Steel bar bending device for building construction

A technology for steel bar bending and building construction, applied in engineering safety devices, manufacturing tools, metal processing and other directions, it can solve problems such as the position that affects the bending of steel bars, the poor fixing effect of steel bars, and easy changes, so as to achieve stable and stable bending process. The effect of convenient processing and fast bending speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

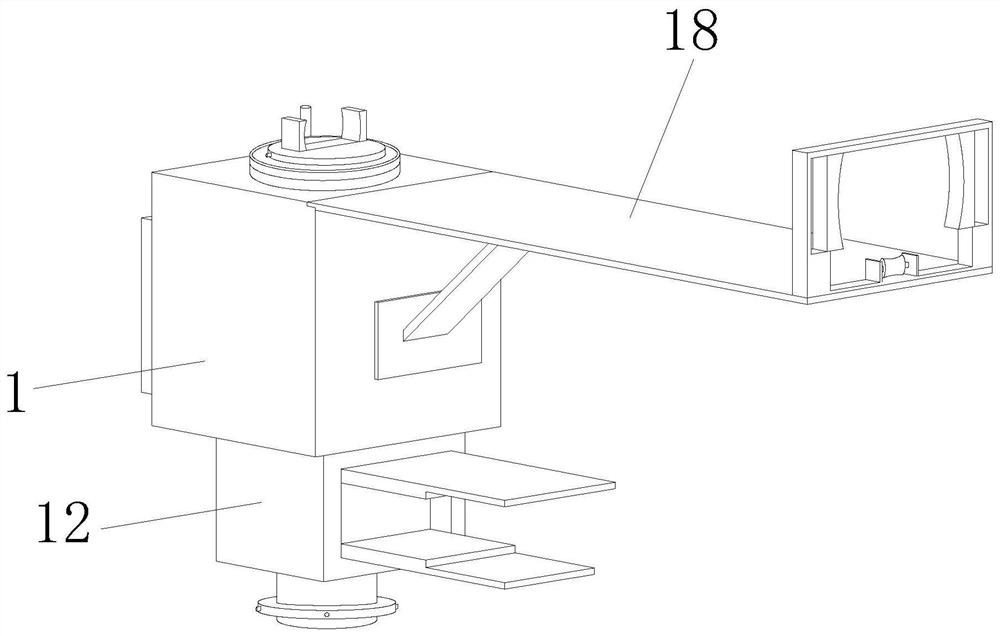

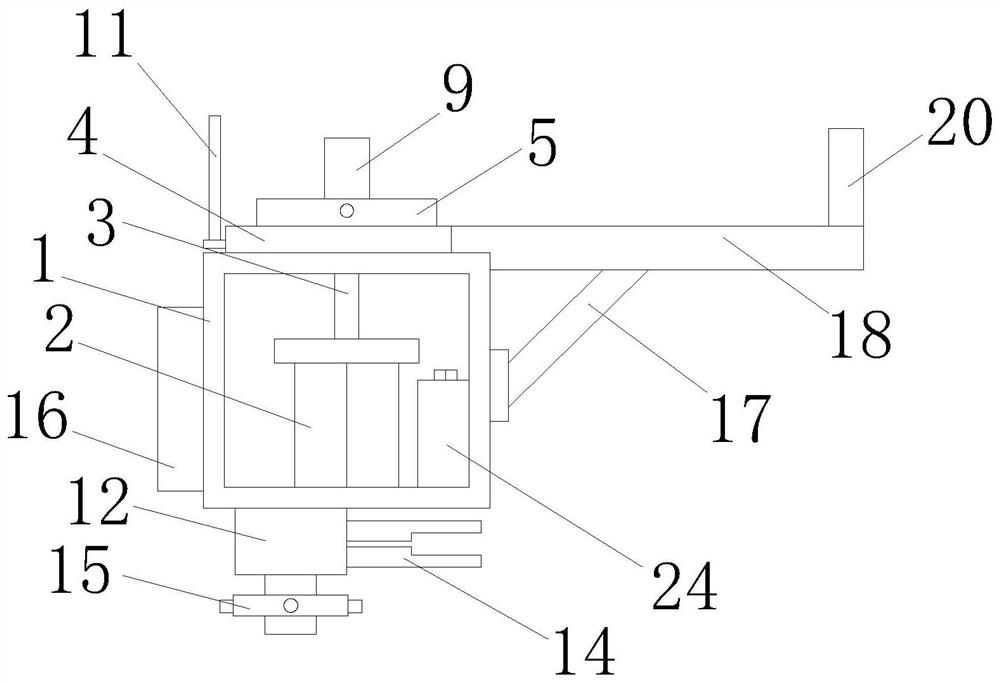

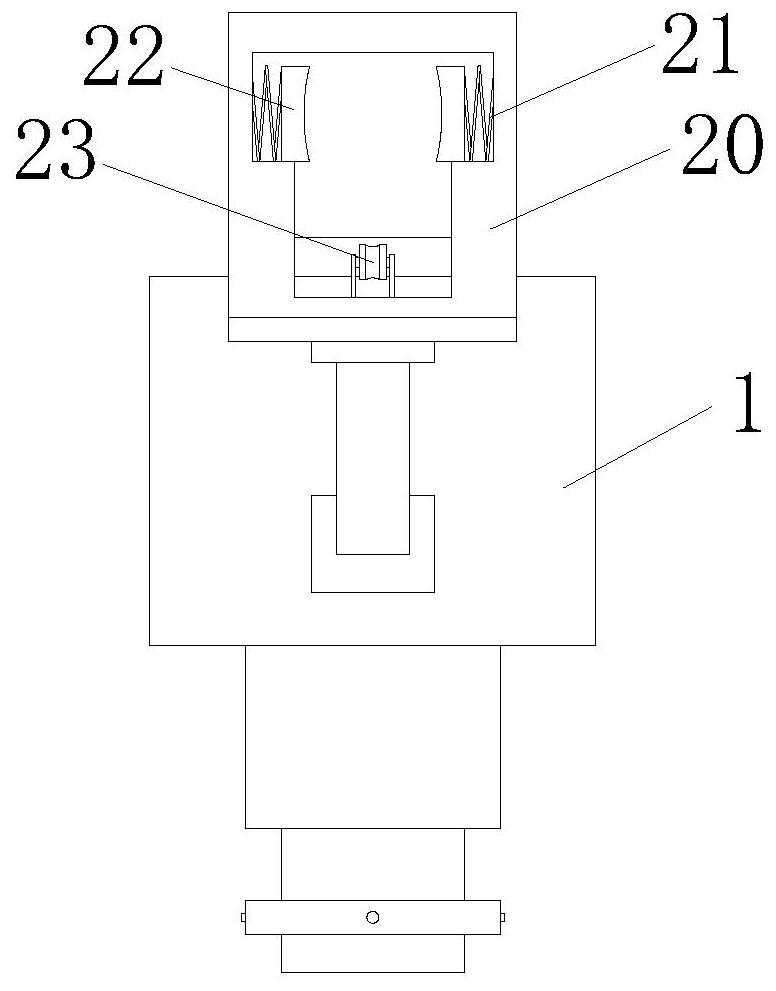

[0027] Embodiment 1, according to Figure 1-Figure 6 , by rotating the steering block 15, the second threaded rod 13 is driven to rotate through the steering block 15, and the two second splints 14 are brought close to each other through the screw thread, clamping the edge of the workbench, and fixing the bending device on the workbench. The overall device can be conveniently installed on the workbench for easy processing. After placing the steel bar that needs to be bent on the roller 23 provided inside the limit frame 20, the third splint 22 is under the action of the spring 21 at this time. Clamp and fix one end of the steel bar, and then continue to deliver the steel bar forward until it is sent between the two first splints 9, at this time, by rotating the first threaded rod 8, the two first splints 9 clamp the steel bar to fix the steel bar The end of the steel bar can be marked with the help of the measuring ruler 19, and the two ends of the steel bar can be well fixed....

Embodiment 2

[0028] Embodiment 2, according to Figure 1-Figure 6, when bending, the control panel 16 controls the action of the motor 2, the rotation of the output end of the motor 2, and the smooth rotation of the motor 2 to realize the bending, which not only reduces the work intensity of the workers, but also reduces the pressure of the smooth bending. The pop-up of the steel bars due to uneven stress protects the lives of workers. When the bearing plate 7 rotates, when the steel bars are in contact with the positioning columns 11, the position of the positioning columns 11 is fixed. Through the cooperation of the positioning columns 11, the steel bars Bending is carried out so that the position of each bending point remains unchanged, which will not affect the bending position of the steel bar and ensure the quality of the bending.

[0029] Working principle: when in use, install the bending device on the workbench, rotate the steering block 15, drive the second threaded rod 13 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com