Cloth winding device with anti-deviation structure and for textile product production

A winding device and anti-deviation technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of untimely tension regulation and deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

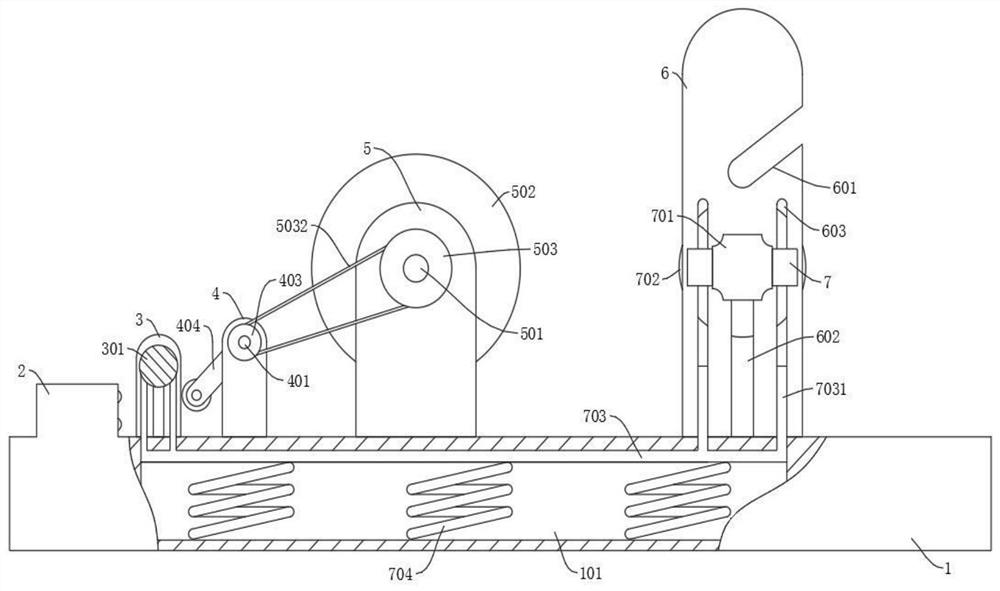

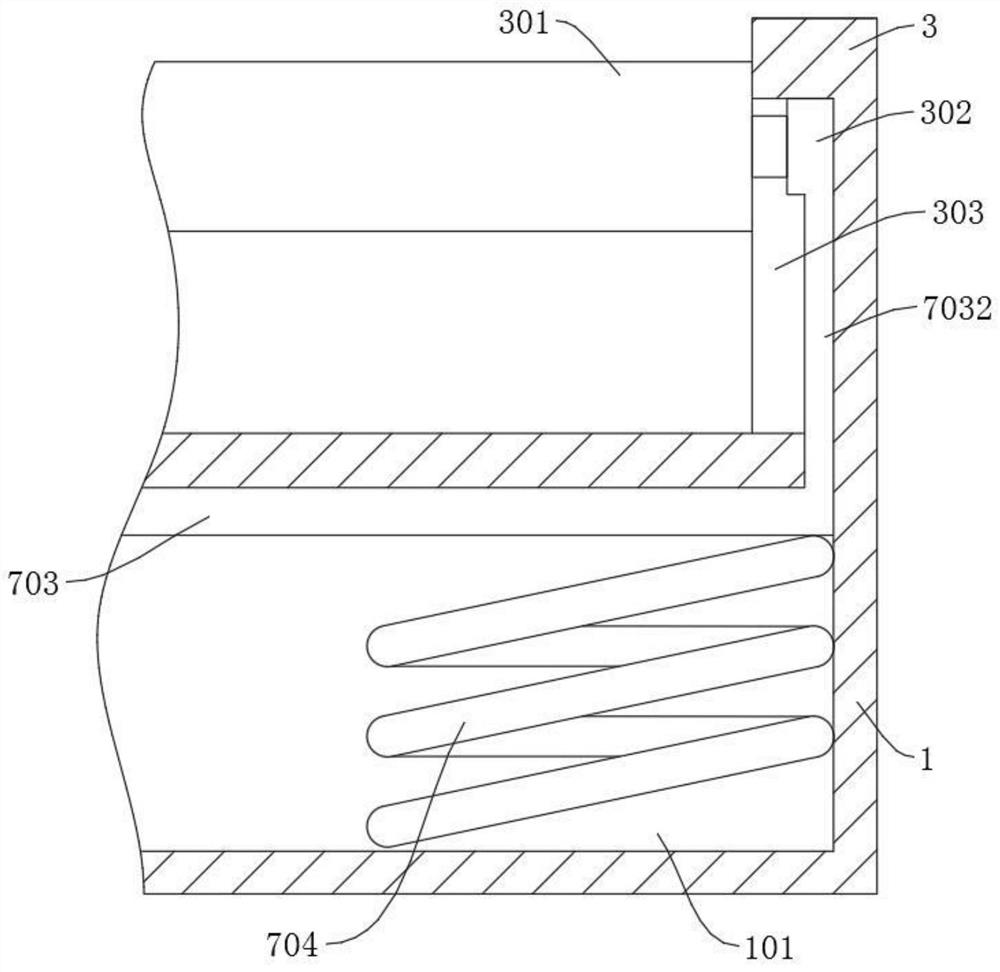

[0029] refer to figure 1 with Figure 4-7, a cloth winding device with an anti-deviation structure for the production of textile products, including a base 1, on which a guide table 2, a first mounting column 3, and a second mounting column 4 are arranged in sequence from left to right , the third installation column 5 and the fourth installation column 6, the guide roller 201 is rotatably connected to the guide table 2, the first installation column 3 is provided with an auxiliary mechanism, the second installation column 4 is provided with a first installation groove 4011, and the second installation column 4 is provided with a first installation groove 4011. A first rotating shaft 401 is rotatably connected in a mounting groove 4011, and one end of the first rotating shaft 401 is fixedly connected with a swing rod 404, and an adjustment roller 402 is rotatably connected to the swing rod 404, and a torsion spring 4012 is sleeved on the first rotating shaft 401. The two ends...

Embodiment 2

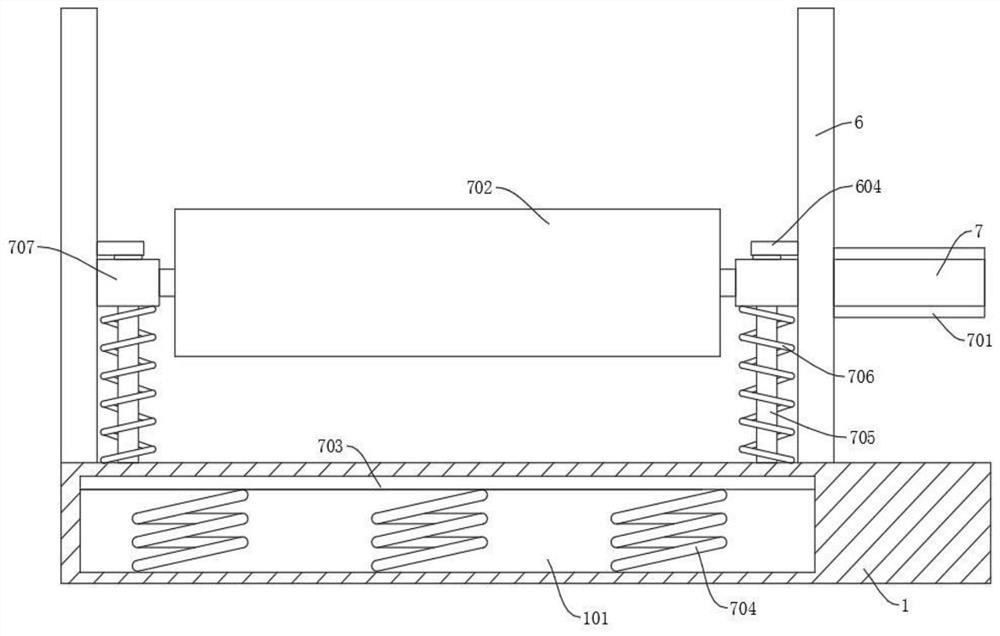

[0032] refer to Figure 1-3 , is basically the same as Embodiment 1, and furthermore, the winding mechanism includes a lifting base 7 and a driving motor 701, the driving motor 701 is fixedly connected to the lifting base 7, and the fourth mounting column 6 is provided with a second chute 602, The lifting seat 7 is slidingly connected in the second chute 602, and the lifting seat 7 runs through the second chute 602 and is fixedly connected with a lifting block 707. The lifting block 707 is rotatably connected with a driving roller 702, and the driving roller 702 is fixedly connected to the drive motor 701. At the output end, a slide bar 705 is fixedly connected to the base 1, a limit block 604 is fixedly connected to the fourth mounting column 6, the top of the slide bar 705 is fixedly connected to the limit block 604, and a second spring is sleeved on the slide bar 705 706, the two ends of the second spring 706 are respectively against the base 1 and the lifting block 707, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com