Defrosting device for refrigeration equipment

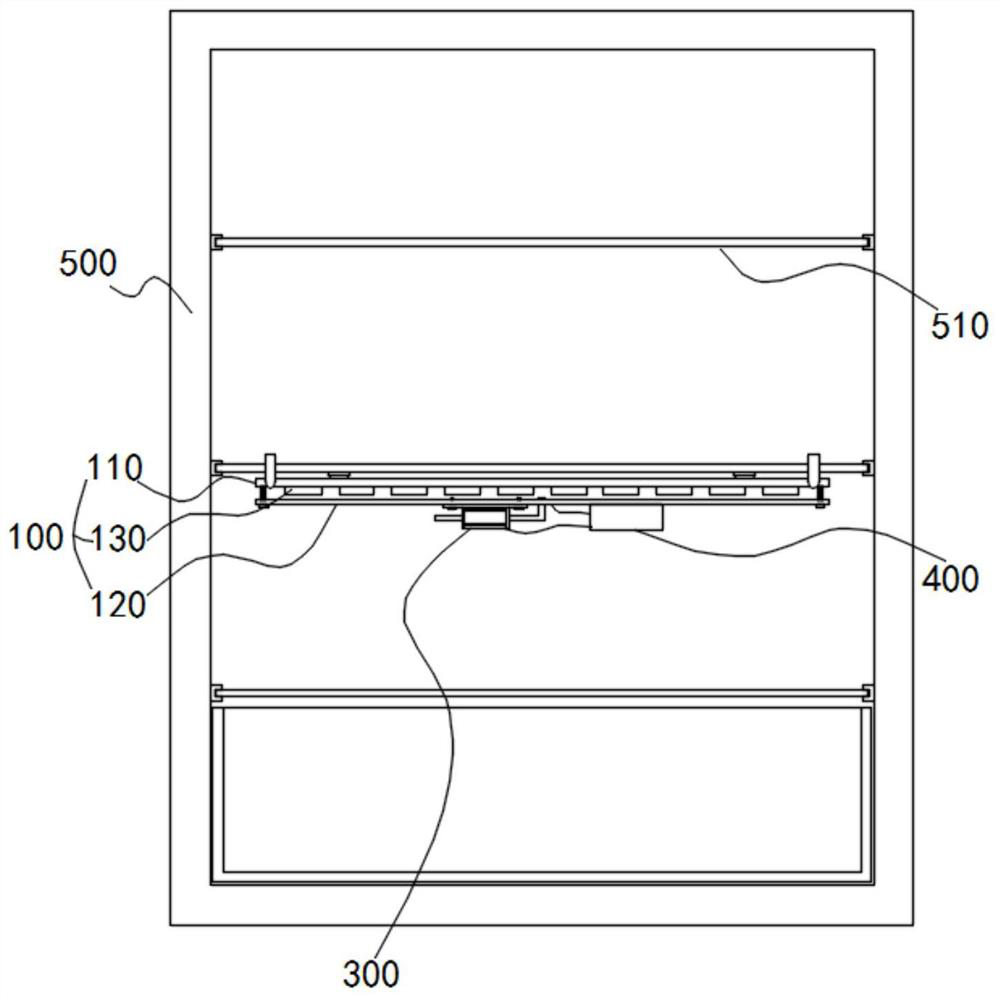

A technology of refrigeration equipment and cavity placement, which is applied to household refrigeration equipment, lighting and heating equipment, defrosting, etc., which can solve the problems of inconvenient maintenance, inability to use, and lack of defrosting function, and achieve the effect of easy maintenance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

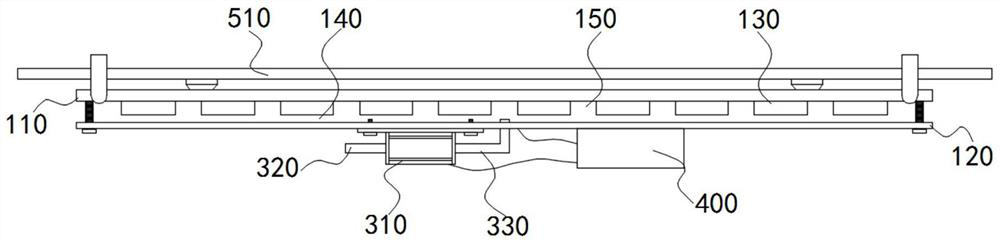

Method used

Image

Examples

Embodiment 1

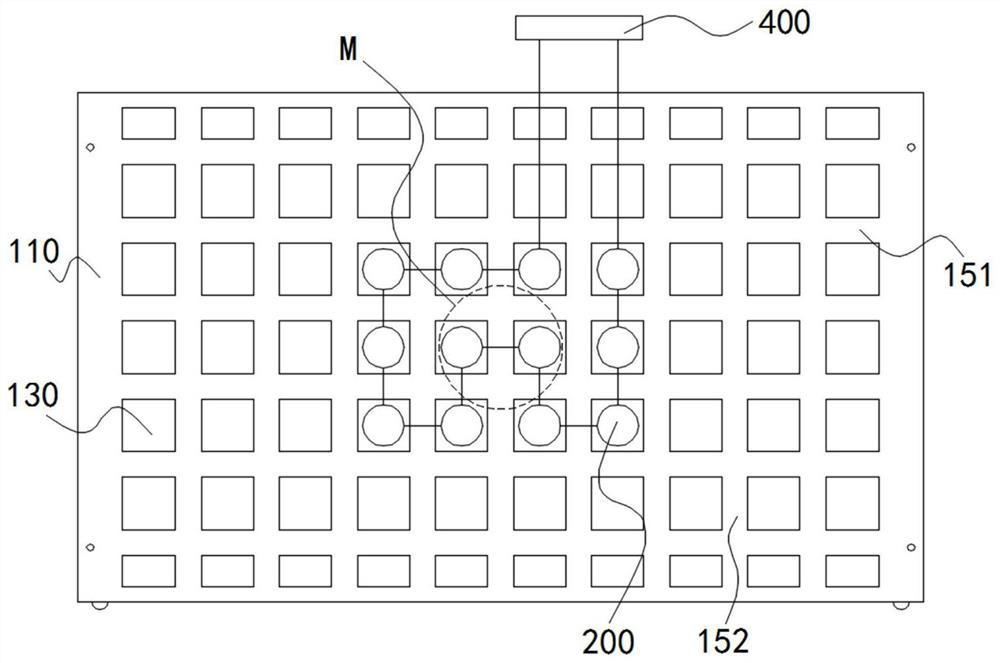

[0045]Such asimage 3 As shown, a plurality of electric heating devices 200 are concentrated at the center of the cover 120, that is, at the air outlet of the air supply assembly 300. The area where the air supply assembly 300 blows into the air guide gap 140 is the area M. When the assembly 300 blows air, the air entering the air guide gap 140 is directly heated by a plurality of electric heating devices 200, and hits the connecting plate 110, and diffuses from the area M to the surroundings.

Embodiment 2

[0047]Such asFigure 7 As shown, a plurality of electric heating devices 200 are arranged along the central circumference of the cover plate 120. When the air blowing assembly 300 blows air, the area where the air blowing assembly 300 blows into the air guiding gap 140 is the area M and enters the air guiding gap 140 The air hits the connecting plate 110 and diffuses from the area M to the surroundings. The air diffused to the surroundings is heated by a plurality of electric heating devices 200.

Embodiment 3

[0049]Such asFigure 8 As shown, a plurality of electric heating devices 200 are centrally arranged and arranged staggered from the air outlet of the air supply assembly 300. When the air supply assembly 300 delivers air, the area where the air supply assembly 300 blows into the air guide gap 140 is the area M. The air entering the air guide gap 140 hits the connecting plate 110, and the air flow diffused from the area M to the surroundings, only one direction of air flow will be heated by the multiple electric heating devices 200, and the air flow in the other directions will be directly discharged from the air guide gap 140 .

[0050]It can be understood that the arrangement of the plurality of electric heating devices 200 is not limited to the arrangement of the above three embodiments. For example, some of the electric heating devices 200 are all facing the air outlet of the air supply assembly 300, and the other The electric heating device 200 and the air outlet of the air blowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com