Vertical deformation and differential deformation control method of super high-rise structures

A technology of vertical deformation and differential deformation, which is applied in instrumentation, geometric CAD, design optimization/simulation, etc., can solve the problems of inconvenient simulation of vertical deformation differential deformation of super high-rise buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

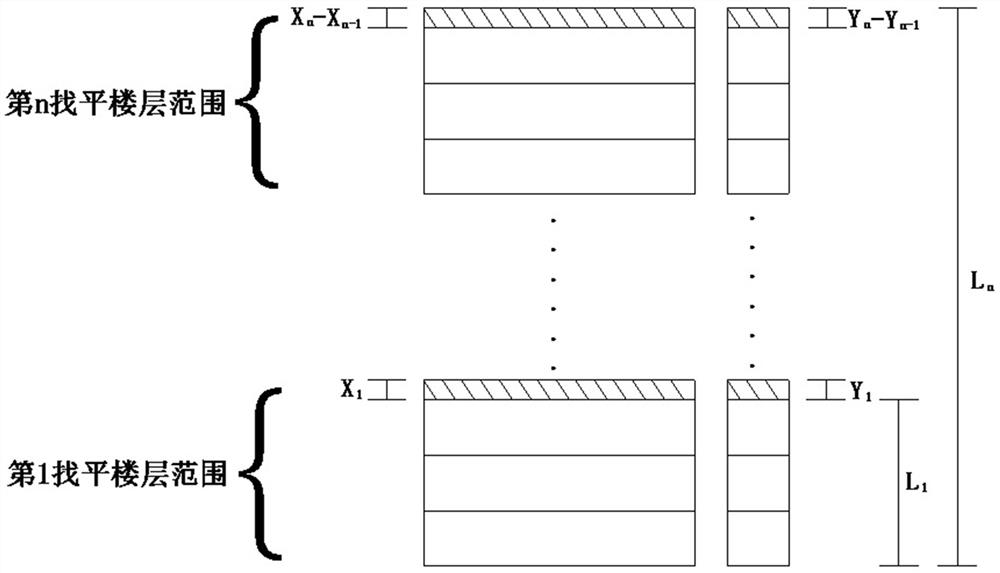

[0040] refer to figure 1 , the present embodiment provides a method for controlling vertical deformation and differential deformation of a super high-rise structure, the technical solution is as follows, including the following steps:

[0041] S1. Determine the structural model according to the drawings, the structural model includes a core tube model and a frame column model;

[0042] S2, according to the actual working conditions, determine the position of each leveling floor in the structural model;

[0043] S3, take the leveling floor as the dividing line, and build the structural model from bottom to top;

[0044] S4, when the structural model is established to the position of the nth leveling floor, calculate and obtain the height L of the structural model after deformation n , core tube model deformation value X n , and the frame column model deformation value Y n ;X n The overall deformation value of the core tube model when the structural model is established to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com