A positioning tool for processing circular mechanical parts

A technology for mechanical parts and positioning tooling, applied to workpiece clamping devices, manufacturing tools, etc., can solve problems such as poor precision and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

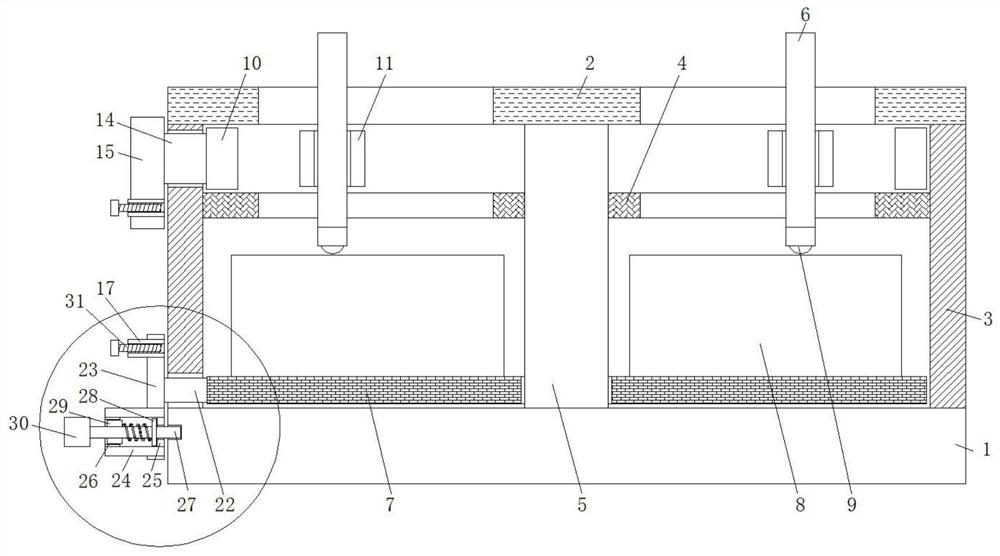

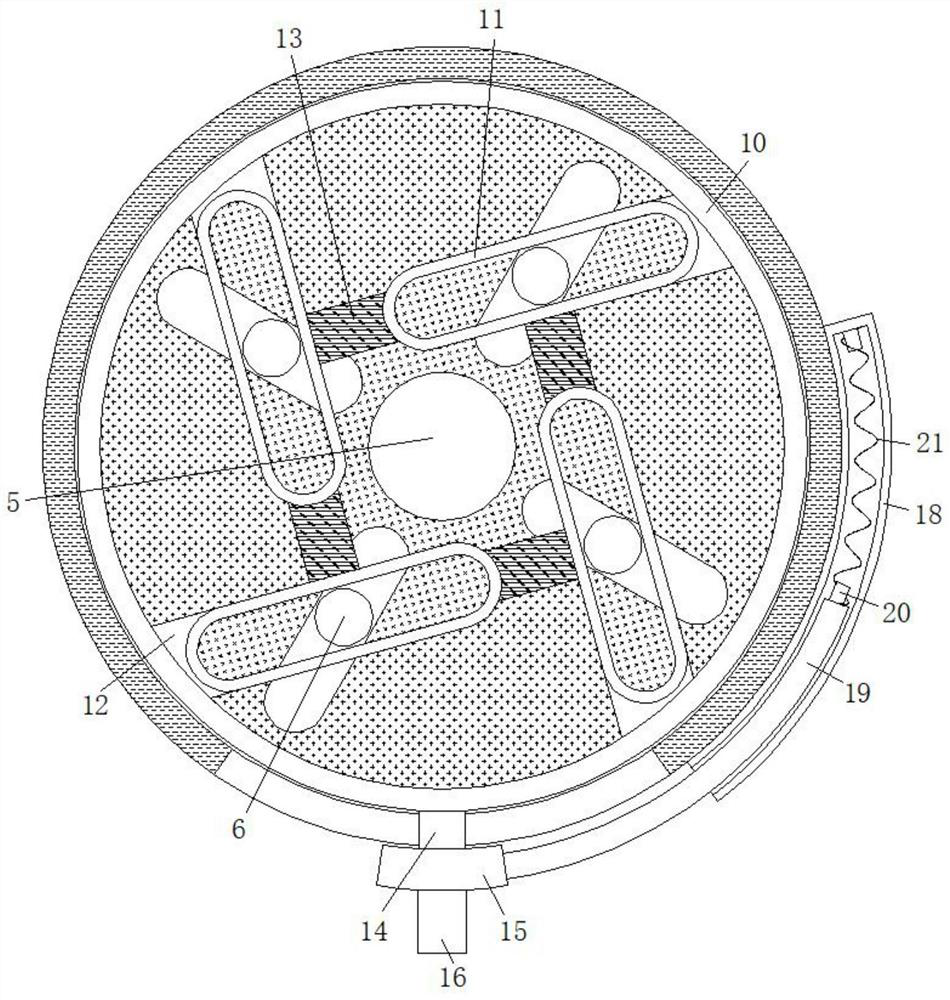

[0024] refer to Figure 1-4 , a positioning tool for processing circular mechanical parts, including a base 1, a worktable 2 is arranged vertically above the base 1, and a partition 4 and a central axis column are fixedly connected between the bottom side of the worktable 2 and the base 1 5. The central axis column 5 is located on the inner side of the support cylinder 3, and the inner wall of the support cylinder 3 is fixedly connected with a partition 4. Both the partition 4 and the work surface 2 are provided with sliding holes, and there are several sliding holes respectively, which are divergent. The positioning clamp rods 6 are slidably connected in the sliding holes, and the positioning clamp rods 6 are vertically arranged. The side is provided with a rotating ring plate 7, and the rotating ring plate 7 is rotatably covered on the outside of the cylinder of the central axis column 5, and the top side of the rotating ring plate 7 is fixedly connected with a fixed-height ...

Embodiment 2

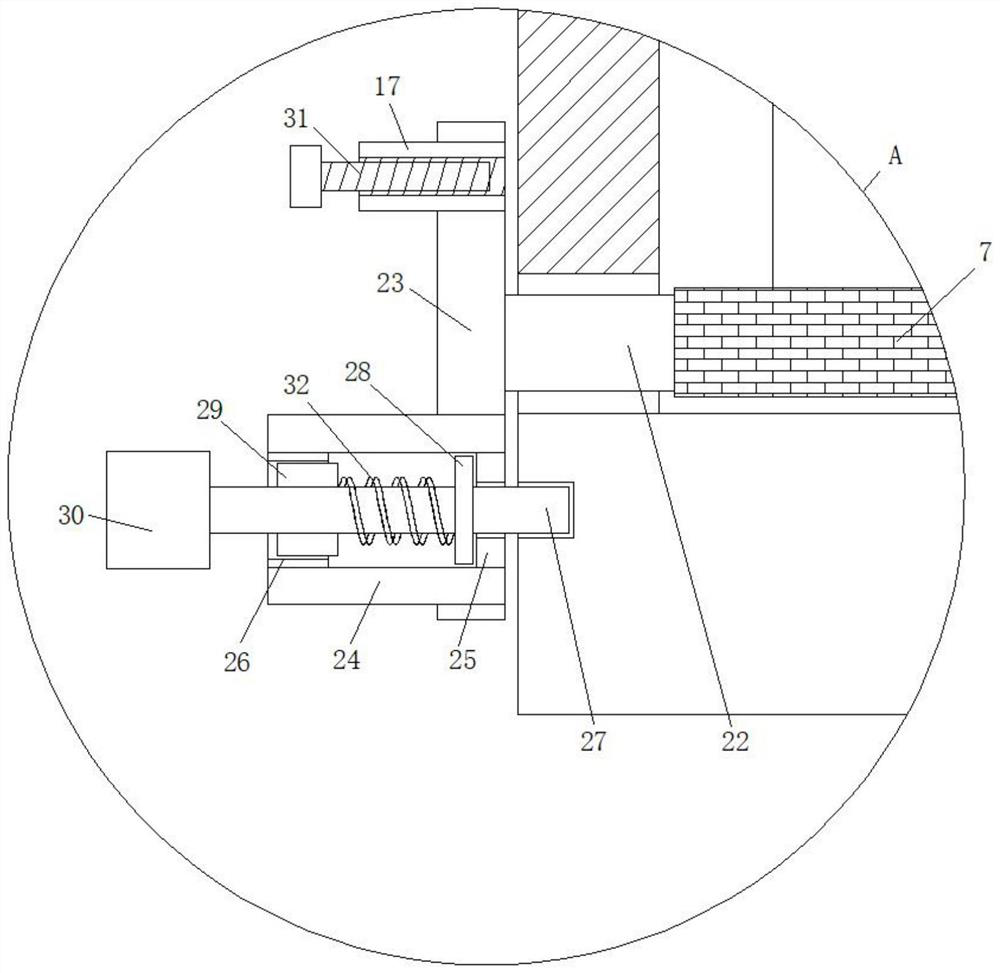

[0028] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the board bodies of outer control board one 15 and outer control board two 23 are provided with horizontal through holes two respectively and are fixedly connected with threaded barrel 17, and threaded barrel 17 is internally threaded. A locking bolt 31 is connected.

[0029] In this embodiment, the locking bolt 31 on the side of the outer control board 15 is used when the workbench not only needs to locate the circular mechanical parts, but also needs to fix them.

Embodiment 3

[0031] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the closed rail enclosures 11 are respectively arranged at an included angle relative to the sliding holes.

[0032] In this embodiment, the closed track coaming plate 11 can push the positioning clamp bar 6 to slide in the sliding hole when it is orbiting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com