Movable assembly type livestock house

A prefabricated, livestock technology, used in animal houses, poultry cages or houses, and poultry farming, etc., can solve the problems of sudden local stress and instability, and achieve position transfer, simple and stable assembly structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

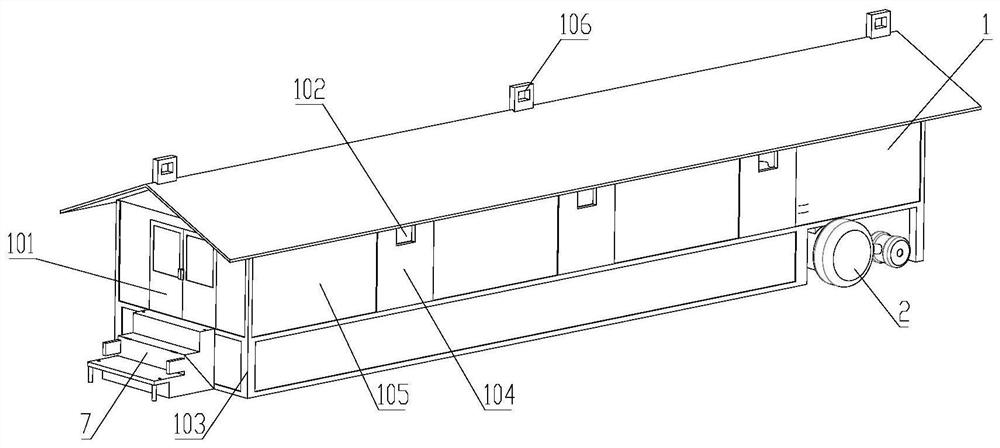

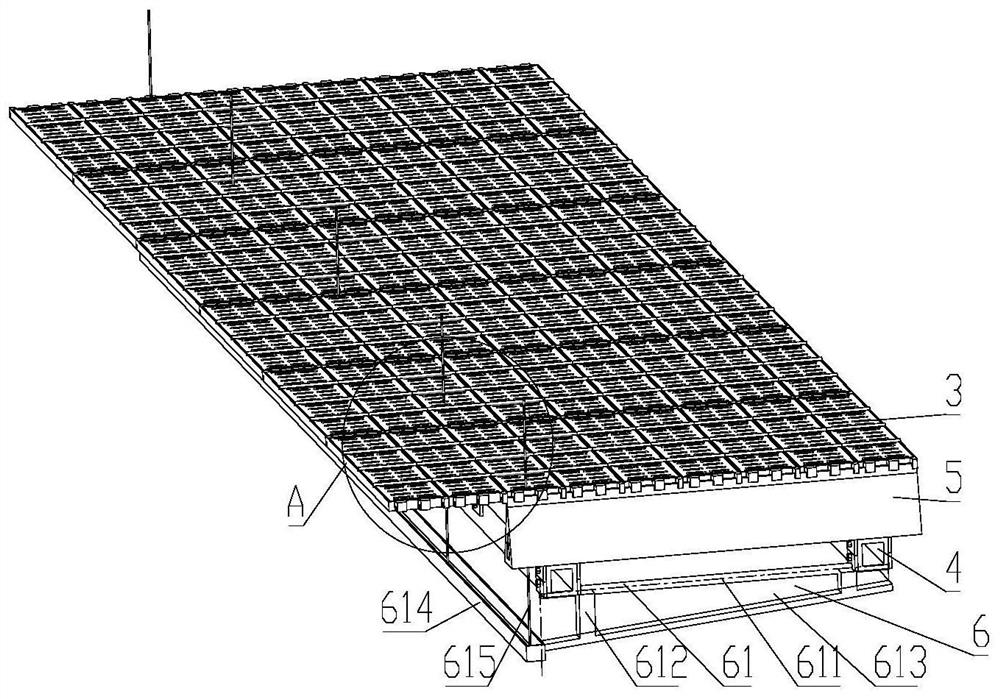

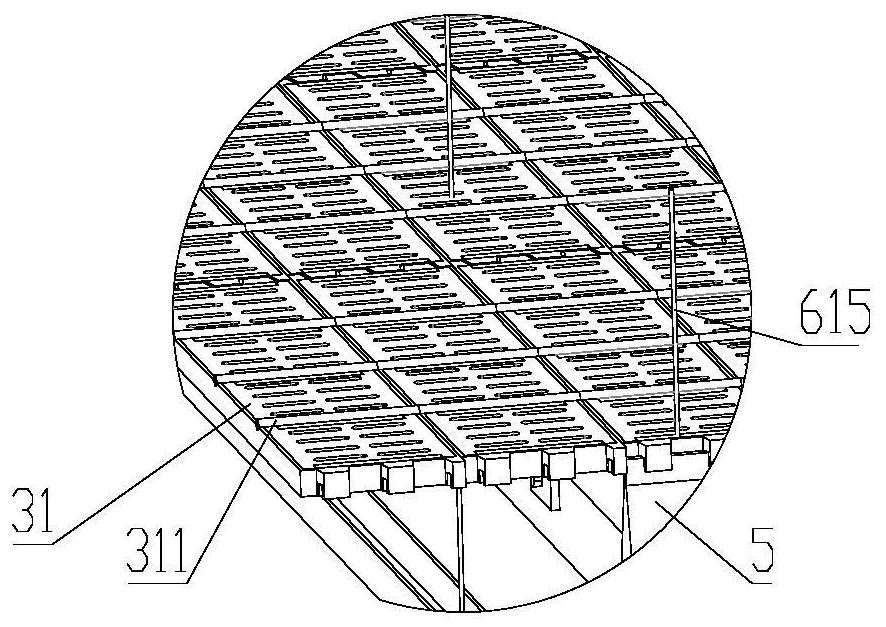

[0064] see Figure 1 to Figure 5 , The present invention provides a mobile assembled poultry and livestock house, including a main body 1 with a ridged roof, the lower part of the main body 1 is a rectangular body corresponding to the amount of transport vehicles, the side wall of the main body 1 is provided with a house door 101, ventilation The window 102 and the ventilation components, the main body 1 is provided with a breeding column, and a channel is set on one side of the breeding column; the interior of the breeding column is provided with an automatic feeding device and a water line for feeding feed, the main body 1 includes a frame 103, and the frame 103 includes upper and lower settings The lower rectangular frame is used as the bottom of the main body 1, the upper rectangular frame is used as the supporting structure of the floor of the cultivation space of the main body 1, and the bottom plate of the cultivation space is a mesh structure; The short vertical pole i...

Embodiment 2

[0086] see Figures 6 to 9 , on the basis of Embodiment 1, the mobile assembly 2 includes a suspension plate 201 fixedly connected to the inside of the main body 1, and the lower side of the suspension plate 201 is fixedly connected to the fixed cylinder 203 through a hook 202; the suspension plate 201 and the hanger 202 only need It is sufficient to have sufficient supporting force for the lower fixing cylinder 203, the specific structure is not limited, only the existing connection structure can be used to cooperate with the strengthening structure to ensure that when the lower fixing cylinder 203 is lifted upwards, this part has sufficient supporting force . In other words, the connection between the fixed cylinder 203, the hook 202 and the suspension plate 201 is a fixed structure. This part only requires physical strength and does not need to involve mobility. Therefore, there is no difficulty in design and implementation, and it can be guaranteed The reliability of the ...

Embodiment 3

[0108] see Figure 10 and Figure 11 , on the basis of Embodiment 2, the side of the main body 1 provided with the door 101 is provided with a step group 7 and the step group 7 is located outside the side wall of the main body 1;

[0109] The number of ladders in the ladder group 7 is an odd number, and the ladder group 7 is composed of divided upper ladders 71 and lower ladders 72. The upper ladders 71 and the lower ladders 72 are combined into a complete ladder group. The dividing line between the upper ladders 71 and the lower ladders 72 is The oblique line from the outer corner of the ladder in the middle of the ladder group 7 to the bottom of the ladder group 7;

[0110] The upper step 71 and the lower step 72 divide the step in the middle of the step group 7 into two triangular parts, and the upper step 71 and the lower step 72 are hinged at the middle step of the split; the upper step 71 is fixedly connected to the outer surface of the main body 1;

[0111] A boss 73 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com