Fixing and cutting all-in-one machine special for building special-shaped steel

A special-shaped steel, all-in-one technology, used in grinding frames, grinders, grinding/polishing equipment, etc., can solve the problems of poor cutting safety, single fixing mechanism, poor adaptability, etc., to achieve high safety, simple operation, Easy to adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

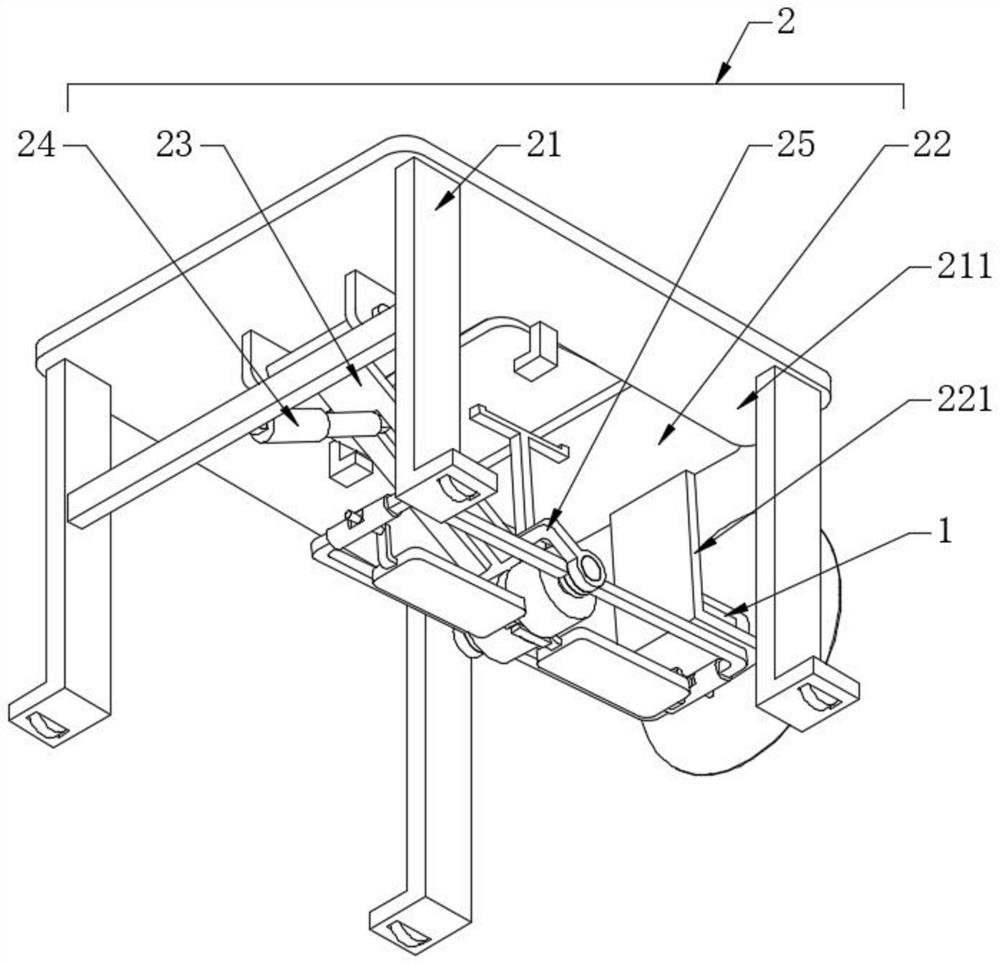

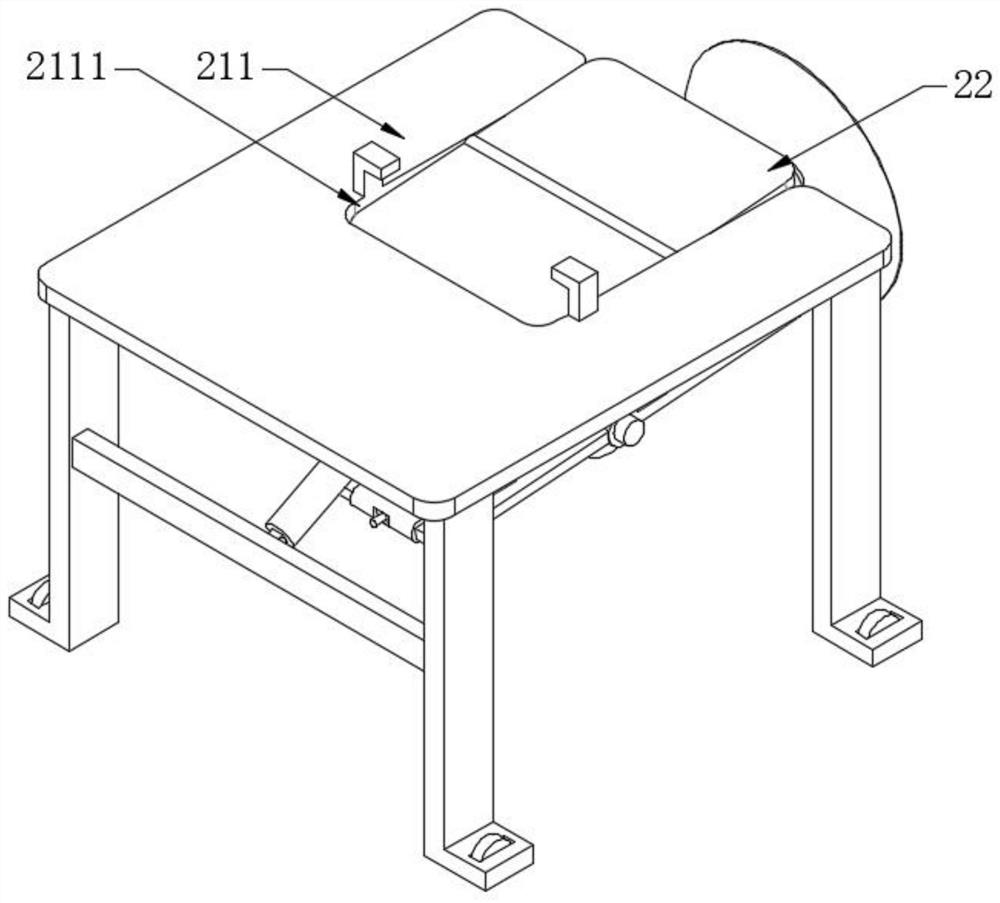

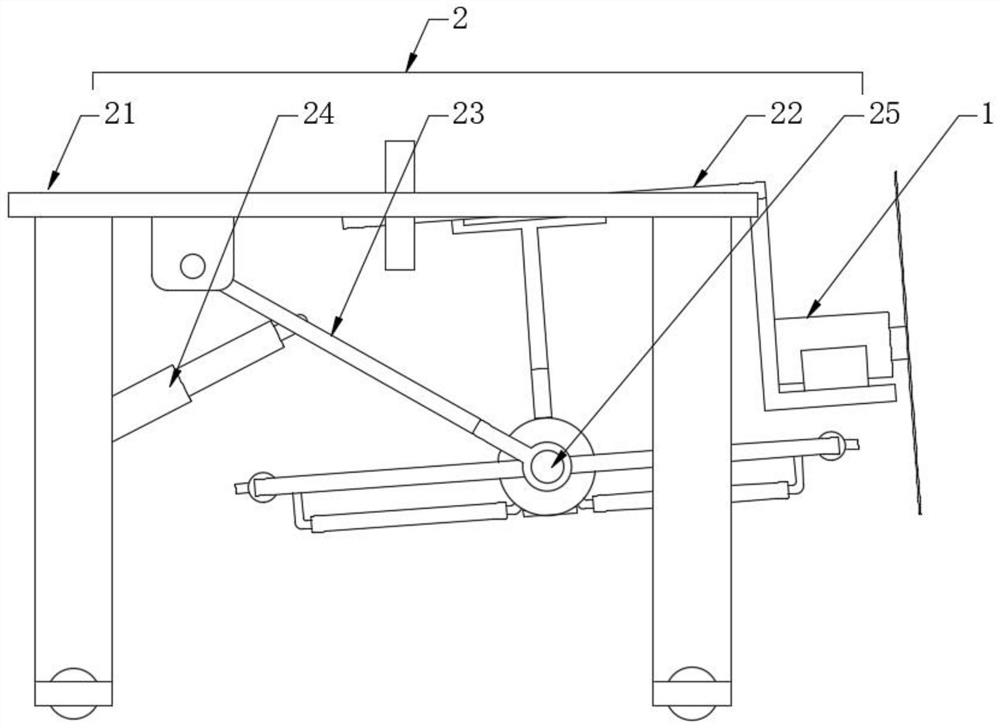

[0031] see Figure 1-5, an all-in-one fixed cutting machine dedicated to special-shaped steel for construction, including a rocker arm type cutting machine 1 and a bearing part 2. In this embodiment, the rocker arm type cutting machine 1 selects a common pressing type grinding wheel type cutting machine (the handle is not shown in the figure). display), the downward movement of the slice is controlled by pressing the handle; the bearing part 2 is used to support the cutting machine on the one hand, and the special-shaped steel on the ground is extracted and fixed on the other hand; the bearing part 2 includes a walking guide frame 21, a cutting machine connecting plate 22. The lifting arm 23, the oil cylinder 24 and the magnetic connection combination 25, the walking guide frame 21 can walk on the ground, the bottom is provided with guide wheels, the top of the walking guide frame 21 is provided with a bearing plate 211, and one end of the bearing plate 211 is provided with a s...

Embodiment 2

[0033] see Image 6 , in the embodiment 1, the extraction, clamping, fixing and cutting of the special-shaped steel are realized. After cutting, it is convenient to move the position. The difference between this embodiment and the embodiment 1 is that the magnetic connection combination 25 also includes a sliding sleeve 255 and a traction rod 256. , the sliding sleeve 255 is sleeved on the vertical rod 25421 of the T-shaped strut 2542, the door-type connecting frame 252 is provided with a pulling rod 2522, and the pulling rod 2522 is hinged through the pulling rod 256 and the outer wall of the sliding sleeve 255, and the magnetic connection combination 25 is also It includes a two-way ratchet drive sleeve 258 and a wire sleeve 257. The wire sleeve 257 is screwed on the vertical rod 25421 and located below the sliding sleeve 255. By rotating the wire sleeve 257, the sliding sleeve 255 can be pushed up, and the sliding sleeve 255 rises to drive the two door types. The connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com