Gluing device and gluing method for large-size flower type reflective patterns

A pattern and pattern technology, applied in the field of large pattern fancy reflective pattern gluing device, can solve problems such as uneven depth, glue overflow, change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

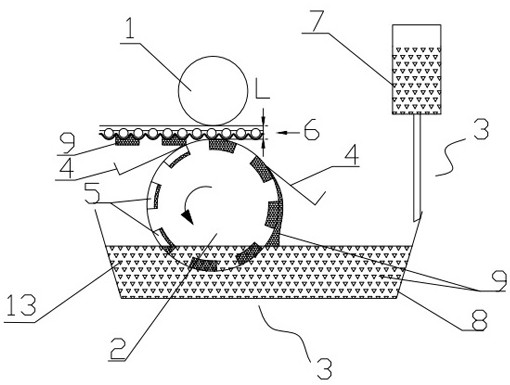

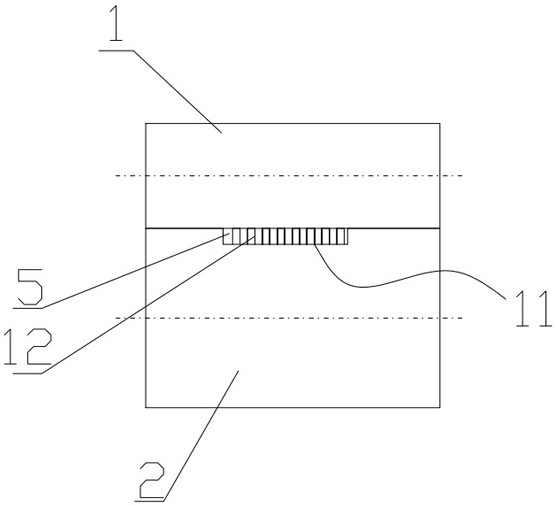

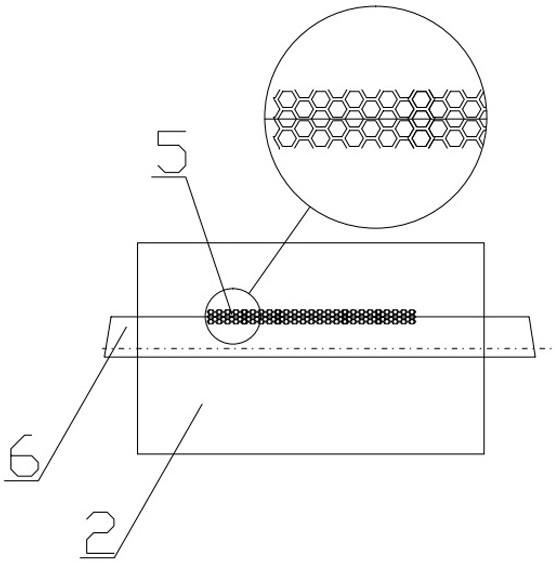

[0039] exist figure 1 In the shown embodiment, a large pattern fancy reflective pattern gluing device includes an upper pressing roller 1, a gravure upper rubber roller 2, a squeegee and a glue supply mechanism for storing and providing glue. The squeegee knife is located on one side of the gravure upper rubber roller 2, and the blade of the squeegee is in contact with the surface of the gravure upper rubber roller 2. The surface of the gravure upper rubber roller 2 is provided with a pattern 11, and the gravure upper rubber roller 2 is placed In the glue supply mechanism and in contact with the glue in the glue supply mechanism; the flower pattern 11 is divided into a number of micro polygonal structure grooves 5 or combined by a number of micro polygon structure grooves 5, the micro polygon structure The grooves 5 are blocked by micro-thin walls 12, and the micro-thin walls 12 are connected to each other. The flower pattern 11 fills the micro-thin walls 12 through the leveli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com