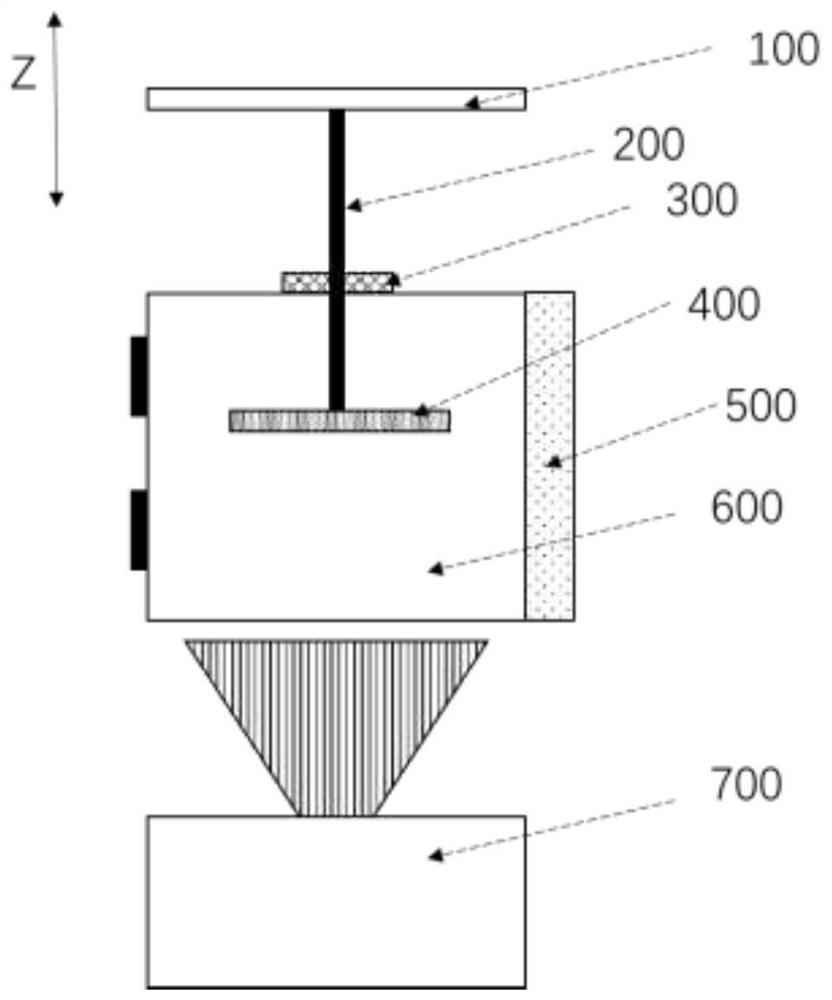

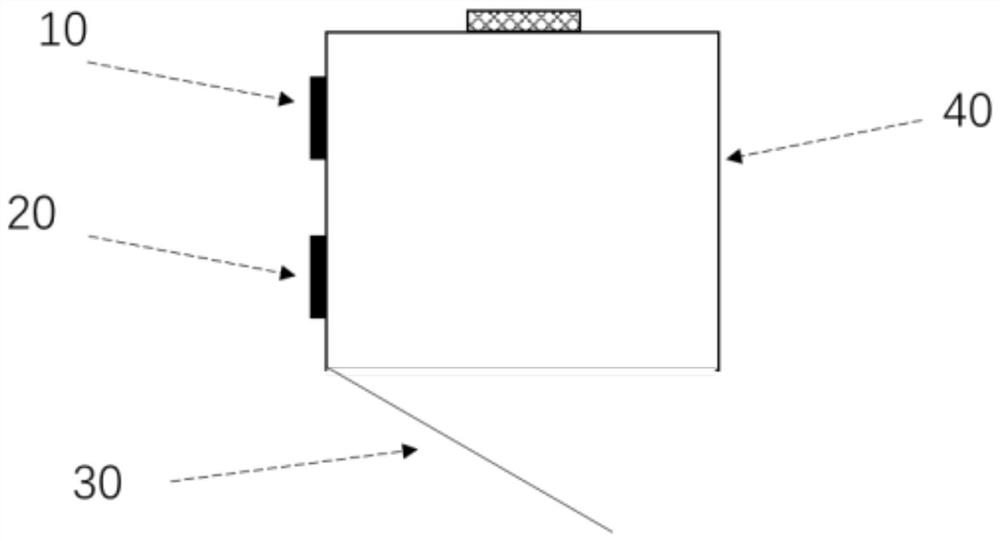

Photocuring 3D printing equipment and printing method applicable to space environment

A 3D printing and space environment technology, applied in the field of 3D printing, can solve the problems of high viscosity ink, difficulty in printing, sacrificing printing efficiency and printing time, and achieve the effect of overcoming the requirement of high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

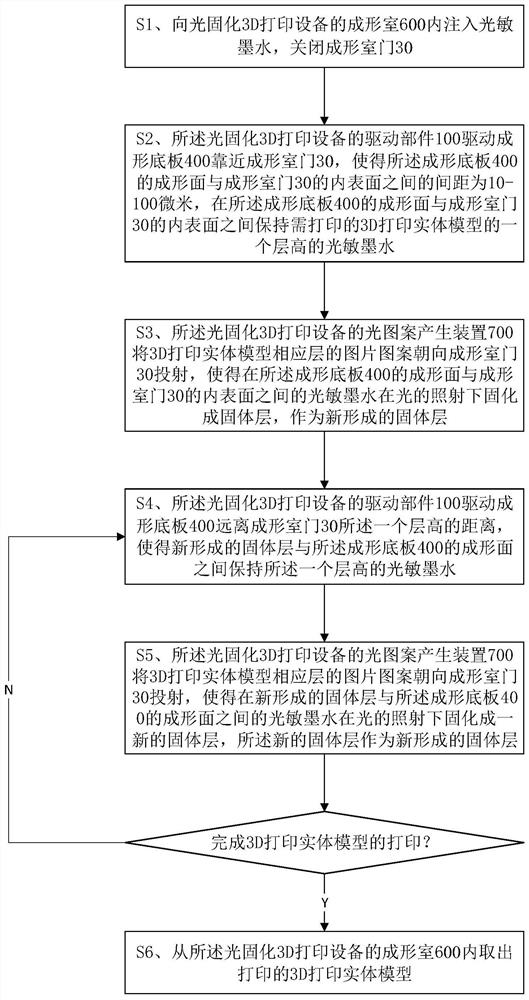

[0067] Example 1 Space printing of three-dimensional in vitro tumor models

[0068] This embodiment proposes a space printing method for a three-dimensional in vitro tumor model, which includes the following steps:

[0069] ·Preparation of photosensitive bioink

[0070] A certain amount of gelatin-methacrylic acid (GelMA) powder (self-made) was dissolved in physiological saline, heated at 70°C for 3 hours until the GelMA powder was completely dissolved, and a 0.05 g / ml GelMA solution was prepared. Then add 0.005g / ml photoinitiator (I2959, 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone, 106797-53-9, Yingli, China) powder dissolved in 0.1 g / ml GelMA solution to make GelMA bioink.

[0071] The lung tumor cells (A549) to be printed were digested, counted, centrifuged, and re-suspended with GelMA bio-ink to obtain 4*10 6 / ml of cell-containing GelMA bioink.

[0072] ·Printing and crosslinking

[0073] Perform plasma cleaning and hydrophilic treatment on the forming bottom...

Embodiment 2

[0074] Embodiment 2 adopts the space printing of the three-dimensional solid model of another kind of photosensitive ink

[0075] Compared with Embodiment 1, this embodiment differs in that the composition of the photosensitive ink in this embodiment is different.

[0076] specific,

[0077] ·Preparation of bio-ink

[0078]A certain quality of poly(ethylene glycol) diacrylate (PEGDA, manufacturer Sigma, molecular weight 700) powder is dissolved in deionized water, and the mass-volume ratio of poly(ethylene glycol) diacrylate is 20% (it can be in the range of 5~ 30% range to select), to make 0.2g / ml PEGDA solution. Then add 0.005g / ml photoinitiator (I2959, 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone, 106797-53-9, Yingli, China) powder dissolved in 0.1 g / ml PEGDA solution to make PEGDA photosensitive ink.

[0079] ·Printing and crosslinking

[0080] Add the photosensitive ink obtained in the above steps into the forming chamber, and install and connect each structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com