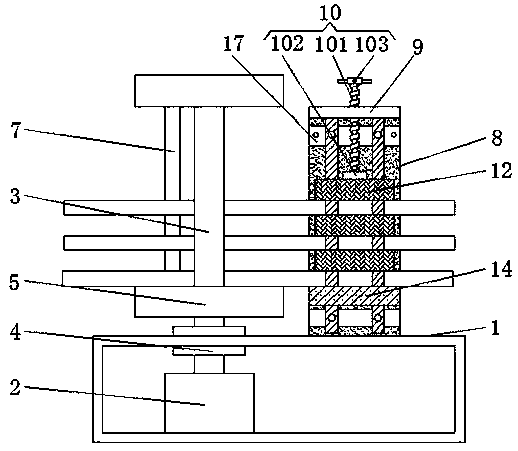

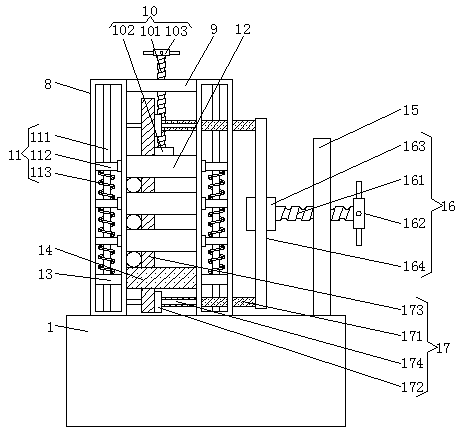

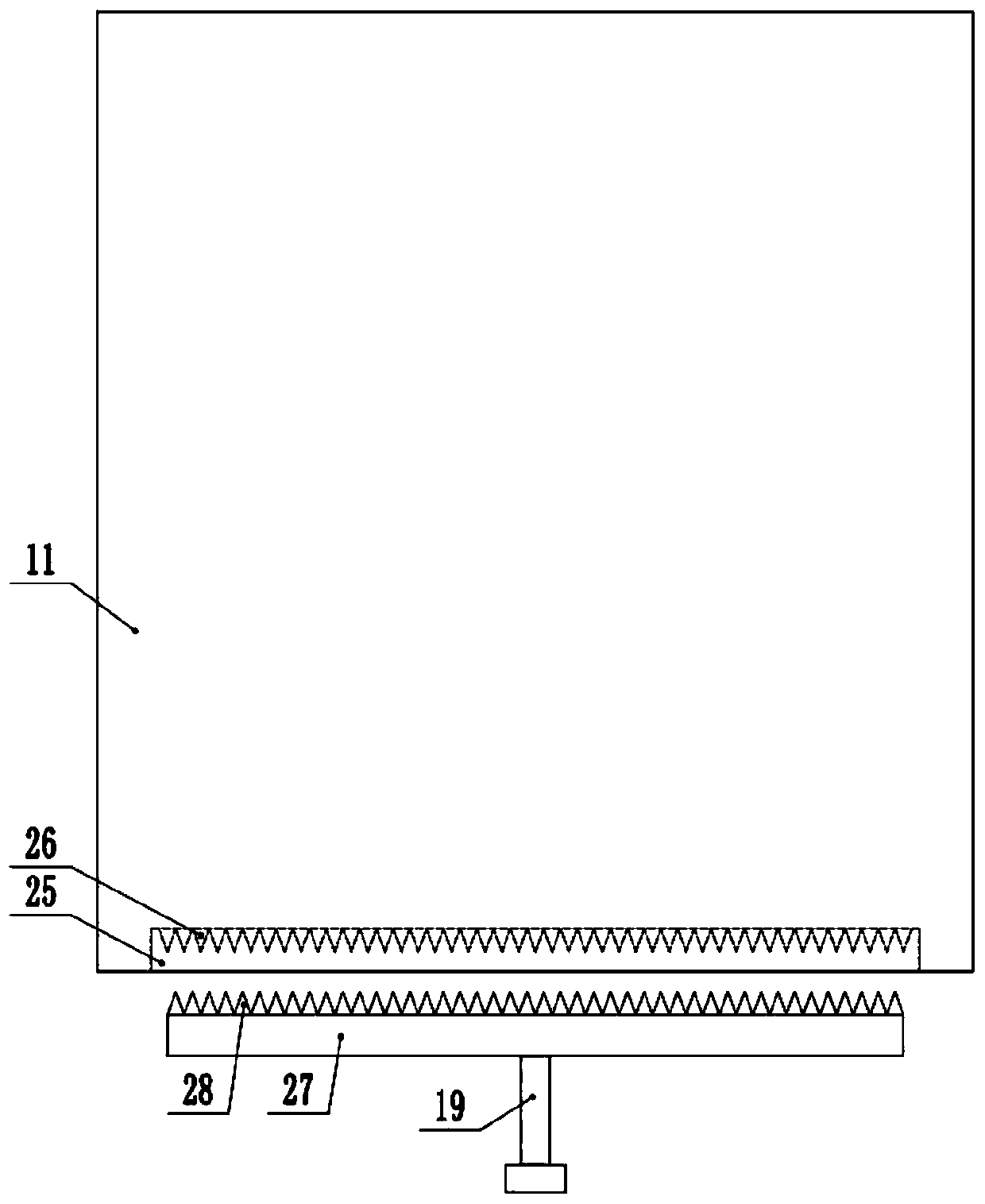

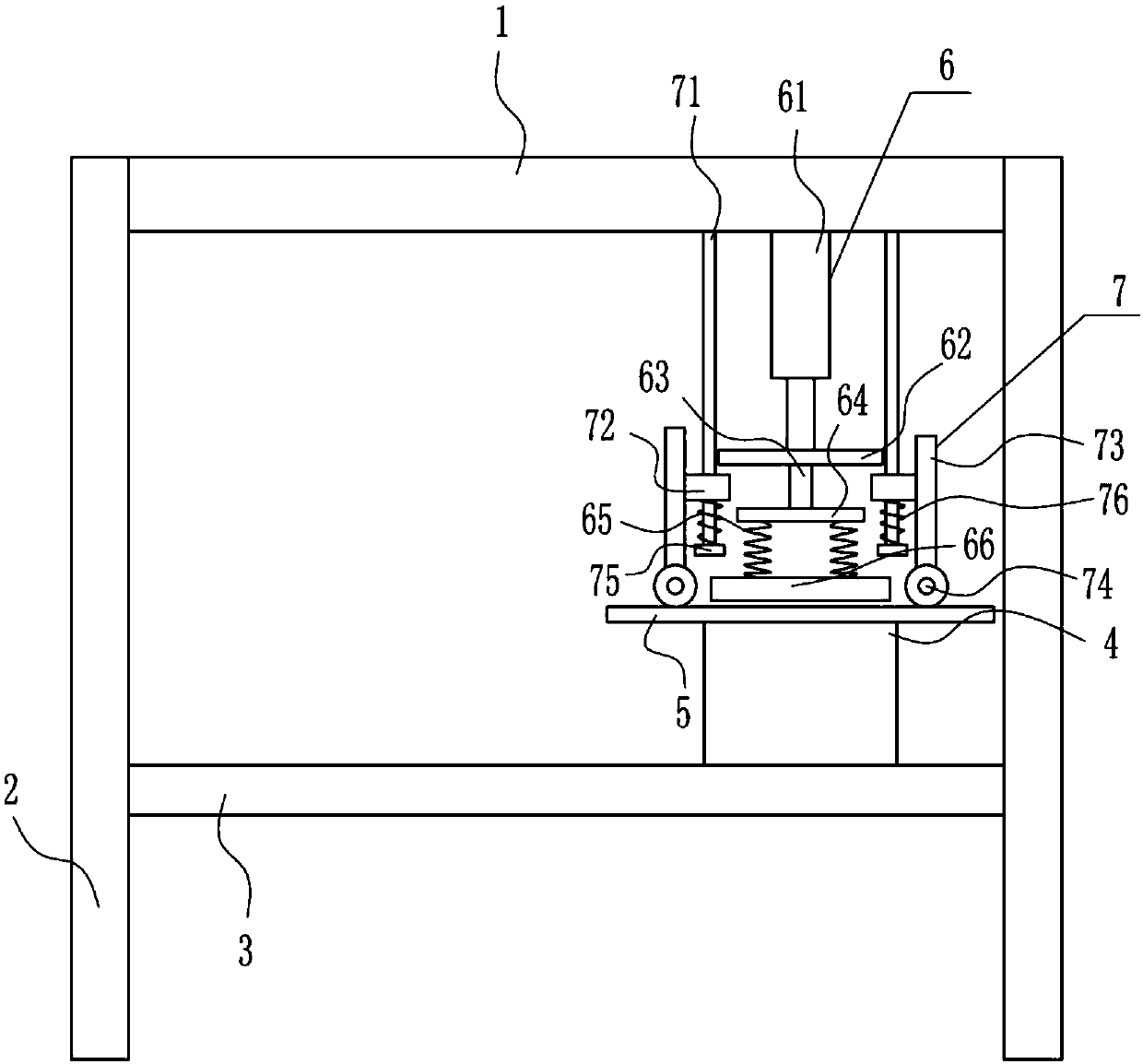

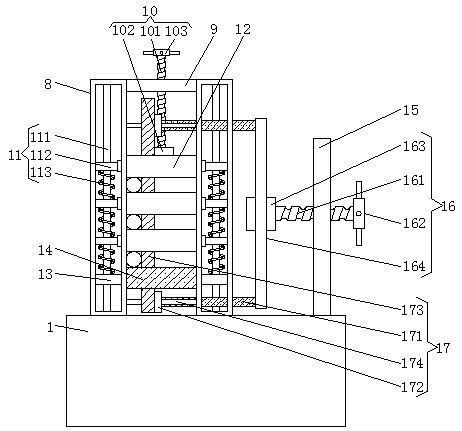

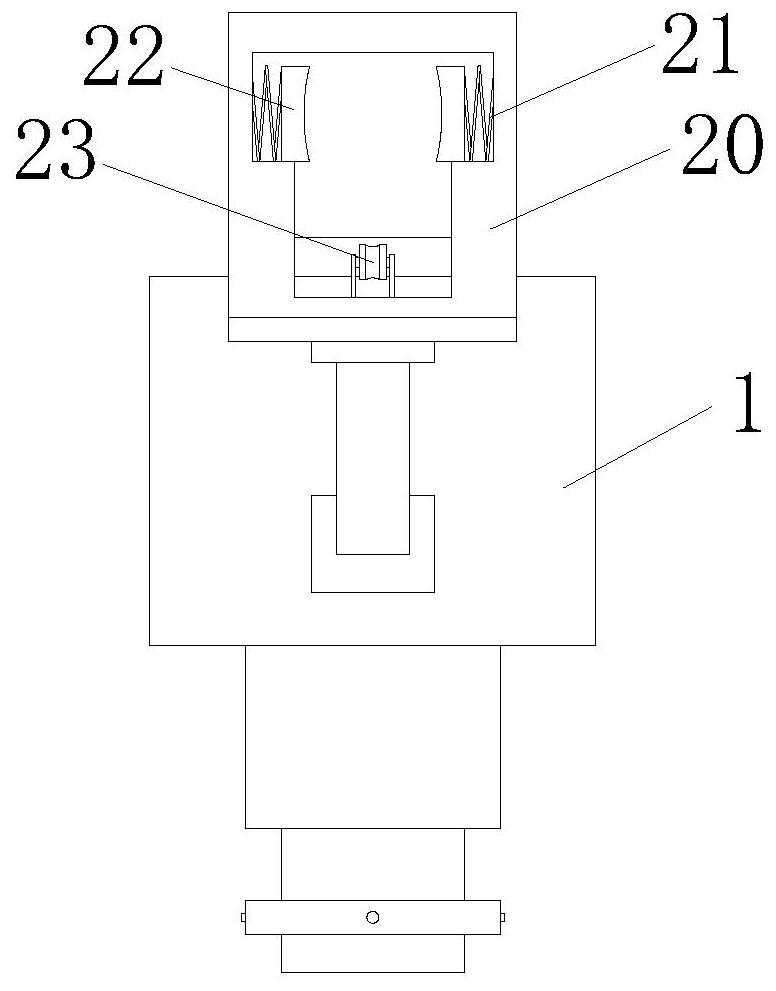

Automobile interior trim plate bending device

ActiveCN108176785ARealize linear motionFast bending speedMetal-working feeding devicesPositioning devicesEngineeringPiston rod

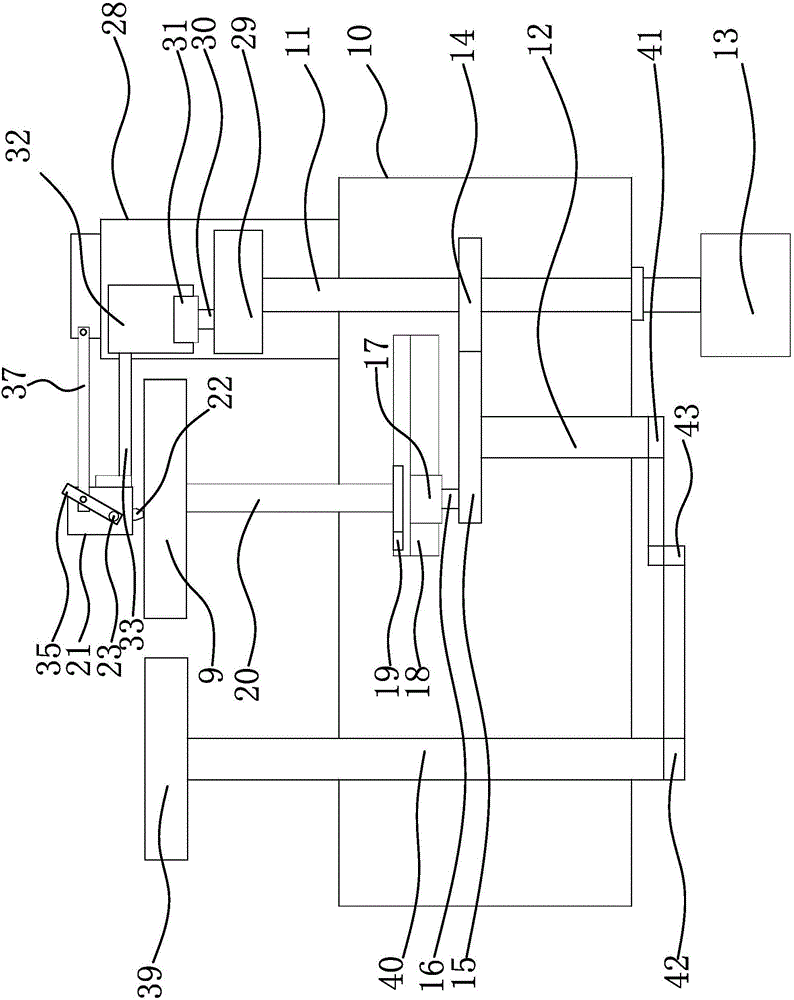

The invention belongs to the field of automobile part machining and particularly discloses an automobile interior trim plate bending device. The automobile interior trim plate bending device comprisesa rack which is provided with a positioning part, a bending part and a conveying part; the positioning part comprises a sliding rod, a pressing plate and a base; the bending part comprises a piston barrel, a rotating shaft and a downward pressing unit, and a first rack is connected to a piston rod; a through hole is formed in the outer wall of the piston rod; the piston barrel is connected with avortex pipe; the end face of the side, away from the piston rod, of the piston barrel is provided with a gas outflow hole which is internally provided with a second gas outflow one-way valve; a firstgear engaged with the first rack is arranged on the rotating shaft; the downward pressing unit comprises a second rack connected to the rack in a sliding manner; the second rack is engaged with the first gear; a supporting rod is connected to the top of the second rack; a bending punch is connected to the supporting rod; and the conveying part comprises a belt for conveying a first roller shaft and a second roller shaft. The scheme is adopted to meet the requirements of automation to automobile interior trim plates in the automobile interior trim plate bending process.

Owner:宁波高新区新柯保汽车科技有限公司

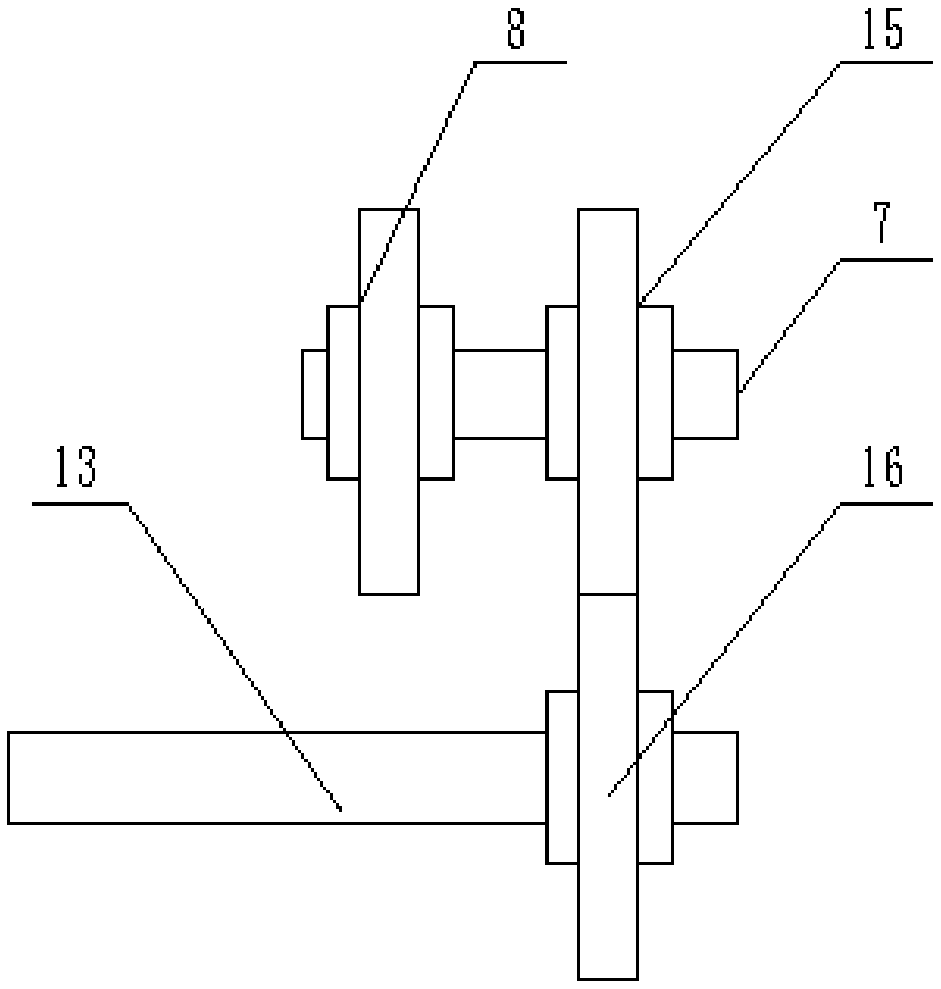

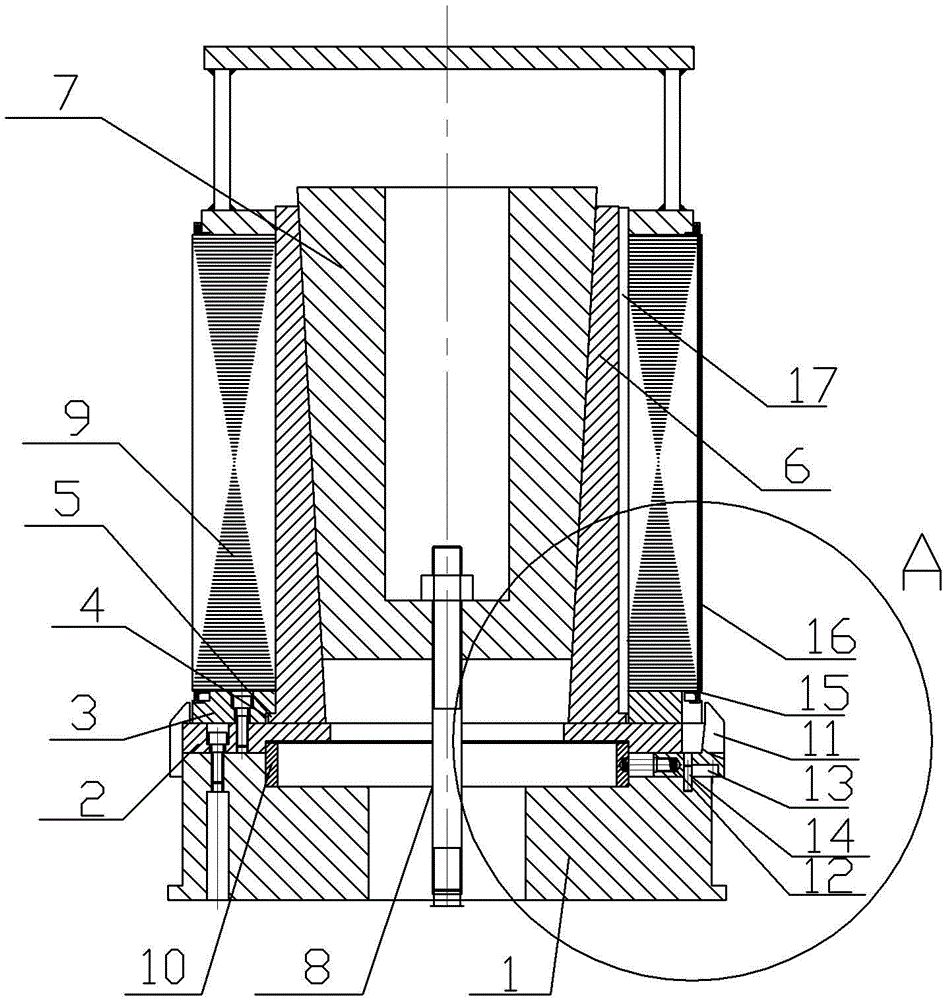

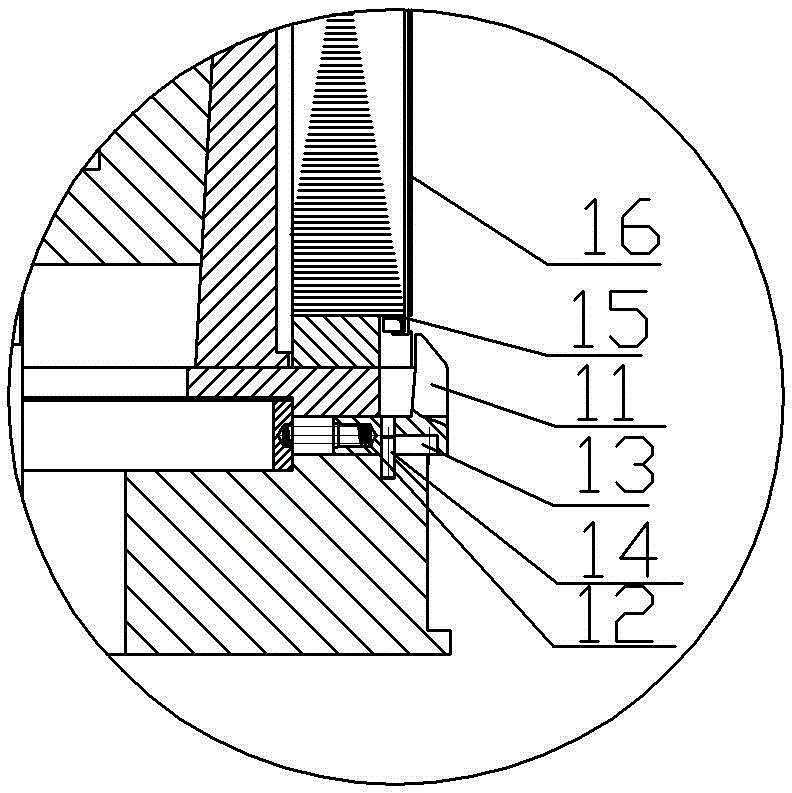

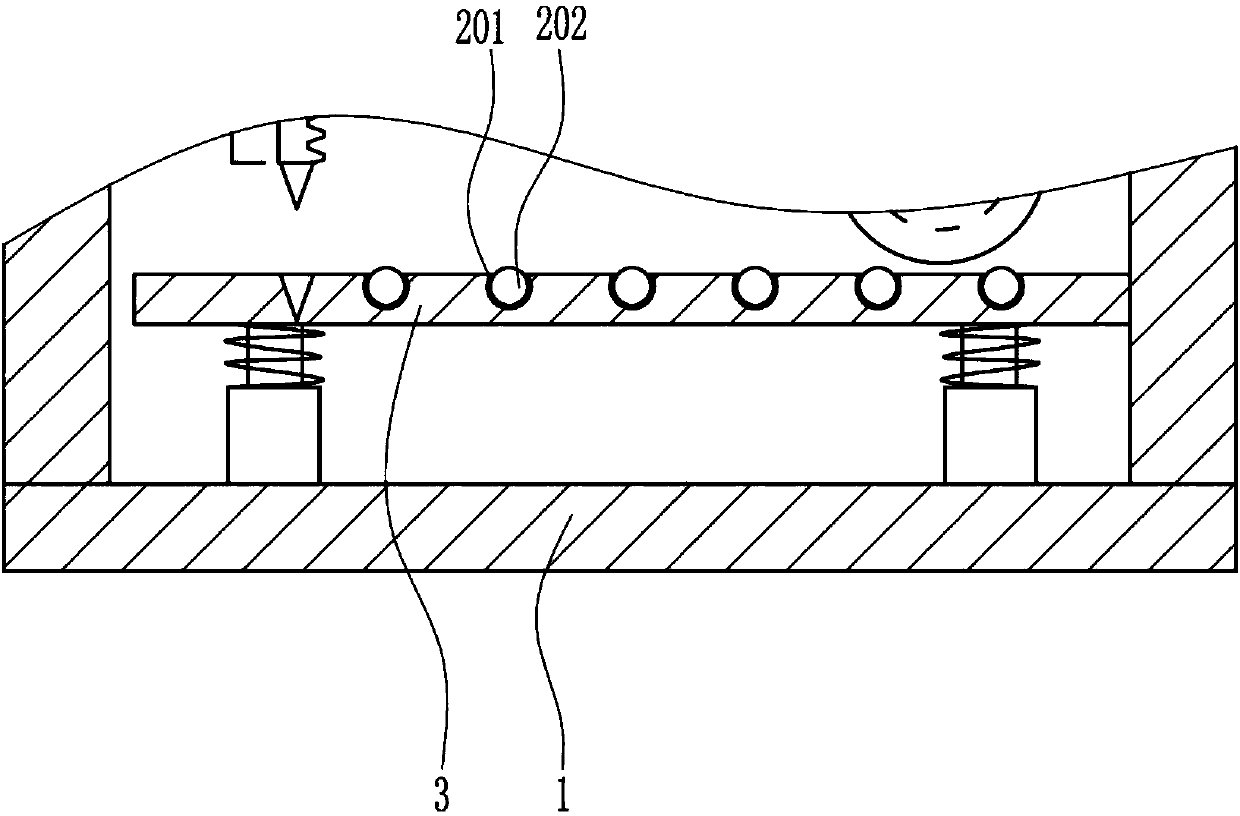

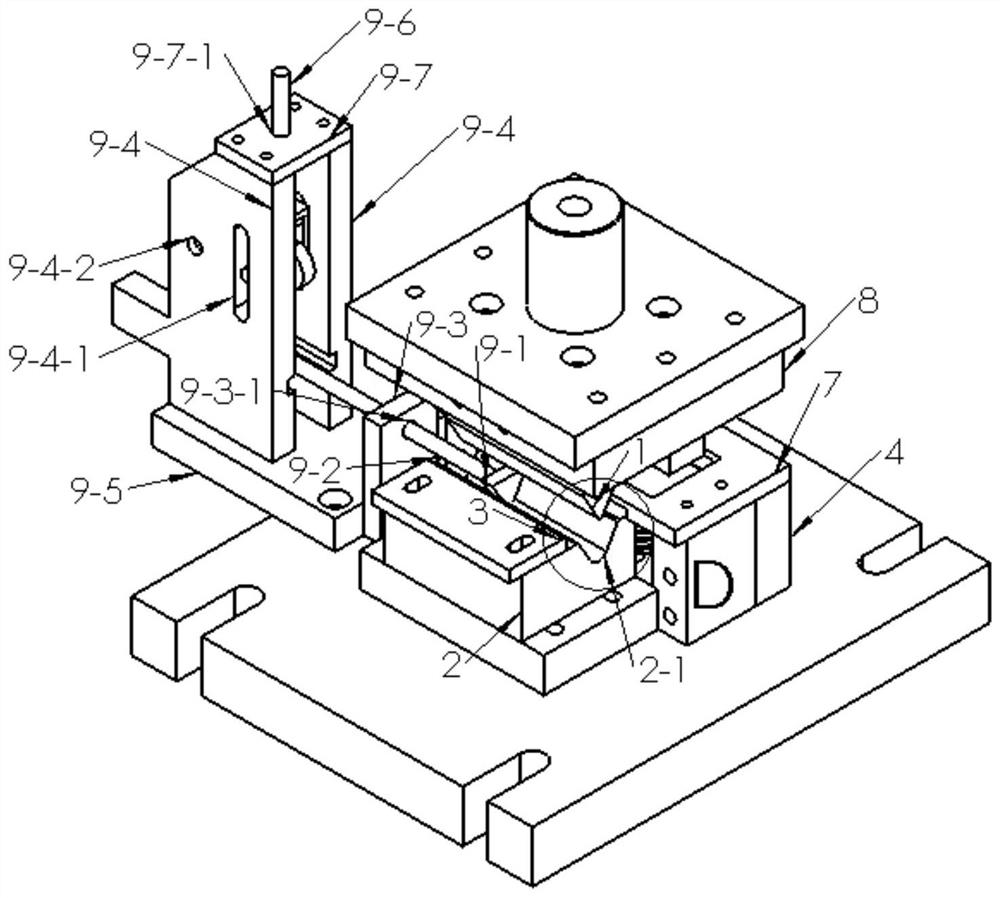

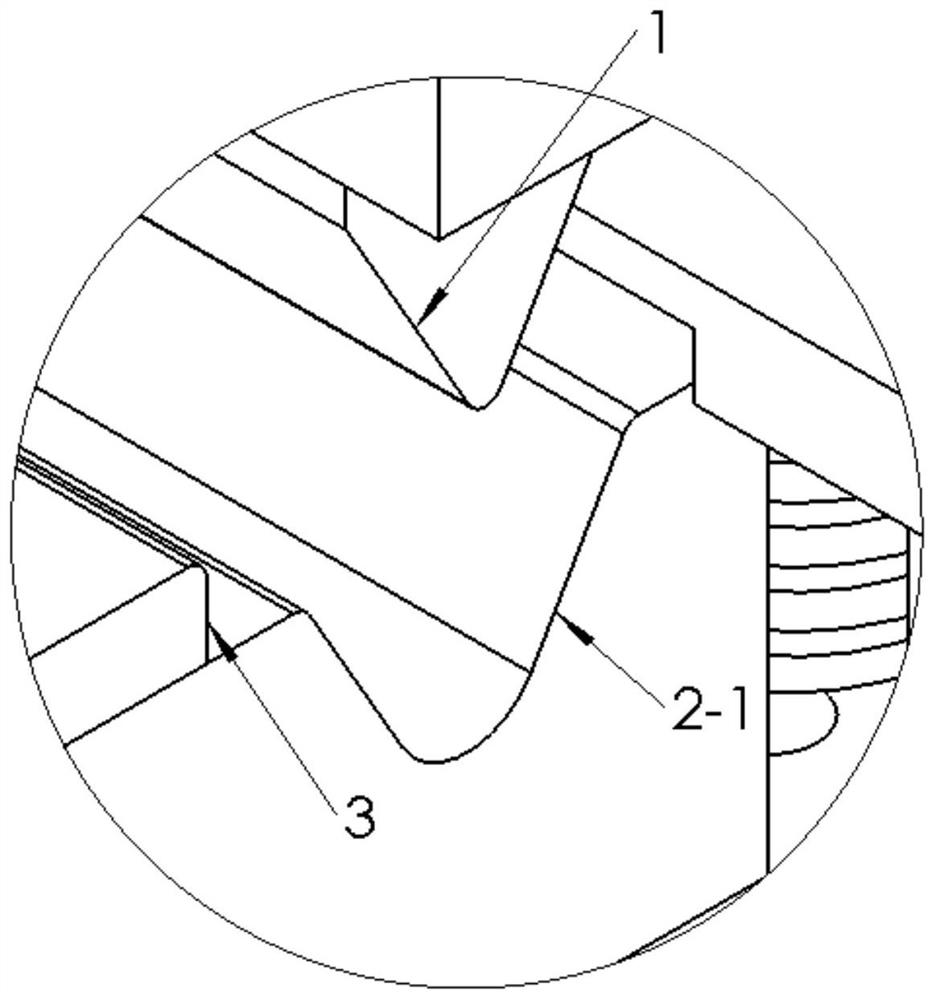

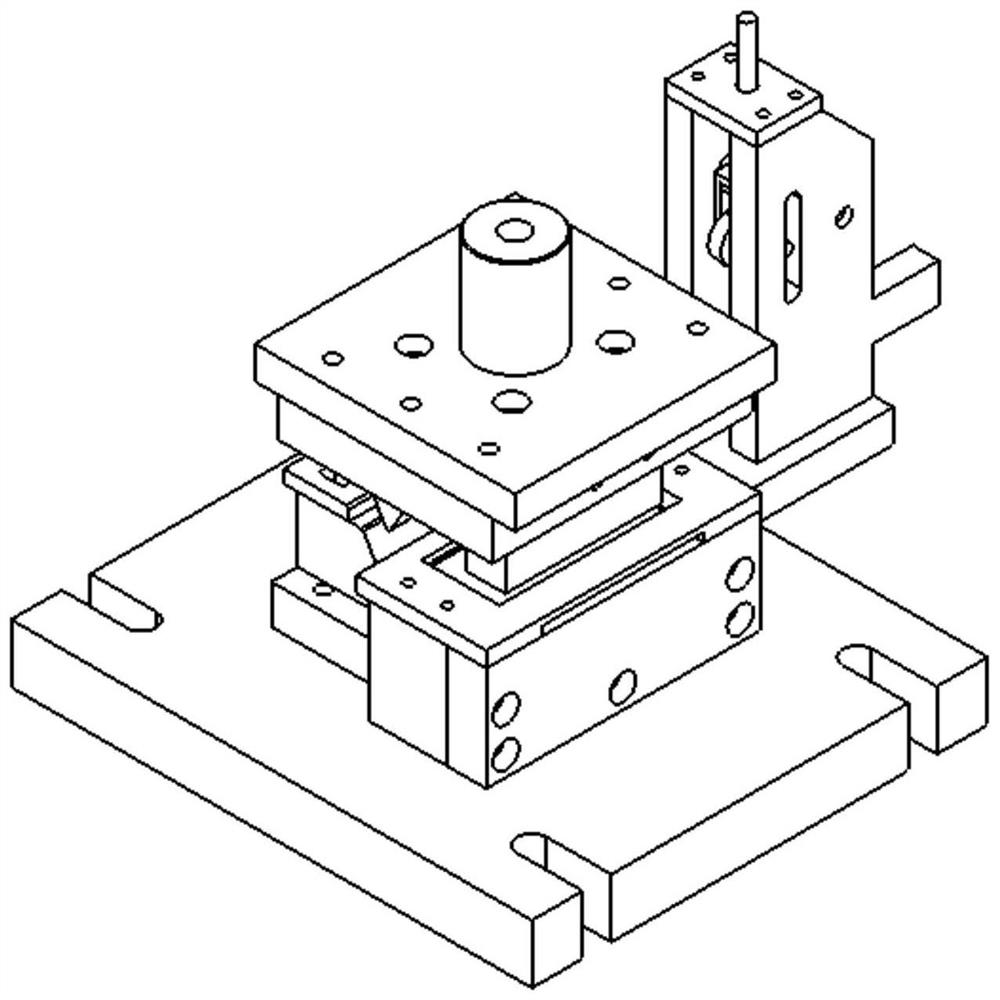

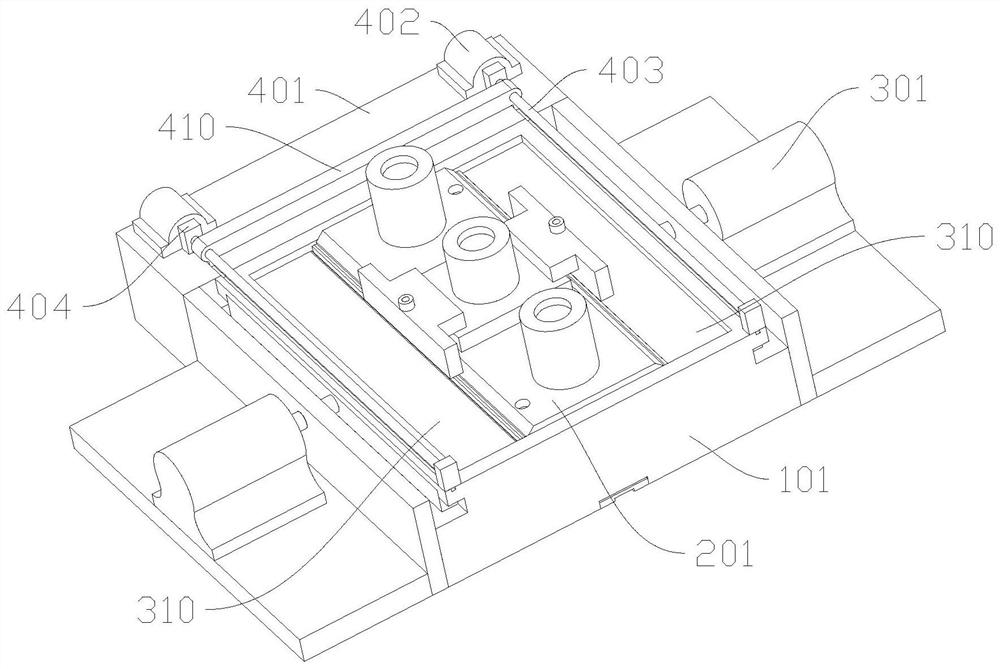

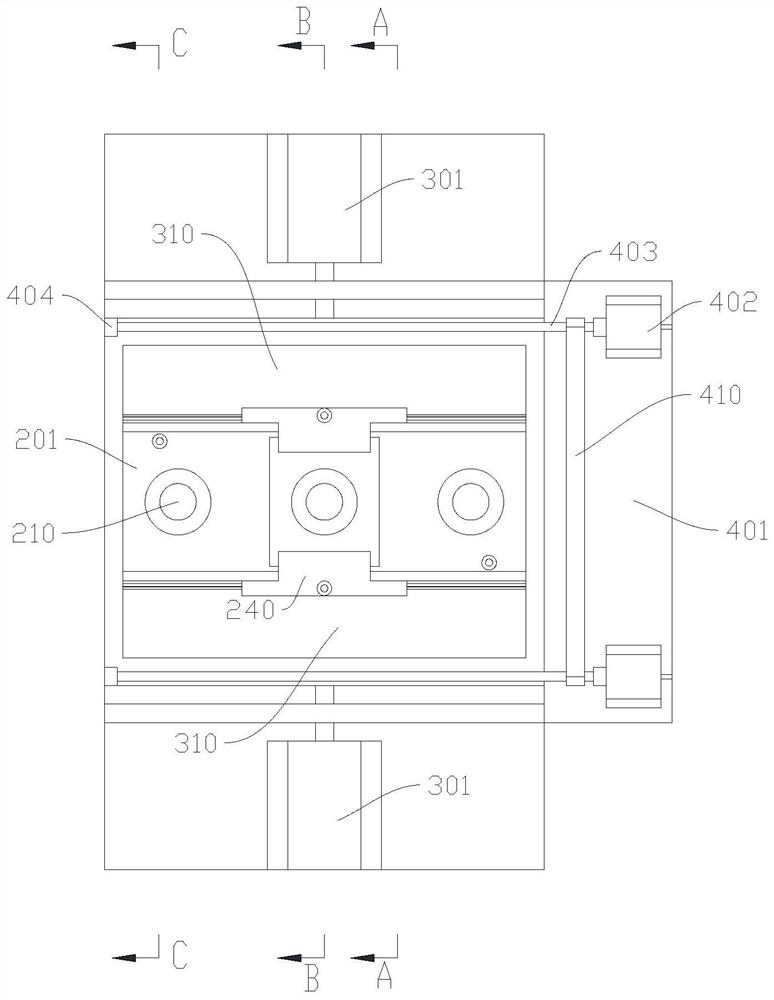

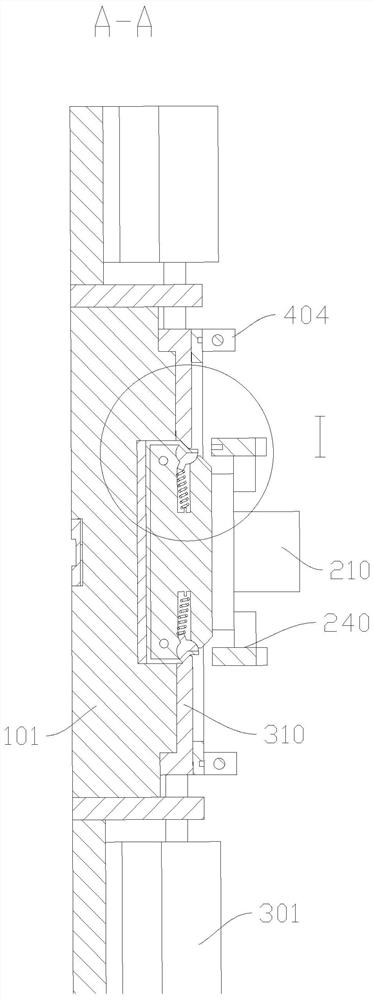

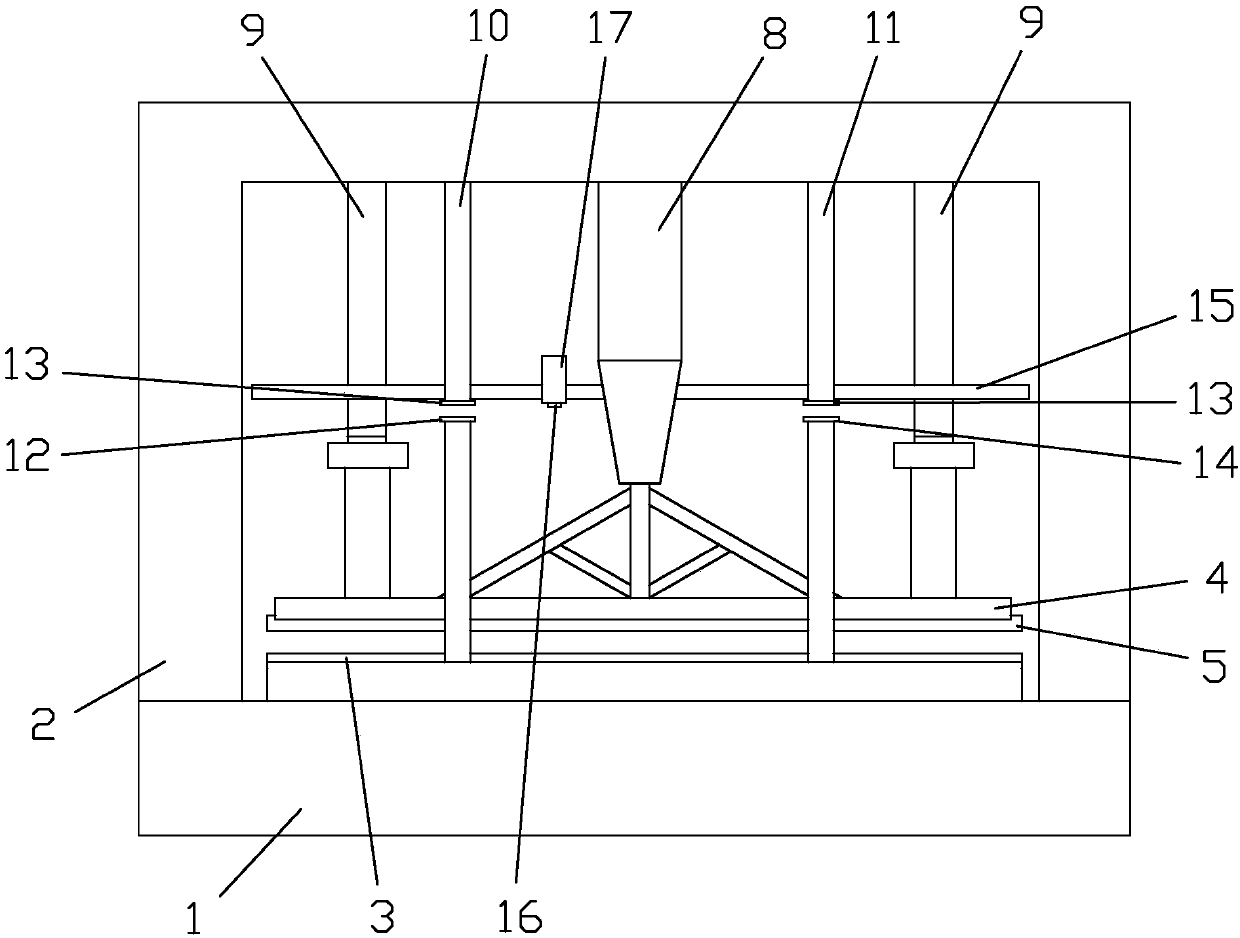

Overlaying buckling sheet tooling

ActiveCN105429386AAvoid offsetImprove bending qualityManufacturing stator/rotor bodiesStructural engineeringMechanical engineering

The invention belongs to the technical field of stator overlaying. The overlaying buckling sheet tooling comprises a base and a core tyre; an annular base plate is fixed on the surface of the base; the core tyre is placed on the base plate; an axle hole is formed in the center of the base; the core tyre is formed by multiple detachable split cores in a spliced manner; an inner hole is formed in the core tyre; the inner hole is a taper hole that is gradually reduced from upper to lower; an expansion tyre is glidingly matched in the taper hole; an annular lower pressing ring is fixed on the surface of the base plate; the lower pressing ring is positioned on the periphery of the core tyre; a matched limiting structure is arranged on the surface, opposite to the split cores, of the inner circle of the lower pressing ring; the expansion tyre, the core tyre and the lower pressing ring are all concentric with the axial ole of the base; two opposite sliding grooves are formed in the base in a radial direction of the axle hole; clamping jaws are glidingly matched in the sliding grooves; the inserting ends, in the sliding grooves, of the clamping jaws are connected with the end parts of the sliding grooves through springs; and stop pins fixed with the base are arranged on the clamping jaws. The scheme of the overlaying buckling sheet tooling is high in universality, high in alignment precision and good in bending quality of the buckling sheet.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

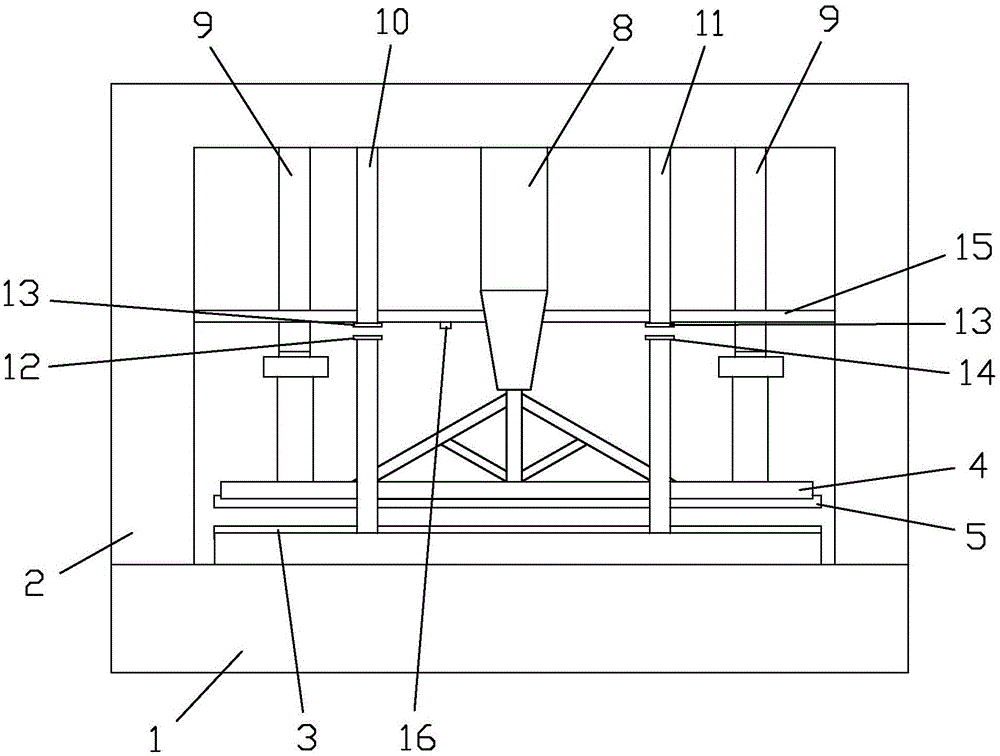

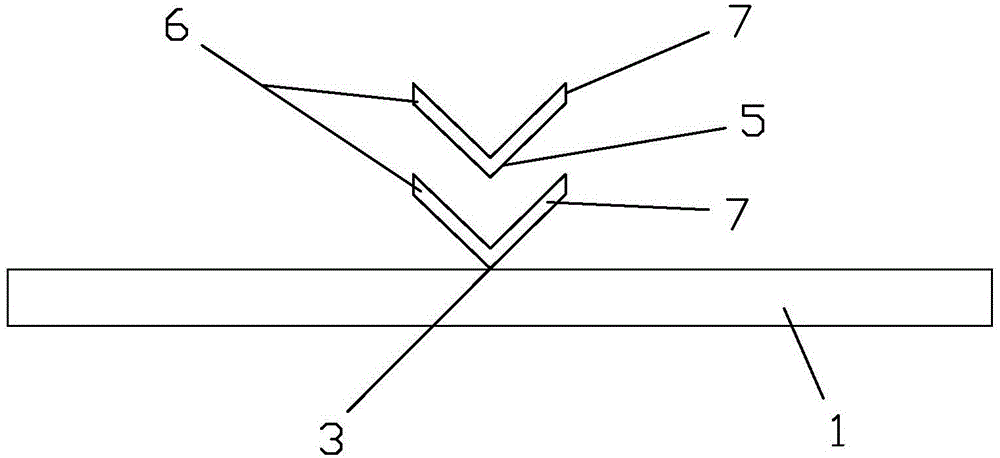

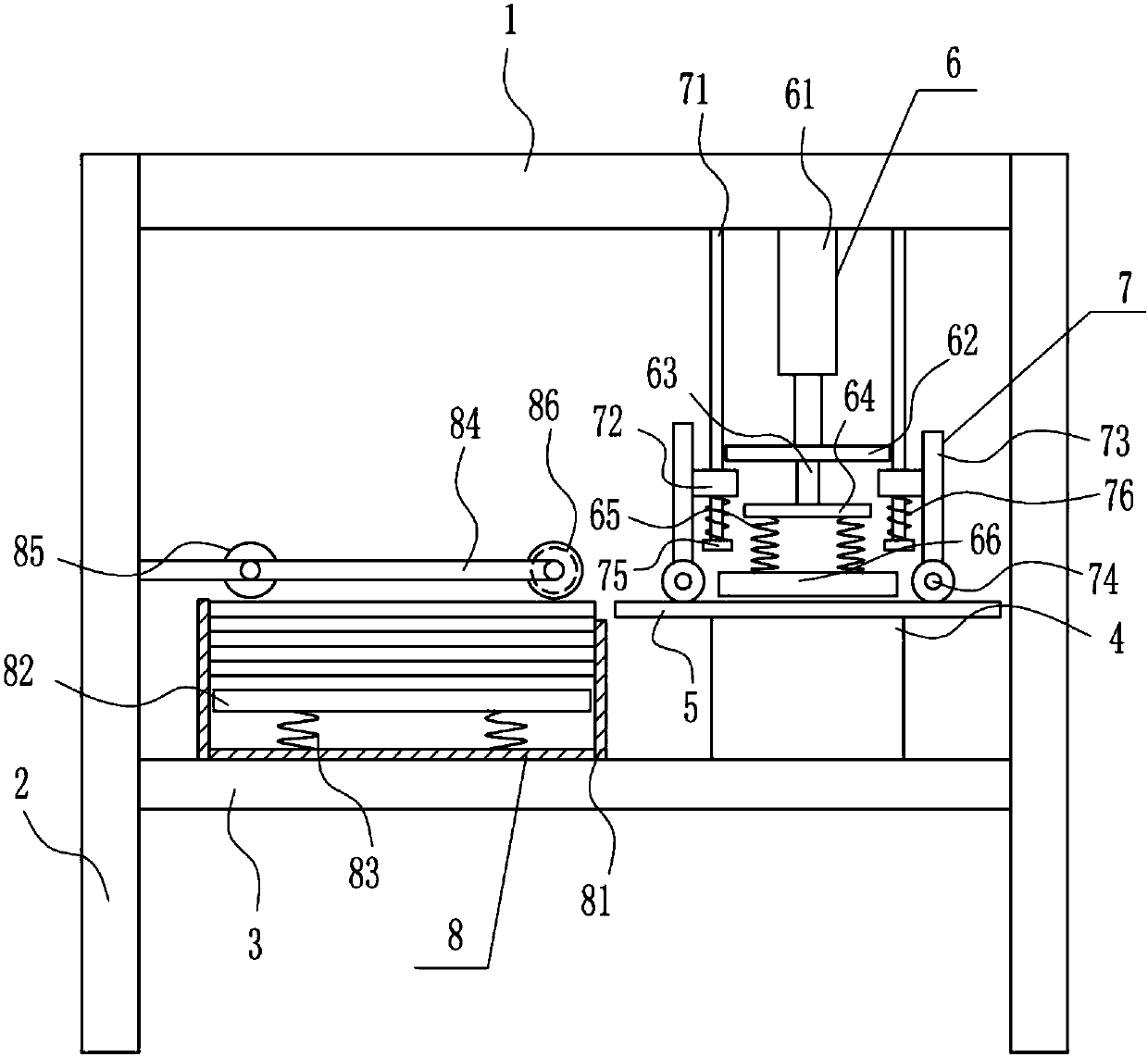

3D glass hot bending machine and 3D glass forming method

ActiveCN109081563AImprove processing qualityReduce energy consumptionGlass reforming apparatusPorosityGraphite

The invention discloses a 3D glass hot bending machine and a 3D glass forming method. The 3D glass hot bending machine comprises a furnace, a first partition plate, a second partition plate, a preheating device, an annealing device and a 3D glass hot bending device. The furnace is internally provided with a chamber, and the 3D glass hot bending device comprises an upper heating module, a lower heating module, a graphite mould and a vacuum generator. The upper heating module comprises a first heating plate and a first heating part, and the first heating part is arranged in the first heating plate and capable of moving up and down; the lower heating module comprises a lower heating plate and a lower heating part, and the lower heating plate is provided with an exhaust passage with an upper port in the upper surface of the lower heating plate; the graphite mould is arranged on the upper surface of the lower heating plate, and porosity of the graphite mould is larger than or equal to 12%;an exhaust port of the vacuum generator is communicated with the exhaust passage. The 3D glass hot bending machine has advantages of long service life, high processing quality, low energy consumption,high hot bending surface quality, high hot bending speed and the like.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Adjustable metal plate bending device

InactiveCN105127249ABending speed is fastBend flat and good qualityShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses an adjustable metal plate bending device which comprises a rack. A frame is arranged above the rack. A bending groove is formed in the upper portion of the rack, and a hydraulic device is arranged in the position, corresponding to the bending groove, of the frame. A pressing frame is arranged at the lower portion of the hydraulic device, and the bottom of the pressing frame is provided with a pressing protrusion matched with the bending groove. A metal plate position moving device is arranged on the frame, and the metal plate position moving device comprises a first support which is formed by extending the frame. The frame is provided with a vertical guide rail, and the first support can move vertically along the vertical guide rail. The adjustable metal plate bending device is high in bending speed, good in bending quality and capable of saving time and labor and lowering labor intensity.

Owner:FOSHAN GAOFU PETROCHINA FUEL ASPHALT

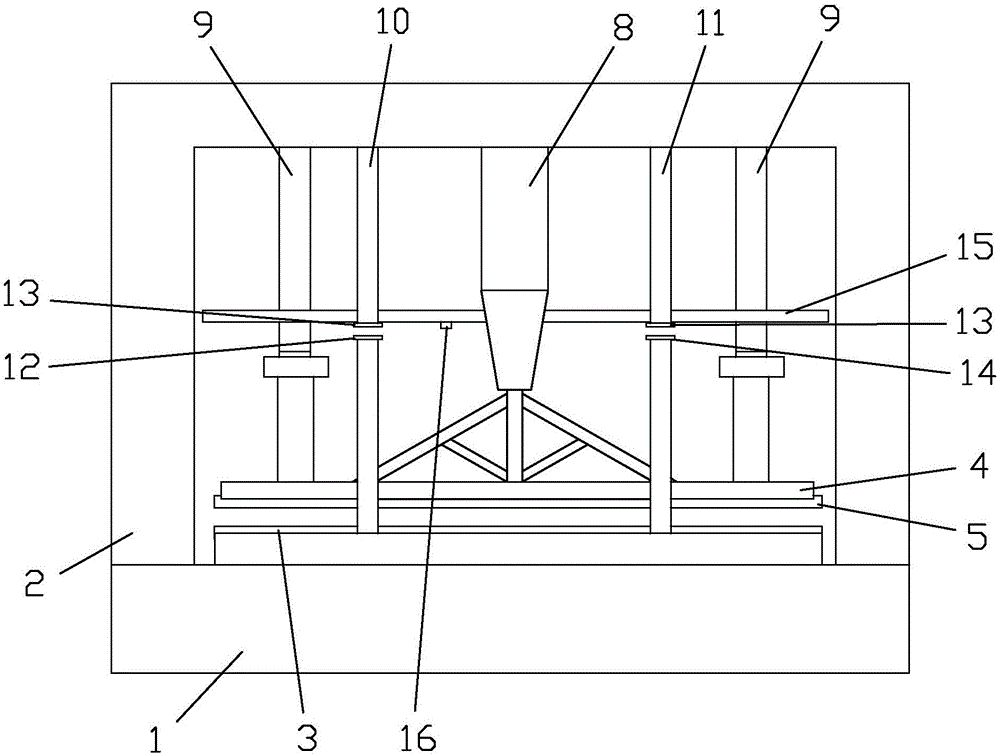

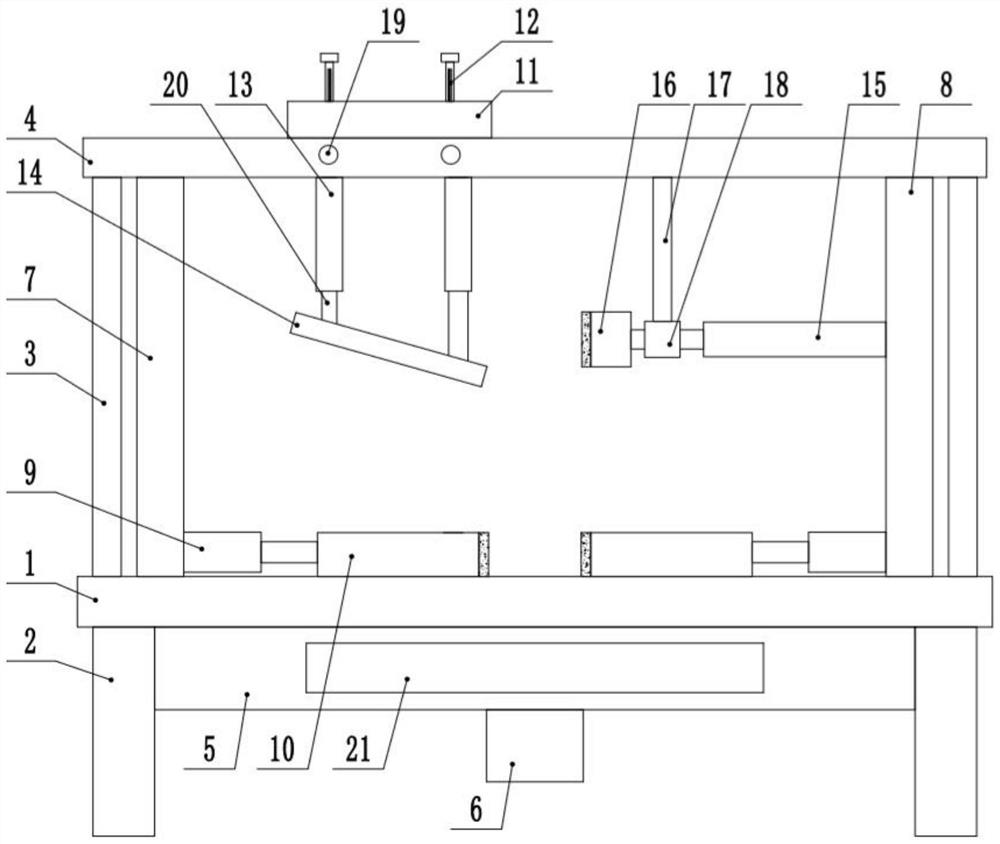

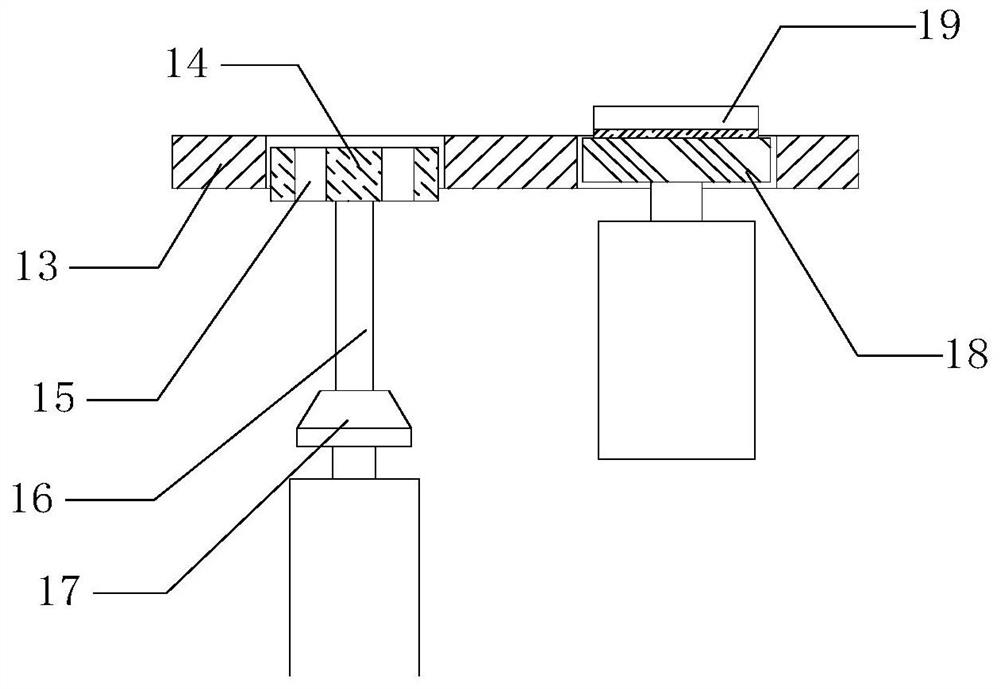

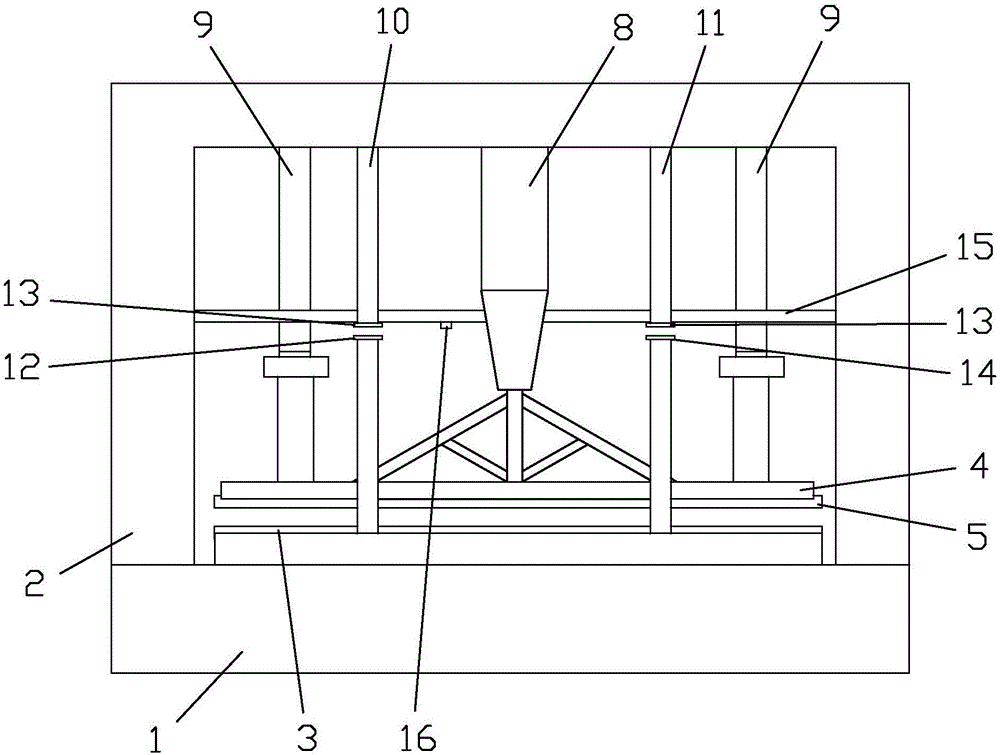

Bilateral bending device for pantograph slide plate production and bending method thereof

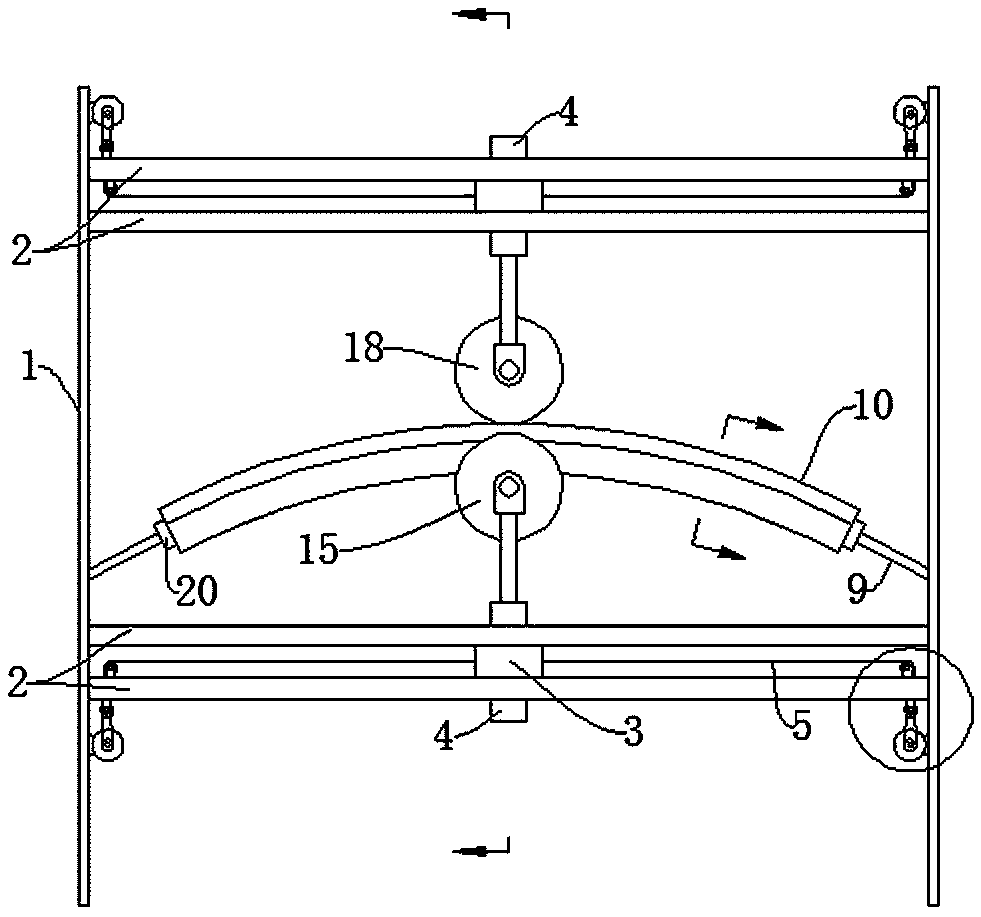

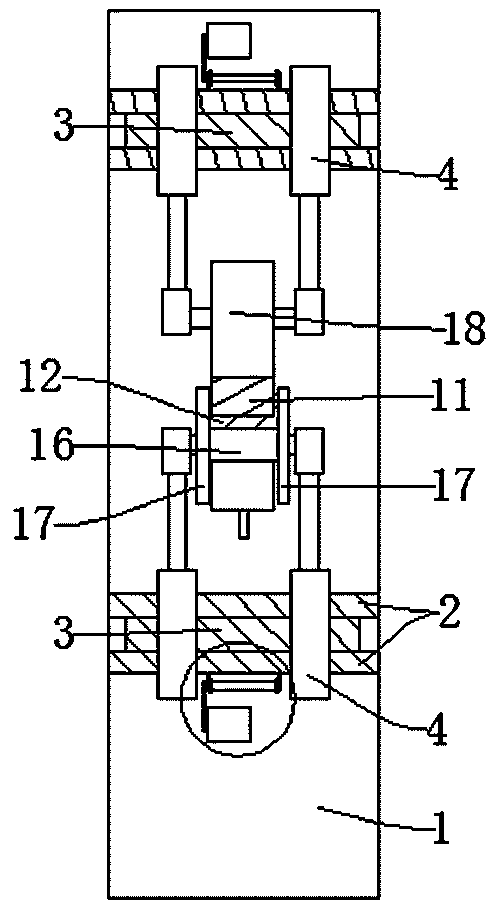

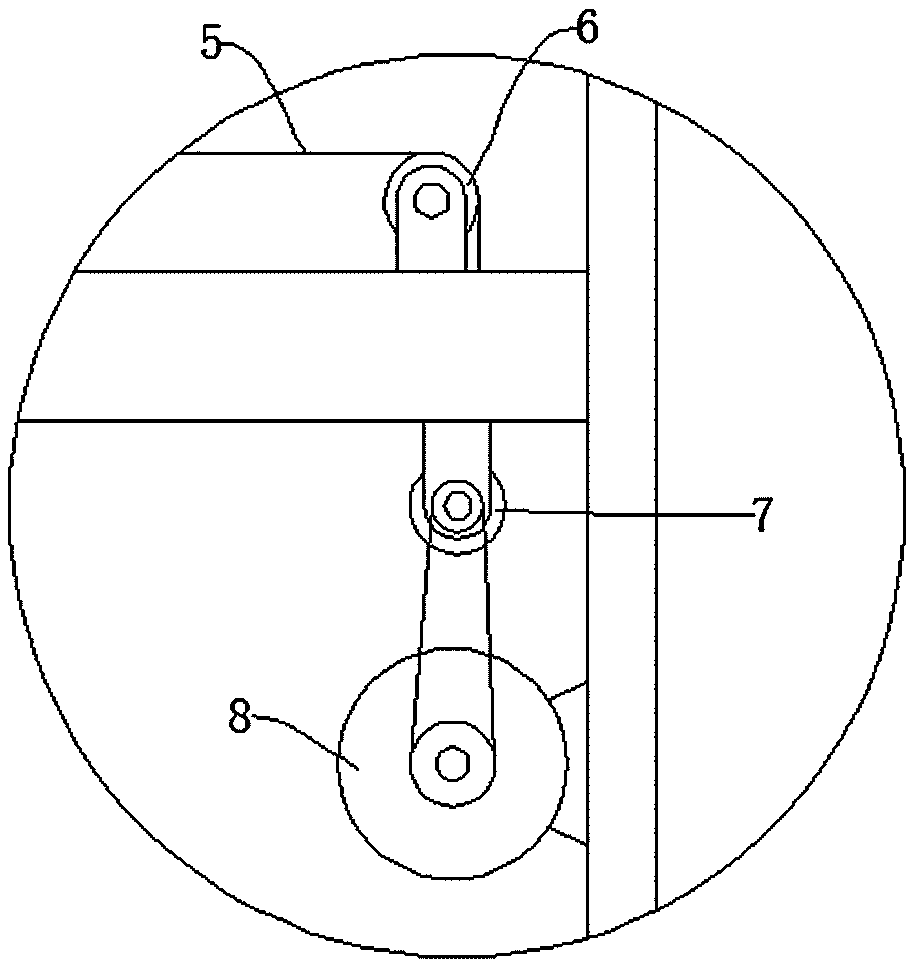

ActiveCN109277772AEasy to operateFast bending speedMetal working apparatusFastening meansSlide plateEngineering

The invention discloses a bilateral bending device for pantograph slide plate production and a bending method thereof. The device comprises two vertical plates which are vertically arranged in parallel, two groups of sliding plate assemblies are arranged up and down between the two vertical plates correspondingly, the two groups of sliding plate assemblies are horizontally and fixedly installed between the two vertical plates in a parallel mode, and the two groups of sliding plate assemblies are symmetrically provided with a pair of sliding blocks, a pair of fixed pulleys, a pair of rope winding rollers and a pair of rope winding motors. The bilateral bending device for the pantograph slide plate production and the bending method thereof have the beneficial effects that the connecting strength of a carbon strip and a bearing frame is enhanced by bending clamping plates at the two ends of the bearing frame to clamp the carbon strip, compared with a traditional connecting mode only depending on glue pasting, the carbon strip and the bearing frame can be firmly fixed, and the bending method is simple and convenient to operate, high in bending speed, high in efficiency and good in practicability.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Bending machine for steel pipes

The invention discloses a bending machine for steel pipes, which comprises a pressing plate, a hydraulic cylinder, a hydraulic driving device, a storage box, a motion frame, a turntable, a workbench, a support plate, a half-toothed gear, a base, a fixed plate, a limit pin, The second transmission shaft, the second motor, the first motor, the first transmission shaft, the motor mounting plate and the connecting rod are characterized in that, the upper surface of the base is fixedly connected with a motor mounting plate, and one side of the motor mounting plate A first electric motor is fixedly connected. This product can reduce the work intensity of the workers, improve the bending efficiency, and the bending degree is fixed, the bending quality is controllable, and will not affect the assembly of the subsequent process; this product has a storage box, which can facilitate the temporary storage of workers' items. The design is more user-friendly; the fixed height of the workbench of this product can be adjusted, allowing workers to bend steel pipes at a comfortable working height, thereby reducing the discomfort of workers and improving the bending efficiency of steel pipes.

Owner:王祖友

Steel bar bending equipment for building construction

The invention relates to the technical field of building construction equipment, and discloses steel bar bending equipment for building construction. The steel bar bending equipment for building construction comprises a base, wherein a hydraulic rotating oil cylinder is fixedly mounted on one side of the bottom of a base inner cavity; a supporting shaft is fixedly arranged on the top of the hydraulic rotating oil cylinder in a sleeving mode; the top end of the supporting shaft extends to the outside of the top end of the base; a bearing fixedly sleeves the supporting shaft; and the outer edgeof the bearing is fixedly connected with the top of the base in a sleeved mode. By using the steel bar bending equipment for building construction, one ends of three steel bars are sequentially placedbetween a positioning pressing plate and three moving pressing plates for fixing; the other ends of the three steel bars penetrate between the supporting shaft and a limiting rod, and the three steelbars are bent by rotating of the limiting rod around the supporting shaft; therefore, the three steel bars can be conveniently bent at the same time, the bending speed of the steel bars is increased,and the efficiency of the building construction is improved.

Owner:湖北国丰建设有限公司

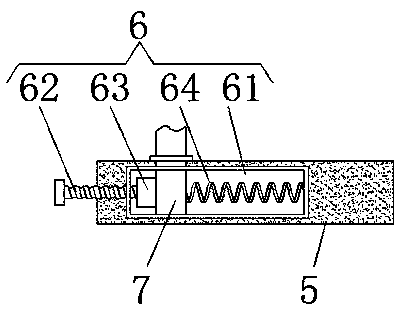

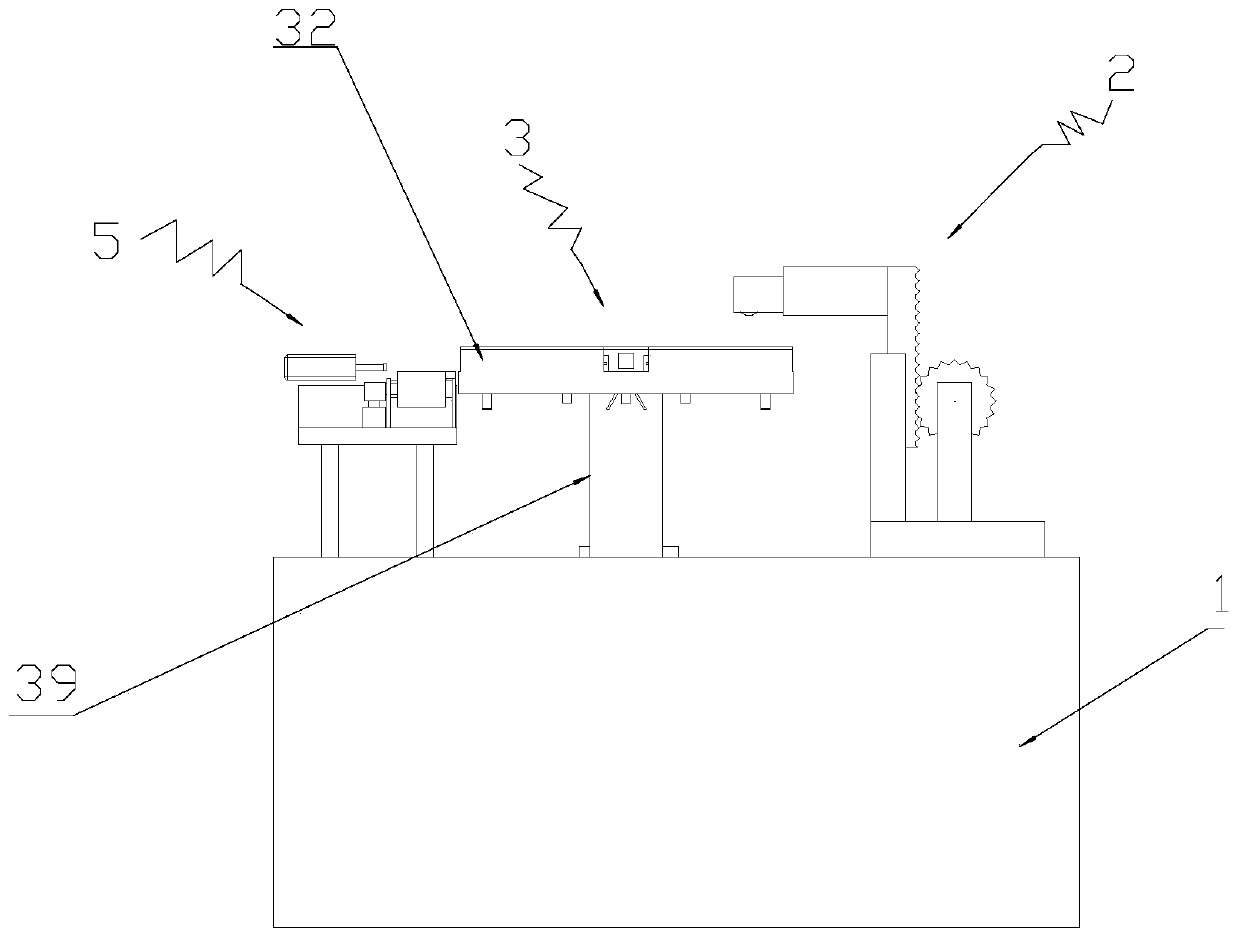

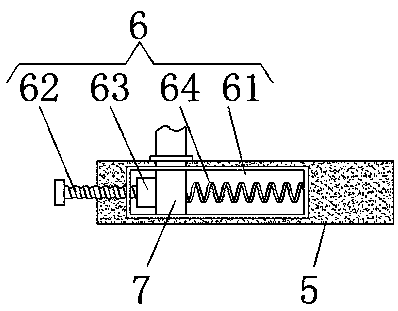

S-shaped spring machining device

The invention provides an S-shaped spring machining device and belongs to the technical field of machinery. The problem of low S-shaped spring production efficiency in the prior art is solved. The S-shaped spring machining device comprises a rack and a worktable arranged in the rack, wherein a straightening mechanism capable of straightening a steel wire, a forming device capable of coiling the straight steel wire to be S-shaped, a reshaping device capable of adjusting a pitch of the S-shaped spring and a cutting-off device capable of cutting off the S-shaped spring are sequentially arranged on the worktable. The forming device comprises a forming plate arranged on the worktable, a forming ring I and a forming ring II are symmetrically arranged on the forming plate, a channel for the S-shaped spring to pass through is formed between the forming ring I and the forming ring II, a forming piece is fixed to the upper portions of the forming ring I and the forming ring II, the forming plate can be connected with a reciprocating motion mechanism capable of driving the forming plate to perform reciprocating rotation, and an intermittent blocking mechanism capable of blocking advancing of the S-shaped spring in a spaced mode is arranged above the forming plate. The S-shaped spring machining device has the advantage of high S-shaped spring production efficiency.

Owner:浙江心梦享家居有限公司

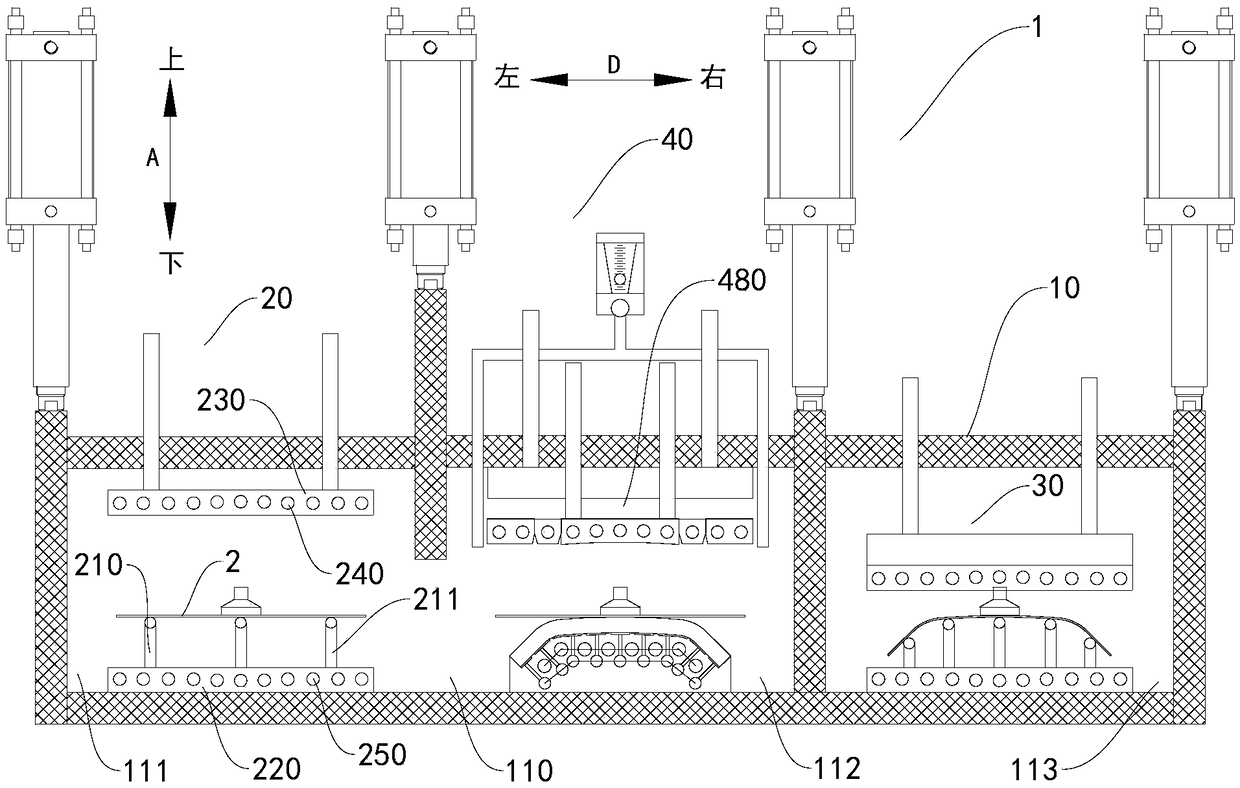

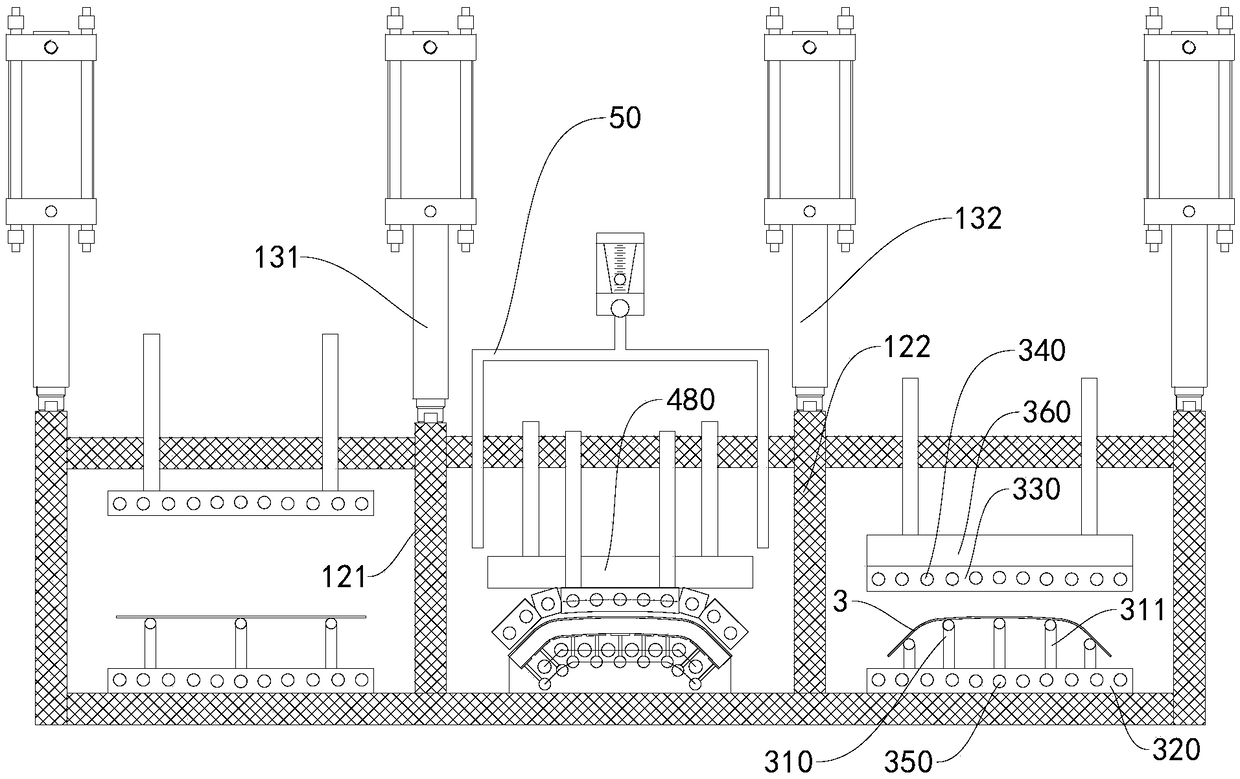

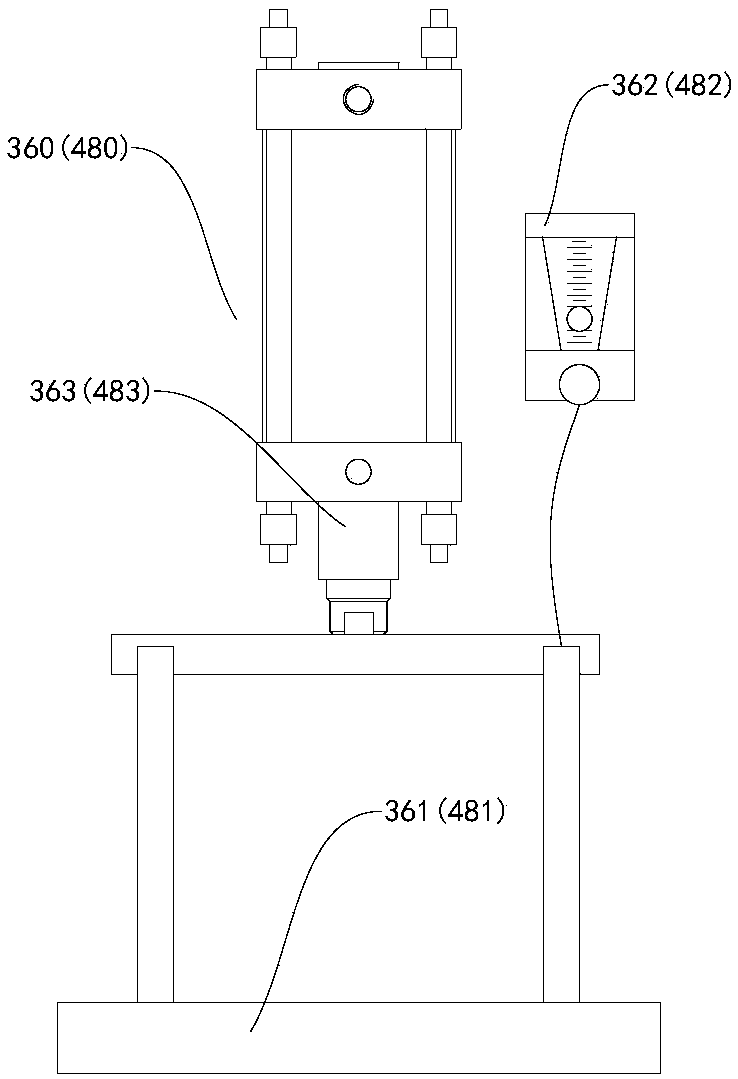

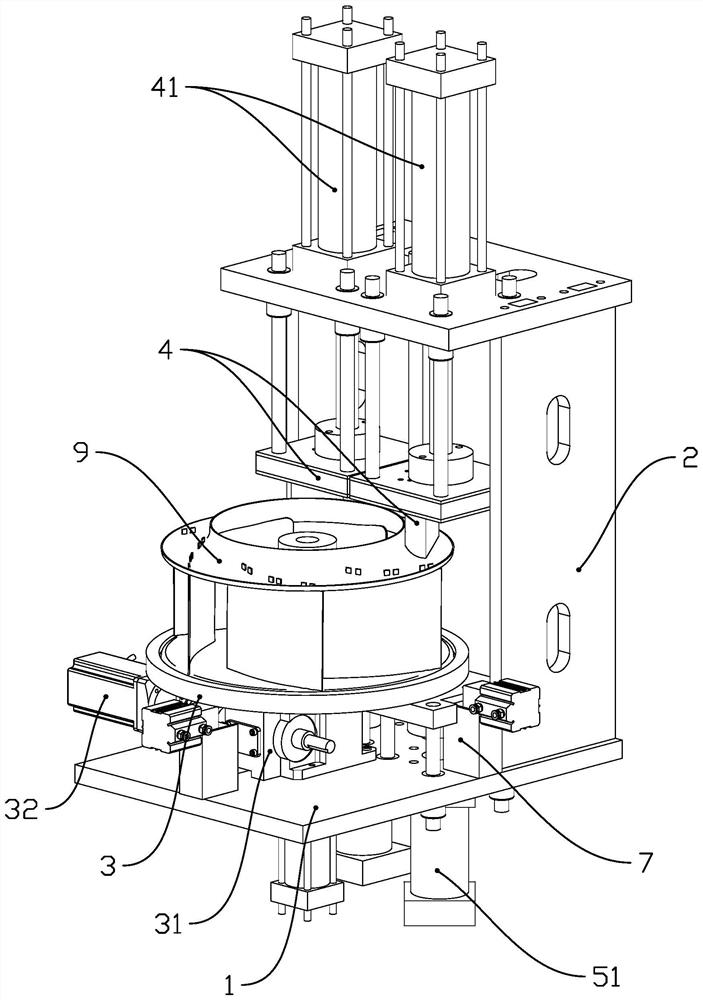

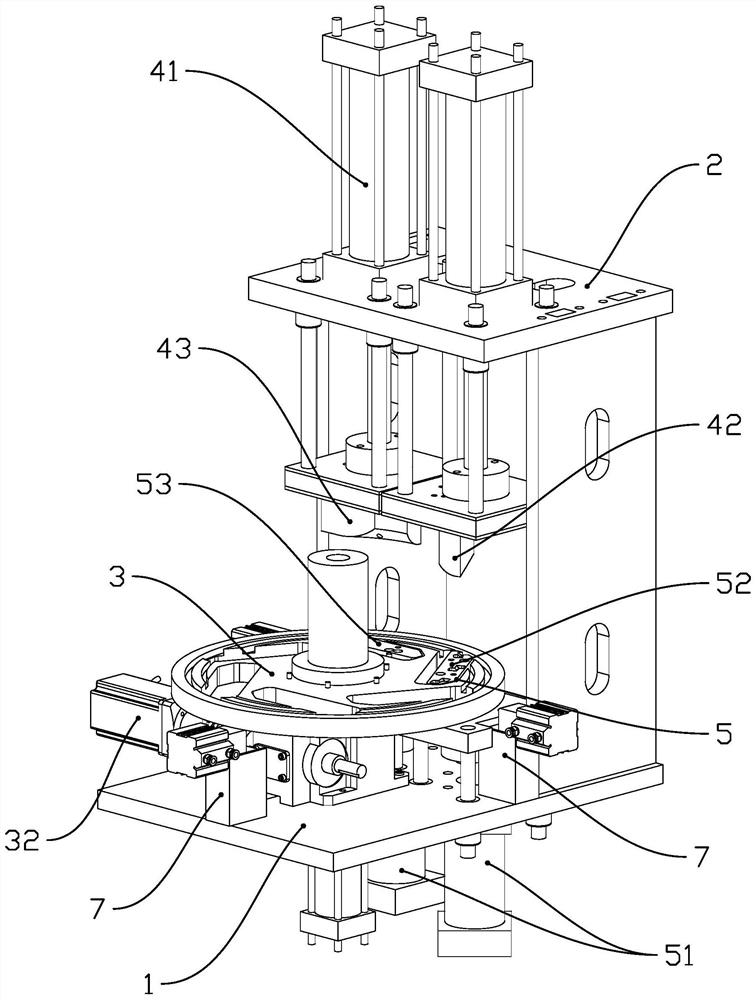

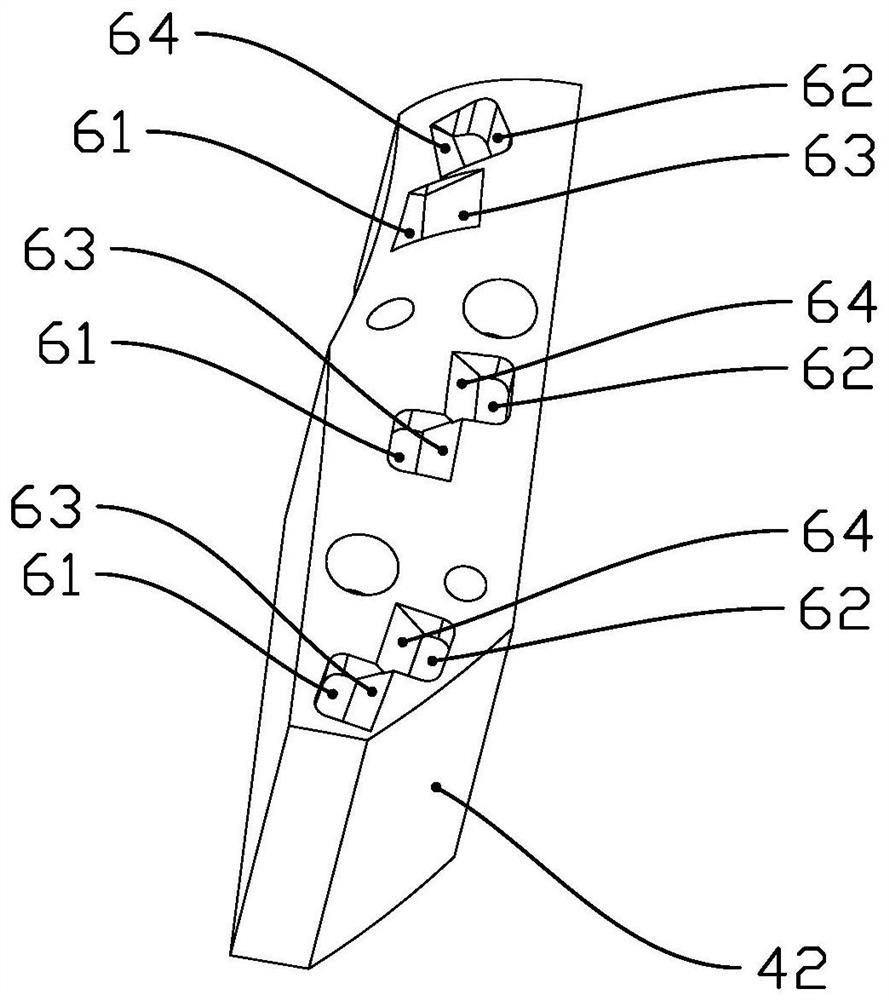

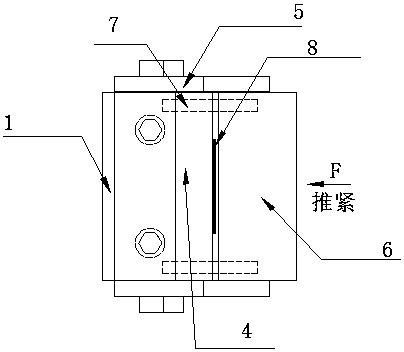

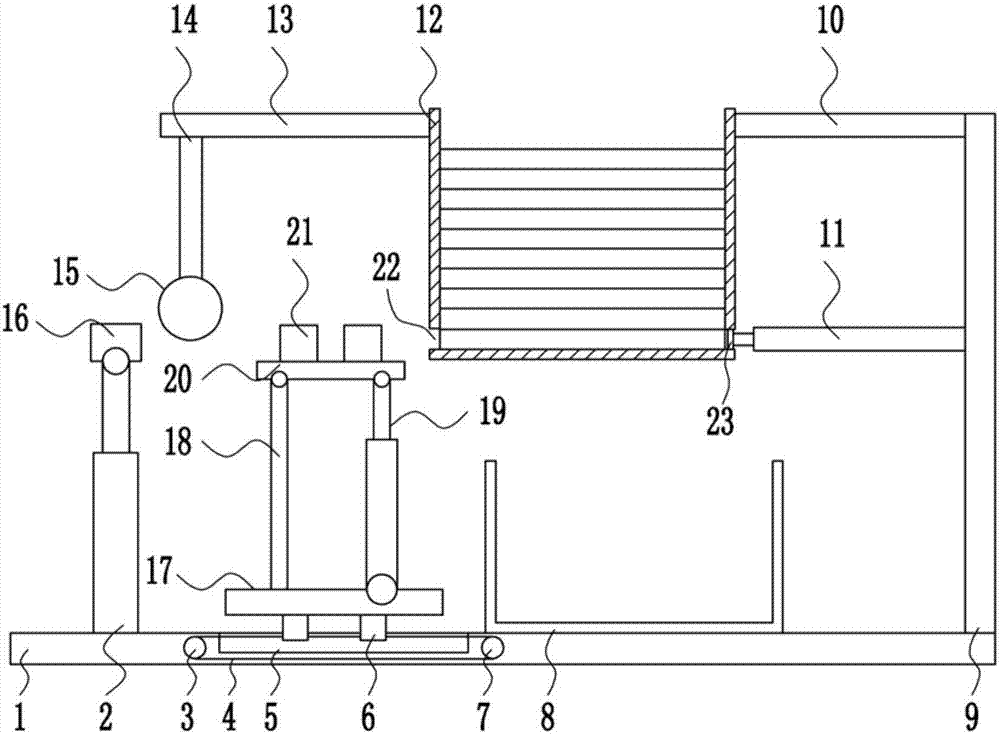

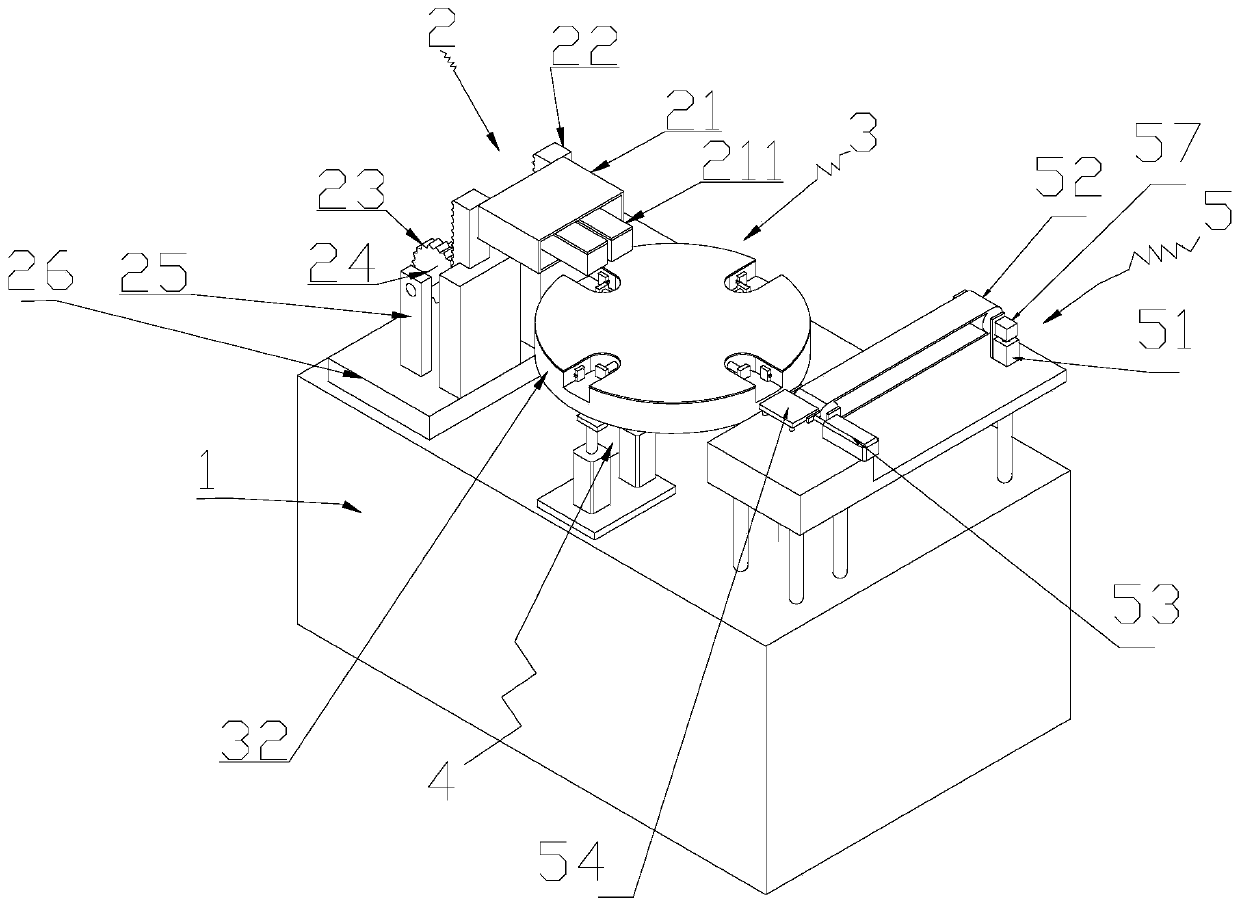

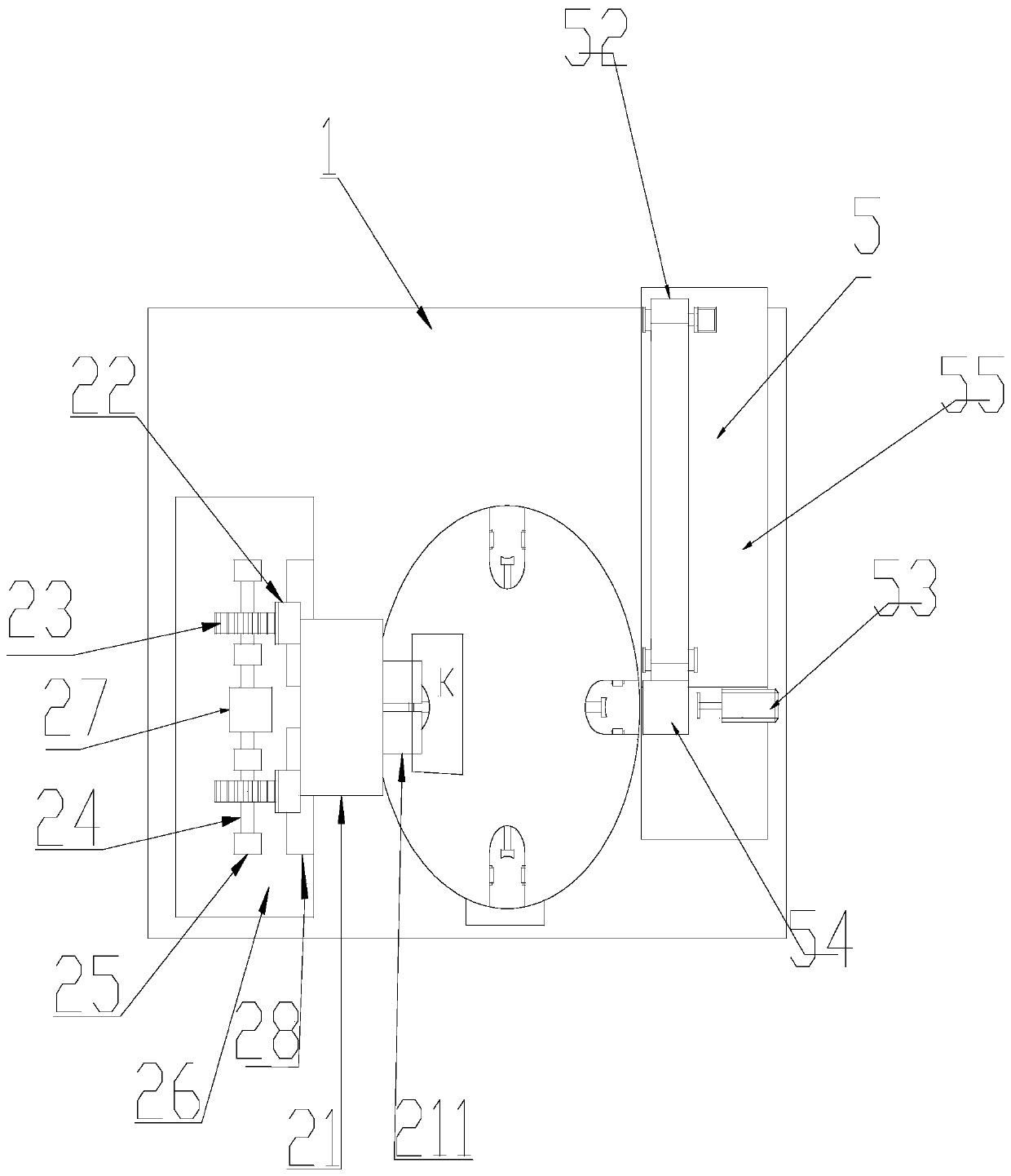

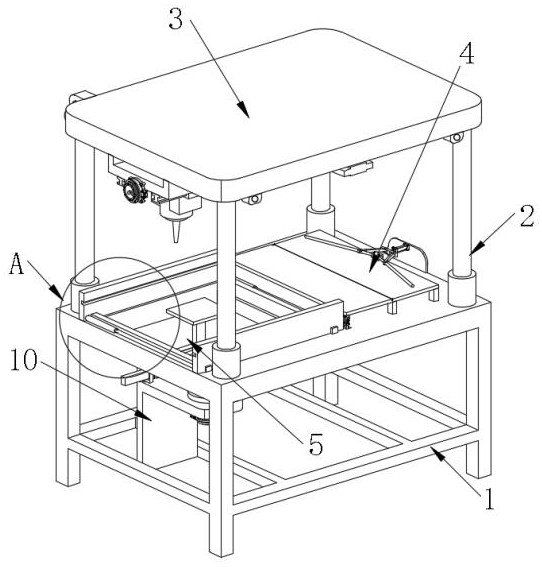

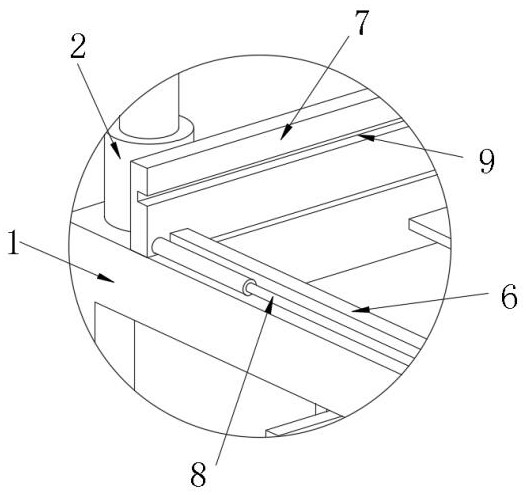

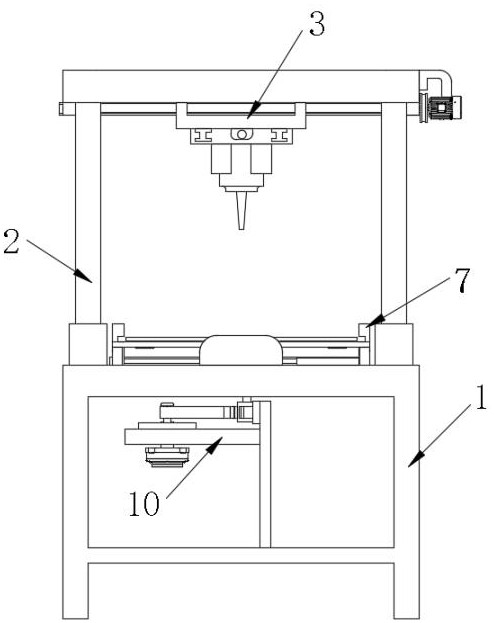

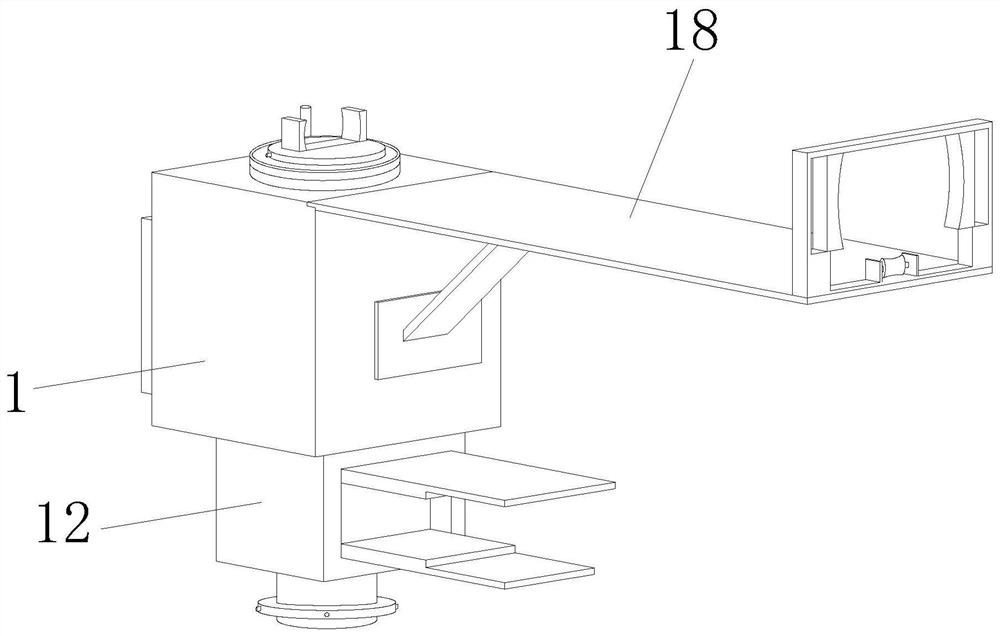

Automatic assembling equipment for blower wheel

ActiveCN112517787AStrong resistanceFirmly connectedMetal-working apparatusWind energy generationStructural engineeringMechanical engineering

Owner:ZHEJIANG MINGZHEN ELECTRIC&ELECTRONICS CO LTD

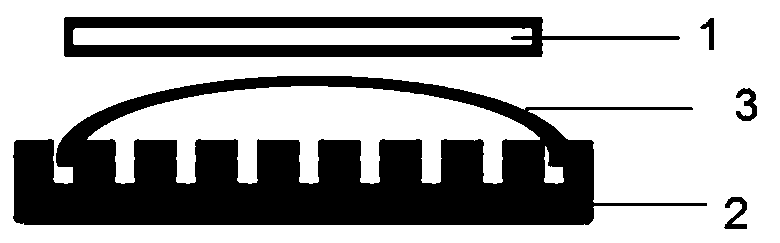

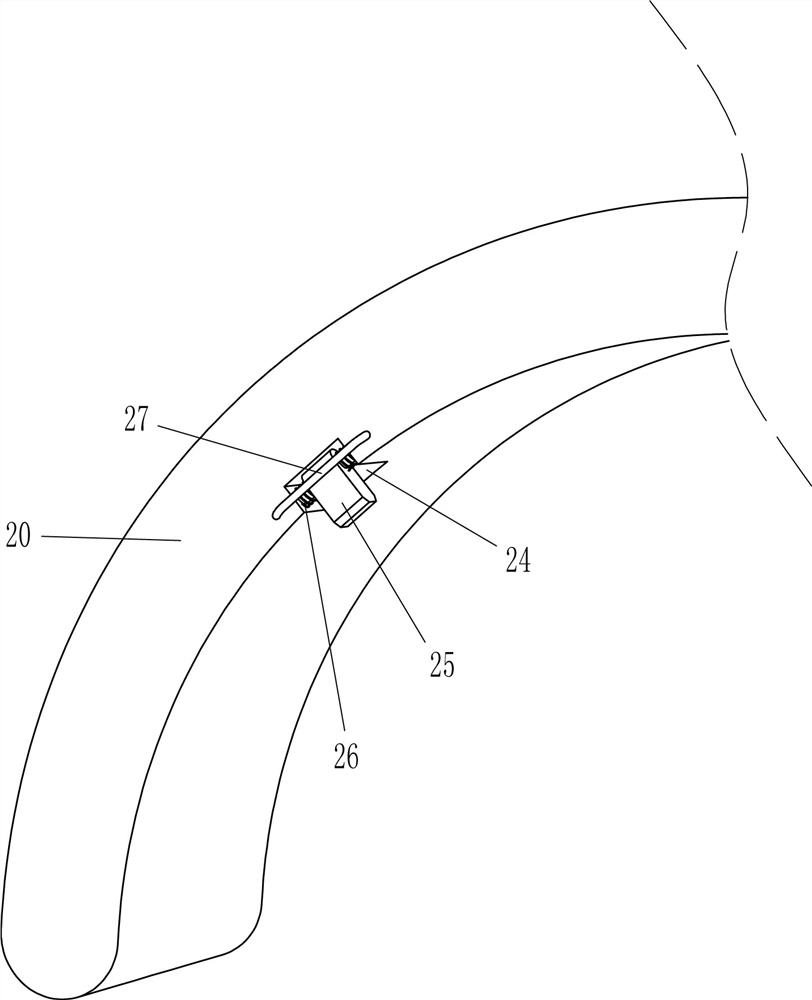

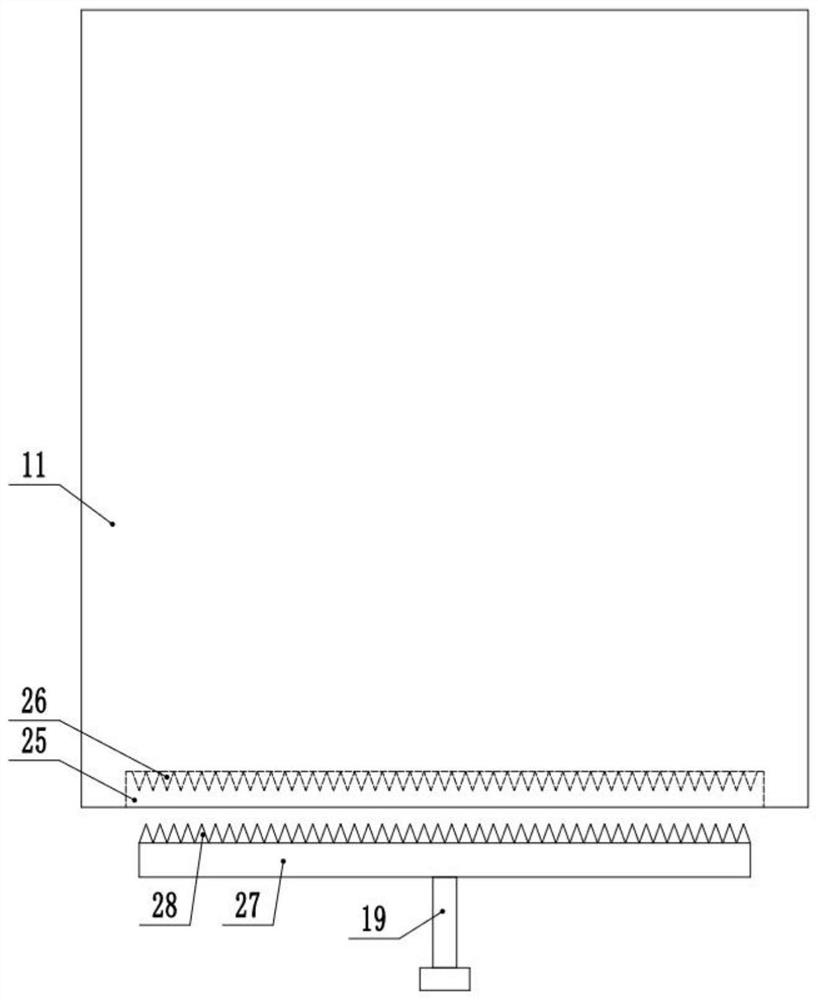

Hot bending forming method and forming device for organic glass

The invention discloses a hot bending forming method and forming device for organic glass. The method comprises the following steps: S1, providing organic glass with a panel; S2, moving the organic glass to the lower side of an infrared heating pipe to heat and soften the organic glass; and S3, putting the heated and softened organic glass in a bending clamp to be formed to obtain 3D organic glass, wherein the bending clamp comprises a clamp body of a plate structure, a plurality of grooves are formed in the upper surface of the clamp body in an array, and a bump is arranged between two adjacent grooves; and two ends of the heated and softened organic glass are embedded into the grooves, separately. By heating and softening the organic glass by means of the infrared heating pipe and putting the heated and softened organic glass in the special bending clamp to be formed, the 3D organic glass is formed. The formed organic glass is good in surface quality and high in yield. The force doesnot need to be controlled when the organic glass is bent. The forming method and the forming device are high in bending speed and high in efficiency.

Owner:TRULY OPTO ELECTRONICS

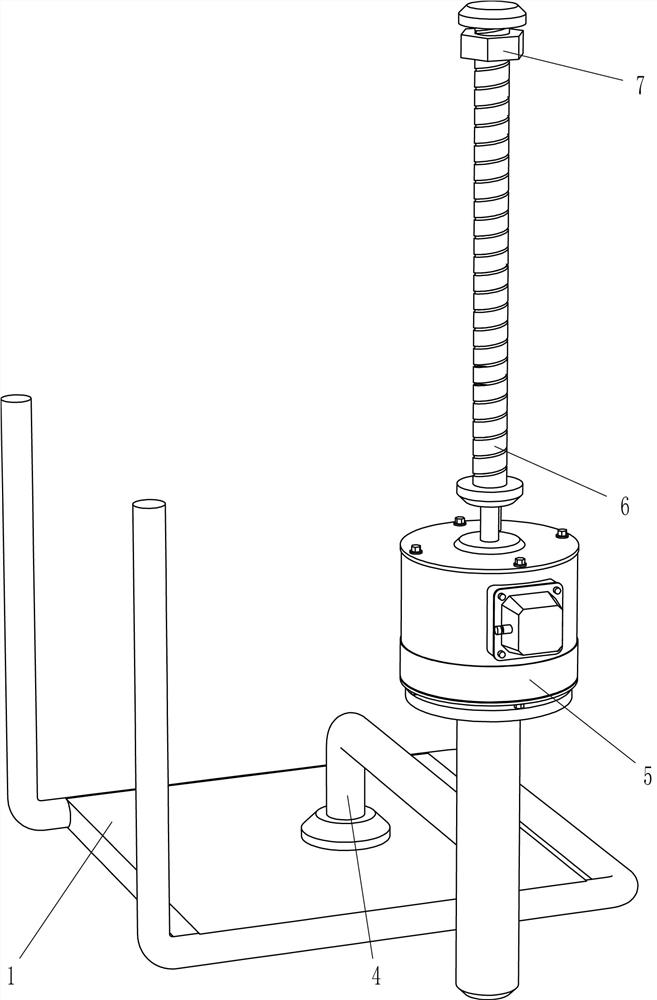

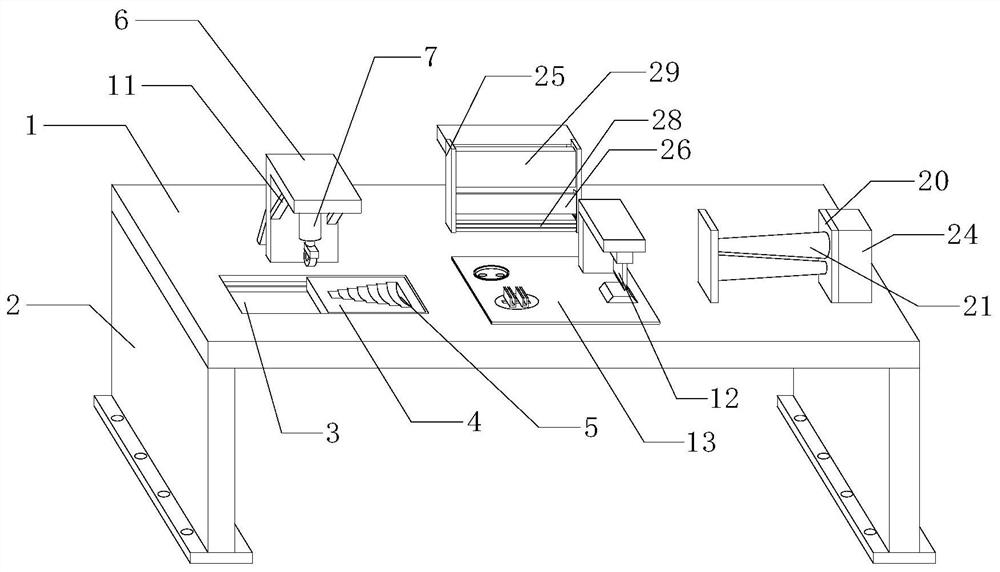

Discharging device for iron sheet bending

ActiveCN111672998ABending speed is fastEquipment use safetyMetal-working feeding devicesPositioning devicesEngineeringEquipment use

The invention relates to a discharging device, in particular to a discharging device for iron sheet bending. According to the discharging device for iron sheet bending, the operation is safe, and using is easy. The discharging device for iron sheet bending comprises a rack, a discharging assembly, a lifting assembly and a pushing assembly; the discharging assembly is installed on the rack and usedfor discharging materials in a lifting mode; the lifting assembly is installed on the rack and is powered by a motor to work; and the pushing assembly is installed between the lifting assembly and the discharging assembly and is used for pushing in a lifting mode. According to the discharging device for iron sheet bending, through cooperation of the discharging assembly and the pushing assembly,iron sheets can be continuously pushed in, the bending speed of the iron sheets is increased, the gear motor can automatically push the iron sheets in for bending, and the equipment is very safe to use.

Owner:青岛华胜万兴工贸有限公司

Improved metal panel bending device

InactiveCN106694640AFast bending speedImprove bending qualityOther manufacturing equipments/toolsEngineeringUltimate tensile strength

An improved metal panel bending device of the invention comprises a rack; a frame is arranged above the rack, a bending groove is arranged in the upper part of the rack, the frame is provided with a hydraulic device corresponding to the bending groove, a pressing frame is arranged on the lower part of the hydraulic device, the bottom of the pressing frame is provided with a pressing bulge matched with the bending groove, the hydraulic device comprises a middle hydraulic rod and jacks on both sides, the lower part of the hydraulic rod is fixedly connected to the pressing frame, and the jacks are located between the frame and the pressing frame. The improved metal panel bending device is high in bending speed, good in bending quality and timesaving and laborsaving, and labor intensity is reduced.

Owner:FOSHAN GAOFU PETROCHINA FUEL ASPHALT

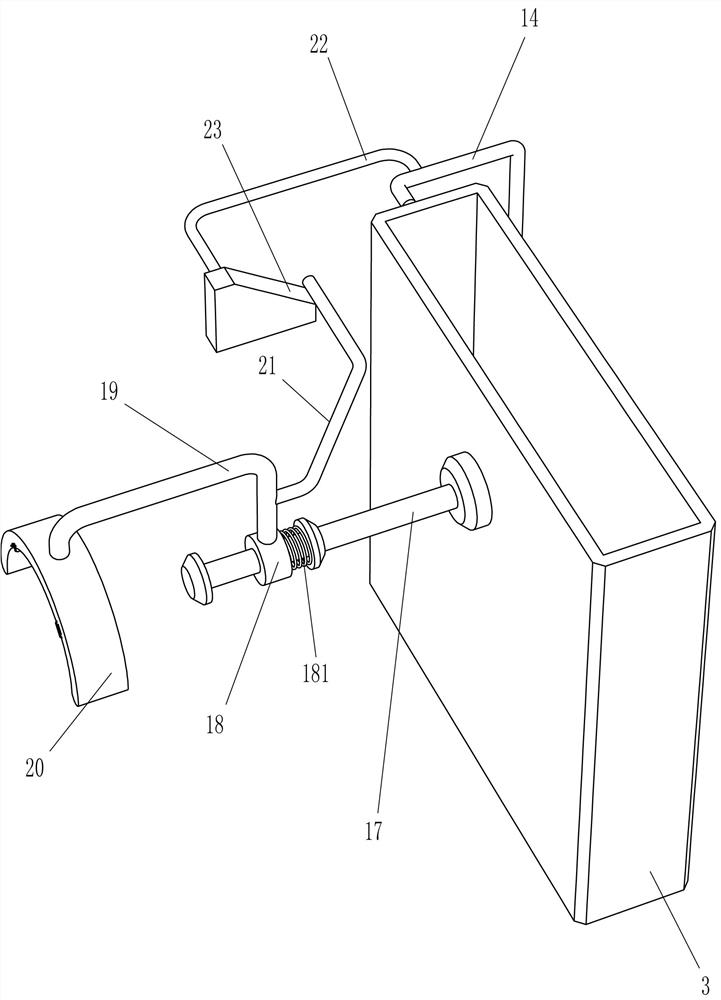

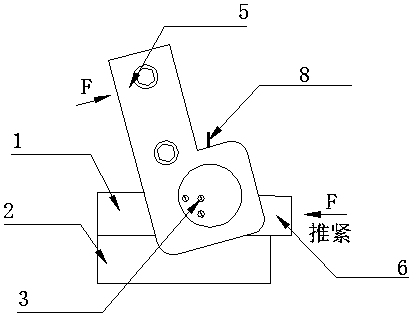

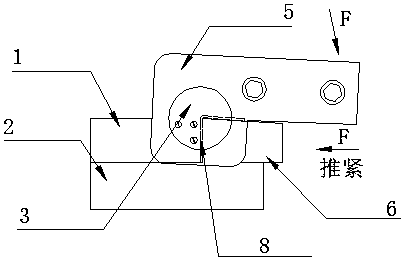

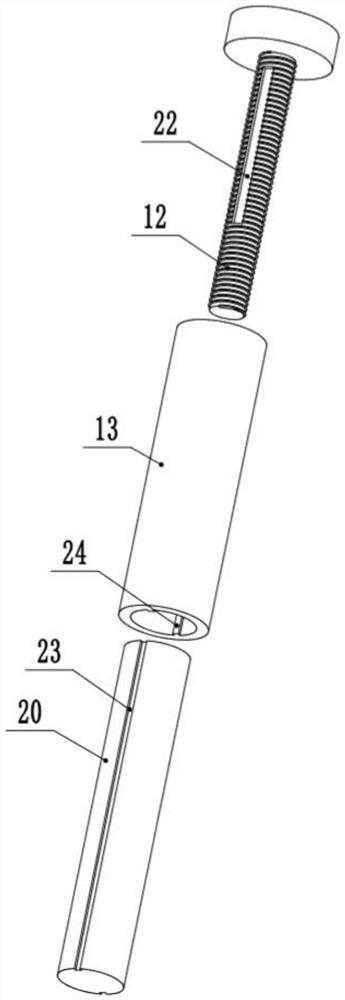

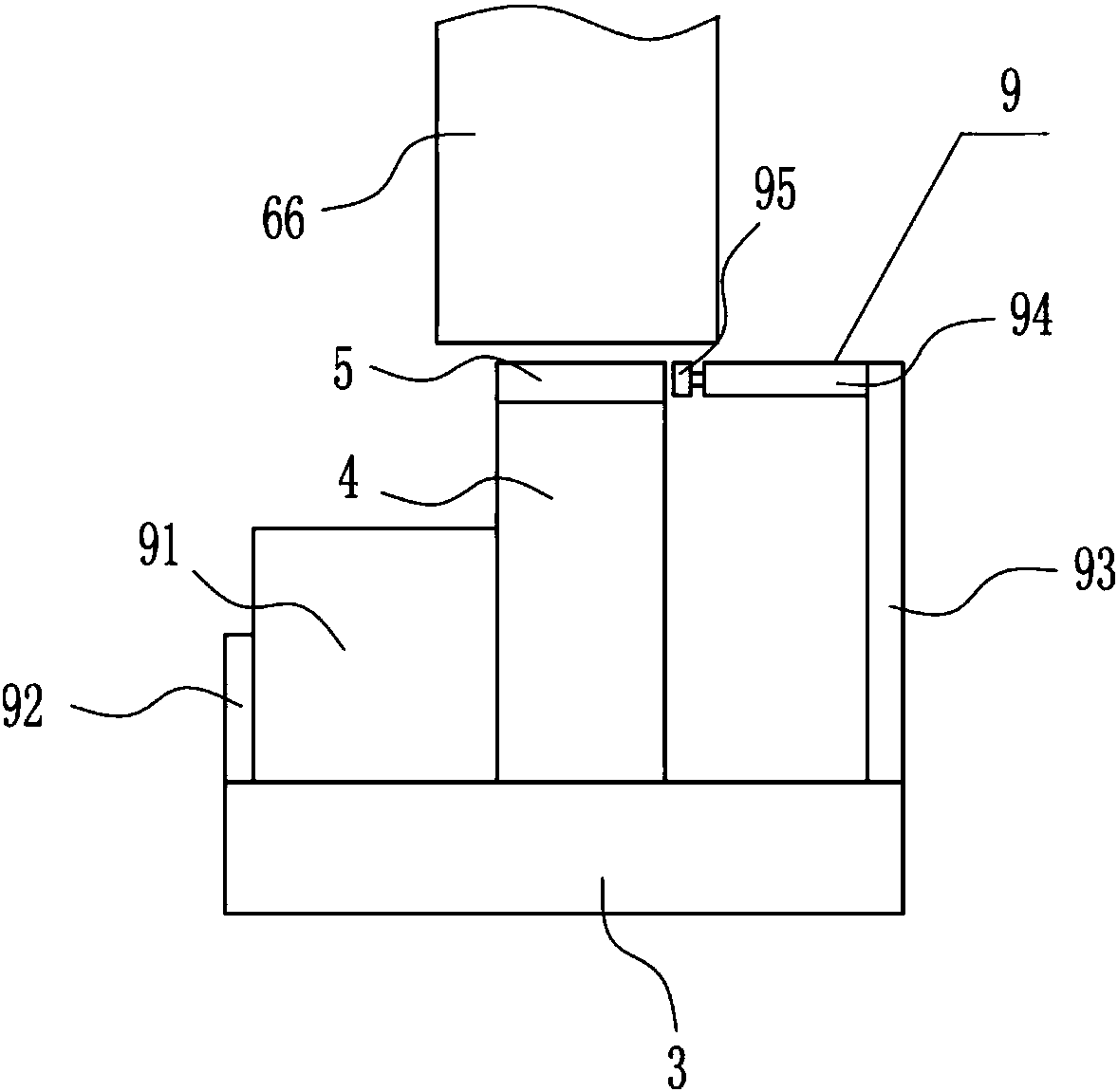

Bending clamp of flat lead

The invention relates to an electronic component processing device, in particular to a bending clamp of a flat lead. The bending clamp comprises a base, a locating block is fixedly installed to one side of the upper portion of the base, a push block is movably installed to the other side of the upper portion of the base, the push block moves in the direction far from or near the work end face of the locating block, and the push block makes the flat lead abut against the work end face of the locating block; a rotary shaft parallel to the work end face of the locating block is further installedon the base, the two ends of the rotary shaft are connected to wrenches respectively, and a press plate is fixedly installed between the wrenches; the press plate is located at the upper portion of the work end face of the locating block. Through the bending clamp of the flat lead, the flat lead can be bent with one hand, the stress is even in the bending process, the flat lead is good in state, there is no problems of deviation, bruise and the like, and the qualification rate is high; there is no need to control the force intensity when the flat lead is bent, and bending is high in speed andefficiency; the size of one side of the flat lead can be adjusted finely by adding or reducing gaskets between the locating block and the base, and the universality is high.

Owner:宜兴市吉泰电子有限公司

A high-efficiency bending device for steel pipes

ActiveCN105772548BFast bending speedImprove bending effectMetal-working feeding devicesPositioning devicesDrive wheelSteel tube

Owner:山东宏真精工机械有限公司

Improved adjustable metal plate bending device

InactiveCN106391776AFast bending speedImprove bending qualityShaping toolsOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses an improved adjustable metal plate bending device which comprises a rack. A frame is arranged above the rack. A bending groove is formed in the upper portion of the rack. A hydraulic device is arranged at the position, corresponding to the bending groove, of the frame. A pressing frame is arranged at the lower portion of the hydraulic device. The bottom of the pressing frame is provided with a pressing protrusion matched with the bending groove. The frame is provided with a metal plate position moving device. The metal plate position moving device comprises a first support extending out from the frame. The frame is provided with a vertical guide rail. The first support can move vertically along the vertical guide rail. The improved adjustable metal plate bending device is high in bending speed and good in bending quality, in addition, time and labor are saved, and the labor intensity is lowered.

Owner:FOSHAN GAOFU PETROCHINA FUEL ASPHALT

Metal plate bending device for case machining

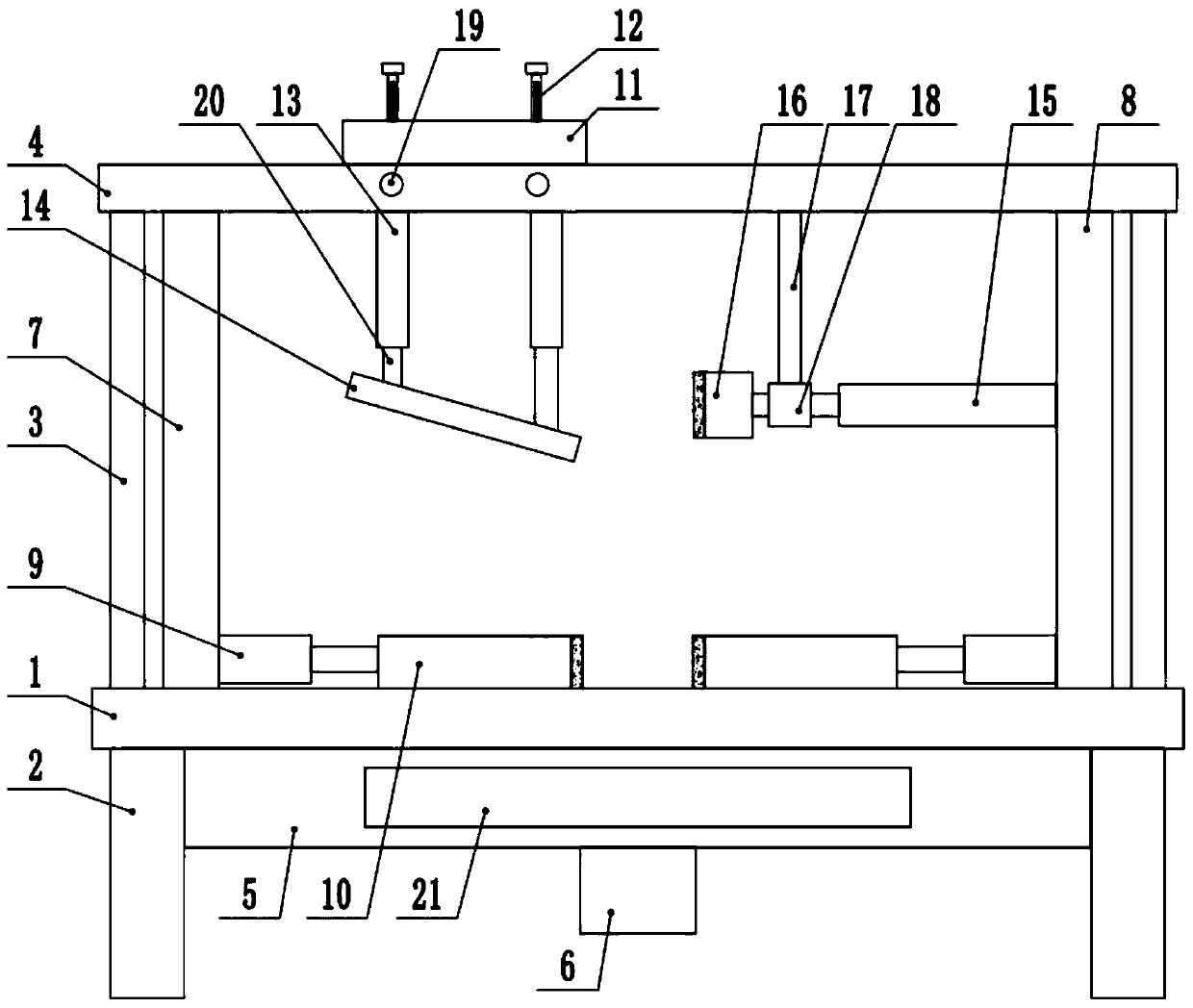

ActiveCN111229875AFast bending speedImprove accuracyMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention discloses a metal plate bending device for case machining, and relates to the technical field of case machining. The metal plate bending device comprises a workbench. The four corners ofthe bottom end of the workbench are all fixedly connected with supporting legs, the four corners of the top end of the workbench are all fixedly connected with supporting columns, the top ends of thesupporting columns are fixedly connected with a top plate, the two ends of the top surface of the workbench are fixedly connected with a first hydraulic pipe column and a second hydraulic pipe columncorrespondingly, the bottom end of the workbench is fixedly connected with a hydraulic tank, a hydraulic driving motor is arranged at the bottom end of the hydraulic tank, the hydraulic tank communicates with the first hydraulic pipe column and the second hydraulic pipe column, and the telescopic end of a first hydraulic telescopic rod is fixedly connected with a clamping seat. By arranging the hydraulic driving motor, the clamping seat and a pushing block can be driven to move in a hydraulic driving form so that a case shell can be bent; and the bending angle can be preset by arranging a material blocking device so that the case shell can be directly bent to the preset angle without human control, the bending speed is high, and the accuracy is high.

Owner:HANGZHOU FENGHENG ELECTROMECHANICAL

Electronic component pin bending equipment

InactiveCN111545671ANon-stop automatic operationHigh degree of automationConveyor partsEngineeringElectronic component

The invention relates to the field of electronic component manufacturing, in particular to electronic component pin bending equipment. The electronic component pin bending equipment comprises an electric cabinet and a conveying device, and also comprises a rotating shaft, a rotating fixed disc, a hydraulic pusher, a pressing baffle plate, a first compression spring, a compressor, a tension rod, aconnecting box fixedly arranged at the other end of the tension rod, a connecting block fixedly arranged on the bottom wall of the interior of the connecting box, and a thrust plate fixedly arranged at the lower end of the connecting box, and the tension rod is fixedly connected with the compressor; the hydraulic pusher comprises a first hydraulic push rod fixedly arranged at the bottom of the hydraulic pusher in the vertical direction, a second hydraulic push rod fixedly arranged on the side wall of the hydraulic pusher in the horizontal direction and a push block fixedly arranged at the other end of the second hydraulic push rod. According to the equipment, the bending precision of electronic component pin bending is improved, the consistency is high, the qualification rate is high, andthe equipment automation degree is high.

Owner:HANGZHOU RUJIAN ELECTRONICS EQUIP CO LTD

A sheet metal bending device for chassis processing

ActiveCN111229875BFast bending speedImprove accuracyMetal-working feeding devicesPositioning devicesElectric machineryEngineering

The invention discloses a sheet metal bending device for case processing, relates to the technical field of case processing, and includes a workbench. The four corners of the bottom end of the workbench are fixedly connected to the support legs, the four corners of the top end of the workbench are fixedly connected to the support column, the top of the support column is fixedly connected to the top plate, and the two ends of the top surface of the workbench are respectively fixedly connected to the first hydraulic pipe column and the second hydraulic pressure column. The bottom end of the workbench is fixedly connected to the hydraulic tank, and the bottom end of the hydraulic tank is equipped with a hydraulic drive motor. The hydraulic tank is connected with the first hydraulic tube column and the second hydraulic tube column. Connecting the clamping seat, the present invention can drive the clamping seat and the push block to move in the form of hydraulic drive by setting the hydraulic drive motor, so that the chassis shell can be bent, and the bending angle can be adjusted by setting the stopper device It can be bent directly to the preset angle without manual control, and the bending speed is fast and the accuracy is high.

Owner:HANGZHOU FENGHENG ELECTROMECHANICAL

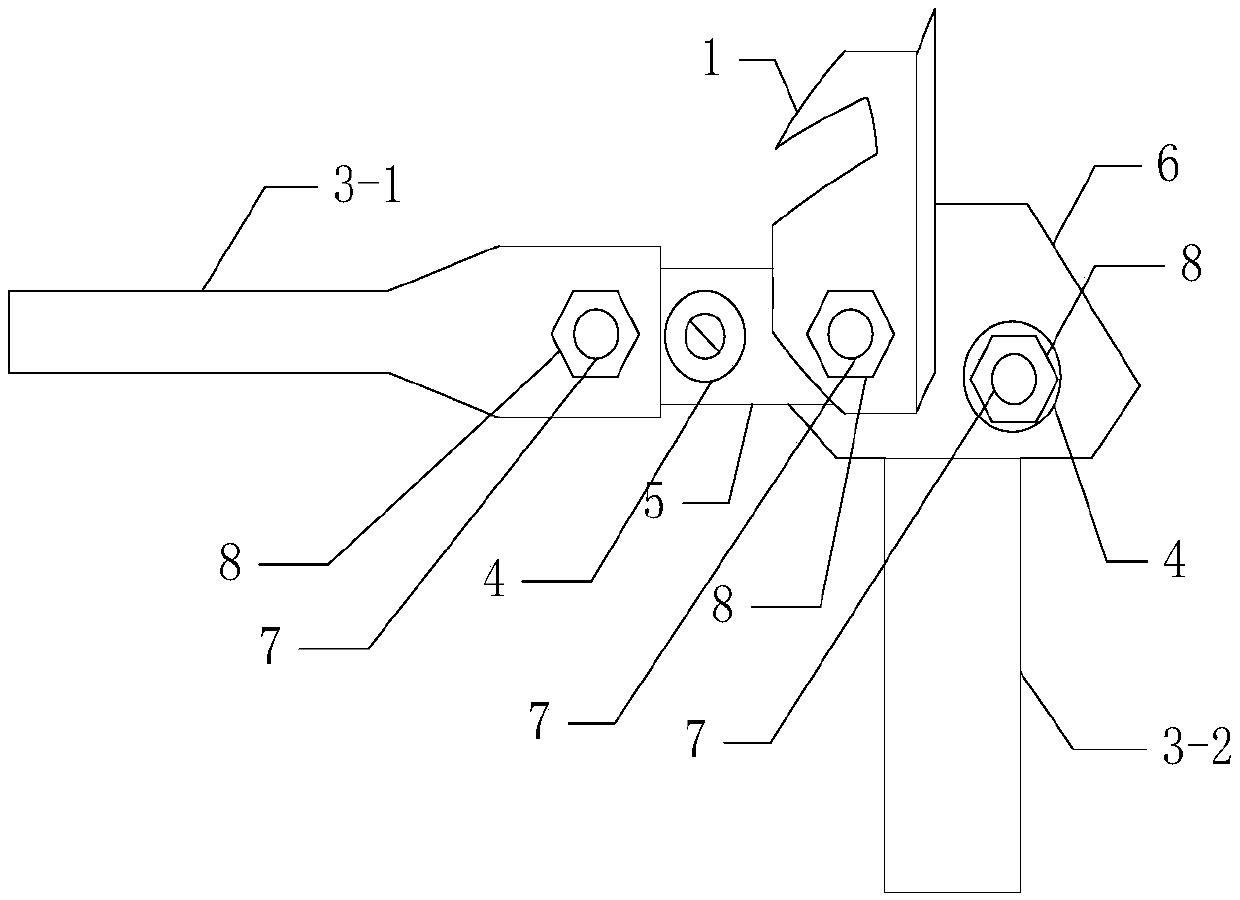

Automatic punching and bending packaging box production equipment

ActiveCN112895591AImprove convenienceImprove practicalityBox making operationsPaper-makingEngineeringManufacturing engineering

The invention discloses automatic punching and bending packaging box production equipment, and relates to the technical field of punching and bending equipment. The s automatic punching and bending packaging box production equipment comprises a workbench, first hydraulic rods are fixedly installed at the four corners of the top of the workbench correspondingly, a punching assembly is fixedly installed at the telescopic ends of the four first hydraulic rods jointly, a bending assembly is fixedly installed on one side of the top of the workbench, a through hole is formed in the other side of the top of the workbench, second supporting plates are arranged on the two sides of the through hole correspondingly, and a pushing assembly is fixedly installed at the top of the workbench and located in the through hole. According to the structure, punching and bending integration is achieved, the structure is simple, operation is easy, compared with traditional equipment, a large amount of input cost is saved, meanwhile, in the using process, a punching position can be adjusted in multiple directions, the use convenience, practicability and accuracy are improved, more time and labor are saved, and the labor cost is reduced, so that the production efficiency is improved, and wide application can be realized.

Owner:AMB GUANGZHOU

Steel strand bending machine

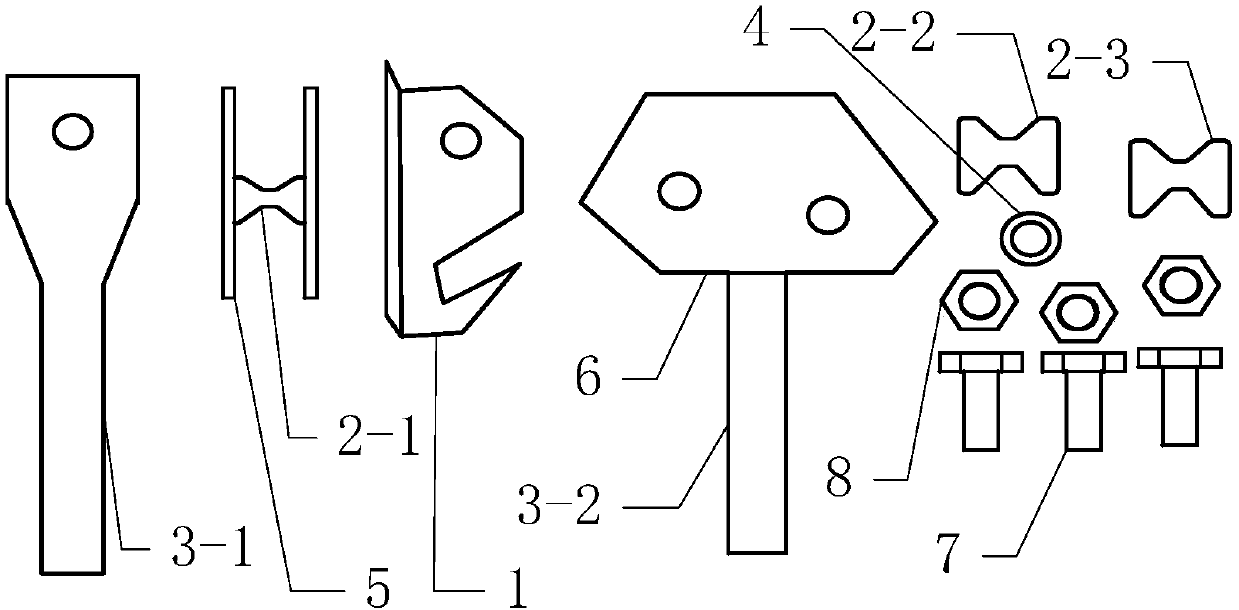

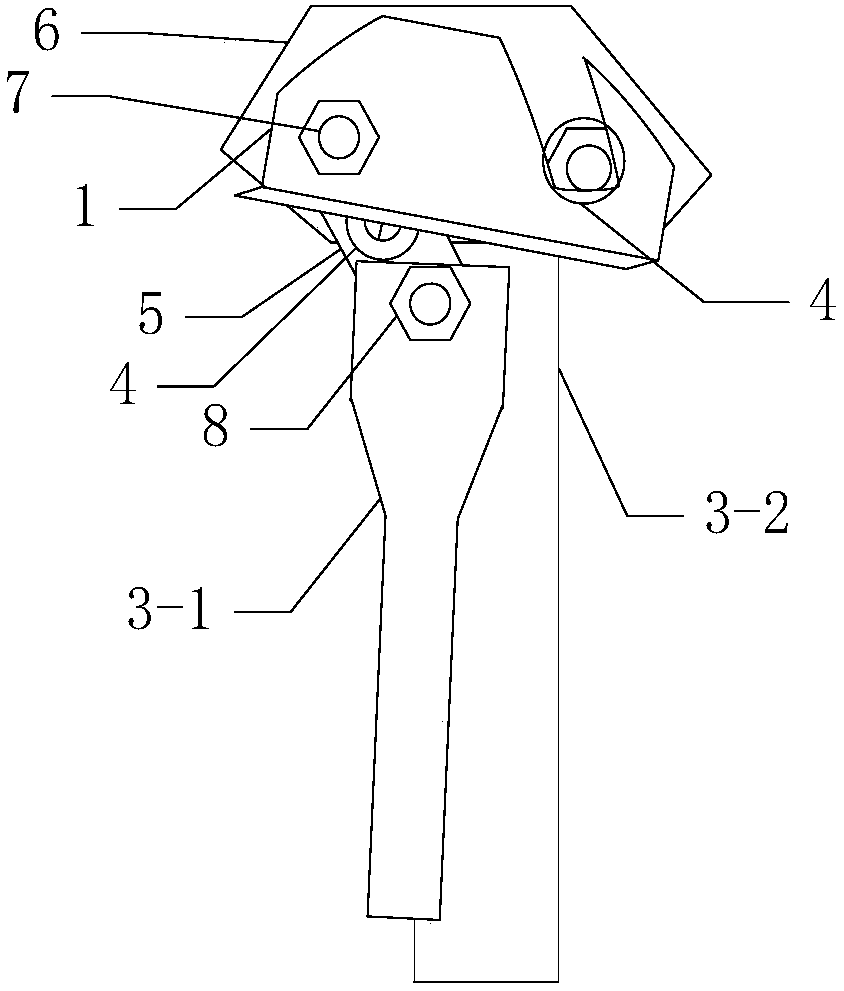

InactiveCN107617701AFix the angle problemSolve protection problemsArchitectural engineeringWorking environment

The invention discloses a steel strand bending machine and relates to a bending machine for electrical power construction. The invention aims at solving the problems that the bending speed of a steelstrand is low, the angle is not easy to control and rust prevention coating cannot be protected. The steel strand bending machine comprises a baffle, pulleys, a movable handle, a fixed handle, connection plates, a fixed plate, screws, nuts and spacers. The working principle of the steel strand bending machine is that the baffle is buckled between the spacers of the third pulley, and the movable handle is spread so that the included angle between the movable handle and the fixed handle can be maximum; at this moment, the first pulley is located on the outer side of the third pulley, and the steel strand is inserted into the portion between the second pulley and the third pulley; the movable handle is rotated, then the first pulley is rotated to the outer side of the second pulley, the steelstrand surrounds the second pulley and is bent by the first pulley and the third pulley, and thus an angle is formed. The steel strand bending machine is suitable for working environments such as construction and maintenance of electric transmission lines.

Owner:国网黑龙江省电力有限公司七台河供电公司 +1

Steel plate bending device

The invention relates to bending devices, in particular to a steel plate bending device. The technical problem to be solved is to provide the steel plate bending device. The steel plate bending devicecomprises a base, table legs, a table board and the like; the table legs are fixed on the base in a bilateral symmetry mode, the table board is fixedly connected on the two table legs, and a first groove is formed in the left side on the table board; a machine frame is welded on the base, a first support is fixedly connected to the upper portion of the machine frame, and a motor is arranged on the first support; and a first belt wheel is connected on an output shaft of the motor, a second support is fixedly connected to the upper portion of the interior of the machine frame, and the second support is positioned on the left side of the first support. According to the bending device, the automatic bending function is achieved, and the automatic conveying function is also realized; and the bending device has the characteristics of being high in bending speed, accurate in bending, convenient to operate, simple to manufacture, low in manufacturing cost and convenient to popularize.

Owner:广西振钢再生资源有限公司

Bending machine for iron artware machining

InactiveCN113617908AMeet various bending needsApplicable to various bending requirementsShearing machinesOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses a bending machine for iron artware machining. The bending machine comprises an operating table, supporting plates are fixedly connected to the two sides of the bottom of the operating table, a fixed seat is fixedly connected to the bottoms of the supporting plates, a plurality of fixing holes which are distributed at equal intervals are formed in the fixed seat, an impressing and bending mechanism is fixedly mounted at one side of the operating table, the impressing and bending mechanism comprises a sliding groove, the inner wall of the sliding groove is slidably connected with a bending base plate, a bending groove is formed in the top of the bending base plate, a bending jacking piece is fixedly installed at one side of the sliding groove, and a torsion bending mechanism is fixedly installed in the middle of the operating table. According to the bending machine, the impressing and bending mechanism, the torsion bending mechanism, a right-angle bending mechanism and other structures are arranged, the diversified bending requirements for iron raw materials in various forms and states are met, multiple air cylinders and a motor are used for providing power to bend the iron raw materials, the bending speed is increased, and manpower consumption is reduced.

Owner:阜南县德盛隆工艺家具有限公司

Steel bar bending equipment for building construction

The invention relates to the technical field of building construction equipment, and discloses steel bar bending equipment for building construction. The steel bar bending equipment for building construction comprises a base, wherein a hydraulic rotating oil cylinder is fixedly mounted on one side of the bottom of a base inner cavity; a supporting shaft is fixedly arranged on the top of the hydraulic rotating oil cylinder in a sleeving mode; the top end of the supporting shaft extends to the outside of the top end of the base; a bearing fixedly sleeves the supporting shaft; and the outer edgeof the bearing is fixedly connected with the top of the base in a sleeved mode. By using the steel bar bending equipment for building construction, one ends of three steel bars are sequentially placedbetween a positioning pressing plate and three moving pressing plates for fixing; the other ends of the three steel bars penetrate between the supporting shaft and a limiting rod, and the three steelbars are bent by rotating of the limiting rod around the supporting shaft; therefore, the three steel bars can be conveniently bent at the same time, the bending speed of the steel bars is increased,and the efficiency of the building construction is improved.

Owner:湖北国丰建设有限公司

Improved adjustable metal sheet bending device

InactiveCN106734396AFast bending speedImprove bending qualityShaping toolsMetal-working feeding devicesMetal sheetUltimate tensile strength

The invention discloses an improved adjustable metal sheet bending device which comprises a rack. A frame is arranged above the rack. A bending groove is formed in the upper portion of the rack. A hydraulic device is arranged at the position, corresponding to the bending groove, of the frame. A pressing frame is arranged on the lower portion of the hydraulic device. A pressing protrusion matched with the bending groove is arranged at the bottom of the pressing frame. The frame is provided with a metal sheet position moving device. The metal sheet position moving device comprises a first support extending out of the frame. The frame is further provided with vertical guide rails. The first support can move up and down along the vertical guide rails. The improved adjustable metal sheet bending device disclosed by the invention is high in bending speed, good in bending quality, and capable of saving time and labor and relieving labor intensity.

Owner:FOSHAN GAOFU PETROCHINA FUEL ASPHALT

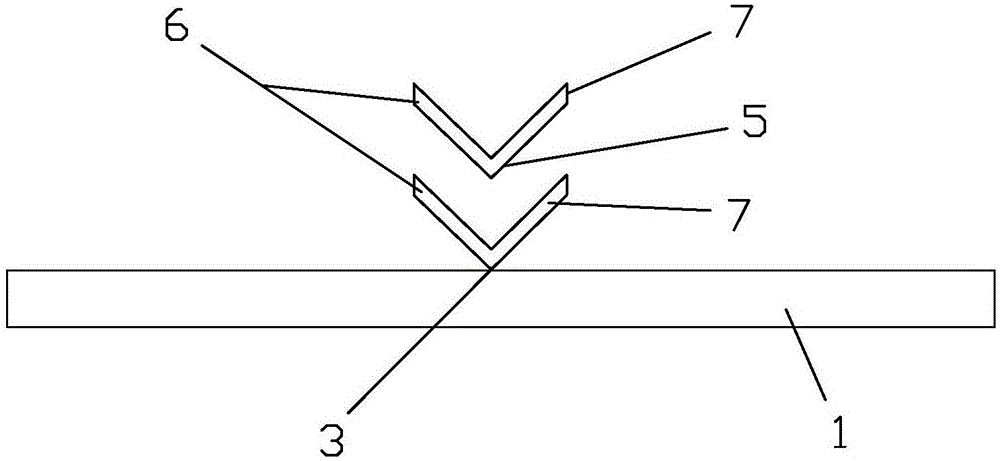

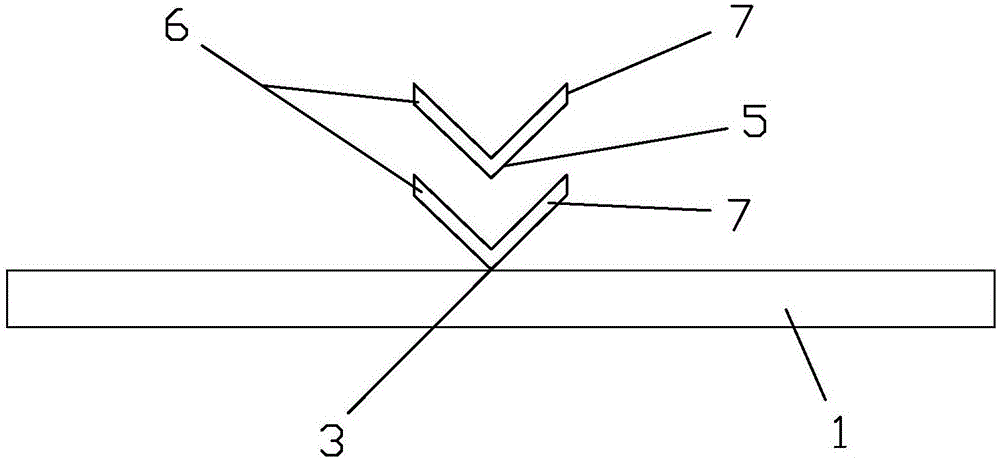

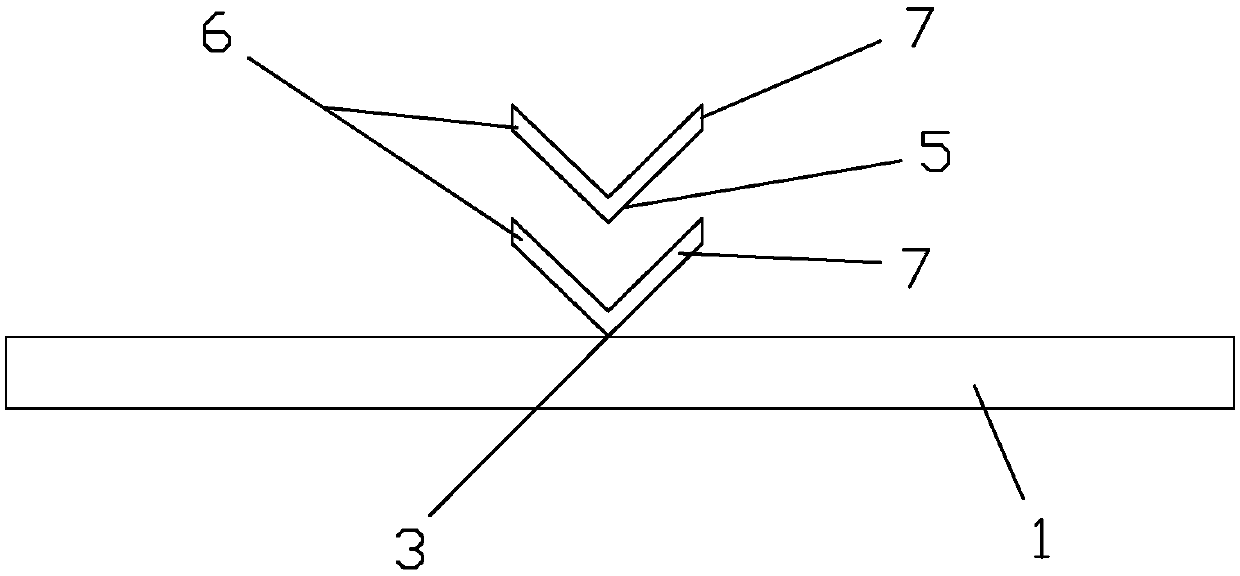

M iron lug plate forming device

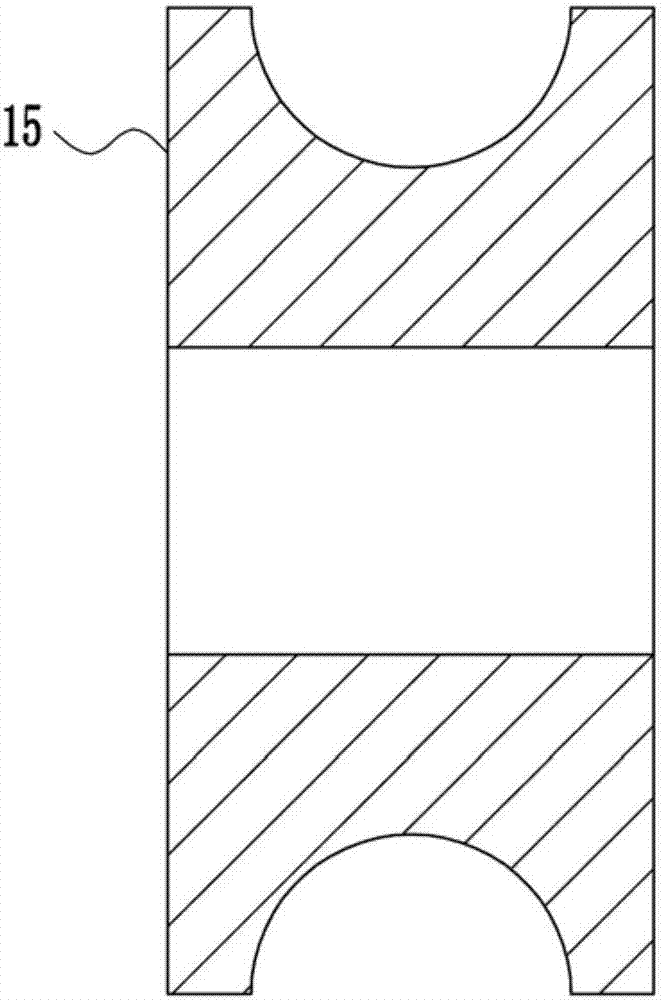

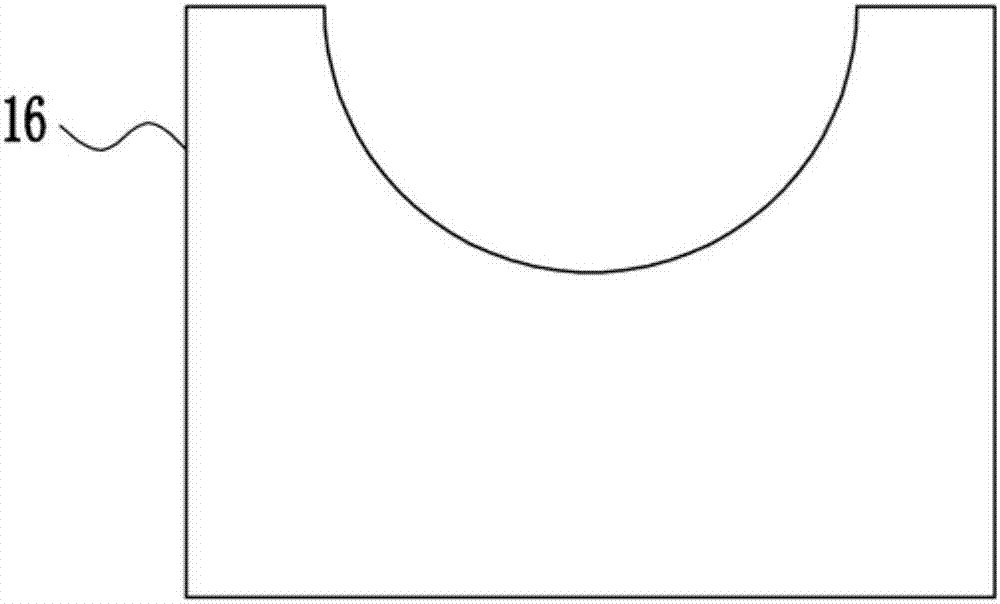

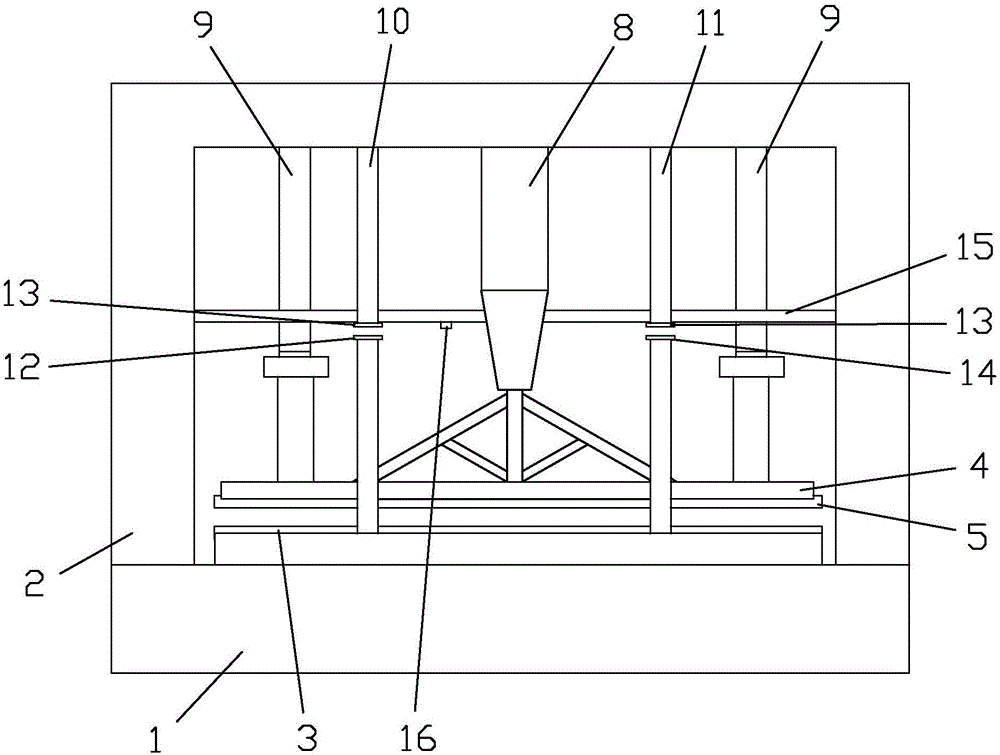

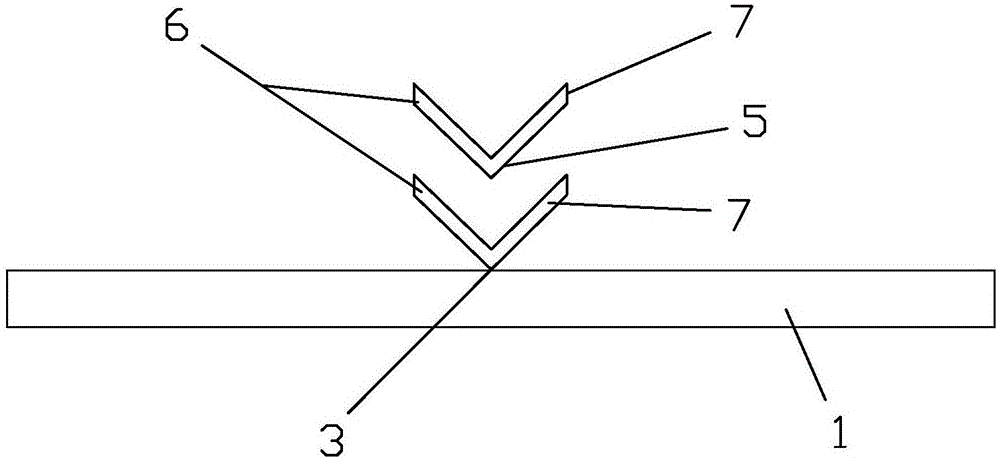

PendingCN112246972ASimple bending actionFast bending speedShaping toolsMetal-working feeding devicesTriangular prismStructural engineering

The invention discloses an M iron lug plate forming device. The M iron lug plate forming device comprises an upper bending die and a lower bending die, wherein the upper bending die is a regular triangular prism cylinder, one side surface of the upper bending die is perpendicular to the moving direction of the bending upper die, the side length of the bottom surface of the upper bending die is 30mm, the chamfered edge of the lower part of the upper bending die is an arc chamfer, and the radius of the arc chamfer is 2 mm; and a groove is formed in the lower bending die, the groove is in a regular triangular prism shape and located under the lower bending die, one side surface of the groove is perpendicular to the moving direction of the upper bending die, the side length of the bottom surface of the groove is 35 mm, the chamfered edge of the lower part of the groove is an arc chamfer, the radius of the arc chamfer is 8 mm, and the intersecting line chamfer of the groove and the upper surface of the upper bending die is 2 mm. The M iron lug plate forming device aims to solve problems of low efficiency, low machining precision and high rejection rate in the prior art.

Owner:贵州长通集团智造有限公司

A kind of beveled edge sheet metal mold

ActiveCN113231510BUniform thicknessIncreasing the thicknessShaping toolsEjection devicesEngineeringMetal mold

The invention discloses a beveled edge sheet metal mold, which comprises: a lower mold, the lower mold is provided with a first groove, a second groove is arranged in the first groove, and the first groove The left and right sides of the upper mold are provided with side grooves; the upper mold is provided with installation arc grooves on both sides of the upper end of the upper mold, and installation grooves are arranged in the installation arc grooves, and the upper mold is arranged above the lower mold; Hemming die, the side wall of the hemming die is provided with a hemming groove, the side wall of the hemming die is provided with a mounting protrusion matching the installation groove, and the hemming die is rotatably installed on the Install in the arc groove; return spring, one end of the return spring is fixed in the installation groove, and the other end is fixed on the installation protrusion, and the return spring pulls the folding die; side mold, the The side molds are slidably installed in the side grooves; fast, stable and accurate production of sheet metal parts is realized, and the structural strength and service life of the sheet metal parts are improved.

Owner:深圳市泰能特模具技术有限公司

Steel bar bending device for building construction

InactiveCN112620526ASimple structureEasy to installEngineering safety devicesMetal working apparatusCircular discElectric machine

The invention discloses a steel bar bending device for building construction. The steel bar bending device comprises a mounting box, a motor is installed in the middle of the bottom end of the interior of the mounting box, a storage battery is installed at one end of the bottom of an inner cavity of the mounting box, a connecting rod is installed at the output end of the motor, a fixed disc is installed at the top of the mounting box, a circular ring is installed at the top of the fixed disc, a steel ball is arranged in the circular ring, a bearing plate is installed at the top of the connecting rod, a first threaded rod is rotatably installed in the bearing plate, a first clamping plate is installed on the outer surface of the first threaded rod in a threaded mode, and a fixing rod is installed on the outer surface of the circular ring. The steel bar bending device is simple in structure and convenient to install, bending operation is carried out under the action of the output end of the motor, compared with manual bending, the bending process is more stable, the bending speed is higher, the situation that due to unstable manual force application, a steel bar is stressed and popped up is avoided, and the life safety of a user is protected.

Owner:云南建丰实业(集团)有限公司

Quick bending and cutting device for metal sheet

The invention discloses a quick bending and cutting device for a metal sheet. The quick bending and cutting device for the metal sheet comprises a rack, a frame is arranged above the rack, the upper portion of the rack is provided with a bending groove, and the frame corresponding to the bending groove is provided with a hydraulic device; and the lower portion of the hydraulic device is provided with a compacting frame, the bottom of the compacting frame is provided with a compacting protrusion matched with the bending groove, the hydraulic device comprises a hydraulic rod in the middle and jacks on both sides, the lower portion of the hydraulic rod is fixedly connected with the compacting frame, and the jacks are located between the frame and the compacting frame. The quick bending and cutting device for the metal sheet is high in bending speed, and good in bending quality; and both time and labor are saved, and labor intensity is reduced.

Owner:广东西江电梯有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com