Shoelace-tying-free safety shoes

A technology for safety shoes and tying shoelaces, which is applied to footwear, shoe bindings, clothing, etc., can solve problems such as falls, and achieve the effect of solving falls and being easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

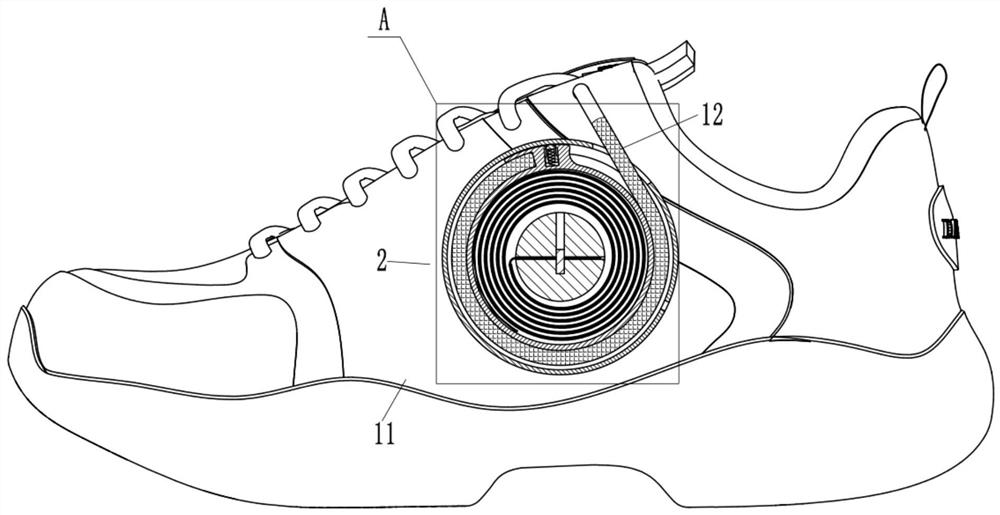

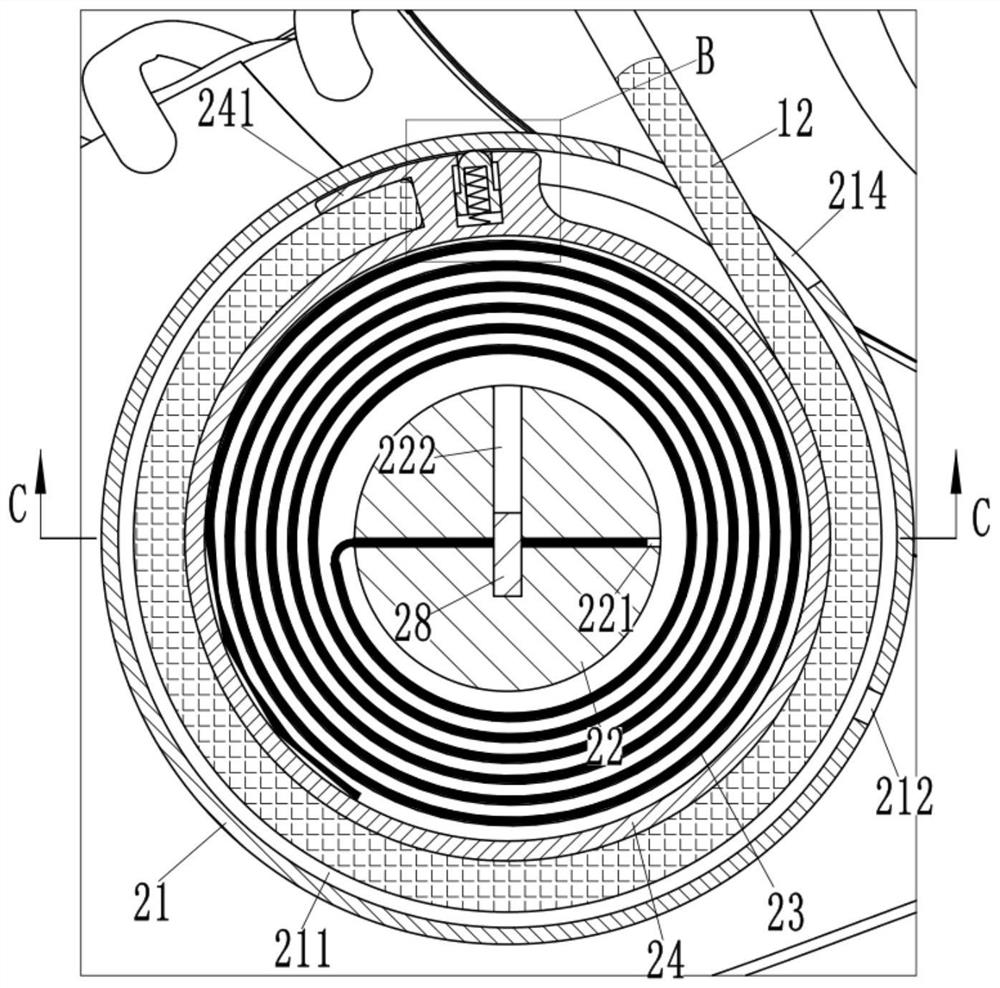

[0019] Examples such as Figure 1 to Figure 4 As shown, a kind of labor insurance shoe without tying shoelaces includes a shoe upper 11 and a shoelace 12, and a shoelace tensioner 2 is connected to each of the two ends of the shoelace 12;

[0020] The shoelace tensioner 2 includes a base plate 21 fixed on the shoe upper 11. The base plate 21 is provided with a tape receiving chamber 211. The base shaft 22 is fixed in the tape receiving chamber 211. The base shaft 22 and the clockwork spring 23 One end is fixedly connected, and the other end of clockwork spring 23 is fixed on the inner wall of tension wheel 24, and the outer wall of tension wheel 24 is formed with shoelace fastening seat 241, and one end of described shoelace 12 passes through base plate 21 The notch 214 is fixed on the shoelace fastening seat 241 around the extended end of the tensioning wheel 24 .

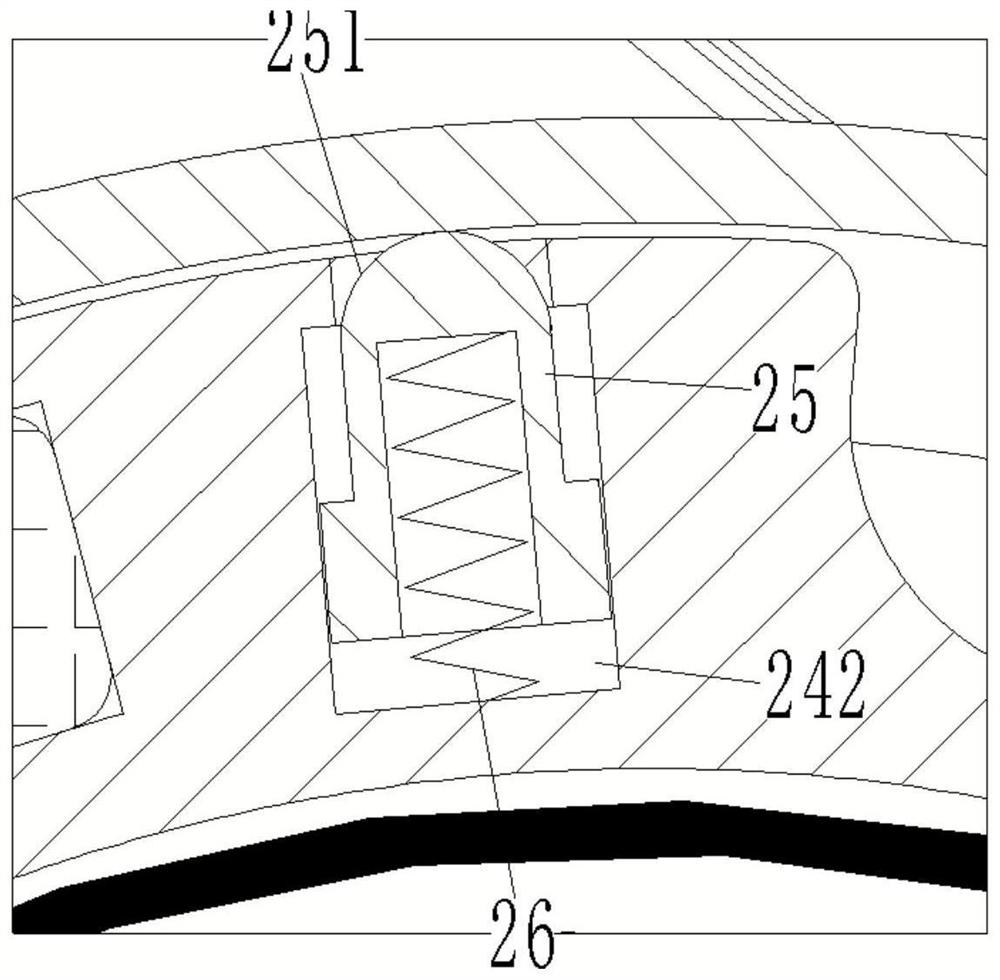

[0021] Furthermore, the shoelace tensioning seat 241 is formed with a stepped hole 242 with a small outside an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com