Novel steel rail anti-climbing device

An anti-dropping device and a technology for steel rails, applied in the field of rail transit, can solve the problems of loosening of the anti-climbing device, failure of anti-climbing, poor elasticity of cast iron, etc., and achieve the effects of convenient maintenance and disassembly, high equipment reliability, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

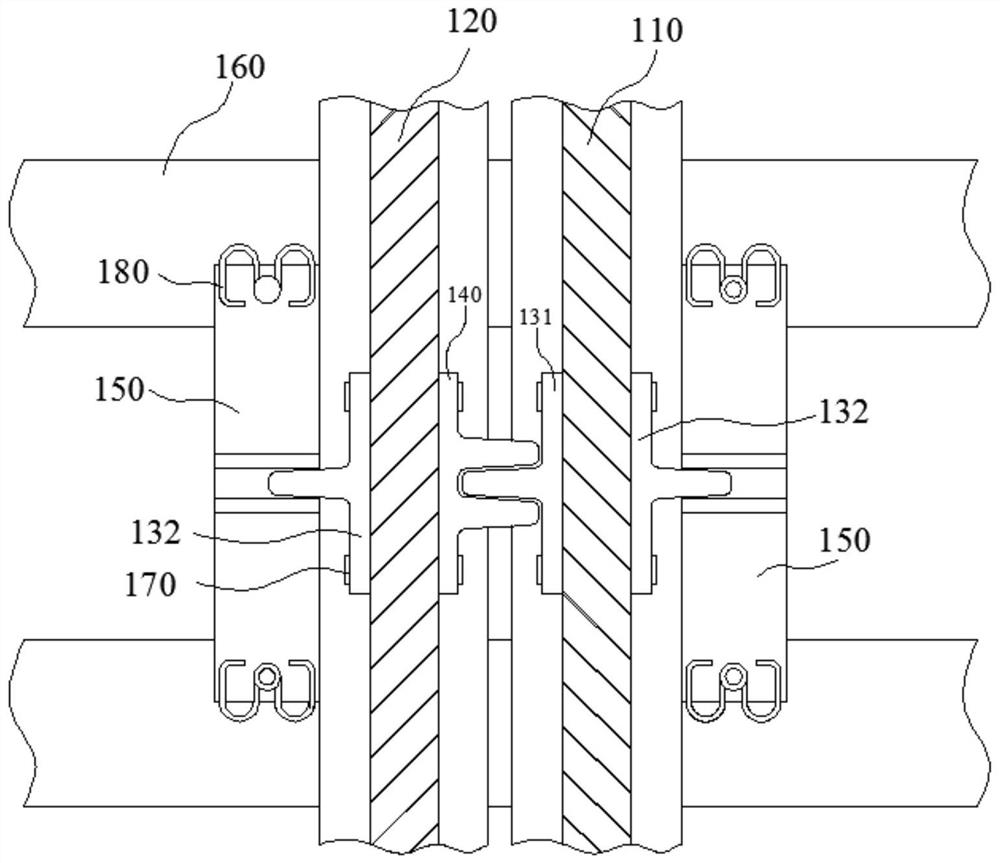

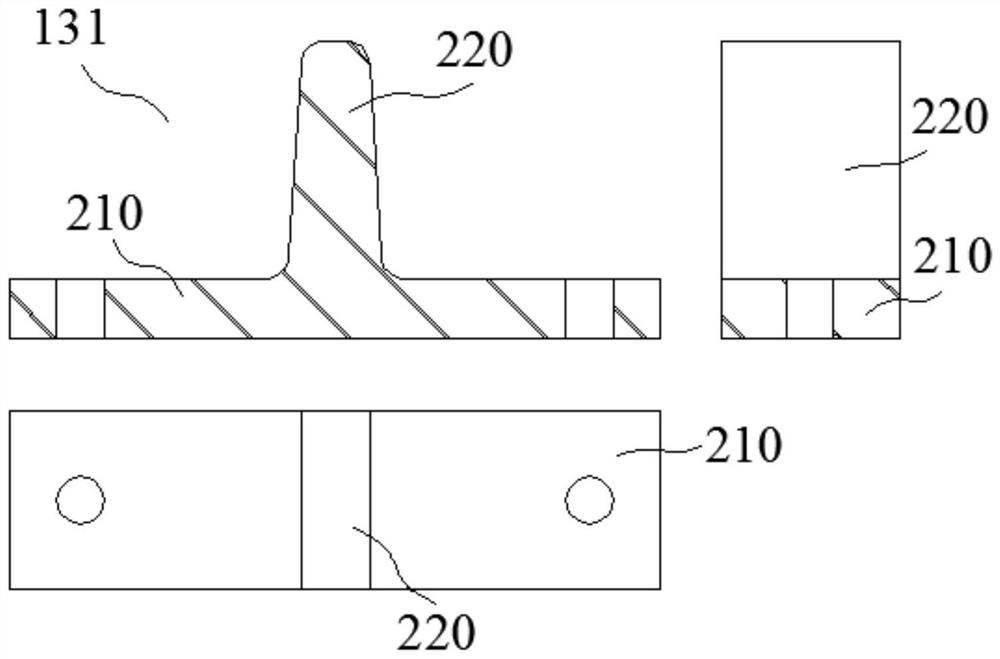

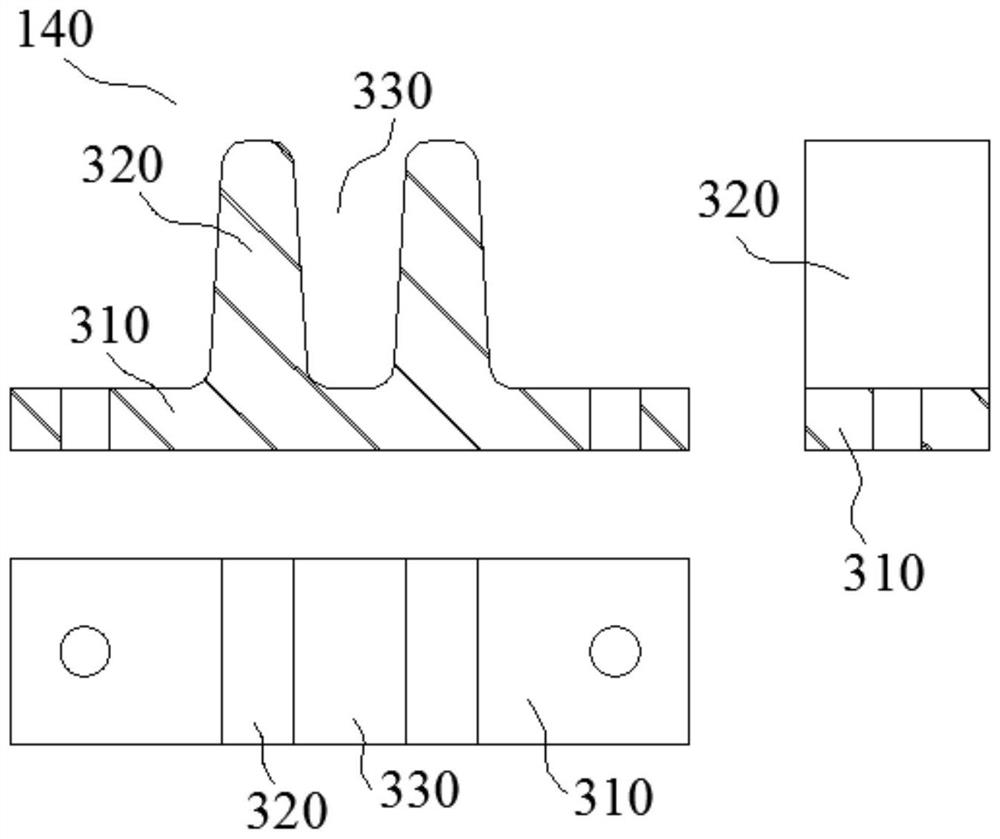

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment provides a novel anti-climbing device for rails, which includes a basic rail 110 and a switch rail 120, the basic rail 110 and the switch rail 120 are installed on the sleeper 160; the inside of the basic rail 110 is fixed with a first limit device 131, the inner side of the tip rail 120 is fixed with an anti-off device 140, and the anti-off device 140 cooperates with the first limiting device 131; The positioning device 132 is matched with a fixing device 150 , and the fixing device 150 is fixed on the sleeper 160 .

[0022] Through the cooperation of the first limiting device 131 and the anti-off device 140, and through the cooperation of the second limiting device 132 and the fixing device 150, the middle switch rail 120 of the turnout is not easy to crawl, and the reliability of the equipment is high, and the damage is easy to be found and damaged. replace.

[0023] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com