A new type of metal feeder

A feeding machine and feeding mechanism technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of inconvenient adjustment of the size and thickness of conveyed products, and inability to apply to the processing of various metal products, so as to reduce potential safety hazards, Strong practicability, safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention is an improvement on the existing feeding mechanism. First of all, the present invention improves the structure of the feeding mechanism so as to overcome the problems existing in the prior art. This is the innovation of the present invention. In the present invention, the feeding mechanism The mechanism is provided with two materials capable of bidirectional feeding, which improves work efficiency and is convenient for people to use. The structure and working principle of the present invention will be described in detail below.

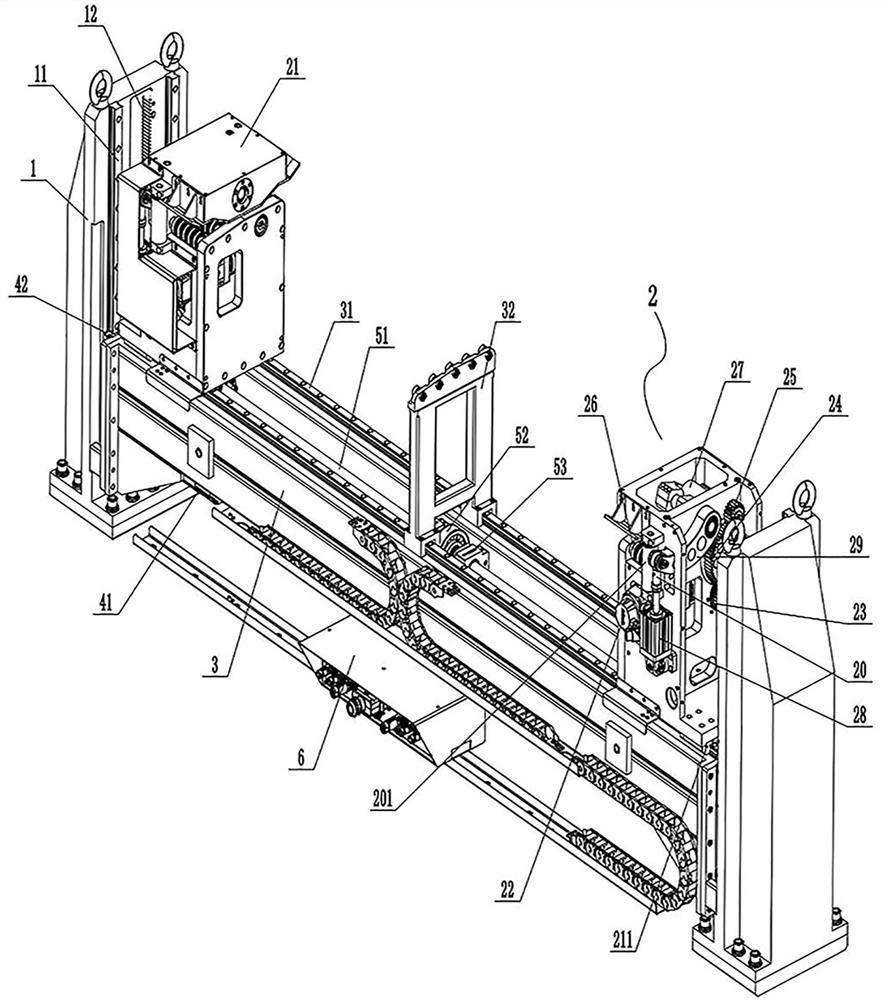

[0020]As attachedfigure 1 As shown, the present invention includes a lifting base 1, a feeding mechanism 2, a width adjusting device, a height adjusting device, and a main beam 3. The lifting base 1 is provided with two and symmetrically arranged at both ends of the main beam 3. The feeding mechanism 2 is provided with two and symmetrically arranged above the main beam 3, above the main beam 3 is provided with a clamping rail 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com