Hot bending forming method and forming device for organic glass

A technology of plexiglass and a molding method, which is applied in the field of hot bending molding method and molding device of plexiglass, can solve the problems of heavy processing work, high cost, poor surface quality of plexiglass, etc., and achieves high yield and fast bending speed. , the effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of thermal bending forming method of plexiglass, comprises the steps:

[0025] S1. Provide a flat plexiglass;

[0026] S2. Move the plexiglass to a preset distance below the infrared heating tube, and heat and soften the plexiglass;

[0027] S3. Place the heated and softened plexiglass in a bending fixture for molding to obtain 3D plexiglass; wherein, the bending fixture includes a plate-shaped fixture body, and the upper surface of the fixture body is provided with several grooves, and protrusions are provided between two adjacent grooves; the two ends of the heat-softened organic glass are respectively embedded in the grooves.

[0028] The bending fixture of the present invention has a simple structure, and the two ends of the heated and softened organic glass are respectively embedded in the grooves of the bending fixture, so that the organic glass can be bent. Only the two ends of the plexiglass are in contact with the bending fixture, the surface quality o...

Embodiment 2

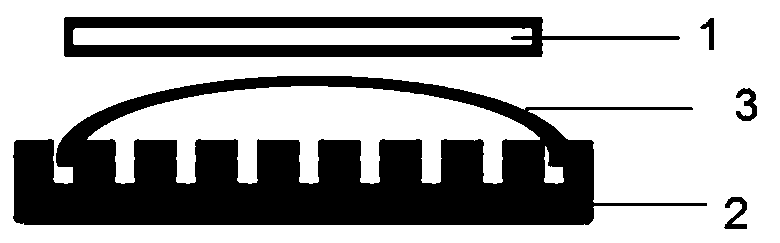

[0041] refer to figure 1 , a thermal bending forming device for plexiglass, comprising:

[0042] an infrared heating tube for generating the high temperature required to soften the plexiglass;

[0043] The bending fixture is arranged under the infrared heating tube, and the bending fixture is used to fix the softened plexiglass to form it into 3D plexiglass; the bending fixture includes a plate-shaped fixture The body, the upper surface of the fixture body is provided with several grooves distributed in an array, and a protrusion is arranged between two adjacent grooves.

[0044] Wherein, the surface of the plexiglass is provided with a functional layer, and the functional layer includes one or more of a hardened layer, an anti-glare layer, an anti-reflection and anti-reflection film, and an anti-fingerprint layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com