Bending clamp of flat lead

A technology for bending fixtures and leads, which is applied in the field of electronic component processing devices, can solve the problems of low bending efficiency of flat leads, easy scratches of flat leads, deflection of flat leads, etc., and achieve fast bending speed and uniform force , The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be described in conjunction with the examples.

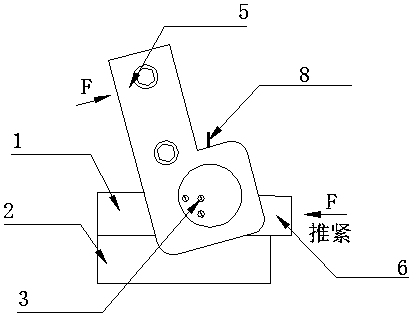

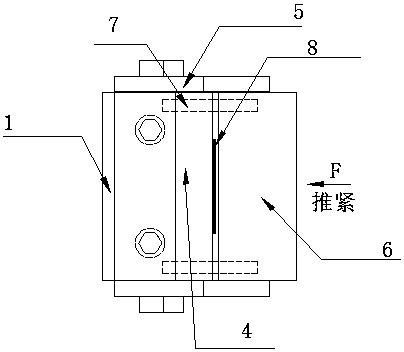

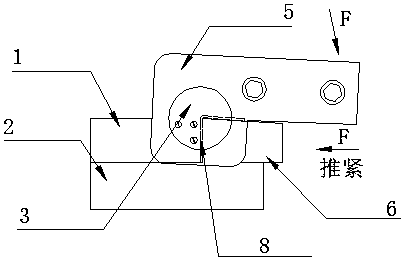

[0023] Such as figure 1 and figure 2 As shown, the bending fixture of the flat lead includes a base 2, a positioning block 1 is fixedly installed on one side above the base 2, and a push block 6 is movably installed on the other side, and the moving direction of the push block 6 is away from or close to the positioning block 1, the push block 6 pushes the flat lead wire 8 against the working end face of the positioning block 1; the base 2 is also equipped with a rotating shaft 3, which is parallel to the working end face of the positioning block 1, and the two ends of the rotating shaft 3 are respectively connected to the wrench 5. A pressure plate 4 is fixedly installed between the wrenches 5; the pressure plate 4 is located above the working end surface of the positioning block 1.

[0024] The working end face of described positioning block 1 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com