Tire burst test platform

A test platform and tire blowout technology, which is applied in the direction of automobile tire testing, vehicle testing, machine/structural component testing, etc., can solve the problem that wheel hub drilling affects the safety of tire blowout testing and training, and the tire blowout device is difficult to meet the requirements of bursting equipment. The tire deflation time requirement, the puncture device can not test the front wheel and the rear wheel independently, etc., so as to improve the accuracy of tire blowout, change the speed and time of take-off and landing, and use flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

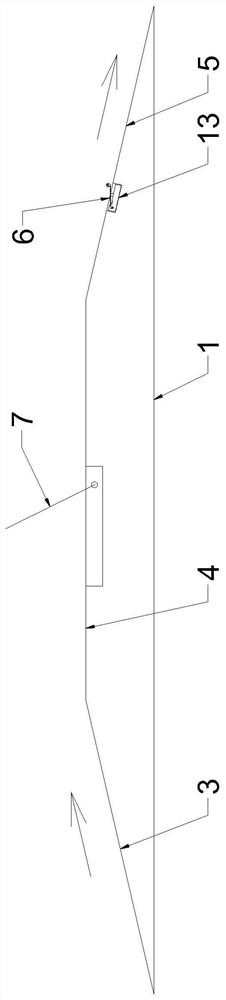

[0028] like Figure 1 to Figure 6 As shown, the present embodiment provides a tire blowout test platform, including a platform body 1 and a tool holder 2, please refer to figure 1 , the cross section of the platform body 1 is trapezoidal, the platform body 1 successively includes an upslope surface 3, a test surface 4 and a downslope surface 5, the test surface 4 is preferably a horizontal plane, the tool holder 2 is installed on the test surface 4, and the micro switch 6 Installed on the downslope 5.

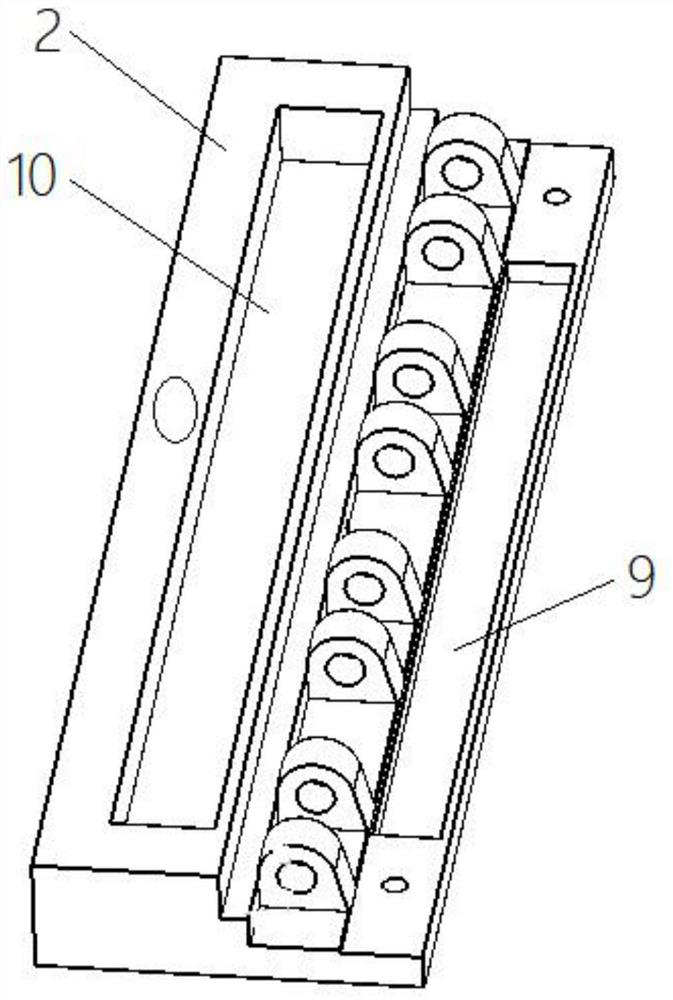

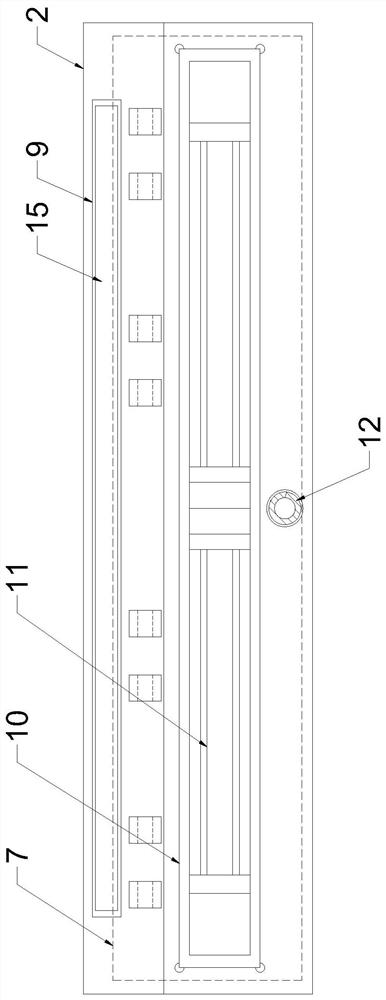

[0029] Specifically, such as figure 2 and image 3 As shown, the test surface 4 of the platform body 1 is provided with a knife seat groove, and the knife seat 2 is embedded in the knife seat groove; the knife seat 2 is hinged with a piercing body 7 with a sharp end through a hinge, and the hinge can be Choose a spring hinge with a fixed angle, which can fix the piercing body 7 at a specific angle of inclination, so that the piercing body 7 stands obliquely in the direction...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap