Air spring damping device and damping method thereof

A technology of air springs and shock absorbers, which is applied in the direction of springs/shock absorbers, springs, shock absorbers, etc., and can solve problems such as equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

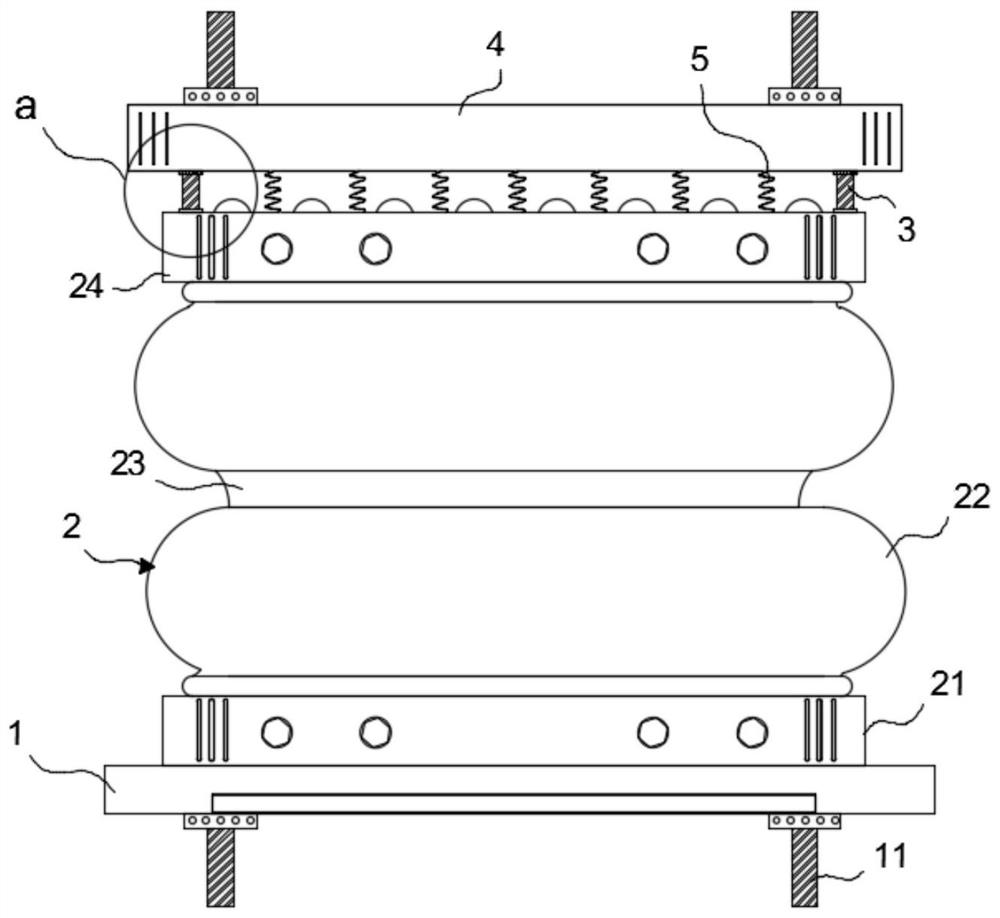

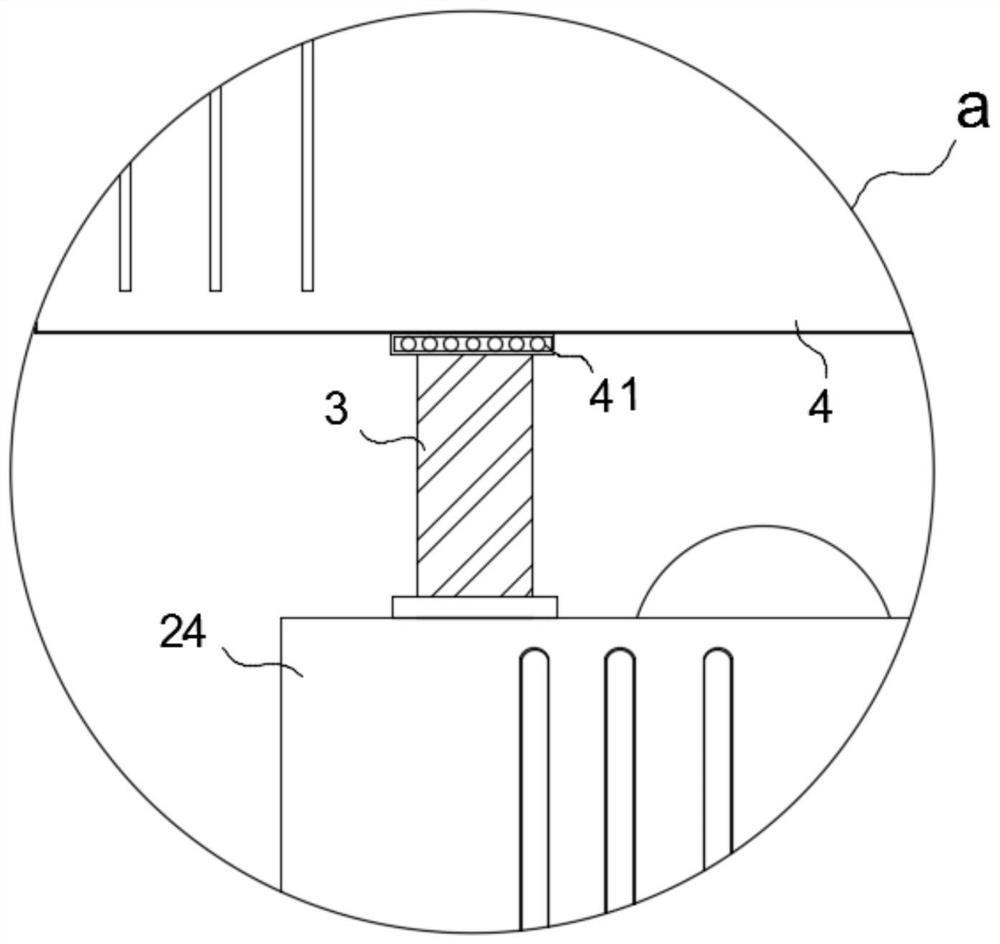

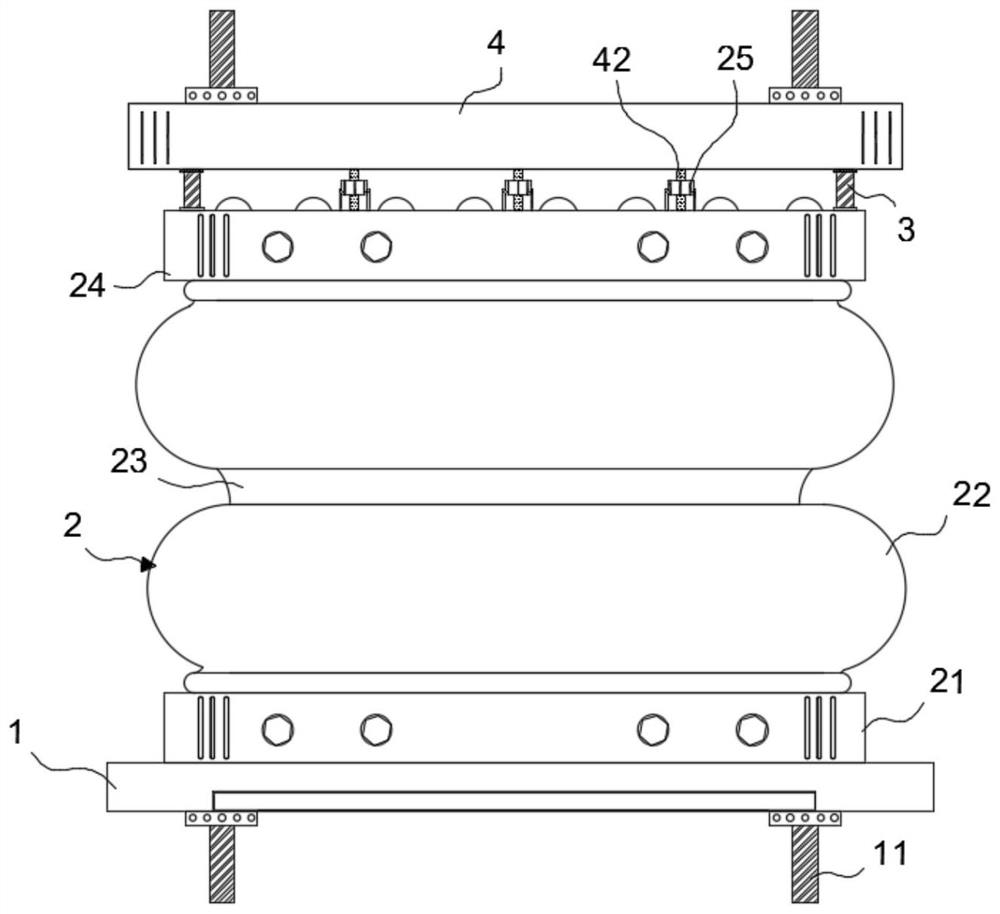

[0025] refer to figure 1 and figure 2 , an air spring damping device, comprising a base connecting plate 1, an air spring body 2, a shock absorbing screw 3 and a top connecting plate 4; several connecting pieces 11 are fixed on the base connecting plate 1 and the top connecting plate 4, the connecting pieces 11. The connecting screw can be selected, and the air spring damping device can be assembled in the related equipment through the connection between the nut and the connecting screw; Screw holes and a damping screw rod 3 form a screw pair; the outer rings of n bearings 41 are fixed with the top connecting plate 4, and the inner rings of n bearings 41 are fixed with n damping screw rods 3 respectively.

Embodiment 2

[0027] This embodiment is limited on the basis of Embodiment 1. The air spring body 2 includes a bottom end seal plate 21, an air flexure 22 and a top end seal 24; the bottom end seal 21 is fixed to the base connecting plate 1; several air flexures 22 are provided, and two adjacent air flexures 22 communicates through the waist ring 23, the air flexure 22 closest to the bottom end seal 21 is glued to the bottom end seal 21, and the air flexure 22 closest to the top end seal 24 is glued to the top end seal 24. The n screw holes that form the helical pair with the n damping screw rods 3 are all opened on the top end sealing plate 24 .

Embodiment 3

[0029] This embodiment is limited on the basis of the second embodiment. The inner layer of the air bellows 22 is made of high-air-tightness rubber, and the outer layer is made of medium-resistant and aging-resistant rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com