A curved glass detection system and method

A curved glass and detection system technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of long detection time for curved glass, incomplete detection defect coverage, and incomplete detection coverage, etc., to avoid detection Incomplete, fast detection, and comprehensive coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. The following is exemplary by way of reference to the accompanying drawings, and is intended to be construed as limiting the invention. Further, the detailed description of the known technique is omitted to illustrate the features of the invention, it is omitted.

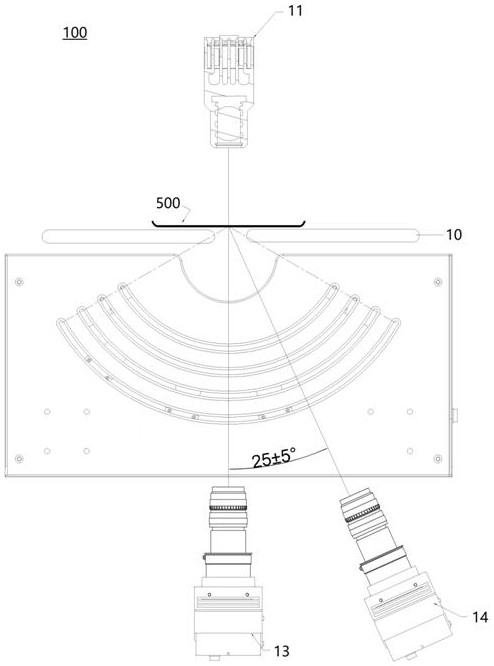

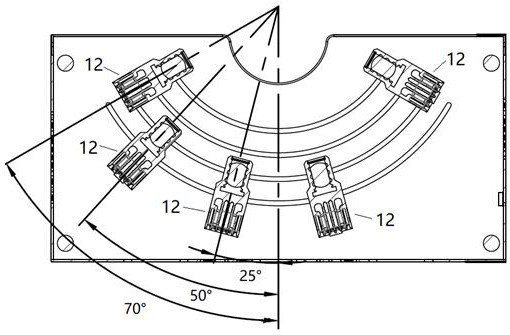

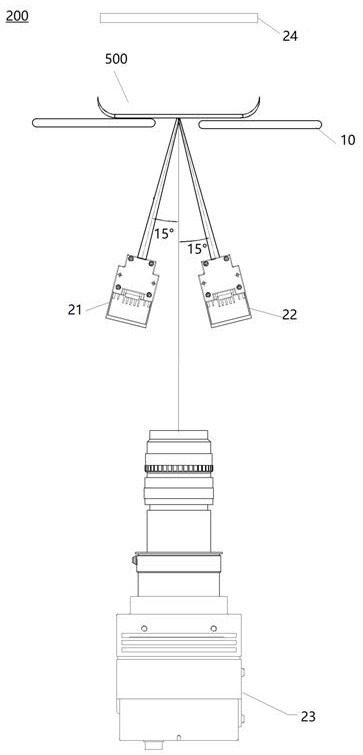

[0043] Please refer to Figure 1 to 5 The embodiment of the present invention provides a curved glass detection system. The curved cross-cross detection system includes: a surface glass control platform, a glass planar portion detection station, a glass surface portion detection station, a light source control module, and a detection analysis module, that is, a planar + curved structure for curved glass, the system Corresponding to a glass plana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com