A two-stage dual-motor hybrid automatic transmission

An automatic transmission and hybrid power technology, applied in the field of machinery and vehicle transmission, can solve the problems that the automatic transmission has no engine shutdown function, and the automatic transmission cannot realize shutdown and energy saving, and achieve the effect of small size and good speed matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

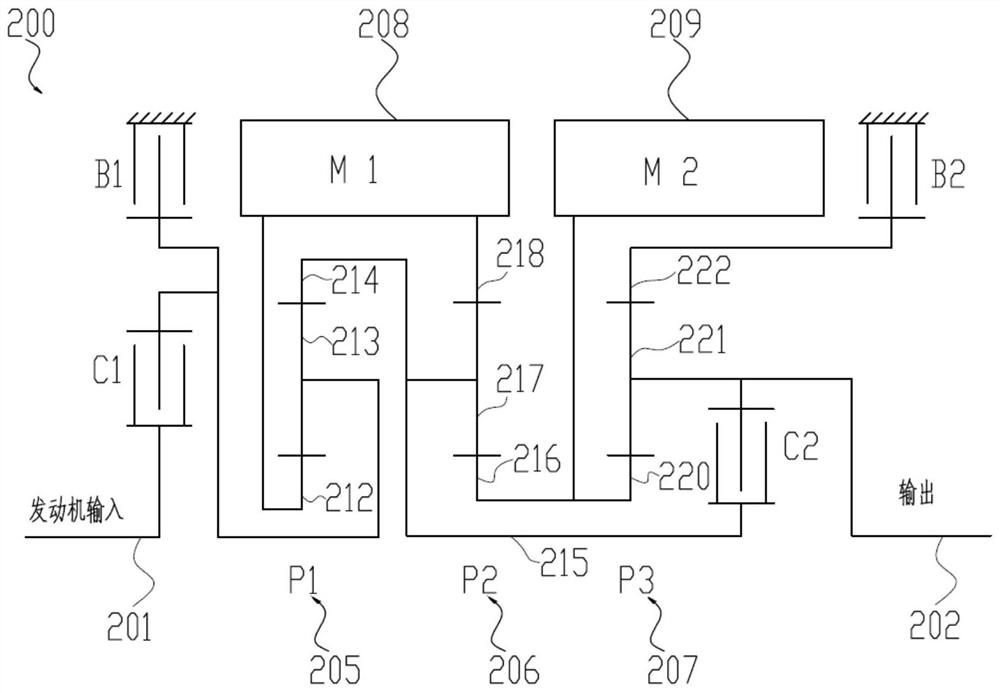

[0017] This embodiment provides a two-stage dual-motor hybrid automatic transmission 200, such as figure 1 As shown, it includes an input shaft 201 connected to an internal combustion engine, an output shaft 202 for power output, a first planetary row 205, a second planetary row 206, a third planetary row 207, a first power motor 208, a second power motor 209, The first clutch C1, the second clutch C2, the first brake B1, and the second brake B2. The first power motor 208 and the second power motor 209 have a drive mode and a power generation mode, and have functions of both power input and power recovery.

[0018] One end of the input shaft is connected to the power source engine, and the other end of the input shaft is connected to the first planetary row frame through the first clutch, and at the same time, the first planetary row frame is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com