Patents

Literature

33results about How to "Easy to adjust the cutting position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

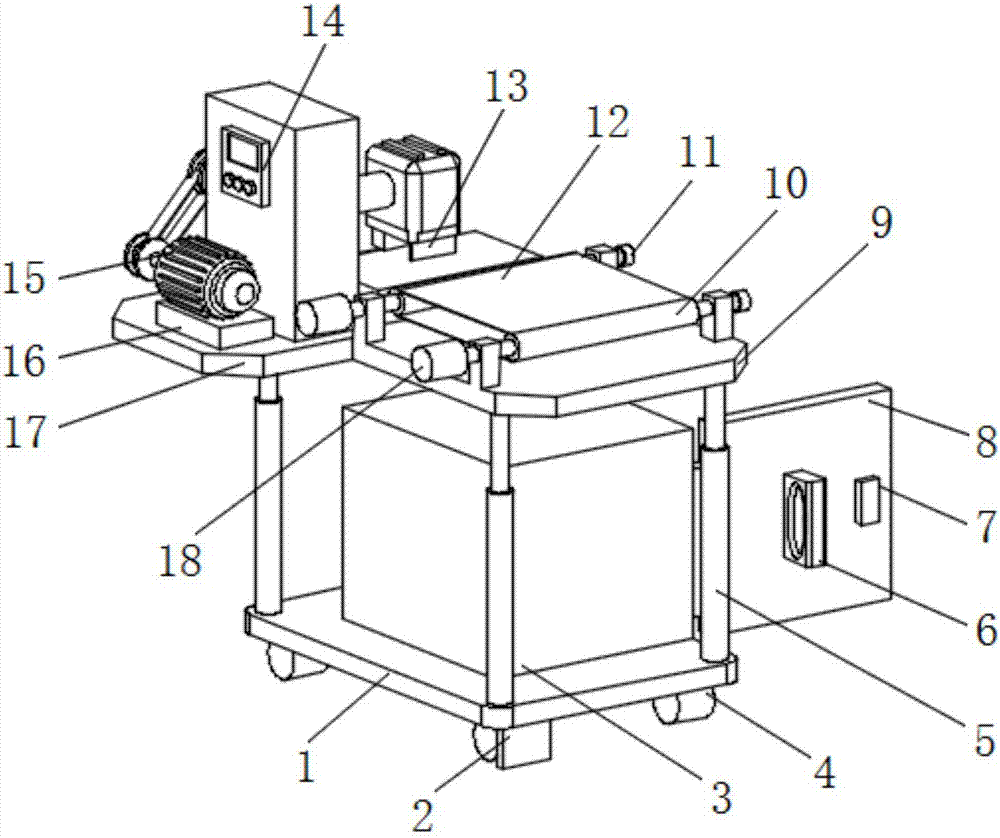

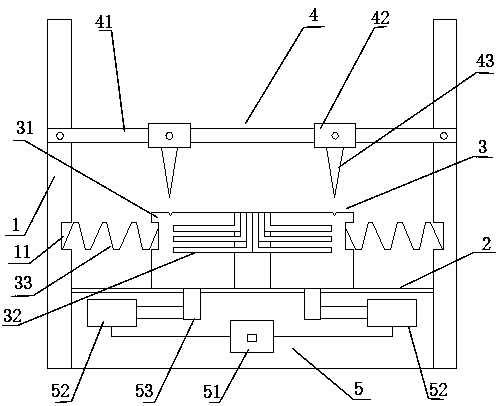

Vehicle accessory grinding tool shearing device for factories

PendingCN107457810AReasonable structurePracticalMetal working apparatusElectric machineMechanical engineering

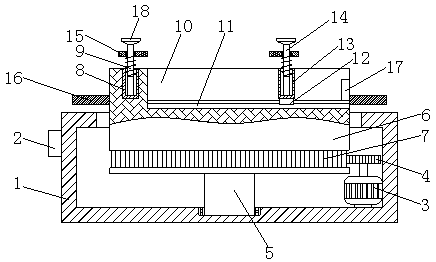

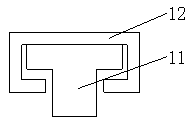

The invention discloses a cutting device for abrasive tools of auto parts used in factories, which comprises a bottom plate, four electric telescopic rods 1 are equidistantly arranged on the upper surface of the bottom plate, and a workbench is arranged on the top of the electric telescopic rod 1 . One end of the upper surface of the workbench is provided with a fixed plate, and a rotating shaft is connected between the fixed plates, and a servo motor is connected to one end of the rotating shaft. The abrasive tool shearing device for factory auto parts has a reasonable structure and strong practicability. , cut the auto parts through the shearing tool, positive and negative motor, rack and pinion, adjust the cutting position of the shearing tool through the electric telescopic rod 2, and conveniently transmit the auto parts through the servo motor, rotating shaft and conveyor belt , Improve the production efficiency, facilitate the placement of auxiliary tools through the tool box, facilitate the movement and braking of the device through universal wheels and brakes, and facilitate the adjustment of the height of the workbench through the electric telescopic rod, which is suitable for popularization and use.

Owner:张家辉

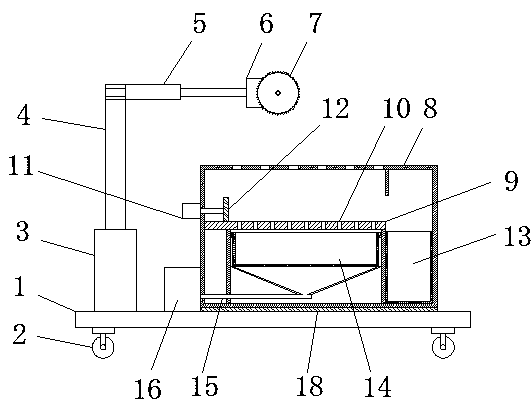

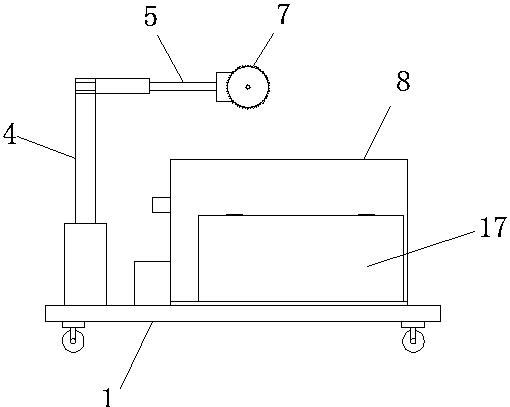

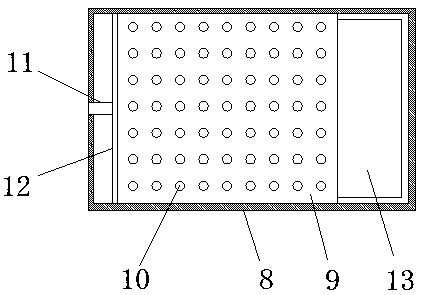

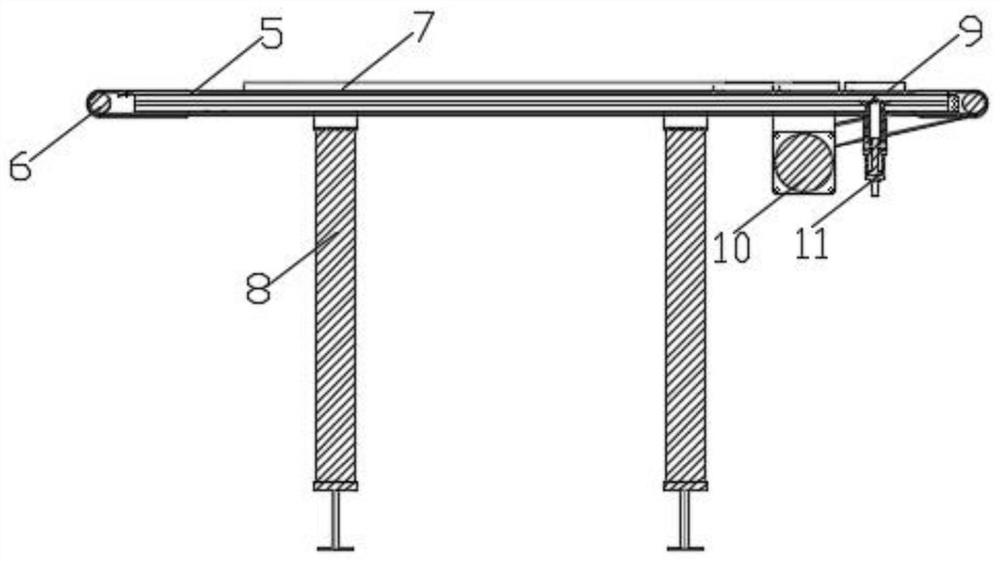

Aluminum cutting machine capable of conveniently recovering wastes

The invention discloses an aluminum cutting machine capable of conveniently recovering wastes. The aluminum cutting machine capable of conveniently recovering the wastes comprises a base and a front cover, wherein universal wheels are arranged under the base; a hydraulic lifting cylinder is arranged above the base; a lifting rod is arranged above the hydraulic lifting cylinder; an electric telescopic rod is arranged above the lifting rod; a cutting motor is arranged on the right part of the electric telescopic rod; a working table is arranged under a cutting blade; a baffle plate is arranged on the inner side of the working table; filter holes are formed above the baffle plate; an electric hydraulic rod is arranged on the left part of the baffle plate; a waste collecting box is arranged onthe right part of the baffle plate; a dust absorbing pipe is arranged under a mesh basket; a dust collector is arranged on the right part of the dust absorbing pipe; and the front cover is located infront of the working table. The aluminum cutting machine capable of conveniently recovering the wastes is provided with the filter holes, and the filter holes can distinguish and filter wastes in different sizes in the use process of the device, so that the device can conveniently classify and recover the wastes in different sizes.

Owner:宁夏丝路征信有限公司

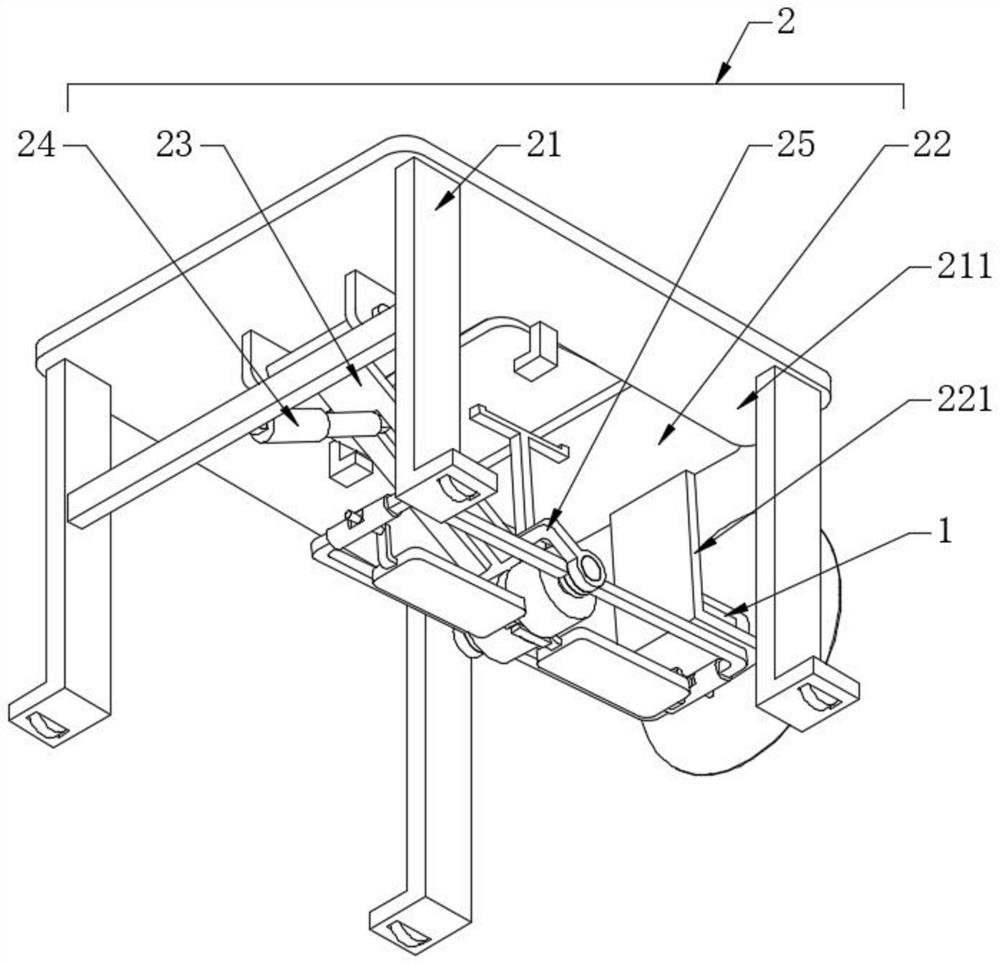

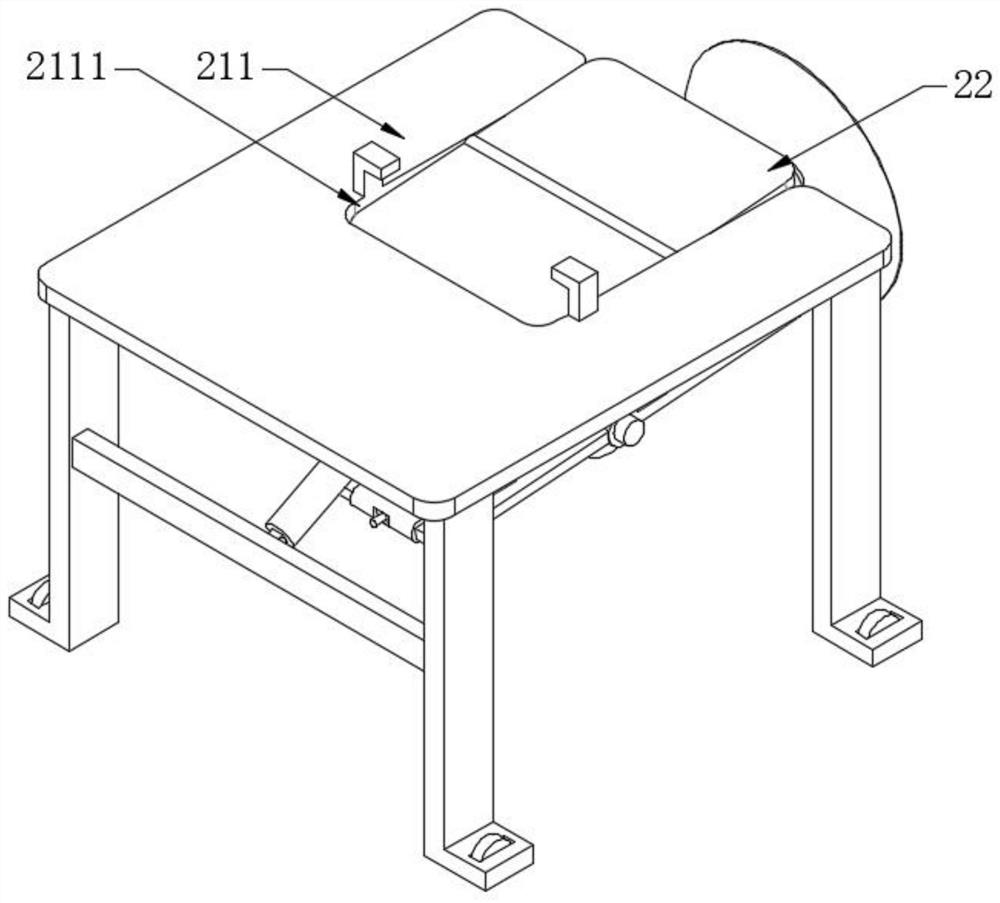

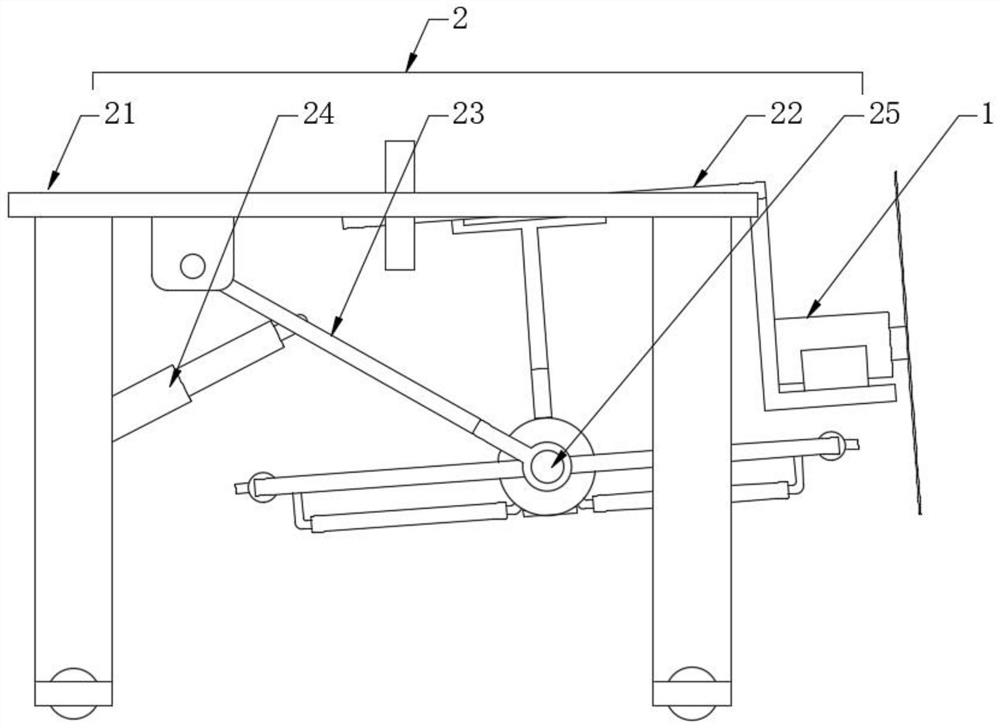

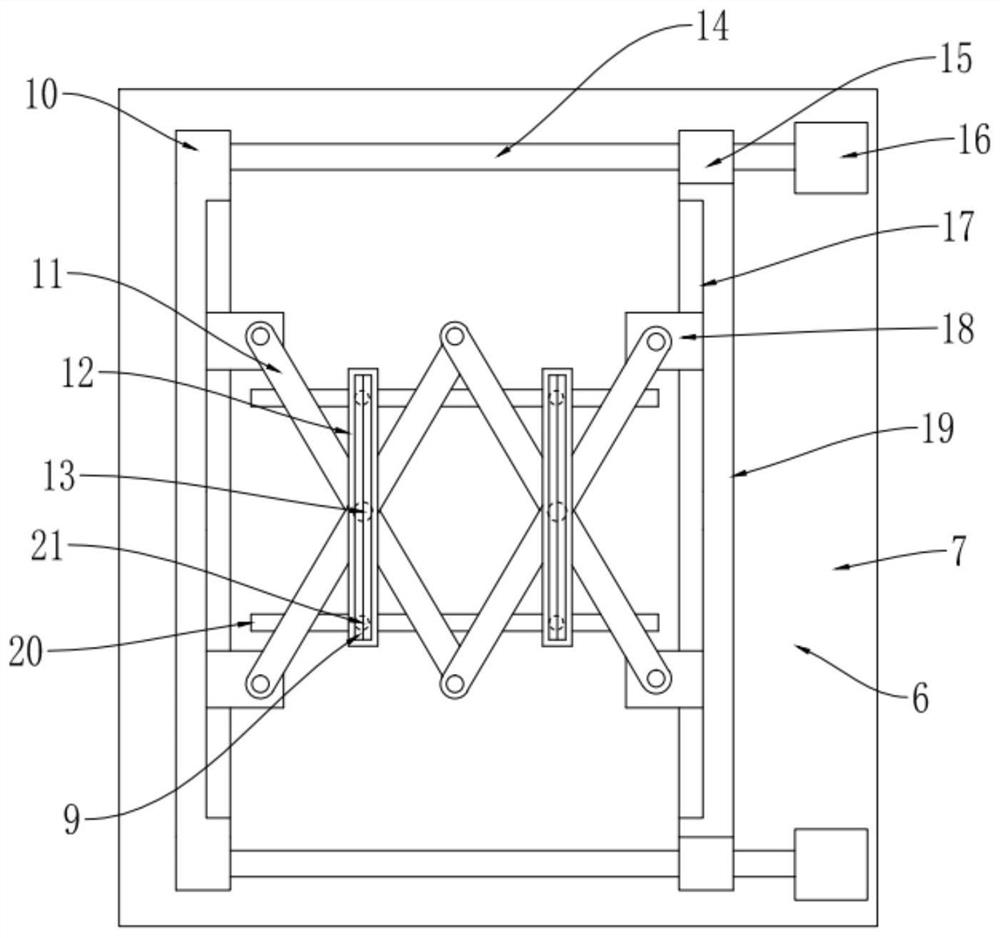

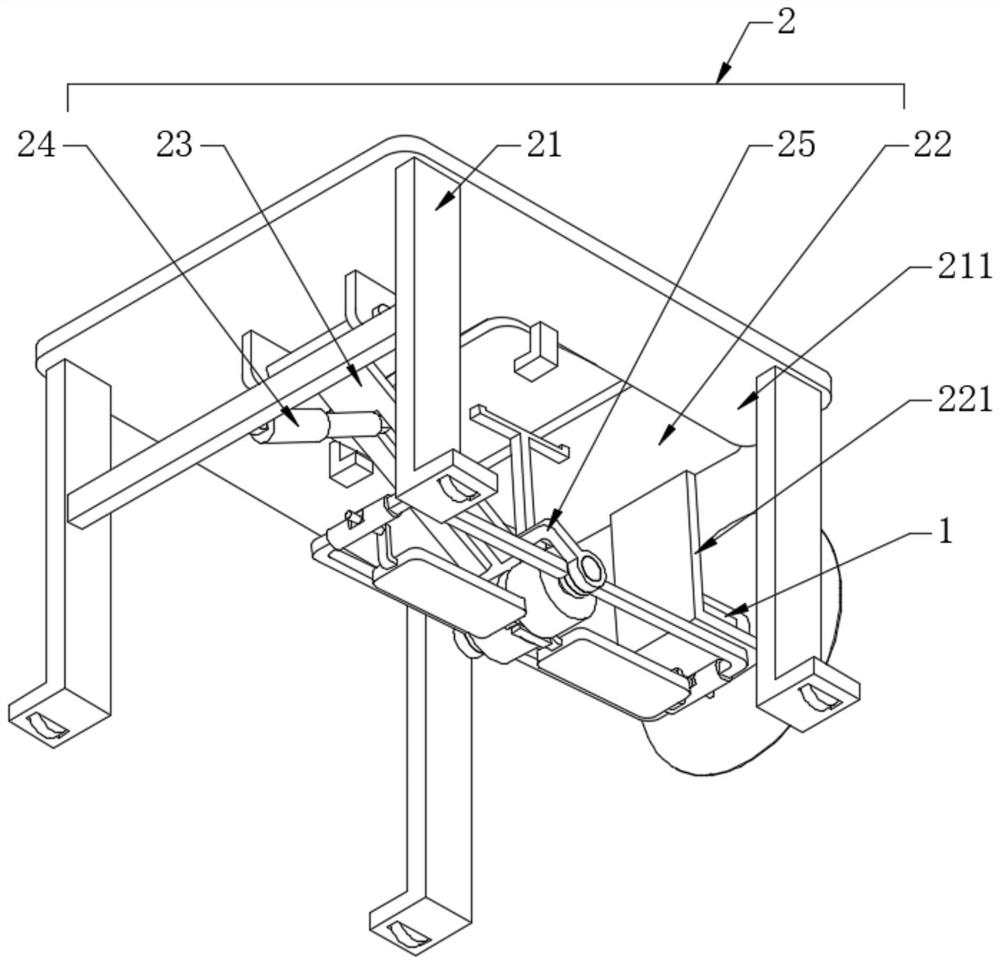

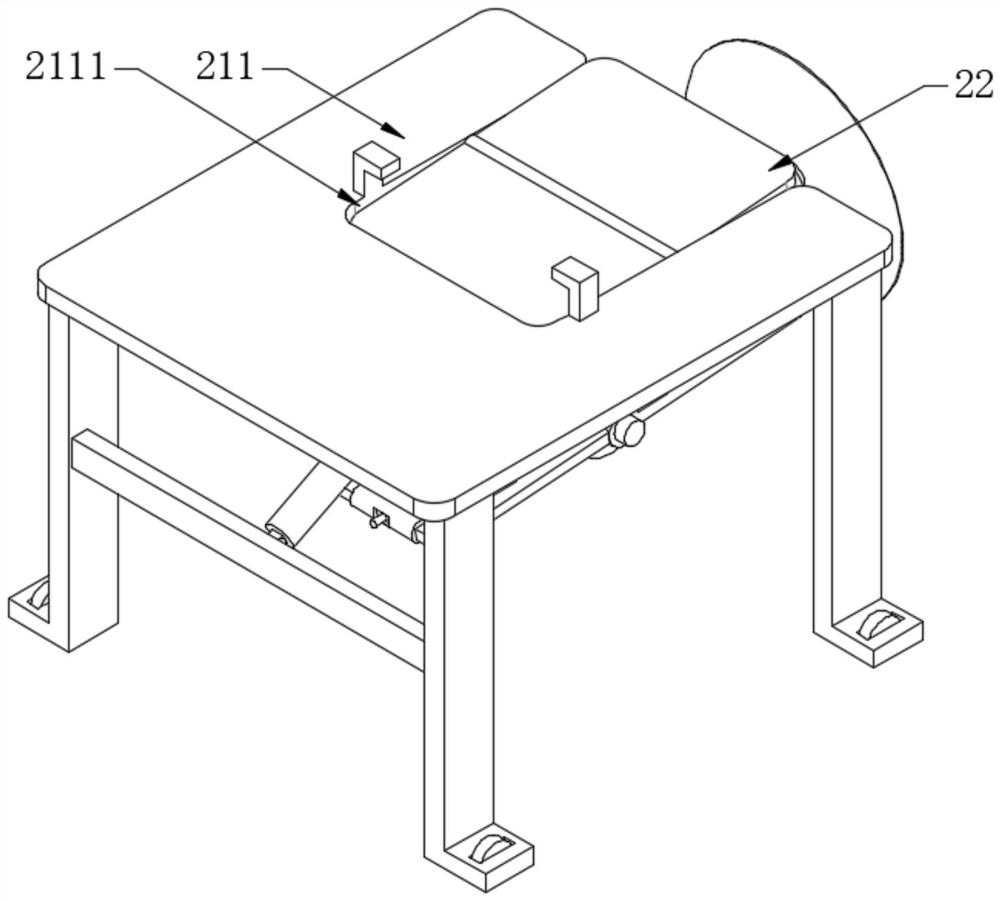

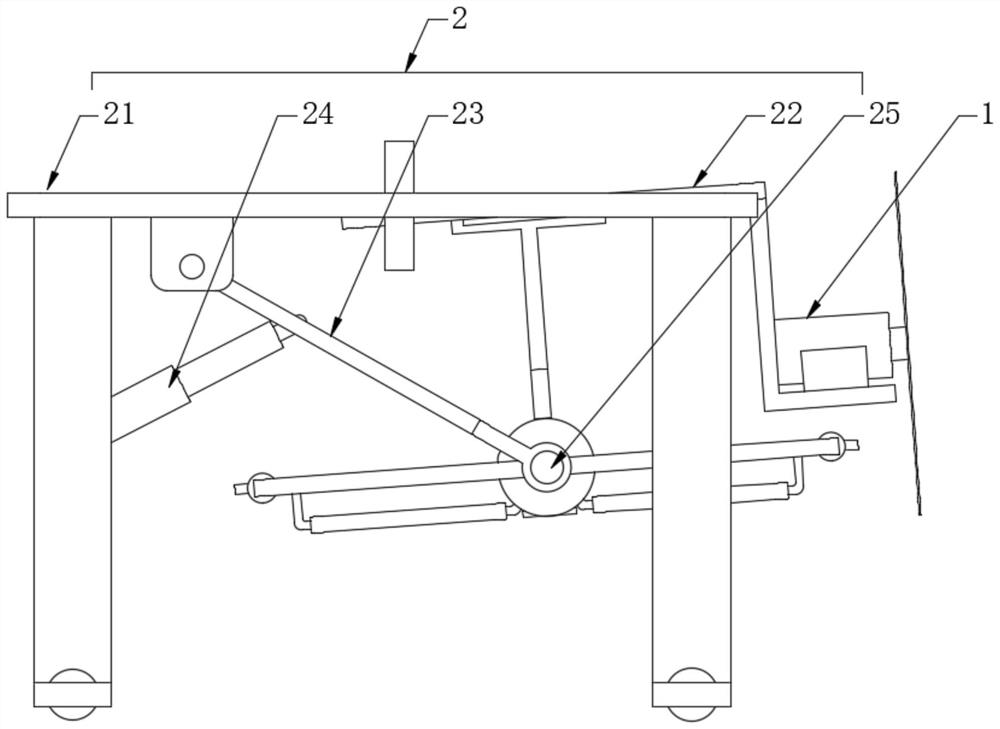

Worktable having adjusting function and used for woodworking cutting

InactiveCN107901135AWith adjustment functionImprove work efficiencyCircular sawsBark-zones/chip/dust/waste removalCouplingArchitectural engineering

The invention discloses a woodworking cutting workbench with an adjustment function, which comprises a support leg, the surface of the support leg is fixedly connected with the workbench, the interior of the workbench is provided with a through hole, and the surface of the workbench is fixedly connected with a first A chassis, the inner wall of the first chassis is fixedly connected with a first support rod, the surface of the first support rod is fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a threaded rod through a coupling. The woodworking cutting workbench with adjustment function, when it needs to be used for cutting, put the wood between the push plate and the workbench, start the motor, the motor drives the threaded rod to rotate, the threaded rod drives the threaded pipe to rotate, and the threaded pipe drives the second The support rod slides and advances inside the chute, which achieves the effect of replacing manual propulsion and improving work efficiency, thus effectively solving the problem that the general woodworking machinery is inconvenient to adjust, consumes a lot of manpower, and affects work efficiency to a certain extent. .

Owner:绍兴新越机械制造有限公司

Adjustable panel cutting device for building construction

InactiveCN108127162APrevent slidingAchieve a fixed purposeProfiling/shaping machinesShearing machinesArchitectural engineeringBuilding construction

The invention discloses an adjustable panel cutting device for building construction, and relates to the technical field of building construction equipment. The adjustable panel cutting device comprises an outer frame, a first motor is fixedly connected to the bottom of the right side of the outer frame, one end of an output shaft of the first motor penetrates through the outer frame and extends into the outer frame, a lead screw is fixedly connected to the end, located inside the outer frame, of the output shaft of the first motor, a mobile block is in threaded connection with the surface ofthe lead screw, a cross plate is fixedly connected to the top of the mobile block, vertical rods are fixedly connected to both sides of the top of the cross plate, and clamping devices are fixedly connected to the tops of the vertical rods. By means of the adjustable panel cutting device for the building construction, the purpose of fixing a panel is achieved, the panel is prevented from sliding in the cutting process, cutting failure is prevented, the cutting position of the panel is conveniently adjusted, the panel can be cut into different sizes according to requirements, people conveniently use the adjustable panel cutting device, the cutting effect is guaranteed, and later use of the panel is facilitated.

Owner:张一天

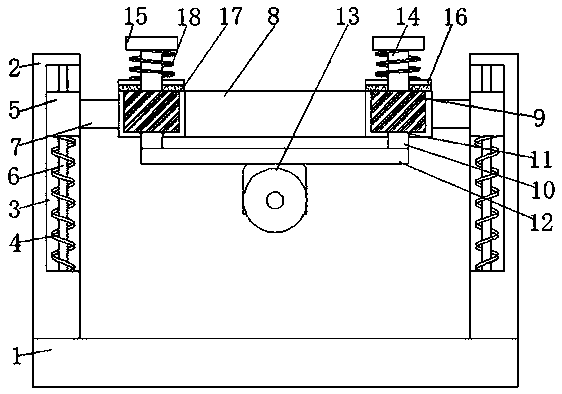

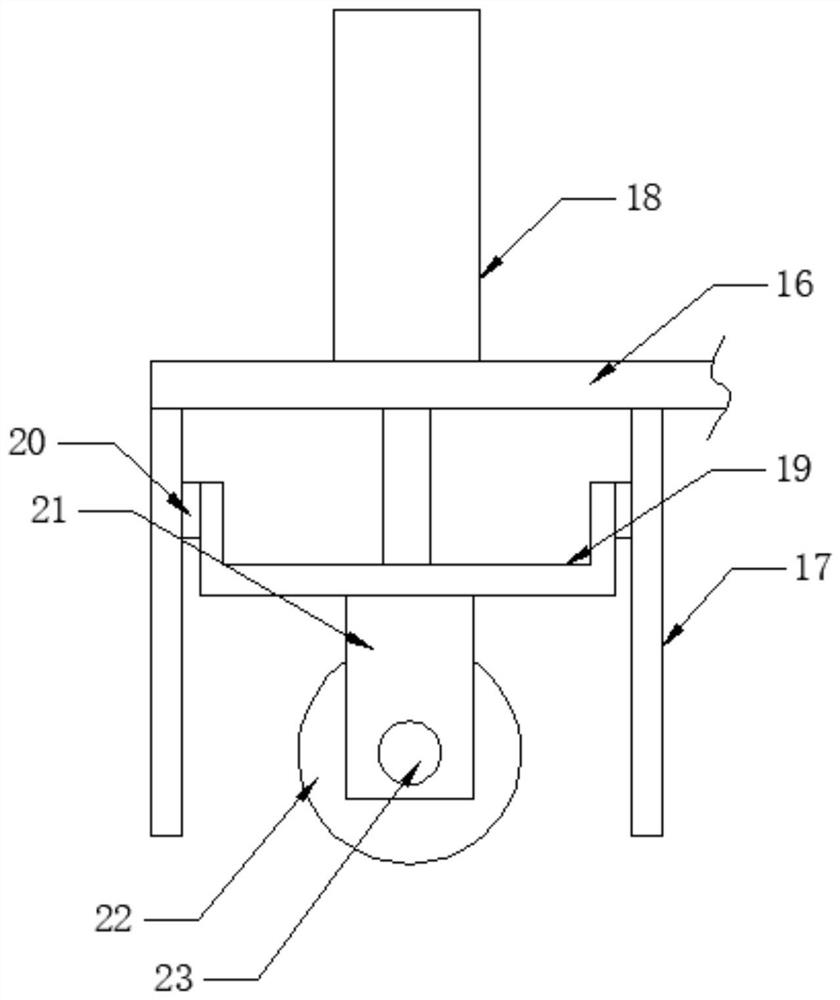

Robot cutting device

PendingCN108436296AEasy to adjust the cutting positionConvenient manual adjustmentProgramme-controlled manipulatorWelding/cutting auxillary devicesSlide plateEngineering

The invention discloses a robot cutting device. The robot cutting device comprises a base. A first mechanical arm is fixedly connected to the top end of the base. A second mechanical arm is fixedly connected to the top of the first mechanical arm. A third mechanical arm is fixedly connected to the bottom of the second mechanical arm. Clamping grooves are formed in two sides of the inner portions of the second mechanical arm and the third mechanical arm. Sliding plates are connected with the clamping grooves in a clamped mode. Transmission gears are arranged on the sliding plates. Connecting blocks are fixedly connected with the sliding plates in the mechanical arms. Indented lines are arranged in the mechanical arms. The transmission gears mesh with the indented lines. A laser head regulator is fixedly connected to one side of a second connecting block, and a laser head is hinged to the bottom of the laser head regulator. According to the robot cutting device, by the arrangement of a motor and the transmission gears, the driving of a motor and the transmission of the transmission gears are used, the cutting position of the laser head can be conveniently adjusted; by arrangement themotor and the laser head with the semi-circular-shaped indented line head, the cutting angle can be conveniently adjusted; and an independent switch is arranged to control various motors, so that manual control is facilitated.

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

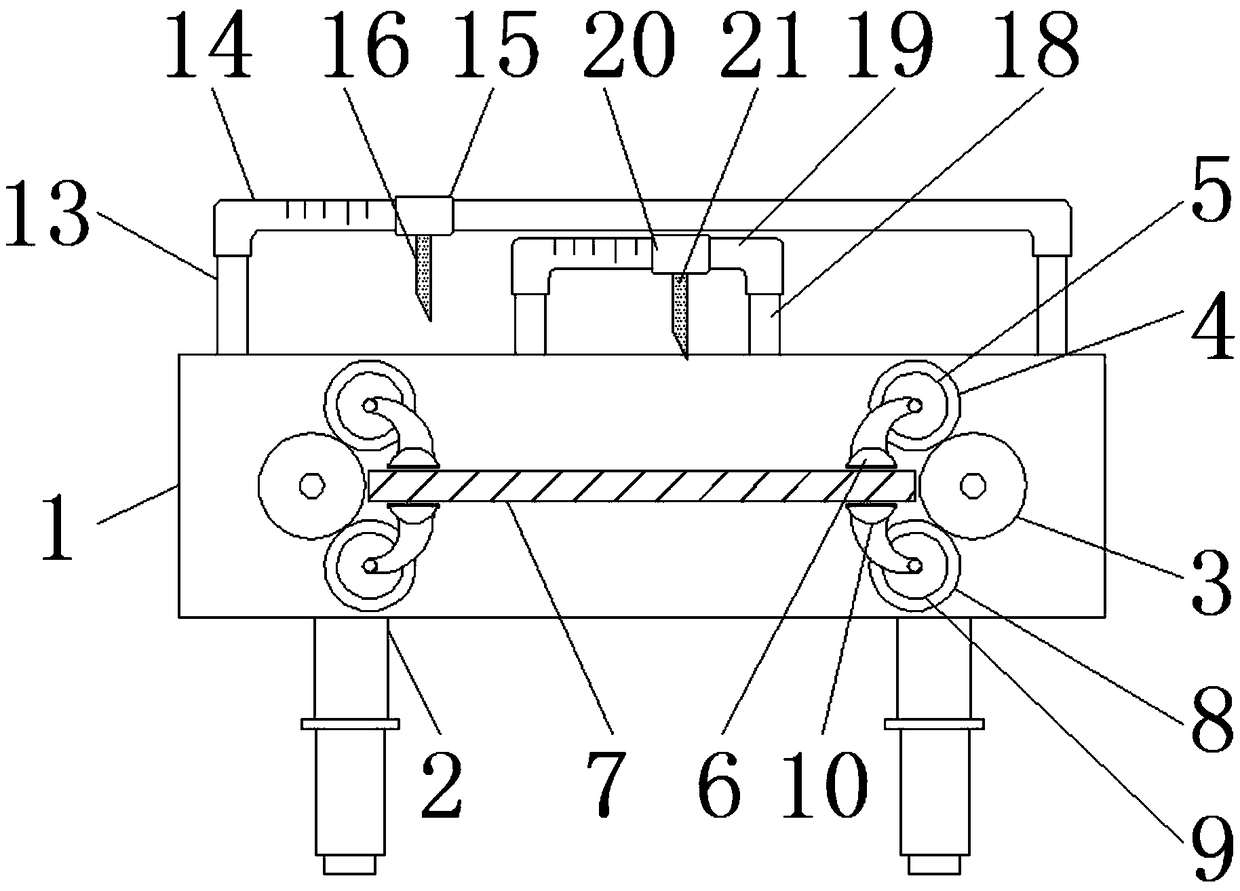

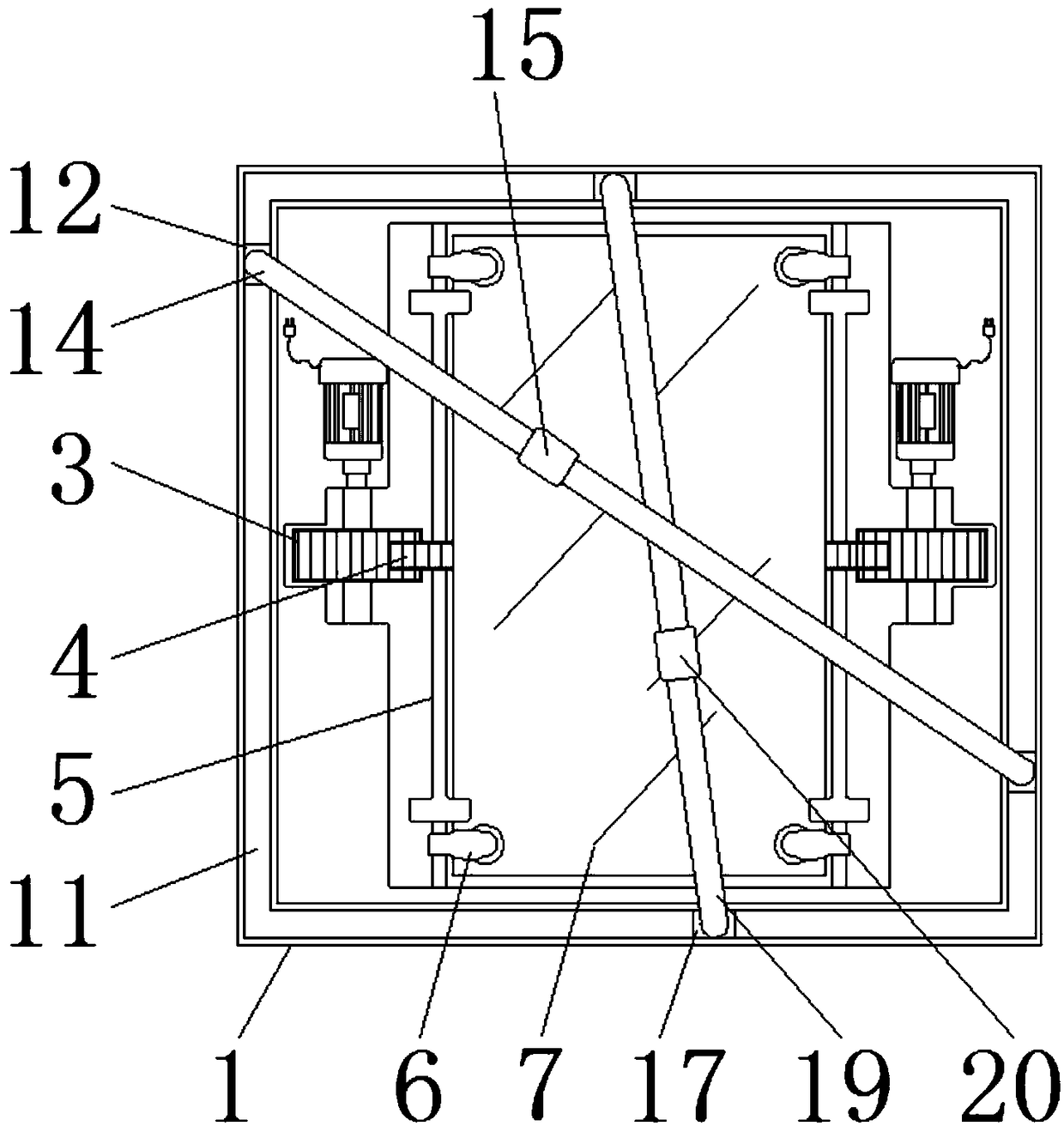

Cutting device for robot part machining

PendingCN110695703ASimple structureEasy to cutOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses a cutting device for robot part machining, and relates to the technical field of robot part machining. Aiming at the problems that the cutting surface of the workpiece can generate burrs for later cleaning, the working procedures are increased and the cutting position cannot be conveniently adjusted in the existing cutting operations, the following scheme is provided, the cutting device comprises a top plate, wherein the top of the top plate is provided with a moving mechanism, the moving mechanism is fixedly connected with a sleeve penetrating through the top plate, amoving rod is movably sleeved in the sleeve, a mounting plate is welded to the outer wall of the left side of the moving rod, a push rod motor is fixedly connected to the bottom of the mounting plate,an output shaft of the push rod motor is fixedly connected with a first bearing, and the first bearing fixedly sleeves an outer ring of the moving rod. According to the cutting device, cutting and grinding are integrally designed and can be carried out at the same time, the structure is simplified, the later procedure is reduced, the practicability of the device is improved, cutting can be accurately controlled, and the product machining quality is facilitated.

Owner:佛山市同泰升精密机电科技有限公司

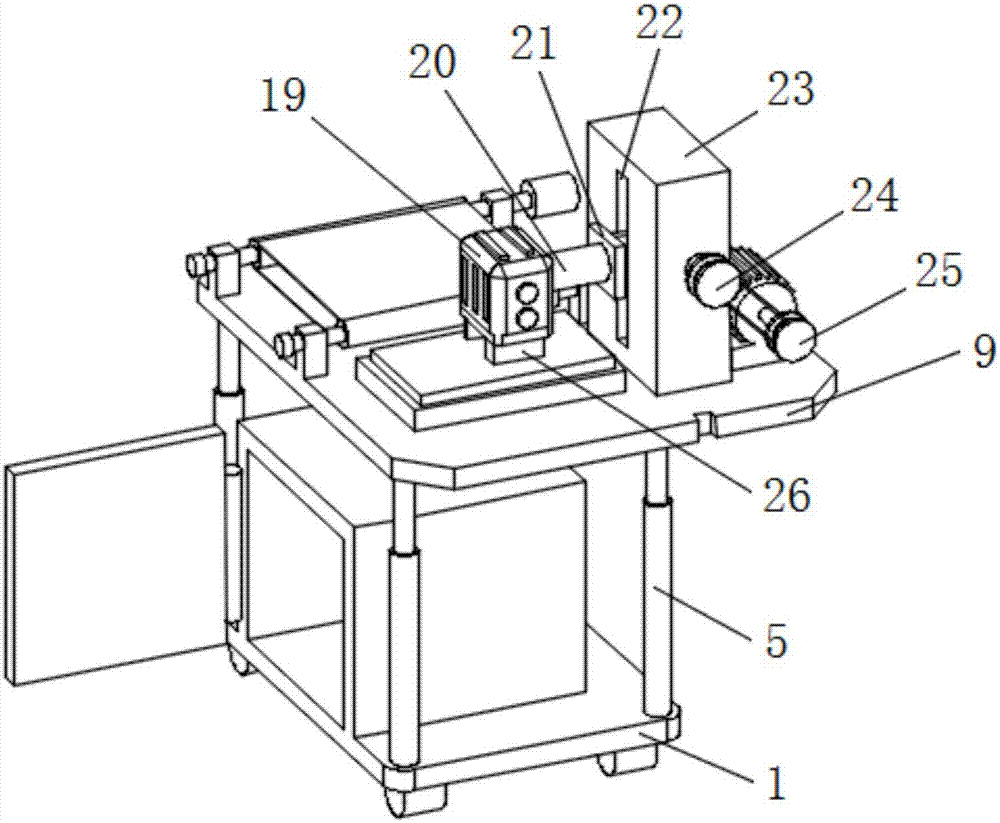

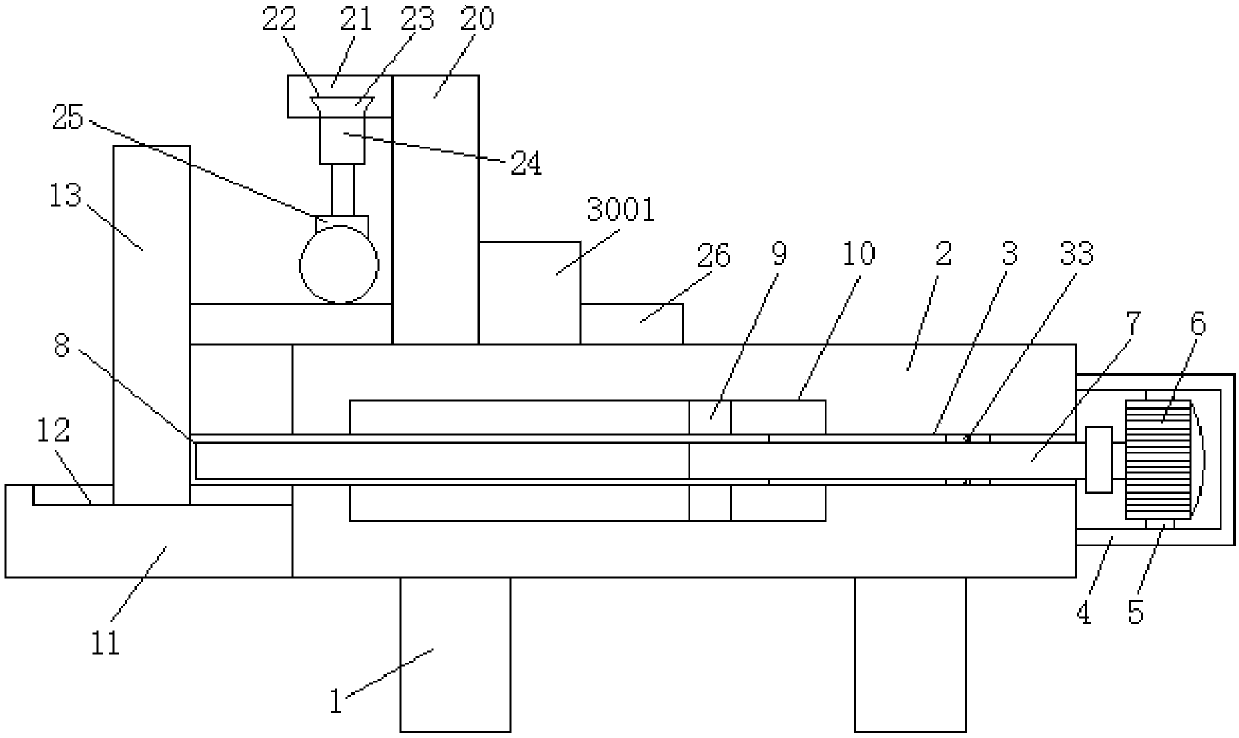

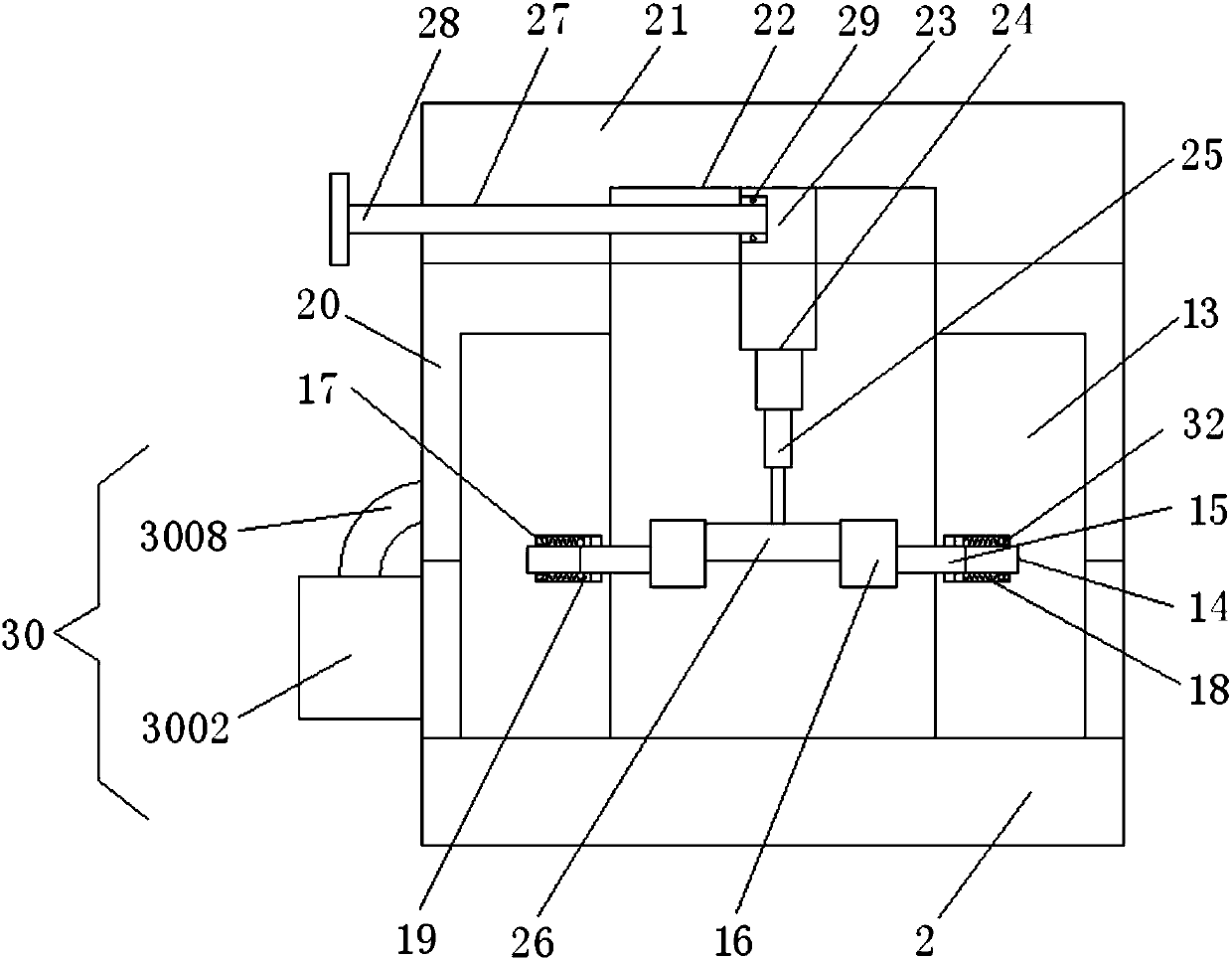

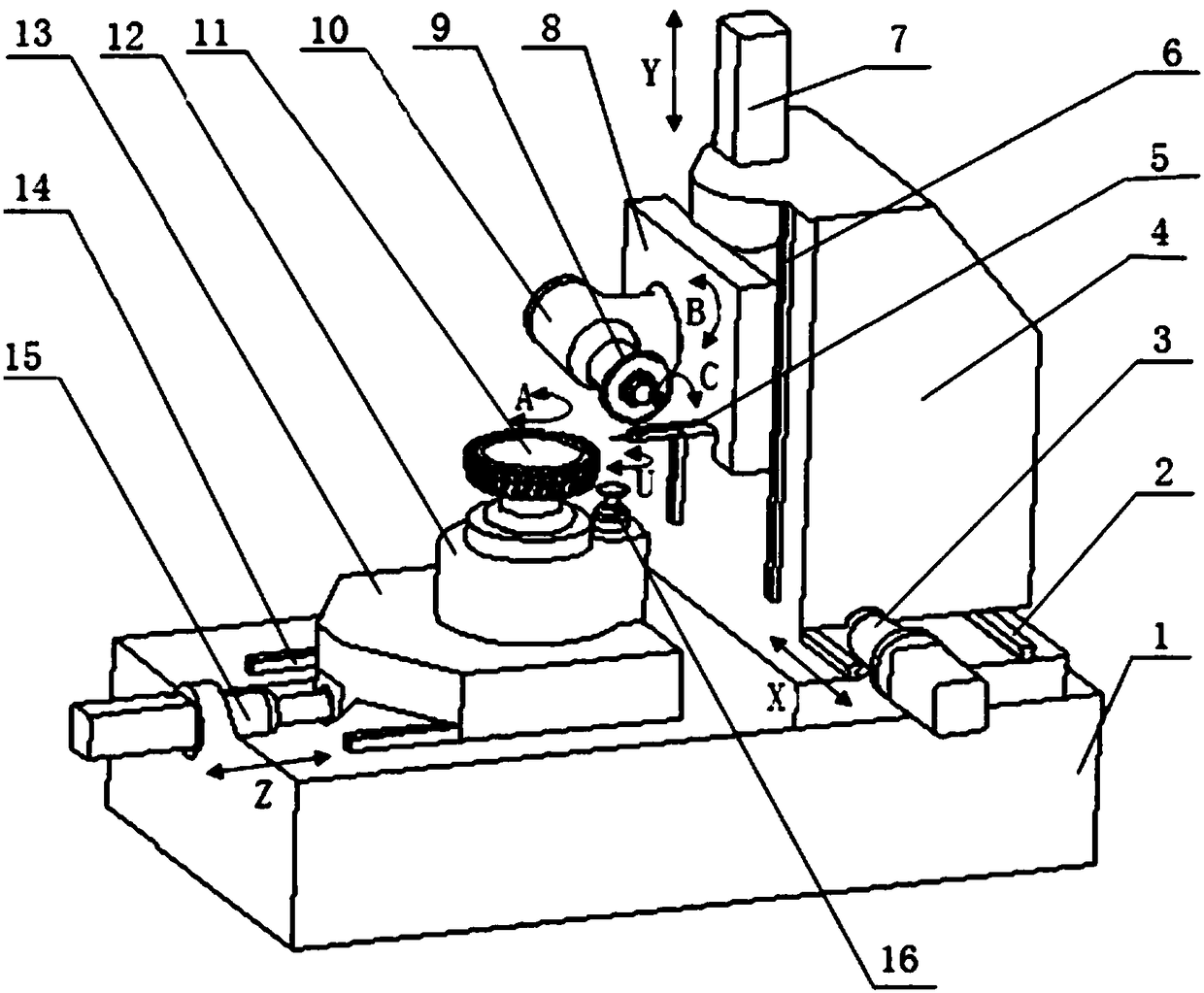

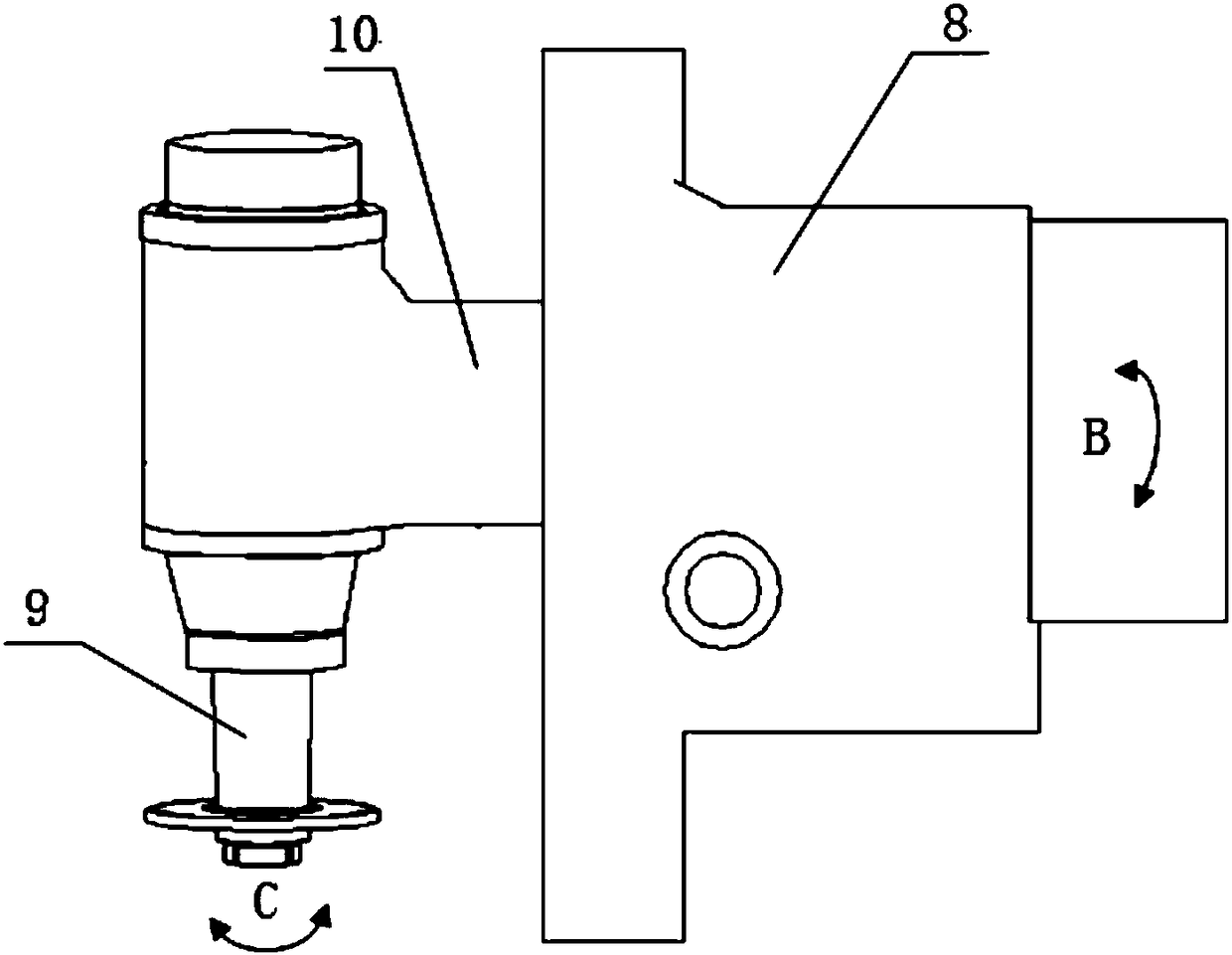

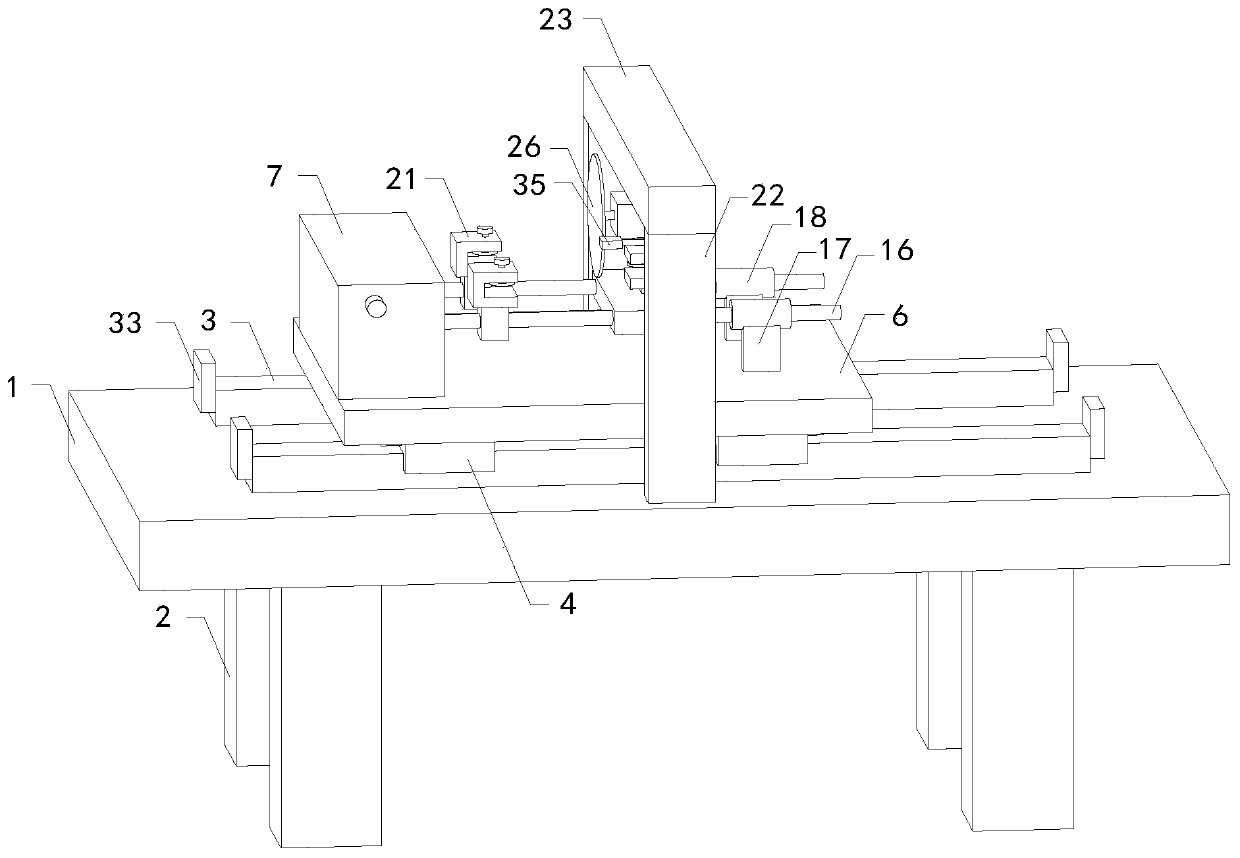

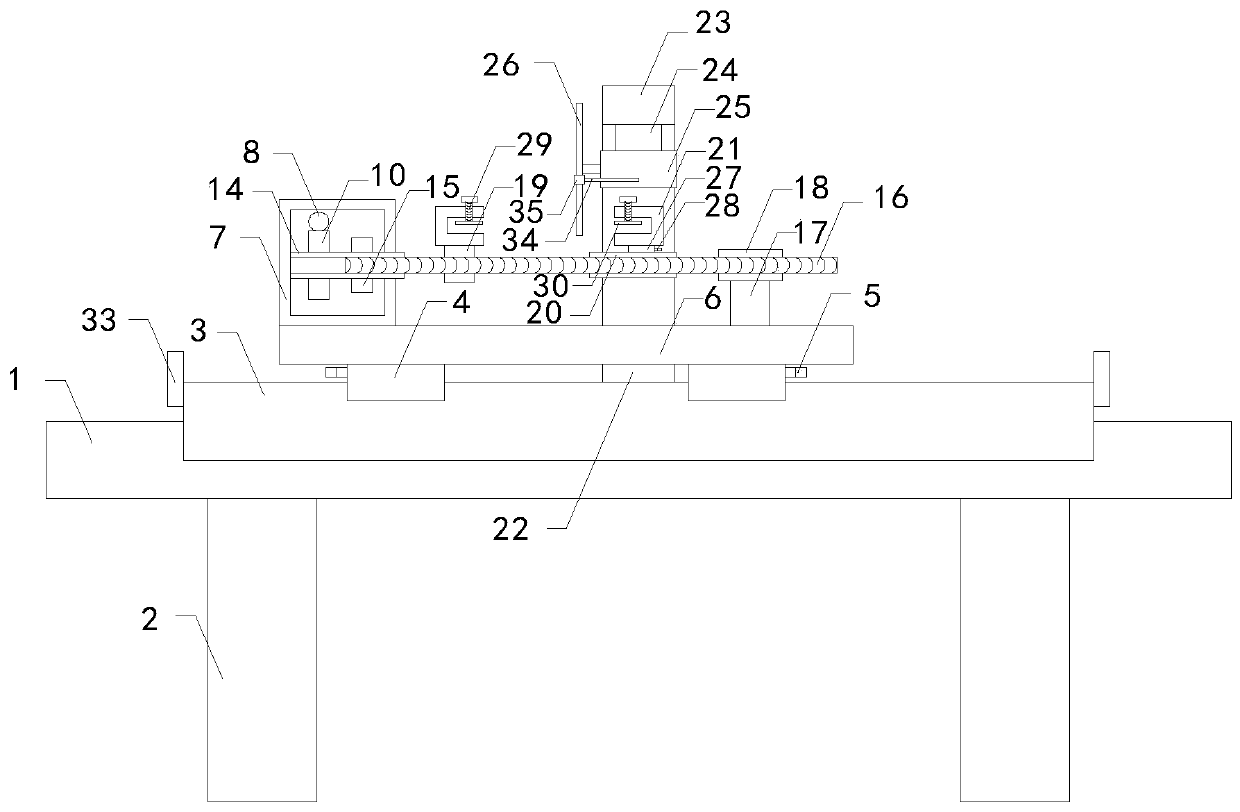

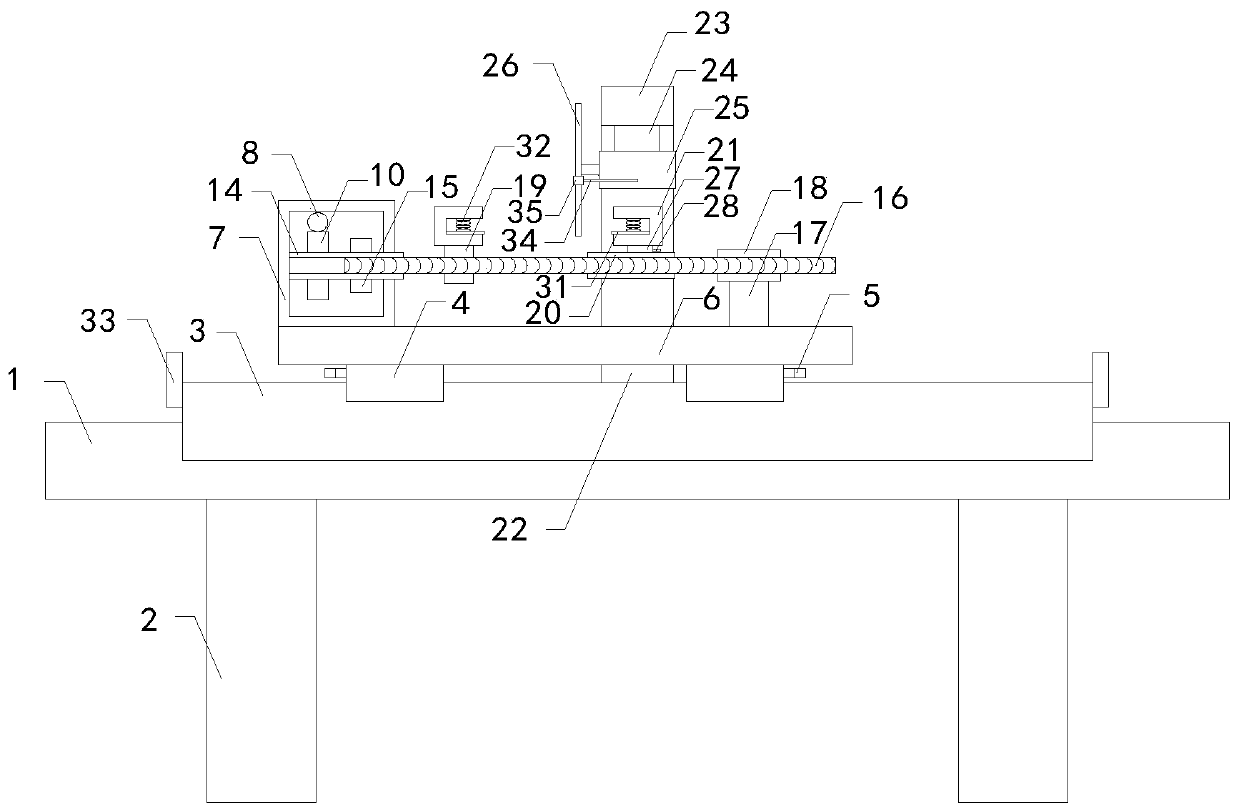

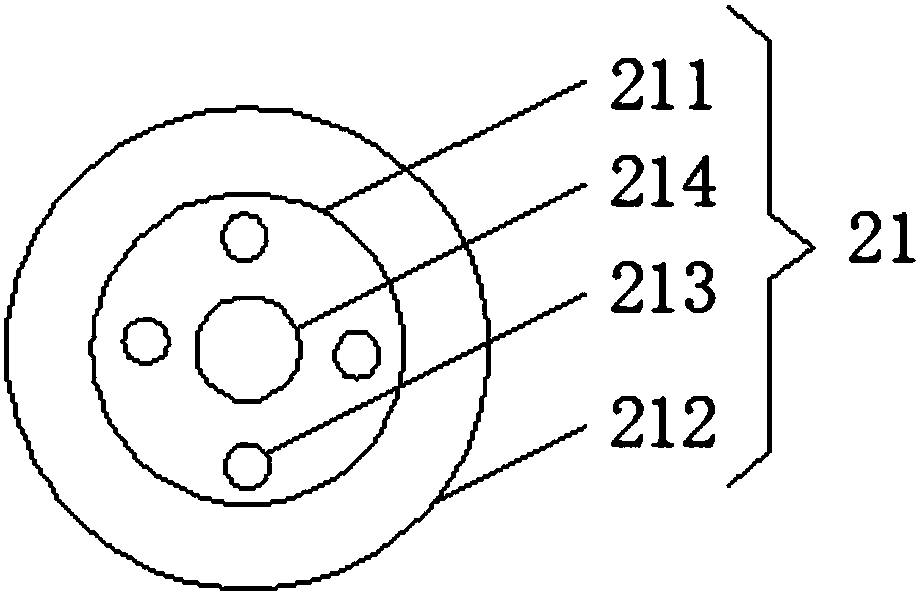

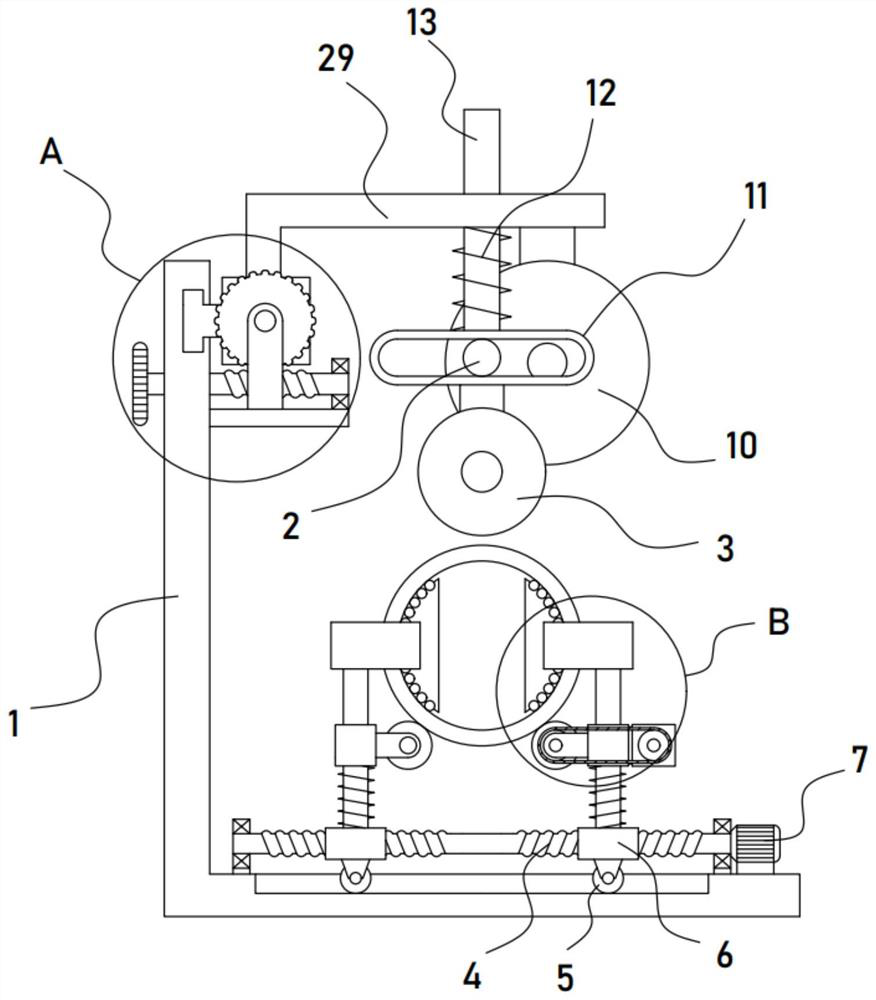

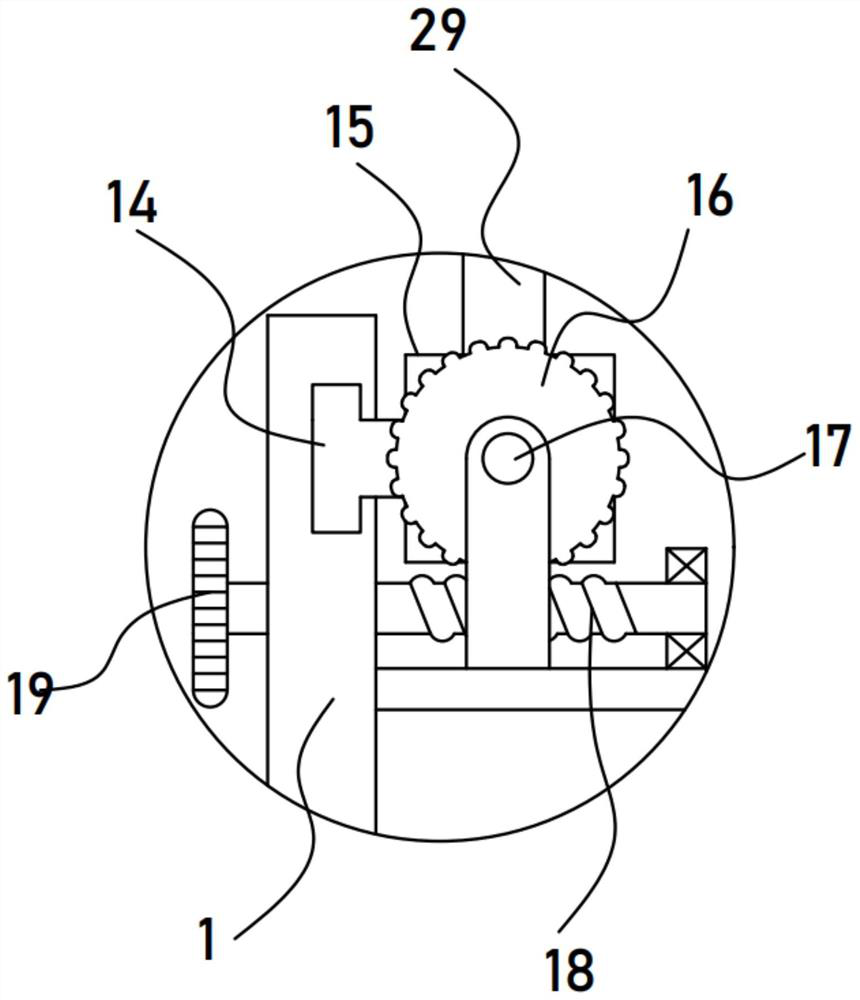

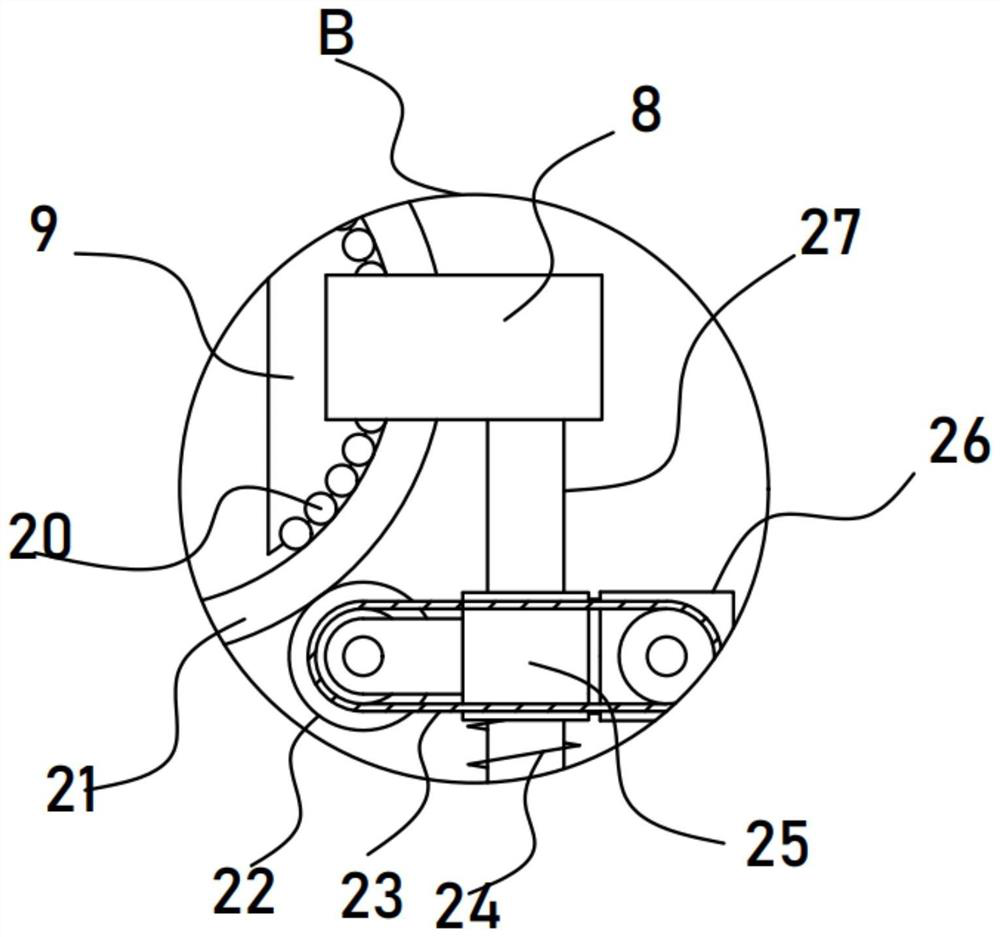

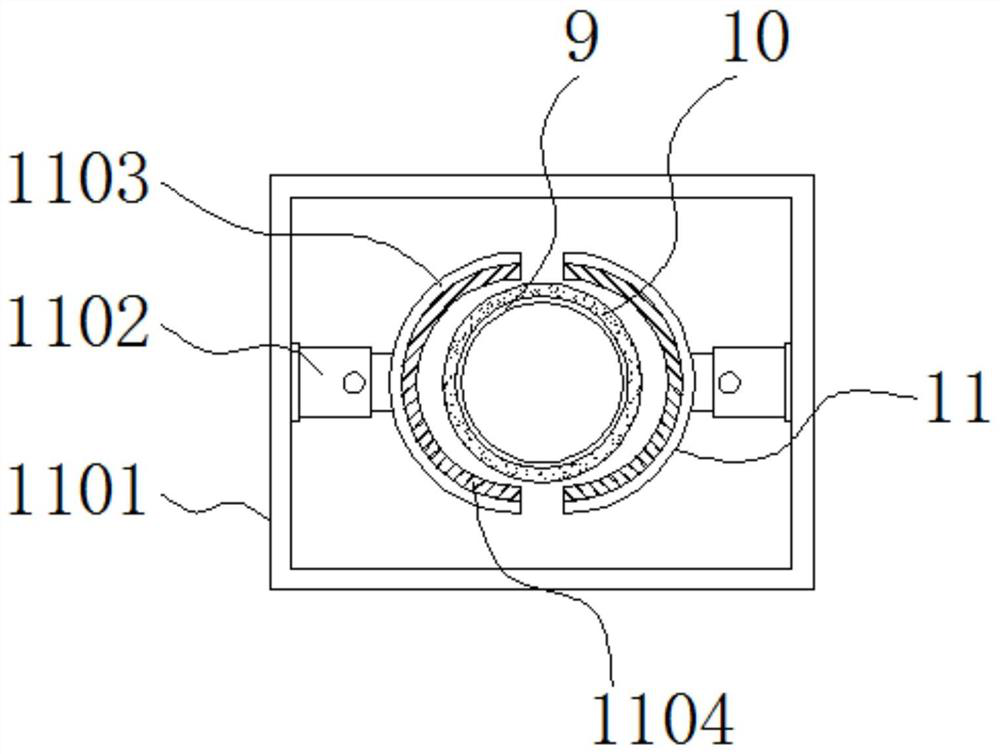

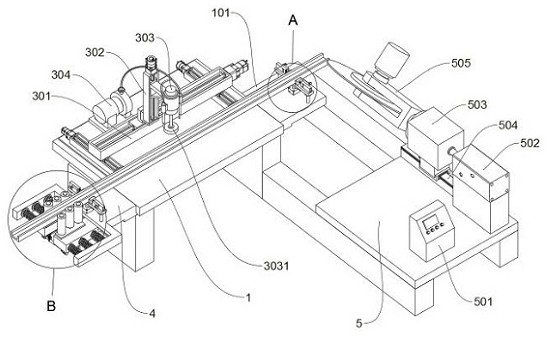

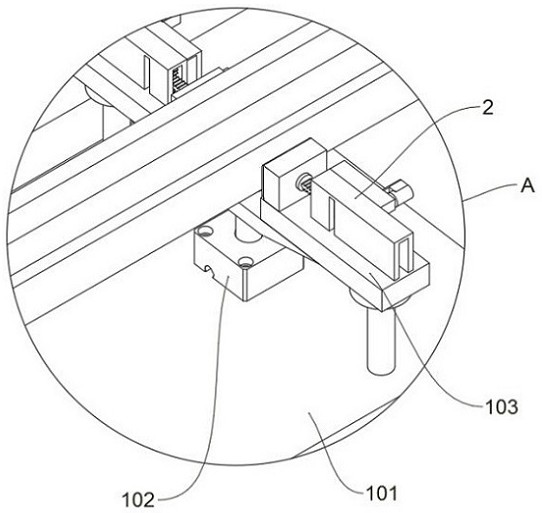

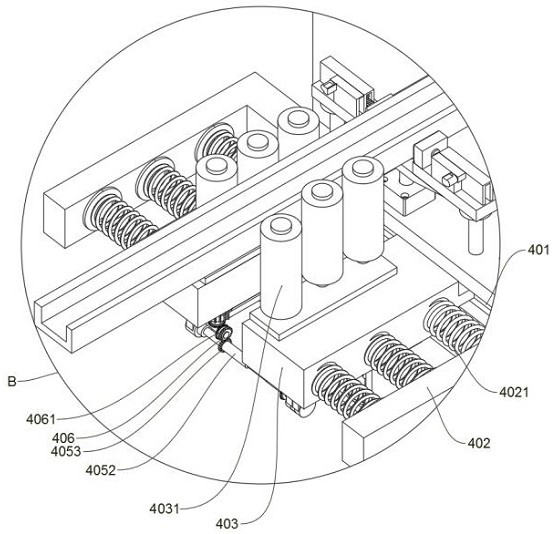

Cutter head grinding device

PendingCN108214125AAdjust cutting positionEasy to adjust the cutting positionGrinding carriagesGrinding drivesRelative motionEngineering

The invention discloses a cutter head grinding device. The cutter head grinding device comprises a lathe bed, a workpiece box body, a stand column, a B-axis box body, a grinding wheel box body and a relative motion driving mechanism. The workpiece box body is arranged on the lathe bed and internally provided with a workpiece rotating shaft, wherein the workpiece rotating shaft is used for allowinga workpiece to be fixedly mounted thereon, and the workpiece rotating shaft is rotatably arranged in the workpiece box body. The stand column is arranged on the lathe bed. The B-axis box body is arranged on the stand column and internally provided with a grinding wheel box body swinging shaft, wherein the grinding wheel box body swinging shaft is used for allowing the grinding wheel box body to be fixedly mounted thereon, and the grinding wheel box body swinging shaft is rotatably arranged in the B-axis box body. The grinding wheel box body is arranged on the B-axis box body and provided witha grinding wheel rotating shaft, wherein the grinding wheel rotating shaft is used for allowing a grinding wheel to be fixedly mounted thereon; the grinding wheel rotating shaft is rotatably arrangedin the grinding wheel box body; and the grinding wheel box body can rotate relative to the stand column, and the rotation axis direction is perpendicular to the grinding wheel rotating shaft. The relative motion driving mechanism is arranged on the lathe bed and used for driving the workpiece box body to move relative to the stand column. By means of the cutter head grinding device, machining efficiency and machining precision are improved.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

Circuit board cutting device capable of adjusting cutting position conveniently

The invention relates to the technical field of electronic product production, in particular to a circuit board cutting device capable of adjusting a cutting position conveniently. The device can accurately adjust the cutting position of a circuit board and improve the cutting precision of the circuit board, and comprises a workbench, four groups of supporting legs, two groups of adjusting guide rails, four groups of adjusting sliding blocks, four groups of first fixing buckles, an adjusting plate, an adjusting box, an adjusting worm, a transmission rod, an adjusting worm wheel, a transmissiongear, two groups of rotating rods, two groups of rotating gears, two groups of adjusting threaded pipes, two groups of adjusting gears, two groups of adjusting threaded rods, two groups of supportingrods, two groups of supporting pipes, two groups of cutting pipes, a supporting plate, three groups of fixing frames, two groups of vertical columns, a transverse plate, a cutting sliding block, a cutting motor and a cutting saw blade. The four groups of supporting legs are fixed on the left front side, the right front side, the left rear side and the right rear side of the bottom of the workbench correspondingly, the front side and the rear side of the top of the workbench are provided with two groups of adjusting grooves, and the two groups of adjusting guide rails are arranged inside the two groups of adjusting grooves correspondingly.

Owner:南京市旗心电子科技有限公司

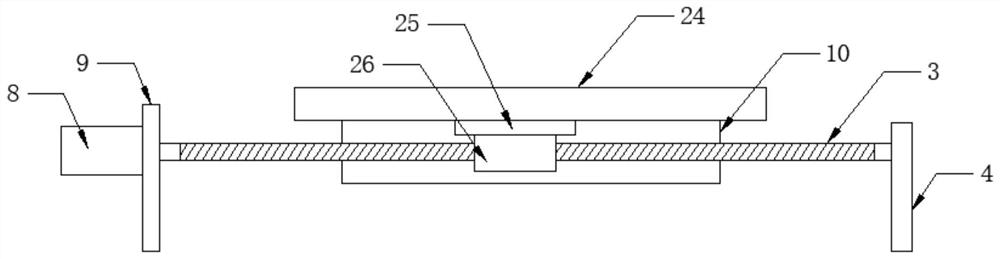

Multi-angle cutting equipment for wood processing, and working method thereof

PendingCN112060226AHigh degree of automationEfficient deliveryProfiling/shaping machinesGauging meansElectric machineryKnife blades

The invention discloses multi-angle cutting equipment for wood processing, and a working method thereof. According to the multi-angle cutting equipment, through adjustment of the cutting angle is completed by adjusting the inclination angle of a cutting blade and the angle of a cutting base, the adjustment of the cutting angle is diversified and convenient, and the two sides of wood are clamped before cutting; the requirement for fixing wood in different sizes can be met, and a conveyor motor II is matched with a lead screw to drive a conveying plate to horizontally move along a supporting base, so that the position of the wood is adjusted; the structure set facilitates adjustment of the cutting position of the cutting blade for the wood; through arrangement of two wood conveying mechanisms and two wood handling mechanisms, the wood can be efficiently conveyed and handled before and after cutting, and the whole process does not involve participation of workers; and the automation degree is high, and the purpose of the multi-angle cutting equipment can be achieved through the following technical scheme.

Owner:程晋芹

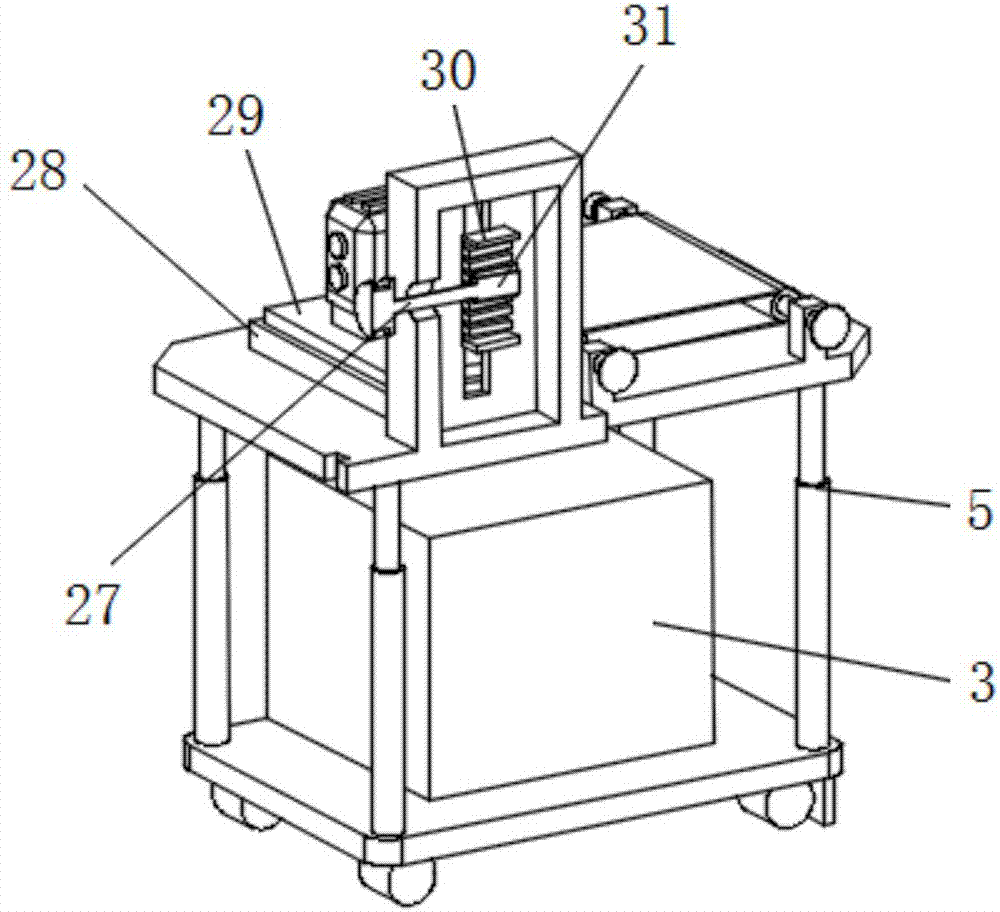

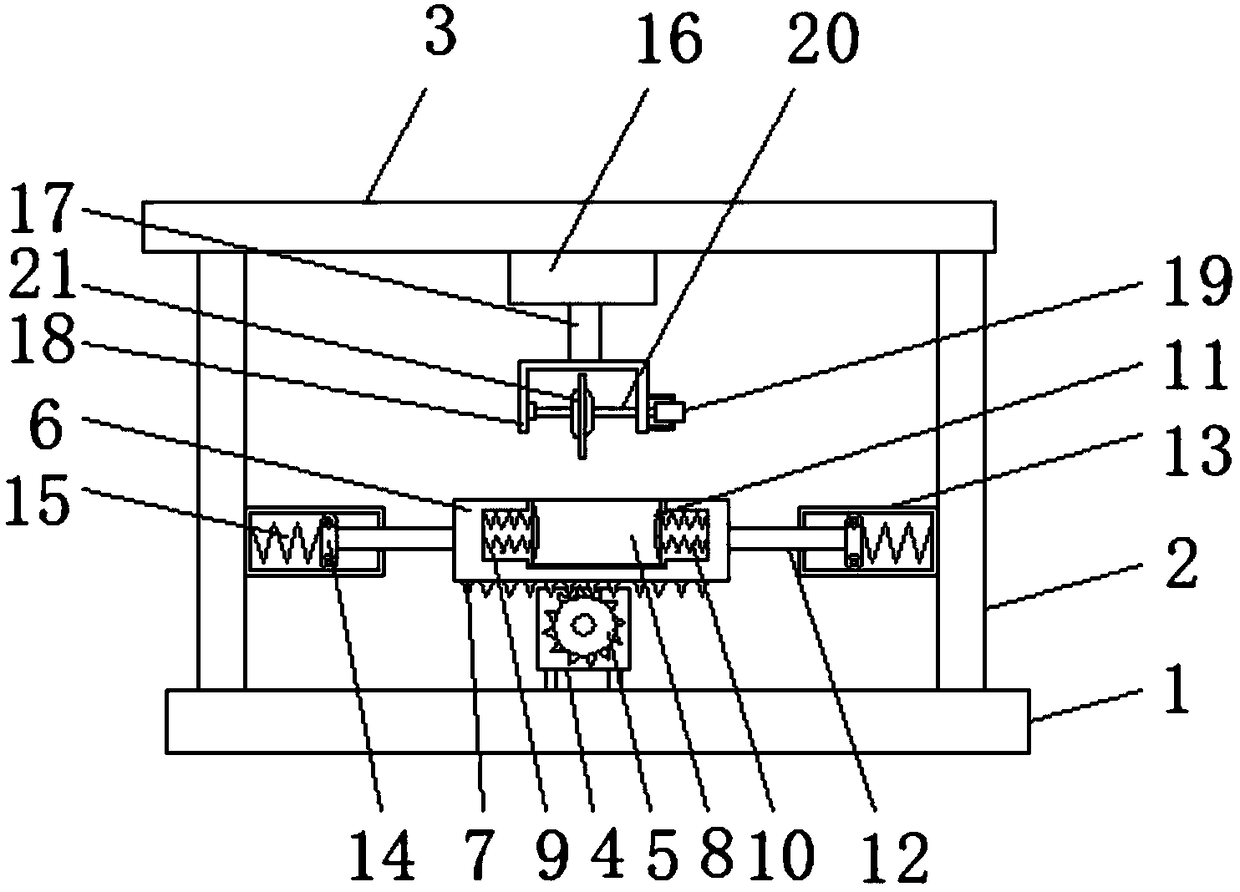

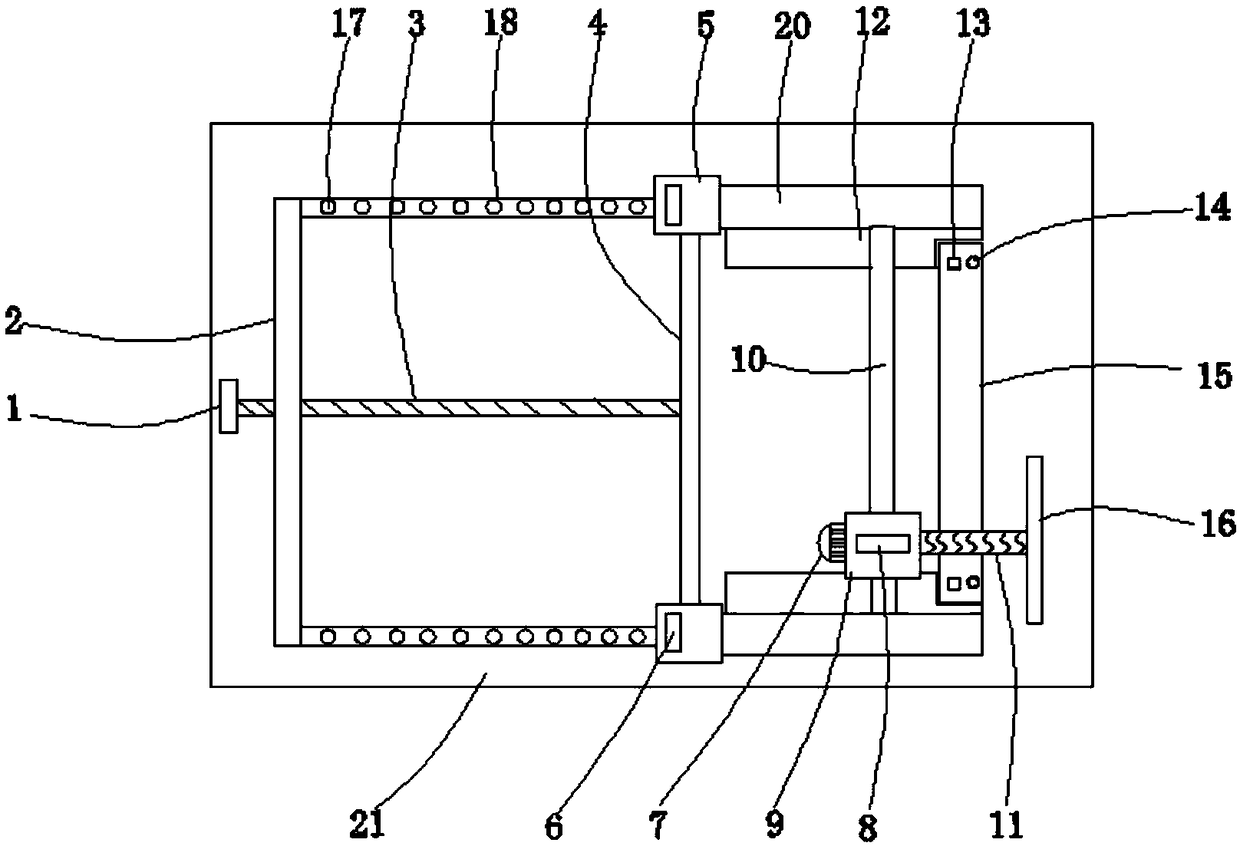

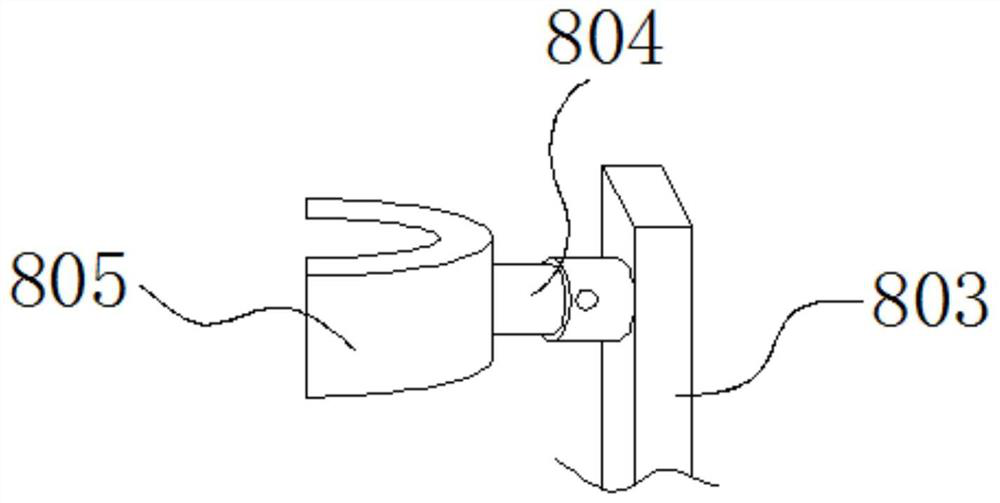

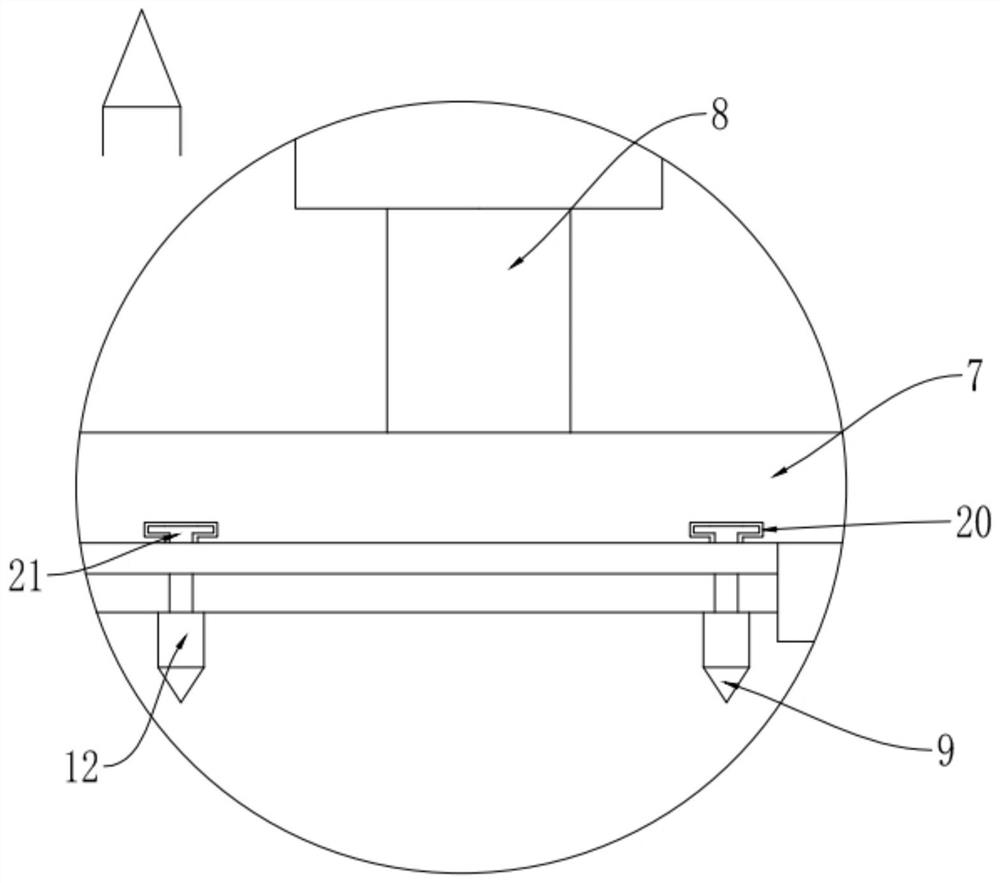

Rapid cutting device for forged ball valve end cover processing

InactiveCN108581035AEasy to adjust the cutting positionImprove flatnessShearing machine accessoriesGear wheelFixed frame

The invention discloses a rapid cutting device for forged ball valve end cover processing, and belongs to the technical field of processing of forged ball valve end covers. The device comprises a base, wherein a rotating motor is mounted in the center of the top part of the base through a fixing frame; a gear is mounted at the front side output end of the rotating motor; a sleeving rod in which asliding block is arranged is inserted at one side, far away from a moving plate, of the connecting rod; a hydraulic device is mounted at the bottom part of a top plate; a telescoping rod is mounted atthe bottom output end of the hydraulic device, and a U-shaped frame is mounted at the bottom part of the telescoping rod. According to the device, a cutting device body is mounted on a rotating shaft; the rotating motor can be started to drive the gear to rotate, thus the moving plate moves, and as a result, the forged ball valve end cover can be conveniently adjusted to a position for cutting; acutting tool is provided for supporting, so that the cutting can be rapidly carried out, a large number of times can be saved, and the working efficiency is improved; and meanwhile, the forged ball valve end cover is positioned into a cutting groove and is clamped and filed through a compressing spring and a pressing block, so that the forged ball valve end cover is greatly prevented form shaking, and as a result, the notch flatness is improved.

Owner:JIANGSU YINGLIU MACHINERY MFG CO LTD

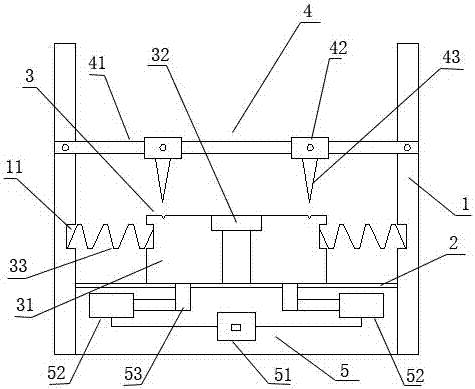

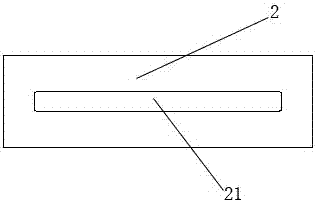

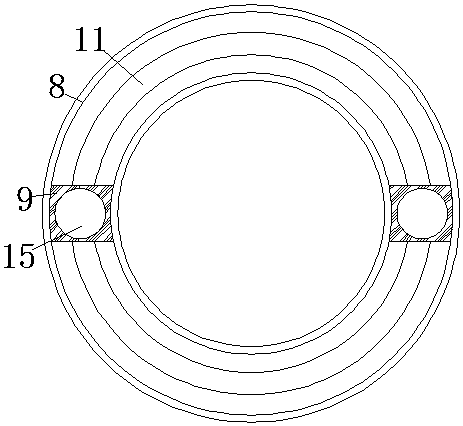

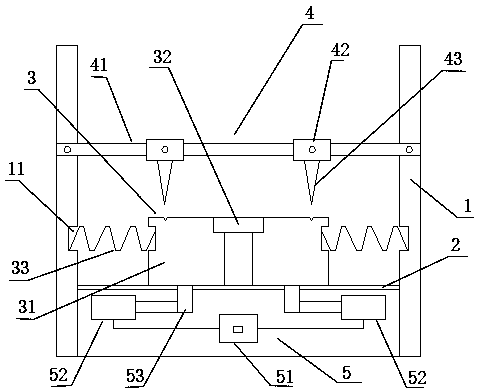

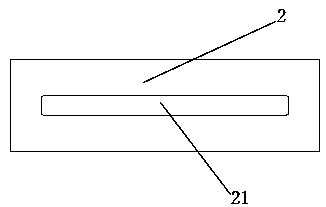

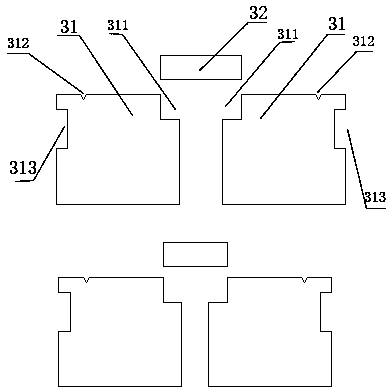

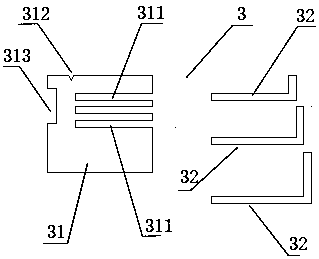

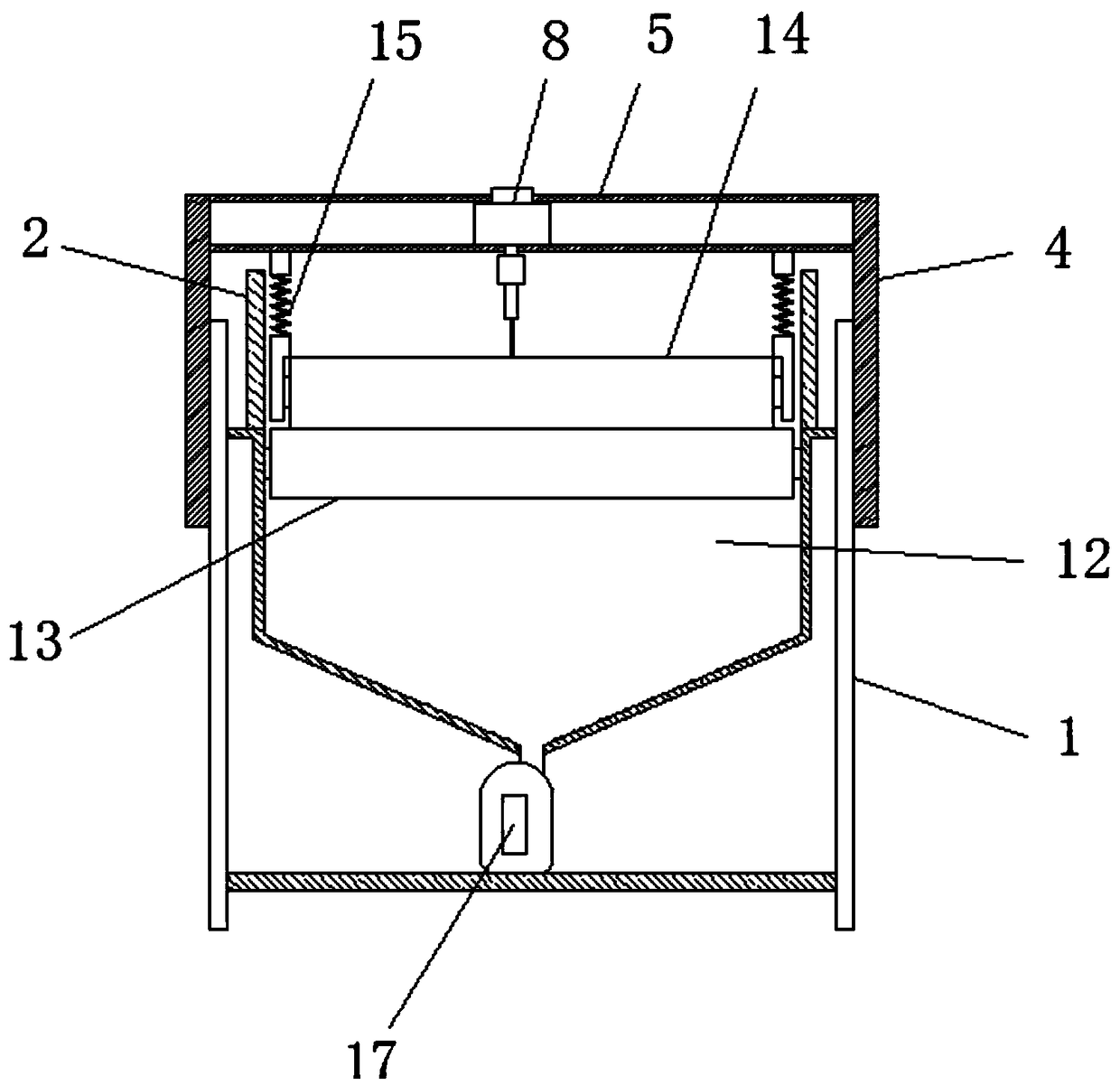

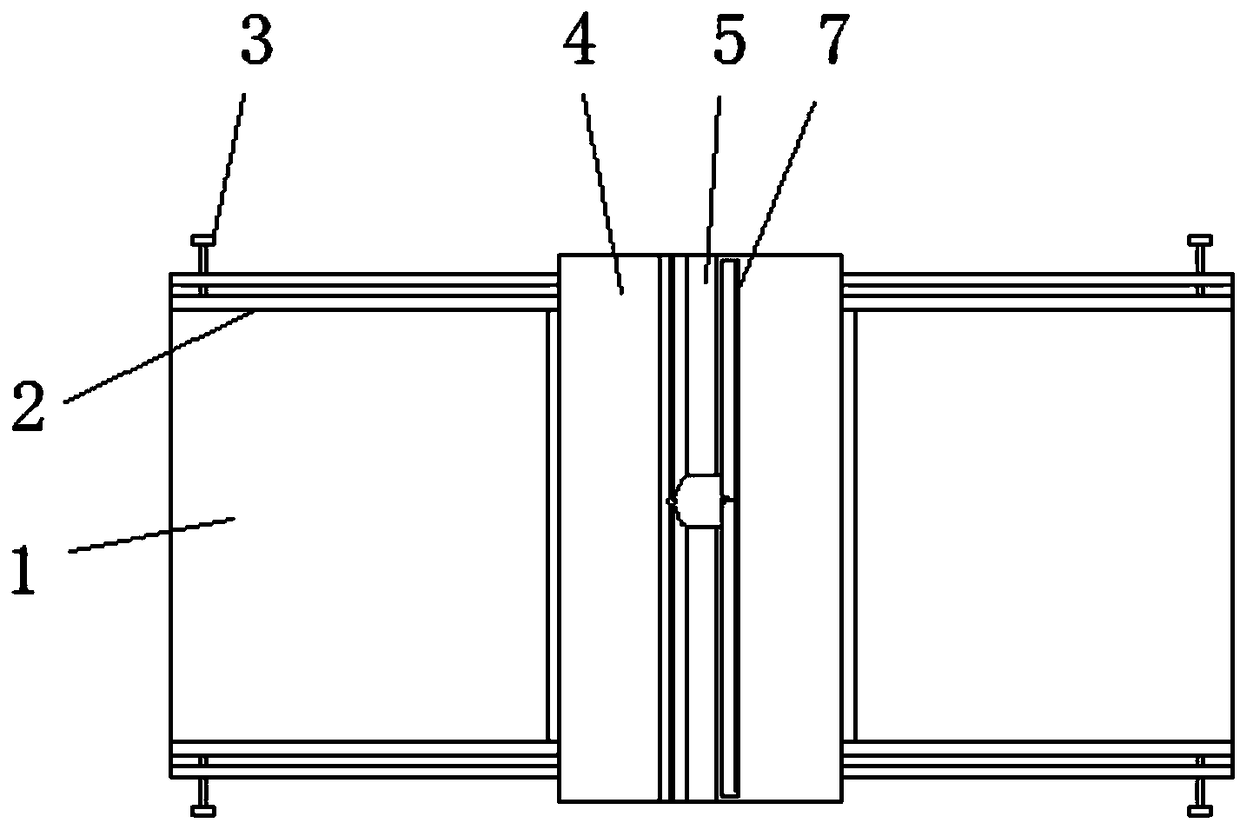

Clamping block adjusting type cutting device for cutting double-layer fabric

ActiveCN107881628AWrinkles won't happenGuaranteed accuracyPile-fabric loomsEngineeringMechanical engineering

The invention discloses a clamping block adjusting type cutting device for cutting a double-layer fabric. The clamping block adjusting type cutting device includes a machine frame, a fixed plate, a cutting carrier and a cutting mechanism. The machine frame is of a U-shaped structure. The fixed plate is mounted at the bottom of the machine frame. The cutting carrier is mounted on the fixed plate. The cutting carrier includes two supporting blocks, two springs and a plurality of clamping blocks. The lengths of the plurality of clamping blocks are different. The supporting blocks are provided with cutting V grooves. The two supporting blocks are oppositely mounted on the fixed plate. The springs are mounted between the opposite outer sides of the two supporting blocks and the machine frame, the opposite inner sides of the two supporting blocks are provided with step-shaped groove bodies respectively, and the clamping blocks are mounted between the step-shaped groove bodies. The upper endfaces of the clamping blocks and the upper end faces of the supporting blocks are located on the same horizontal plane. The cutting mechanism is mounted above the supporting blocks. According to the clamping block adjusting type cutting device, cutting intervals are adjustable.

Owner:JIANGSU LAINADUO INTELLIGENT EQUIP CO LTD

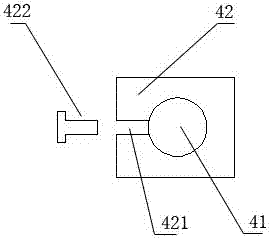

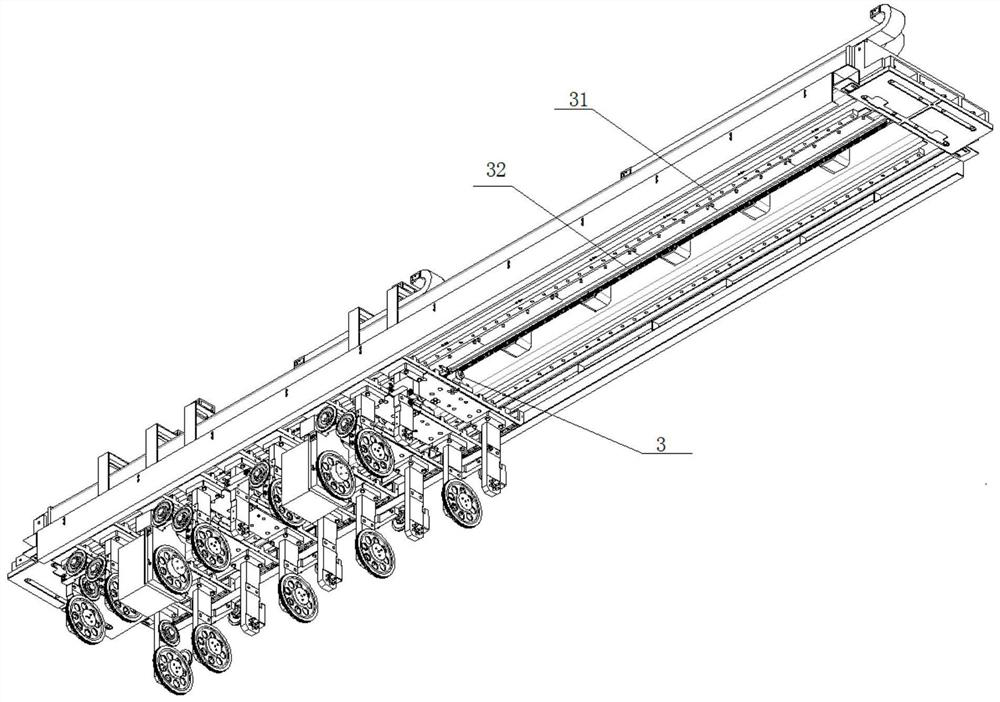

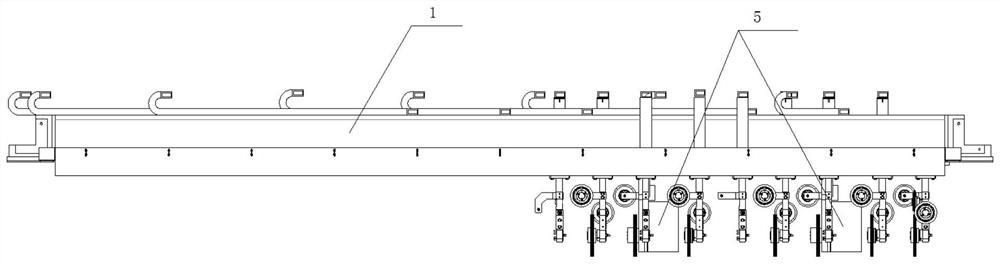

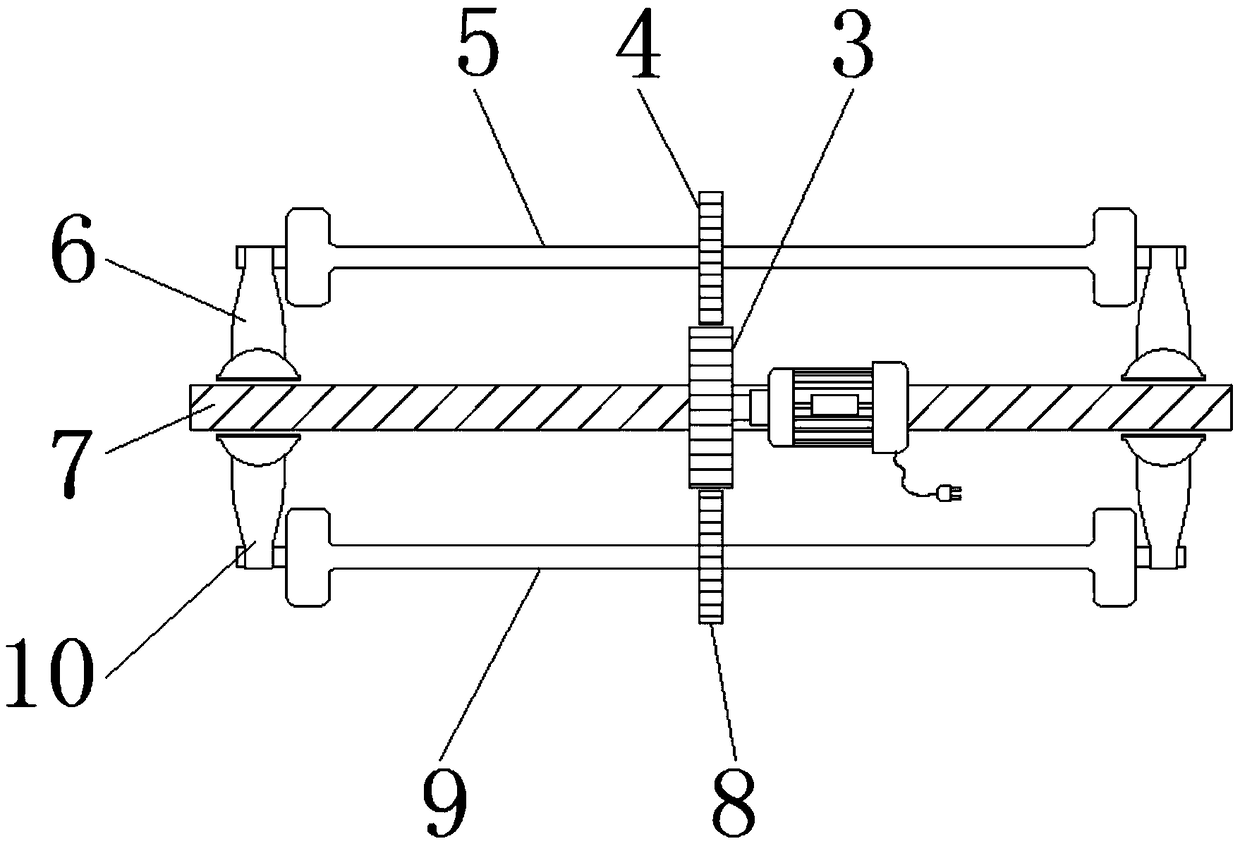

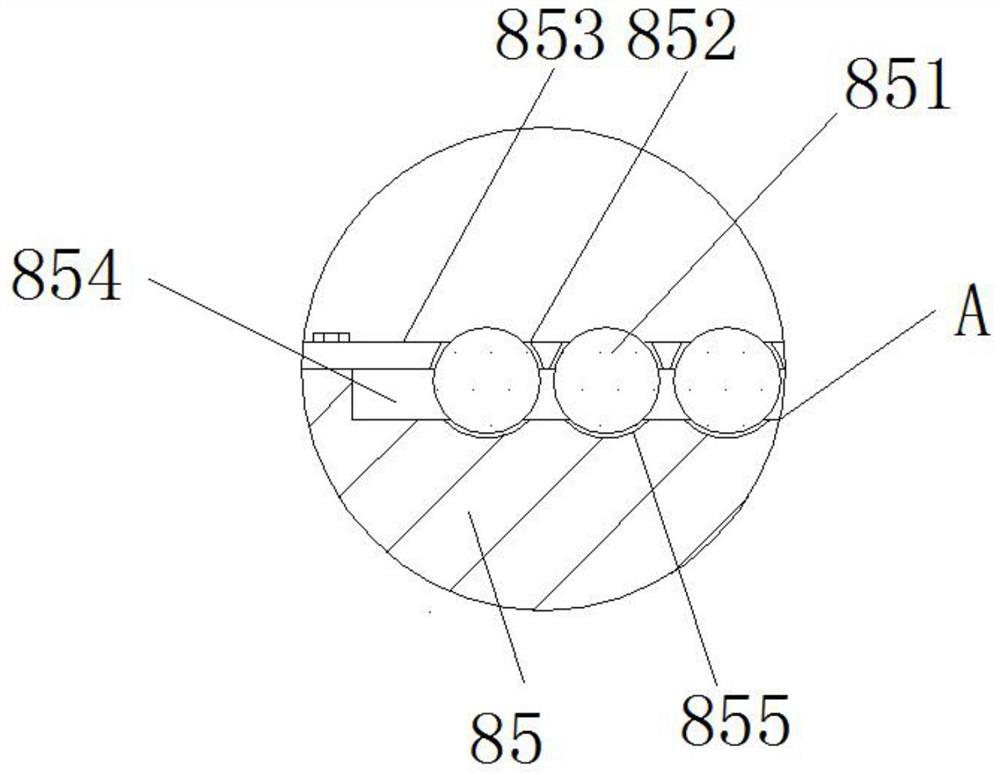

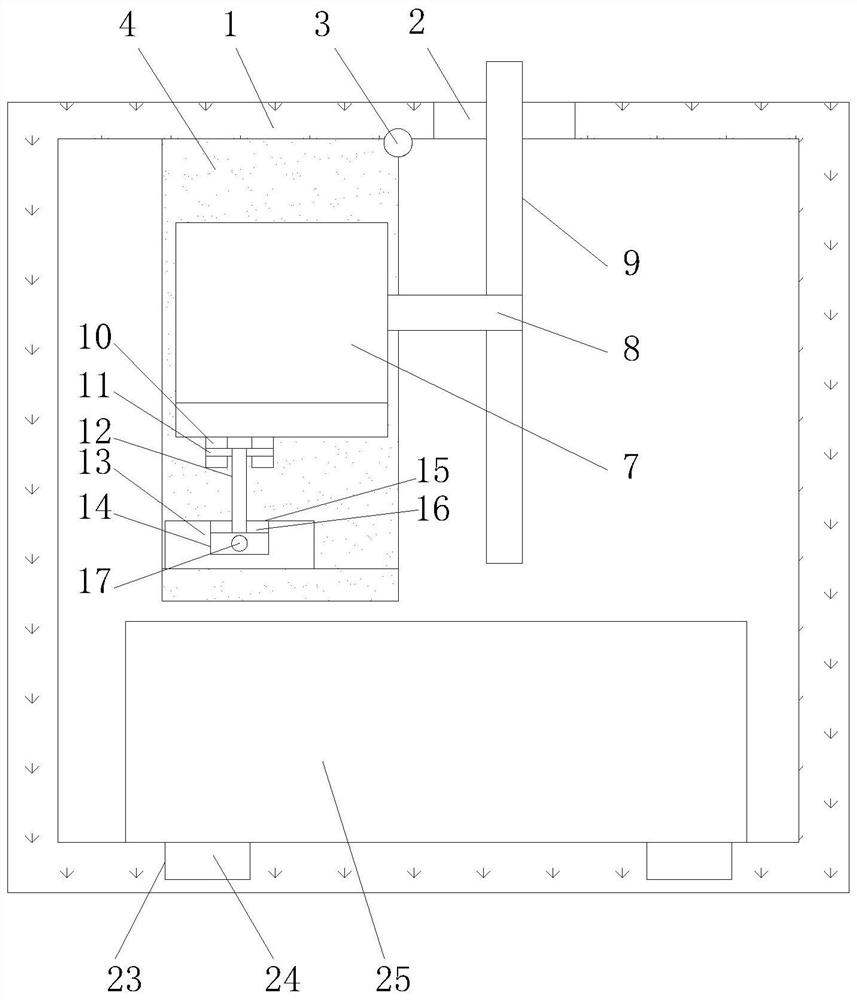

Cut-off cross beam for multi-head cut-off machine

PendingCN111941674AEasy to adjust the cutting positionLow production costWorking accessoriesFine working devicesElectric machineryEngineering

The invention provides a cut-off cross beam for a multi-head cut-off machine. The cut-off cross beam for the multi-head cut-off machine comprises a cross beam body, a plurality of cutting head devicesare arranged on the cross beam, and an axial movement driving device for driving the cutting head devices to move along the axial direction of the cross beam are arranged between the cutting head devices and the cross beam body; one diamond wire sequentially passes through the plurality of cutting head devices, a cutting line segment is formed between the two cutting wheels of each cutting head device, and the extending direction of the cutting line segments is perpendicular to the axial direction of the cross beam body; and in the plurality of cutting head devices, the cutting wheel in at least one cutting head device is connected with a cutting motor. According to the cut-off cross beam for the multi-head cut-off machine, the plurality of cutting head devices are adopted, one silicon rod can be cut into a plurality of silicon rod sections at a time, the machining efficiency is improved, each cutting head device can move in the axial direction of the cross beam through the axial movement driving device, and therefore the cutting position and the length of the cut silicon rod sections can be adjusted conveniently.

Owner:DALIAN LIANCHENG NUMERICAL CONTROL MACHINE

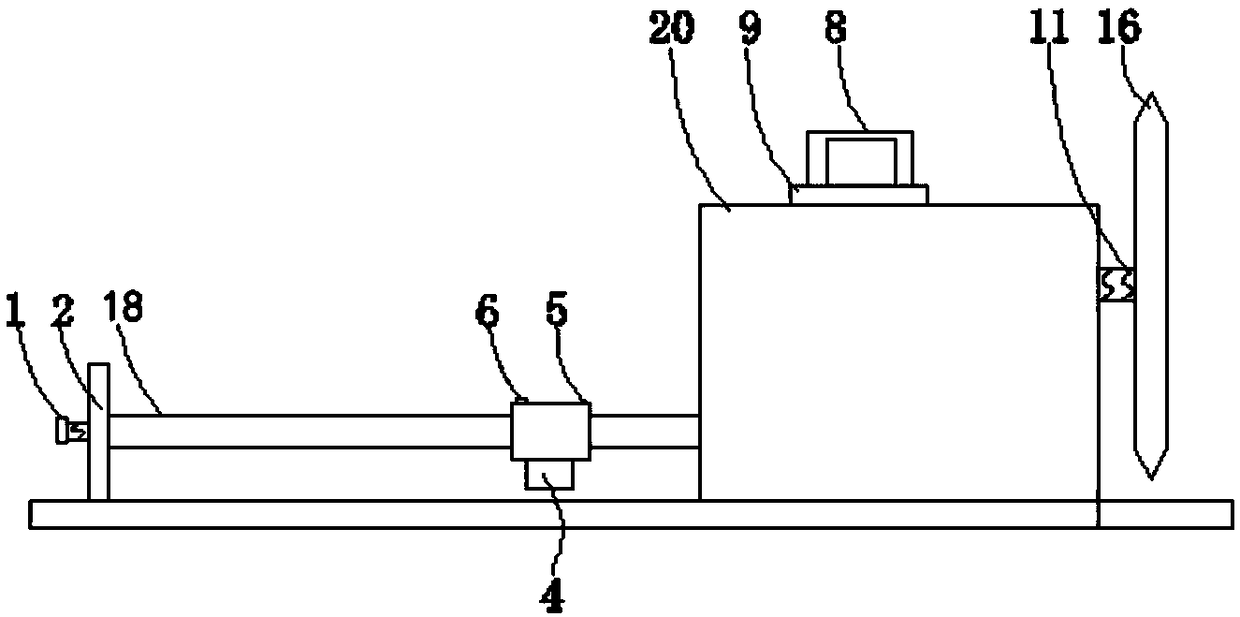

Water conveying pipeline cutting device for building construction

InactiveCN112475441AEasy to adjustImprove cutting efficiencyTube shearing machinesShearing machine accessoriesWater pipeKnife blades

The invention discloses a water conveying pipeline cutting device for building construction, and relates to the technical field of buildings. The water conveying pipeline cutting device comprises a fixing frame, a pair of rotation driving mechanisms for driving a water pipe to rotate is arranged on a limiting mechanism, a hand wheel is rotatably mounted on the fixing frame, and an adjusting mechanism for driving a moving frame to move in the axial direction of the water pipe is in transmission connection with the hand wheel; and a reciprocating lifting mechanism is arranged on the moving frame, and a cutting blade used for cutting the water pipe is rotationally installed at the bottom of the reciprocating lifting mechanism. According to the water conveying pipeline cutting device, the automatic cutting effect on the water pipe is achieved through the rotating cutting blade under driving of the reciprocating lifting mechanism; the arranged adjusting mechanism can flexibly adjust the axial position, relative to the water pipe, of the cutting blade, the cutting position of the water pipe is convenient to adjust, and the cutting efficiency is remarkably improved; and the arranged rotation driving mechanisms can drive the water pipe to rotate, so that the water pipe is fully cut by the cutting blade, and the cutting efficiency of the water pipe is remarkably improved.

Owner:孙琦斌

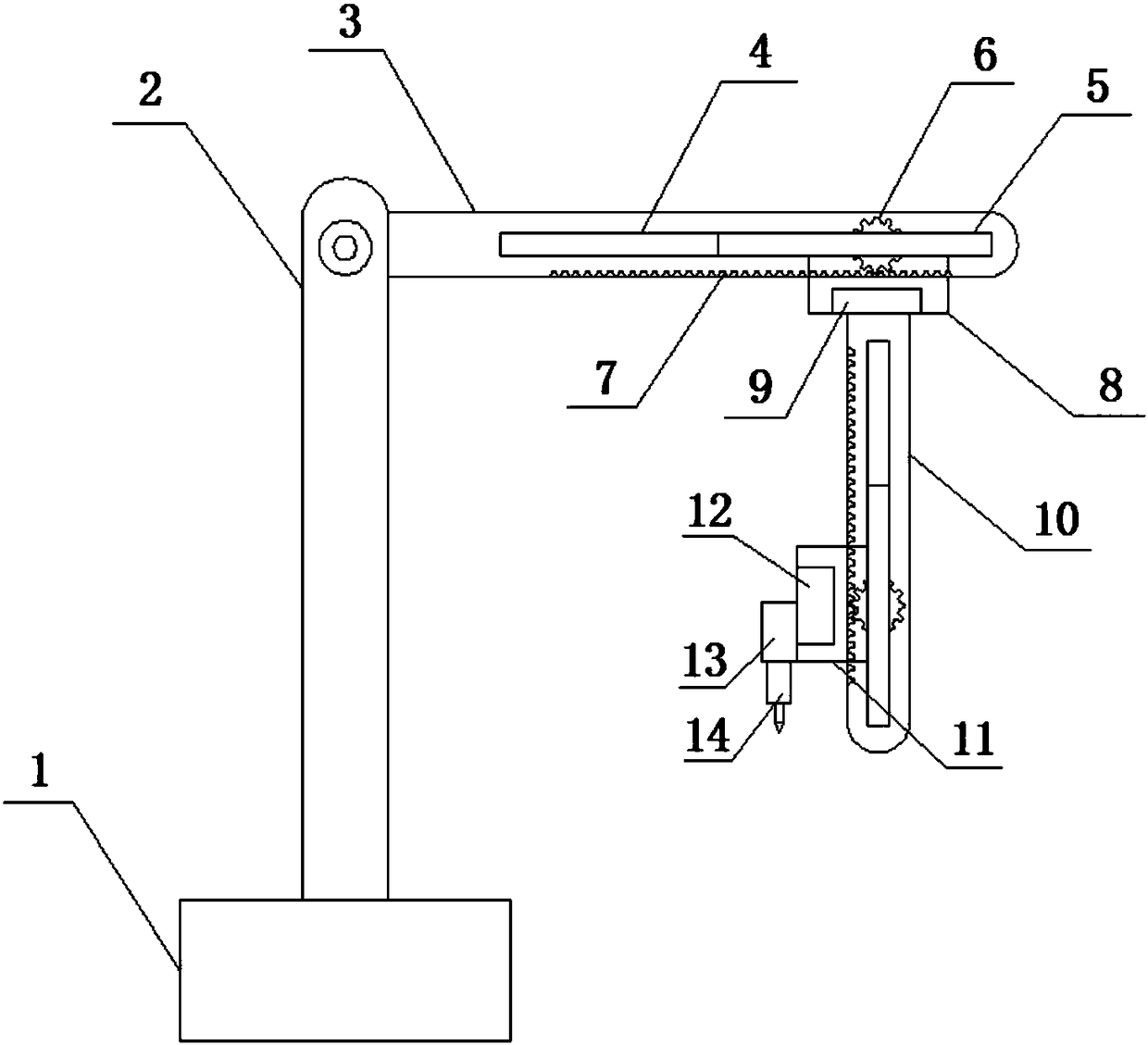

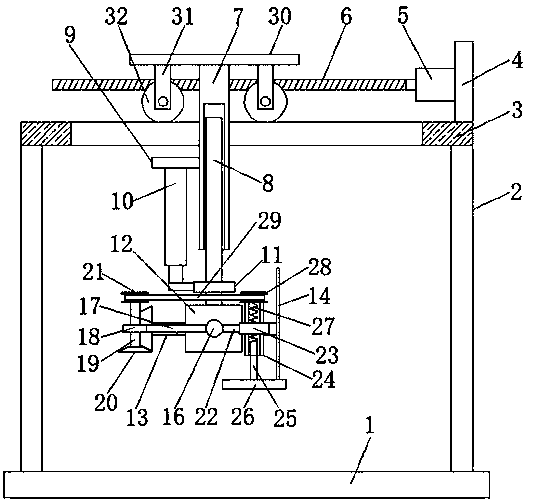

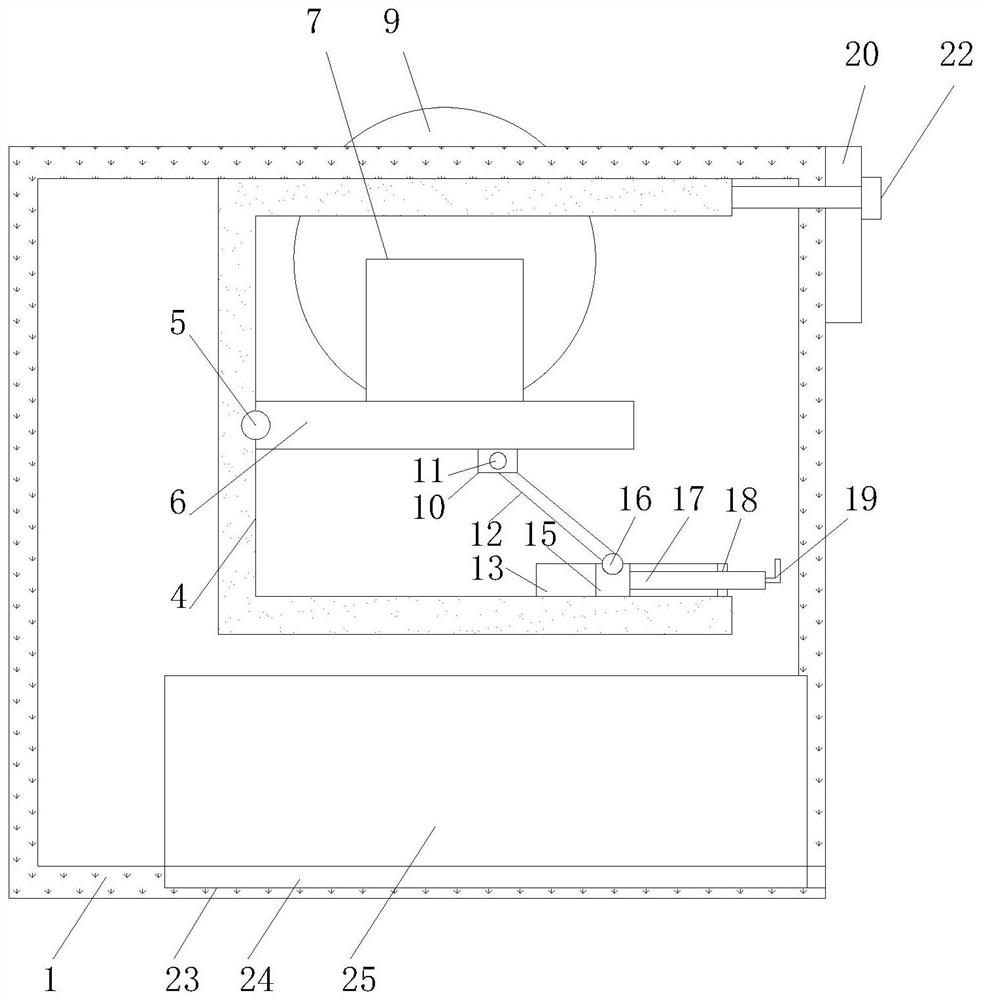

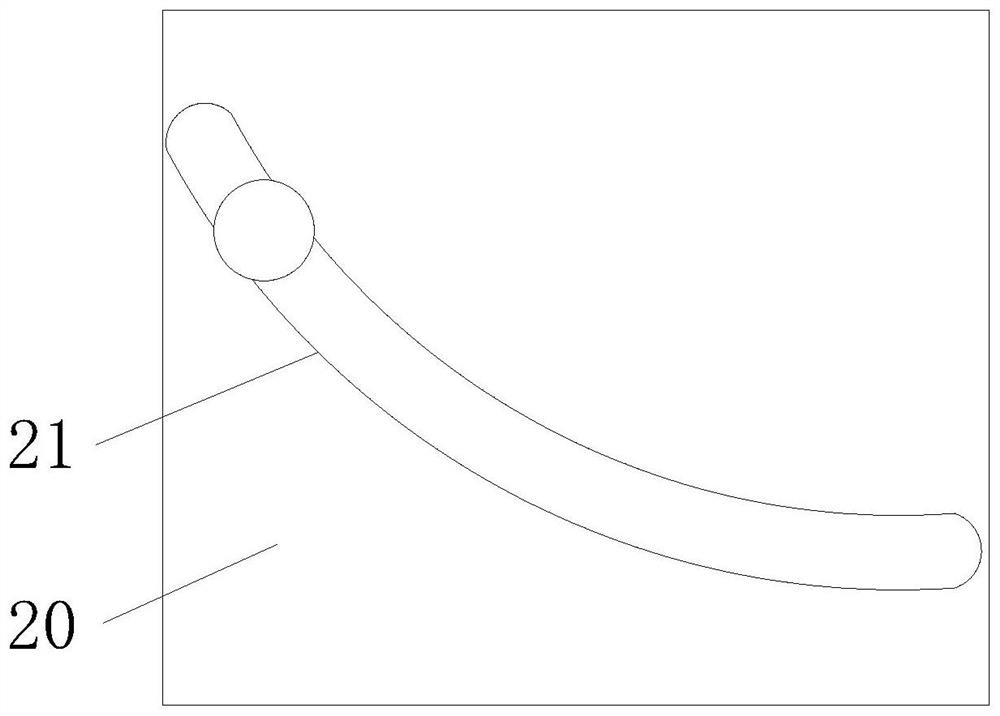

Fixing and cutting all-in-one machine special for building special-shaped steel

ActiveCN112589645AWith tilt adaptive functionEasy cross cuttingGrinding carriagesGrinding machinesConstruction engineeringMachine

The invention discloses a fixing and cutting all-in-one machine special for building special-shaped steel. The fixing and cutting all-in-one machine comprises a rocker arm type cutting machine and a bearing part. According to the fixing and cutting all-in-one machine, the bearing part is arranged and comprises a walking guide frame, a cutting machine connecting plate, a lifting arm, an oil cylinder and a magnetic attraction connecting combination, wherein the lifting arm is arranged in the walking guide frame, one end of the lifting arm is hinged to the magnetic attraction connecting combination, the oil cylinder controls the lifting arm to swing up and down, and the magnetic attraction connecting combination is used for attracting special-shaped steel located on the lower portion of the walking guide frame. In the adsorption ascending process, the inclined self-adaptive function is achieved, meanwhile, the magnetic attraction connecting combination is further used in cooperation withthe cutting machine connecting plate, specifically, after the magnetic attraction connecting combination carries the special-shaped steel to ascend to the limit position, a cutting blade of the rockerarm type cutting machine on the cutting machine connecting plate and the special-shaped steel can be in a vertical distribution state, and transverse cutting and whole feeding are facilitated; and the fixing, lifting and cutting processes are easy and convenient to operate, and the safety is high.

Owner:张建洁

Aluminum plate edge cutting device

InactiveCN108687394AGuaranteed stabilityEasy to adjustShearing machinesShearing machine accessoriesArchitectural engineeringScrew thread

The invention discloses an aluminum plate edge cutting device comprising a base. A connecting plate is fixedly connected to the top of the base and is in threaded connection with a first threaded rod.A first handle is fixedly connected to one end of the first threaded rod. The end, away from the first handle, of the first threaded rod penetrates through the connecting plate to rotate and is connected with a baffle. The two ends of the baffle are each fixedly connected with a first movable block. Through the matched effect of the first handle, the first threaded rod, a bolt, the connecting plate, the baffle, the first movable blocks and the like, the position of a to-be-processed aluminum plate can be adjusted conveniently through the baffle, and thus the cutting position can be adjusted conveniently. Through mutual matching of an abutting plate, a pressing plate, a second threaded rod, a connecting shaft and the like, stability during cutting of the aluminum plate is ensured, finallythrough the synergistic effect of a motor, a second movable block, a rotary shaft and a third handle, a cutter stably cuts the aluminum plate, cutting accuracy is improved, and harm of equipment to operators is lowered.

Owner:蔡宏昕

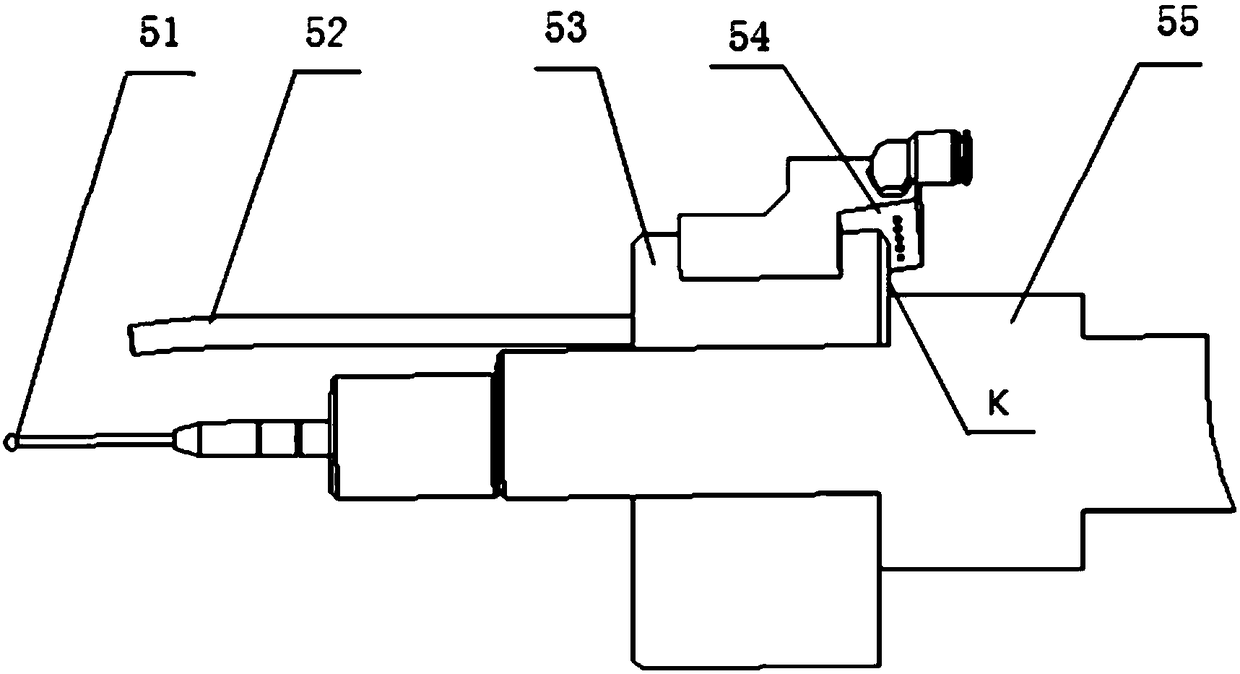

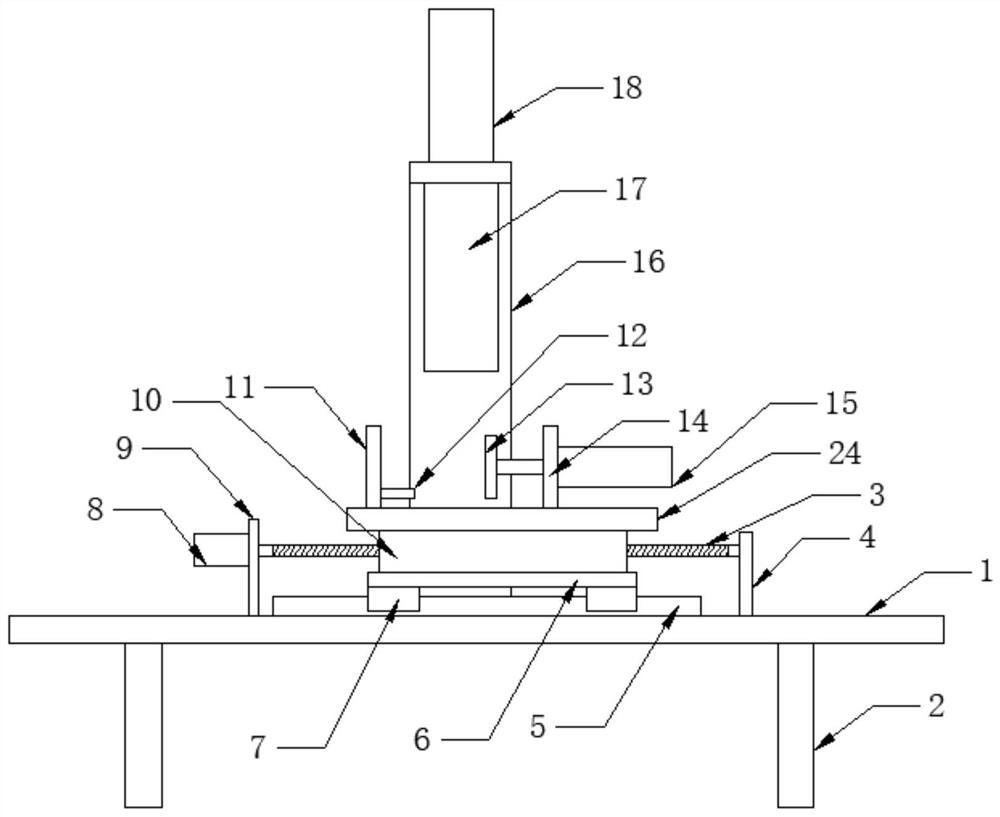

Shearing device for piston rubber ring machining

The invention discloses a shearing device for piston rubber ring machining, and relates to the technical field of piston rubber ring machining. The shearing device comprises a base, a clamping and fixing mechanism, a cutting mechanism and a movable positioning mechanism, a side plate is fixed to the outer side of the upper portion of the base, a hydraulic cylinder is installed above the middle ofthe base, and a piston rod is arranged above the hydraulic cylinder; and a supporting seat is fixed above the piston rod, a driving motor is installed above the supporting seat, a rotating shaft is arranged above the driving motor, an auxiliary steel core is arranged above the rotating shaft in a sleeving mode, and a rubber ring pipe blank is arranged on the outer side of the auxiliary steel core.The shearing device has the following beneficial effects that the auxiliary steel core and the rubber ring pipe blank on the outer side of the auxiliary steel core are conveniently driven to rotate through the arrangement of the driving motor and the rotating shaft, so that the cutting mechanism can rotate for a circle on the outer side of the auxiliary steel core and the rubber ring pipe blank to deepen the cutting effect; and through the arrangement of the hydraulic cylinder and the piston rod, the driving motor and the auxiliary steel core are conveniently driven to ascend and descend, andtherefore the shearing position is conveniently adjusted.

Owner:王水成

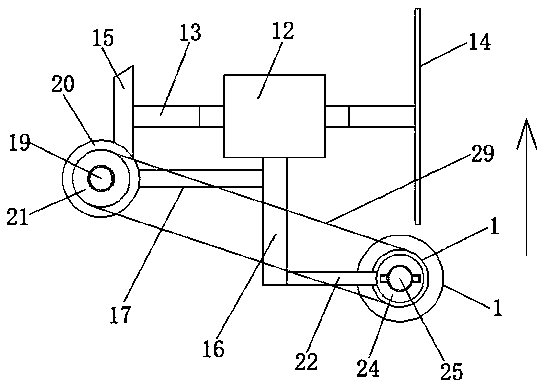

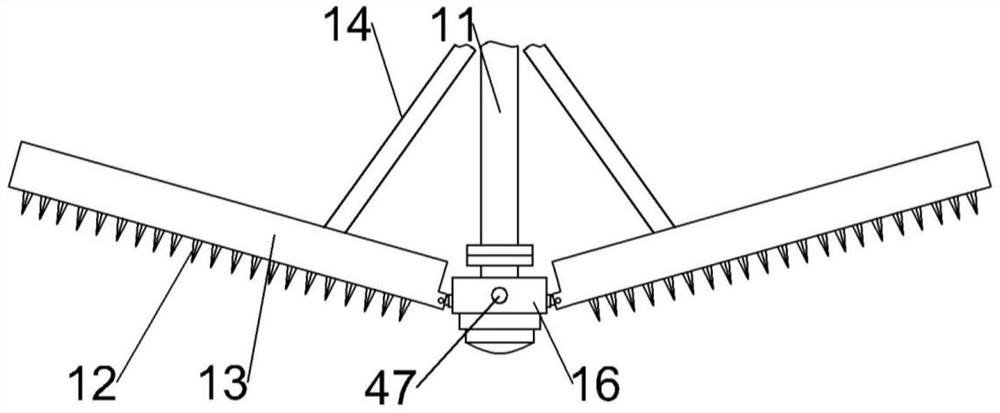

Propeller cutting equipment convenient to adjust

PendingCN107838499AEasy to adjustChange positionAutomatic control devicesFeeding apparatusPropellerEngineering

The invention discloses propeller cutting equipment convenient to adjust. The propeller cutting equipment comprises a bottom plate, vertical plates are fixedly connected to the two sides of the uppersurface of the bottom plate, sliding grooves are formed in the sides, opposite to each other, of the two vertical plates, and the top and the bottom of the inner wall of each sliding groove are connected through a sliding rod; and a movable block is slidably connected inside each sliding groove and is connected to the corresponding sliding rod in a sleeving mode, a return spring is connected the position, located under the corresponding movable block, of each sliding rod in a sleeving mode, the two ends of each return spring are correspondingly and fixedly connected with the bottom of the inner wall of the corresponding sliding groove and the bottom of the corresponding movable block, and the two opposite sides of the two movable blocks are correspondingly and fixedly connected with the two sides of the sides surface of an annular sliding rail through connecting rods. According to the propeller cutting equipment, anti-slid pads are improved, sliding sleeves are pulled upwards so that the anti-skid pads can be separated from the annular sliding rail, after the sliding sleeves are released, under the action of resilience of extrusion springs, the sliding sleeves can drive the anti-skid pads to return, at the moment, the anti-skid pads can be connected on the annular sliding rail again in a lap joint mode, and at the moment, a cutting machine can stably keep the adjusted position.

Owner:镇江市丹徒区顺发船舶螺旋桨有限公司

Glass cutting worktable convenient to use

The invention discloses a glass cutting worktable convenient to use. The glass cutting worktable comprises a tank. A controller is fixedly connected with the top of the left side of the tank, a motoris fixedly connected with the right side of the bottom of an inner cavity of the tank, a gear sleeves a rotary shaft of the motor, a rotary rod is movably connected with the central axis of the bottomof the inner cavity of the tank, a rotary table is fixedly connected with the top of the rotary rod, the top of the rotary table extends out of the tank, a tooth space is arranged on the surface, which is positioned at an end of the inner cavity of the tank, of the rotary table, the gear meshes with the tooth space, a first threaded pipe is fixedly connected with the left side of the inside of the rotary table, and an inner cavity of the first threaded pipe is provided with a first threaded rod. The glass cutting worktable has the advantages that the controller, the motor, the gear, the rotary rod, the rotary table and the tooth space are matched with one another, accordingly, the rotary table can be driven to rotate, cutting locations of glass on the rotary table can be conveniently adjusted, the glass can be conveniently cut by the glass cutting worktable, the cutting efficiency can be improved, and the glass cutting worktable can be conveniently used by people.

Owner:嵊州市和丰玻璃制品有限公司

Plastic product fixing device beneficial to rapid cutting

The invention discloses a plastic product fixing device beneficial to rapid cutting. The plastic product fixing device beneficial to rapid cutting comprises a working panel. Two sets of supporting legs are symmetrically arranged at the lower end of the working panel. The upper end of a main tooth disc is connected with an upper driven disc in an engaged mode. Upper suction blocks are mounted on the outer surfaces of the front end and the rear end of an upper connecting shaft. The lower end of the main tooth disc is connected with a lower driven disc in an engaged mode. Lower suction blocks aremounted on the outer surfaces of the front end and the rear end of a lower connecting shaft. A slideway is arranged in the upper surface of the working panel. A first rotary shaft is connected to a first sliding block through welding. A first ruler rod penetrates through a first sliding cylinder. A second sliding block is connected into the slideway in a clamped mode. A second ruler rod is connected to the upper end of a second rotary shaft. The plastic product fixing device beneficial to rapid cutting can achieve automatic fixing and is unlikely to damage a sample plate, and the cutting angle and the cutting range can be adjusted; and rules used for assisting in cutting are arranged, so that the overall working efficiency is high.

Owner:湖州星润塑业有限公司

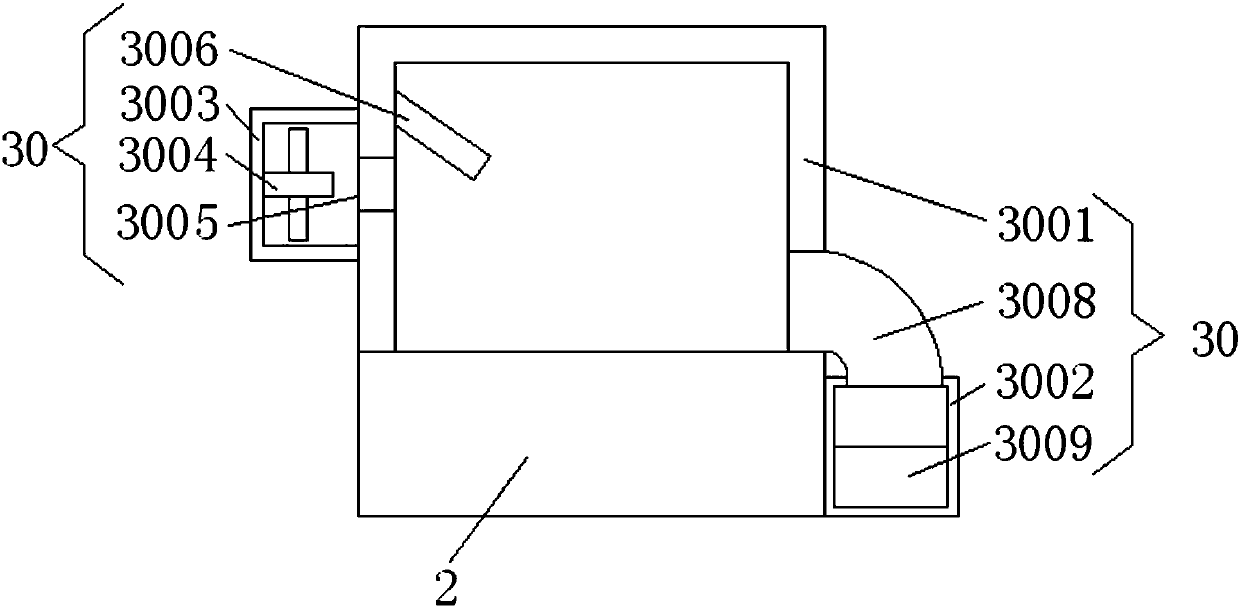

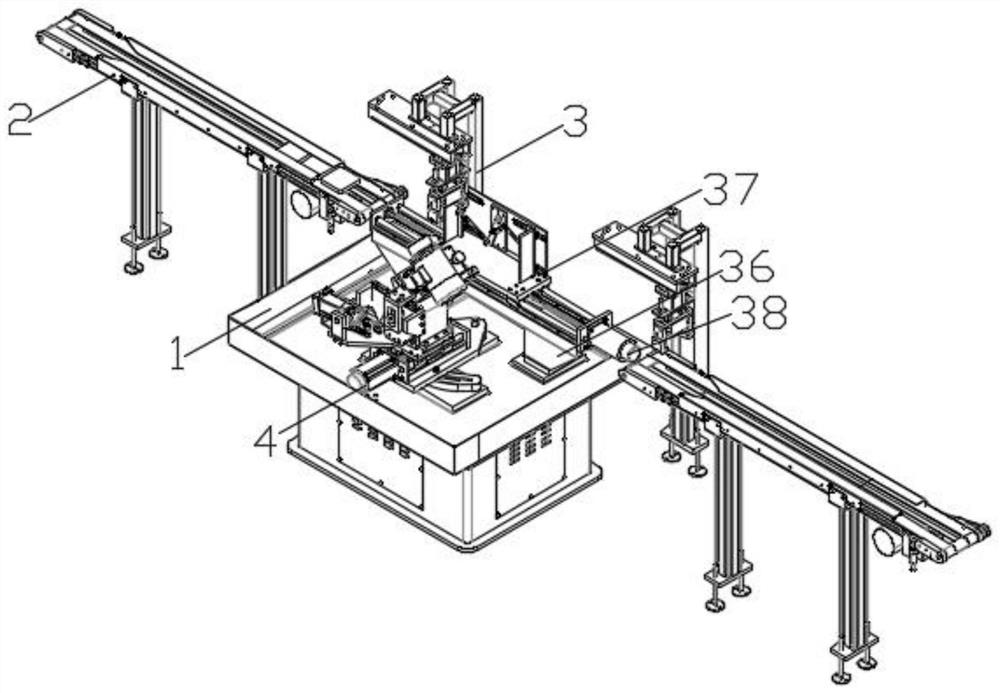

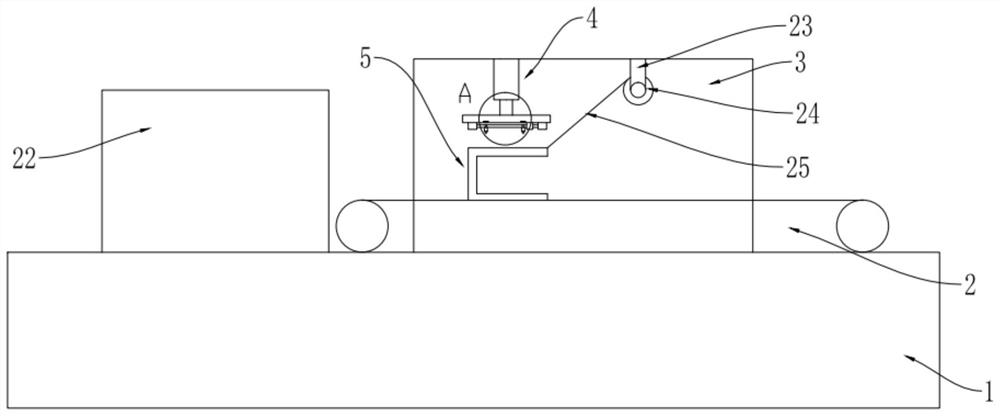

Ham sausage thermoplastic packaging machine

InactiveCN113602601AEasy to adjust the cutting positionShorten the timeWrappers shrinkageWrapper twisting/gatheringPolymer sciencePlastic film

The invention discloses a ham sausage thermoplastic packaging machine. The ham sausage thermoplastic packaging machine comprises a workbench, a conveying device, a supporting shell, a cutting device and a plastic film conveying device, the supporting shell is arranged on the workbench, the cutting device is arranged below the top wall of the supporting shell, and the conveying device penetrates through the supporting shell and is arranged on the workbench; and the plastic film conveying device is arranged below the cutting device. The ham sausage thermoplastic packaging machine belongs to the technical field of thermoplastic packaging machines, and particularly can adjust the cutting distance of a plastic film according to the size of a ham sausage, save the time for secondary cutting and avoid waste of a thermoplastic film.

Owner:临沂金锣文瑞食品有限公司

A clamp block adjustable double-layer fabric cutting device

ActiveCN107881628BWrinkles won't happenGuaranteed accuracyPile-fabric loomsStructural engineeringMechanical engineering

The invention discloses a clamping block adjusting type cutting device for cutting a double-layer fabric. The clamping block adjusting type cutting device includes a machine frame, a fixed plate, a cutting carrier and a cutting mechanism. The machine frame is of a U-shaped structure. The fixed plate is mounted at the bottom of the machine frame. The cutting carrier is mounted on the fixed plate. The cutting carrier includes two supporting blocks, two springs and a plurality of clamping blocks. The lengths of the plurality of clamping blocks are different. The supporting blocks are provided with cutting V grooves. The two supporting blocks are oppositely mounted on the fixed plate. The springs are mounted between the opposite outer sides of the two supporting blocks and the machine frame, the opposite inner sides of the two supporting blocks are provided with step-shaped groove bodies respectively, and the clamping blocks are mounted between the step-shaped groove bodies. The upper endfaces of the clamping blocks and the upper end faces of the supporting blocks are located on the same horizontal plane. The cutting mechanism is mounted above the supporting blocks. According to the clamping block adjusting type cutting device, cutting intervals are adjustable.

Owner:JIANGSU LAINADUO INTELLIGENT EQUIP CO LTD

Mechanical equipment accessory cutting equipment convenient to use

InactiveCN114102707AReduce laborEasy to adjust the cutting positionMetal working apparatusElectric machineryEngineering

The invention belongs to the technical field of accessory cutting equipment, and particularly relates to mechanical equipment accessory cutting equipment convenient to use. Sliding rails are installed on the front side and the rear side of the upper portion of a workbench, a moving plate is arranged on the upper sides of the sliding rails, sliding blocks are installed on the lower side of the moving plate, and the sliding blocks are slidably connected with the sliding rails; a cutting table is arranged on the upper side of the moving plate, a supporting plate is arranged between the cutting table and the moving plate, a motor mounting plate is arranged on the left side of the workbench, a driving motor is mounted on the motor mounting plate, an output shaft of the driving motor is connected with a lead screw, and a lead screw nut is mounted in the middle of the lower side of the cutting table. The upper side of the cutting table is provided with an accessory fixing device, the rear side of the upper portion of the workbench is provided with a support, the upper end of the support is provided with a first air cylinder, the cutting motor drives the cutter to rotate, the first air cylinder is matched to drive the cutter to move downwards, and mechanical equipment accessory raw materials are rapidly cut.

Owner:苏州宛铭辰重型机械有限公司

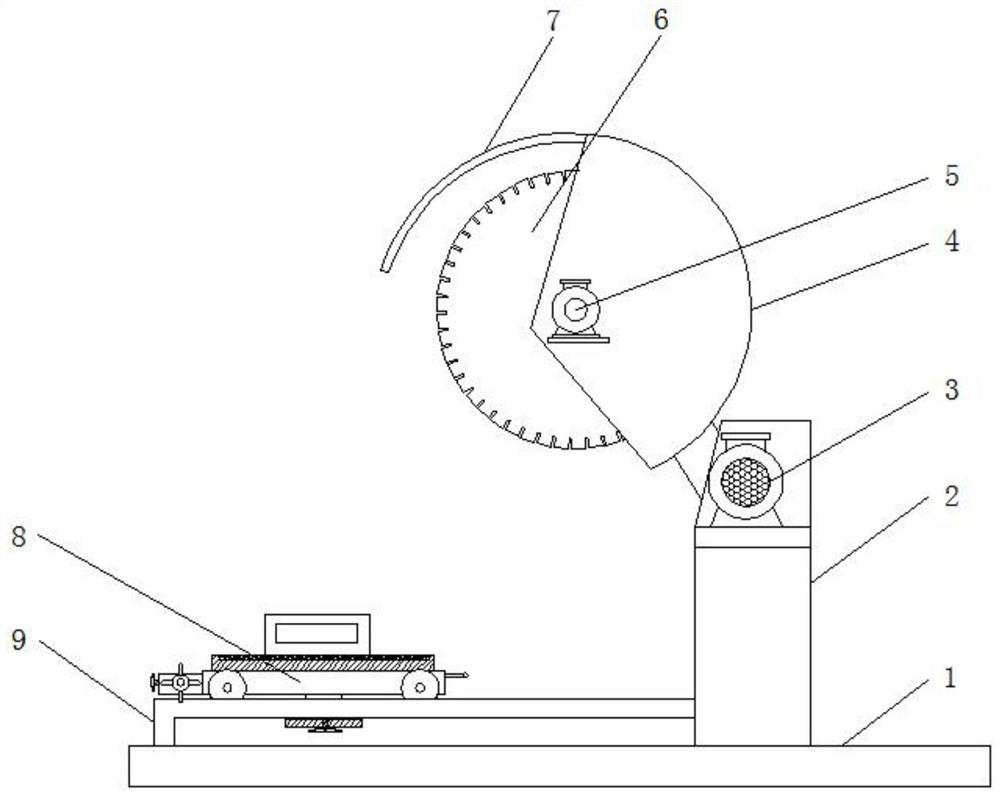

Raw stone cutting machine

PendingCN112824083AEasy to moveEasy to adjust the cutting positionWorking accessoriesStone-like material working toolsElectric machineryEngineering

The invention discloses a raw stone cutting machine. The raw stone cutting machine comprises a bottom plate, a fixing table arranged at one end of the top of the bottom plate, a cutting disc fixing shell hinged to one side of the top of the fixing table, a first motor arranged on one side of the top of the fixing table and used for controlling the cutting disc fixing shell to rotate, a cutting disc arranged in the cutting disc fixing shell and used for cutting raw stones, a second motor arranged on one side of the cutting disc fixing shell and used for driving the cutting disc to rotate, and an arc-shaped baffle arranged on one side of the top of the cutting disc fixing shell, and the raw stone cutting machine is characterized by further comprising a raw stone containing unit arranged on the side, close to the cutting disc fixing shell, of the top of the fixing table. Raw stones are placed at the top of a boss, an arc-shaped groove in the bottom of a groove and an arc-shaped through groove in a cover body limit a rolling ball, when the raw stones are placed on the rolling ball at the top of the boss, the raw stones are pushed to enable the rolling ball to rotate, the raw stones are conveniently moved on the boss, the raw stone cutting position is conveniently adjusted, and use is convenient.

Owner:祁阳县合力塑胶有限公司

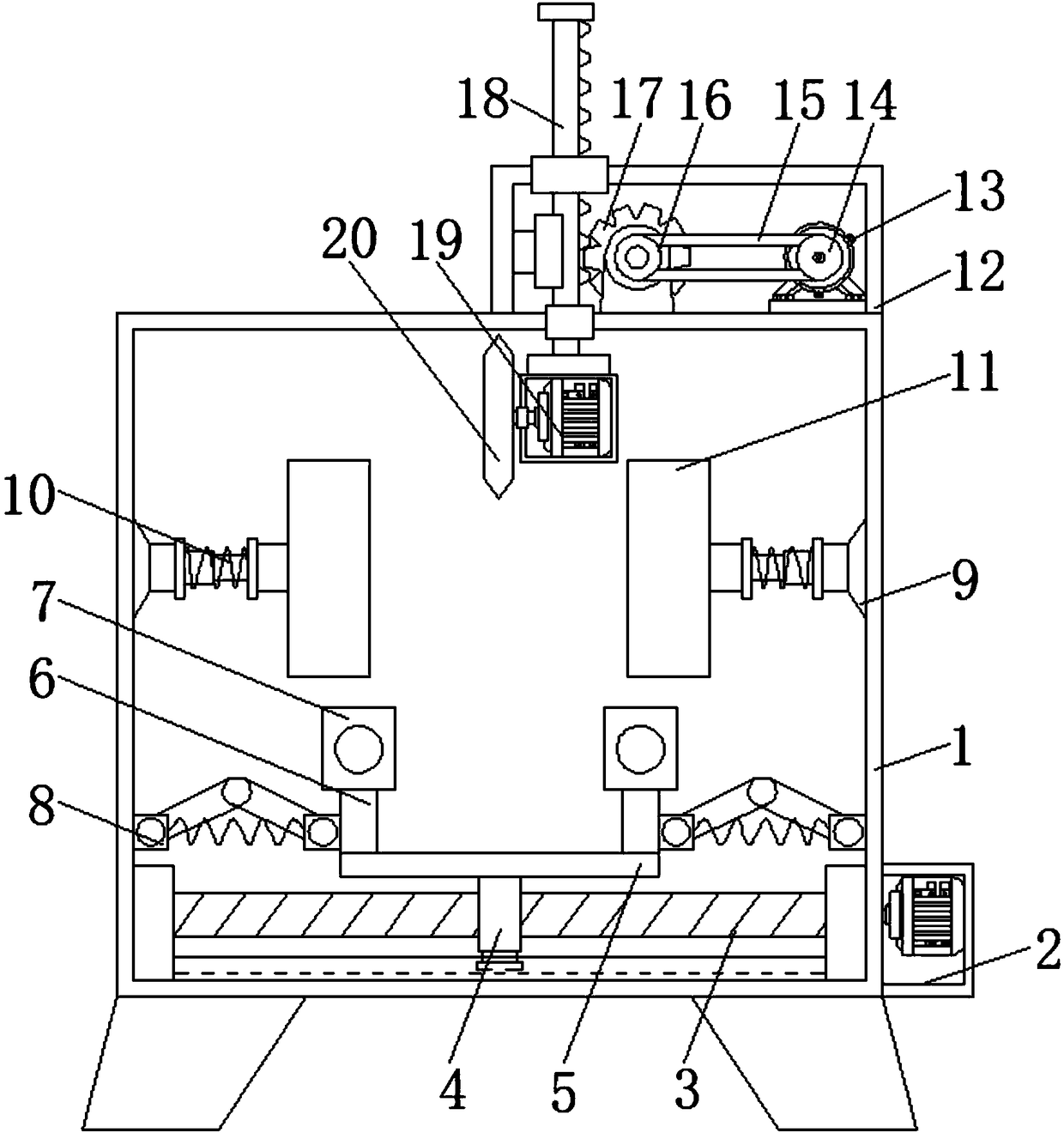

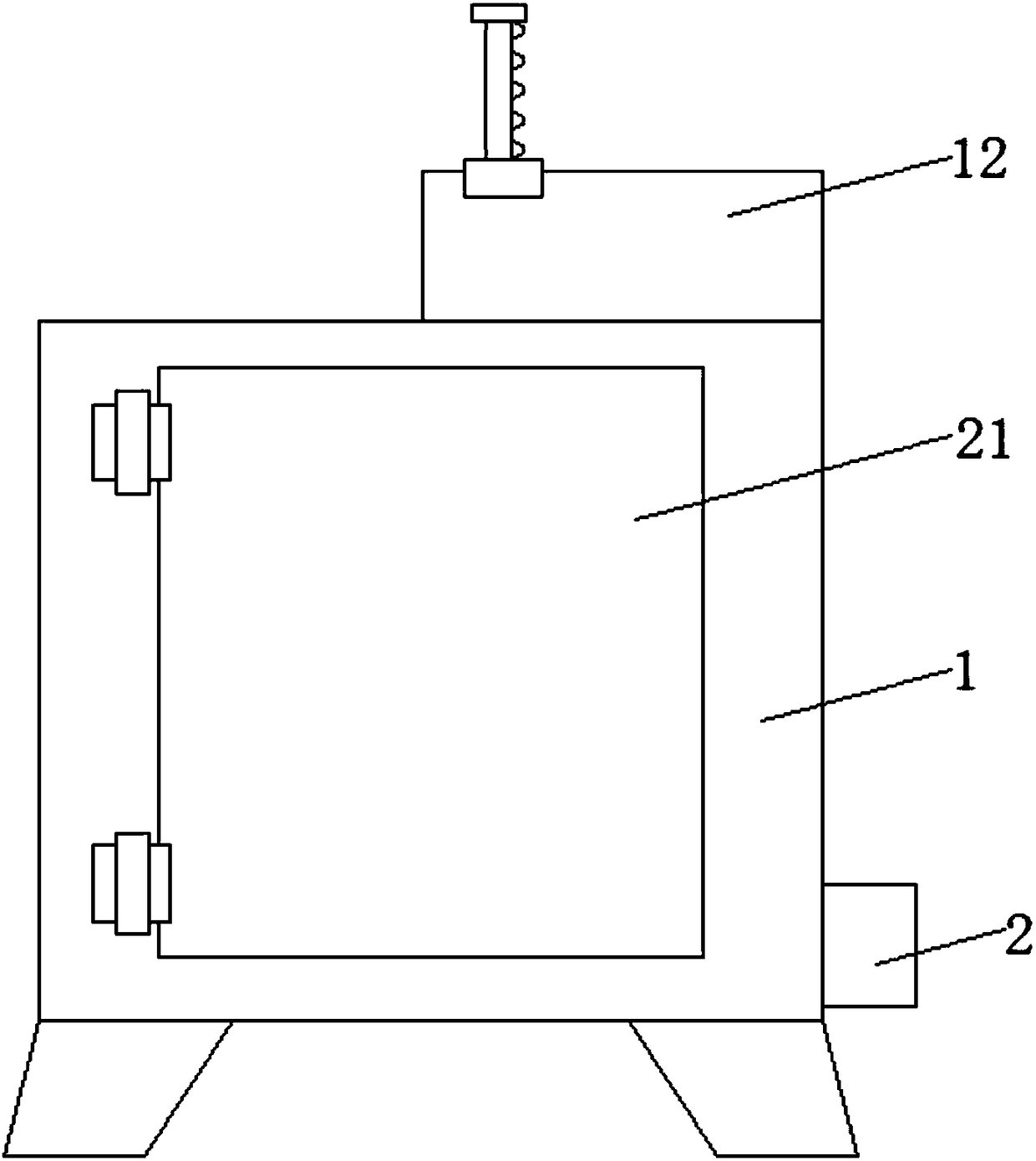

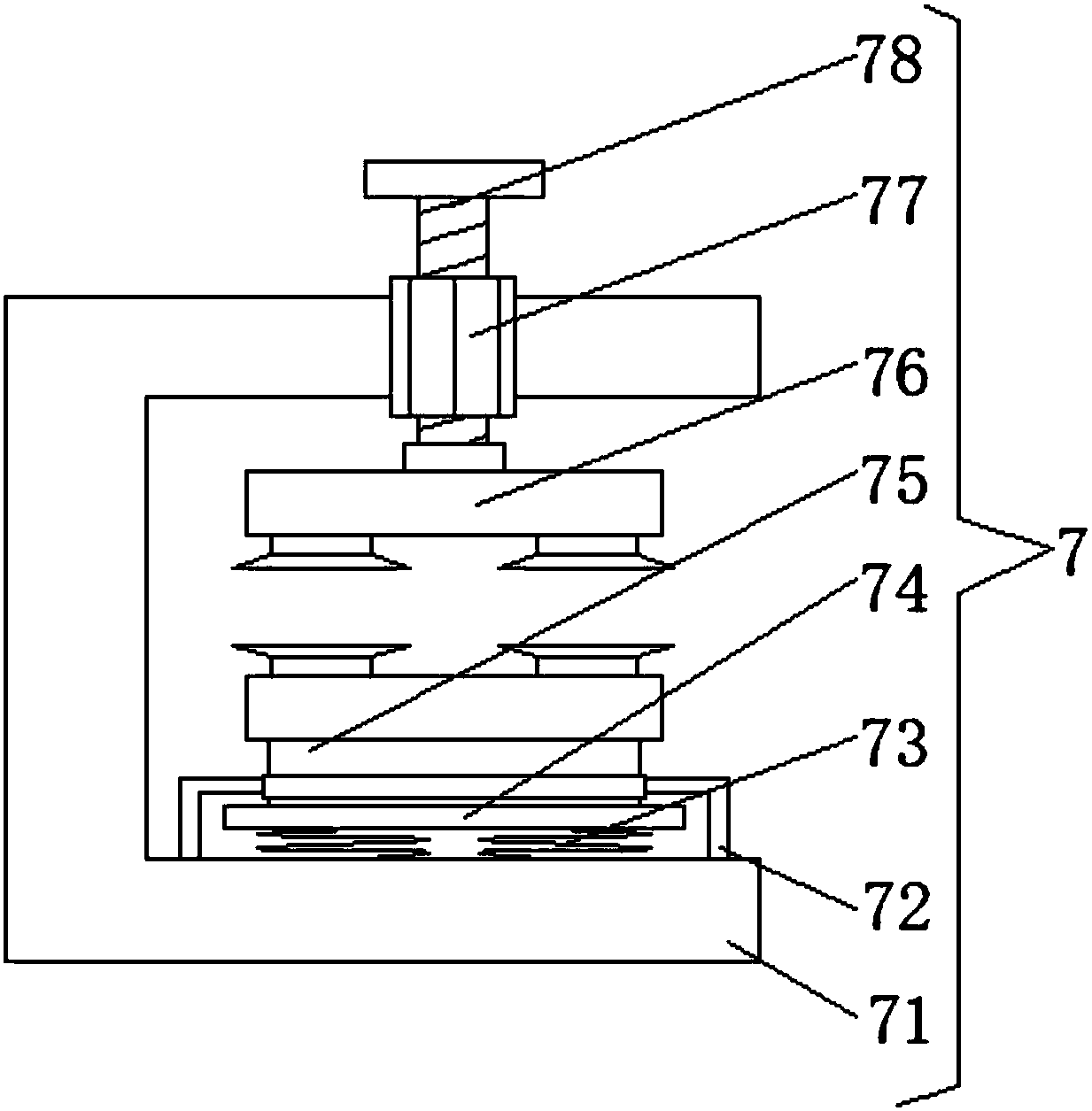

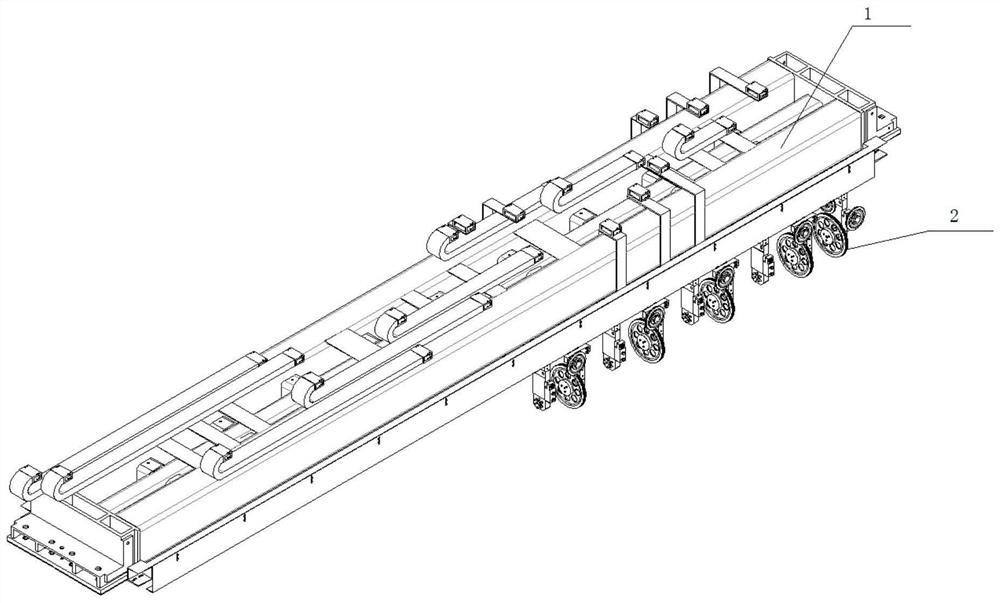

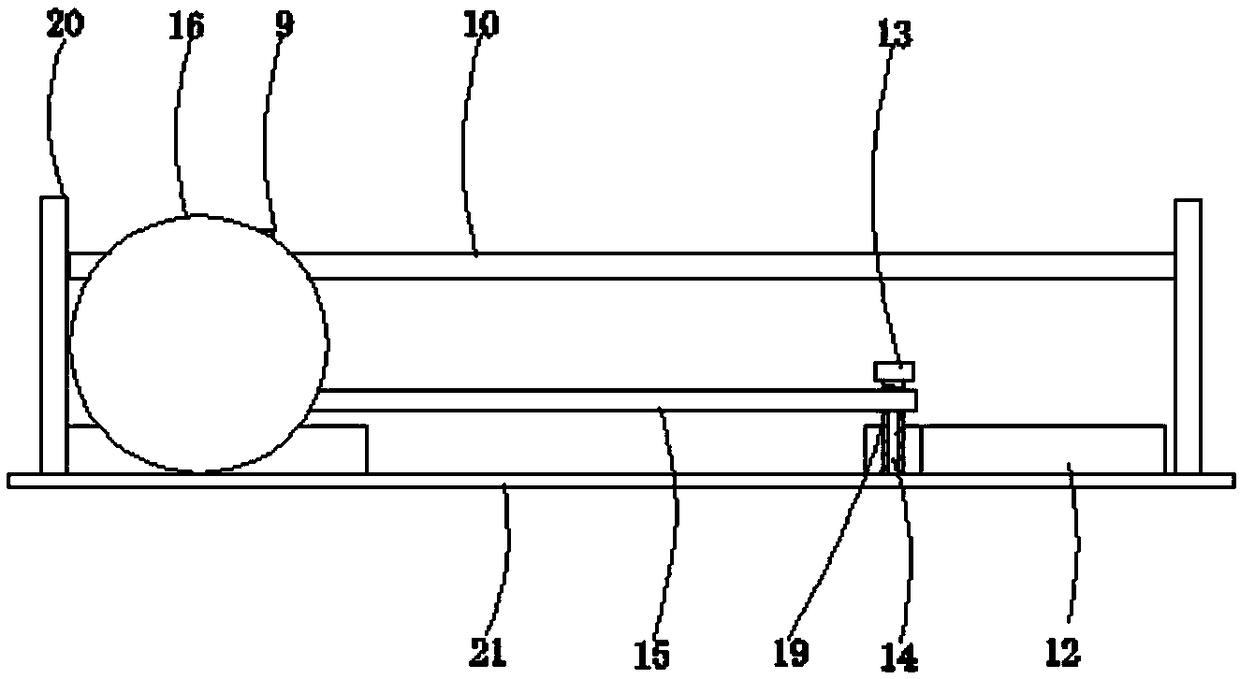

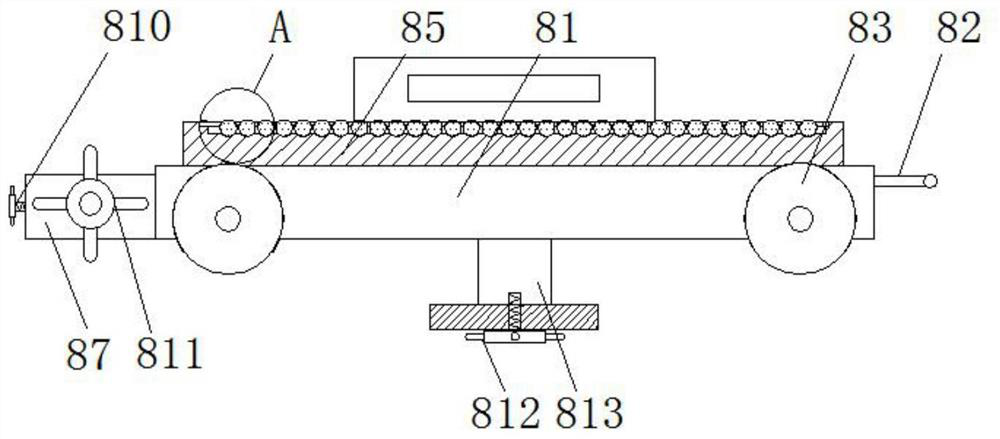

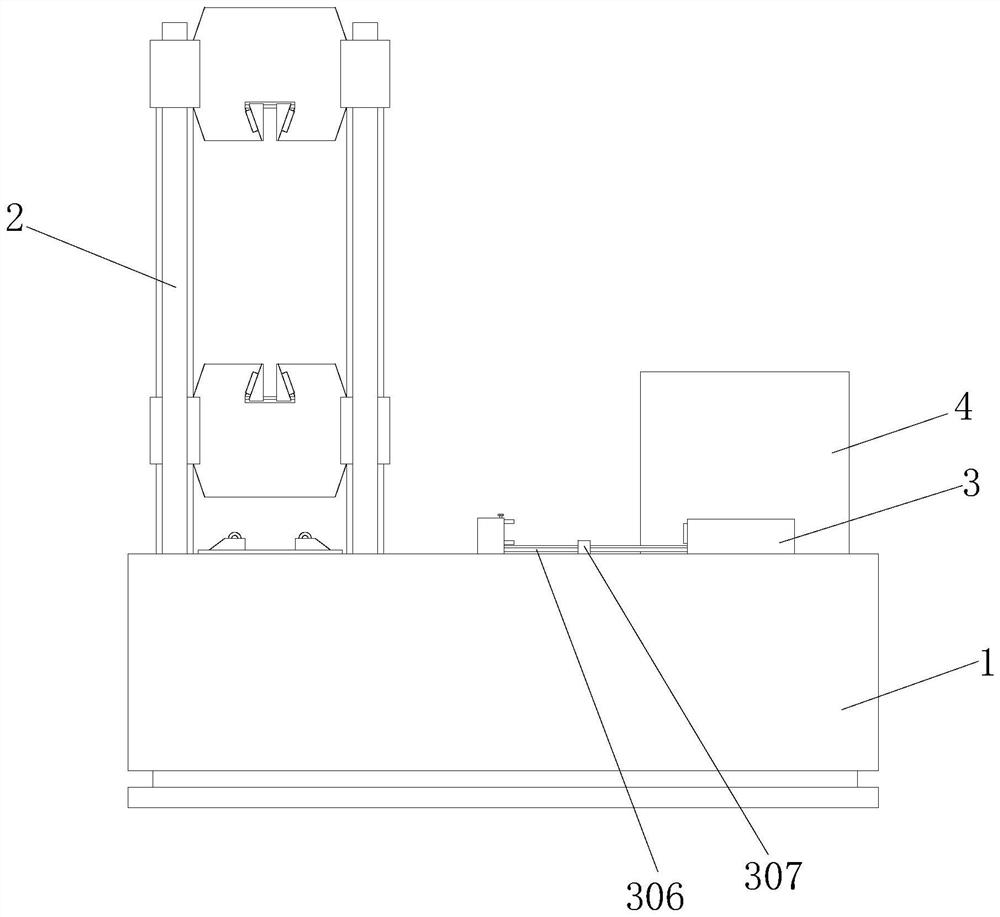

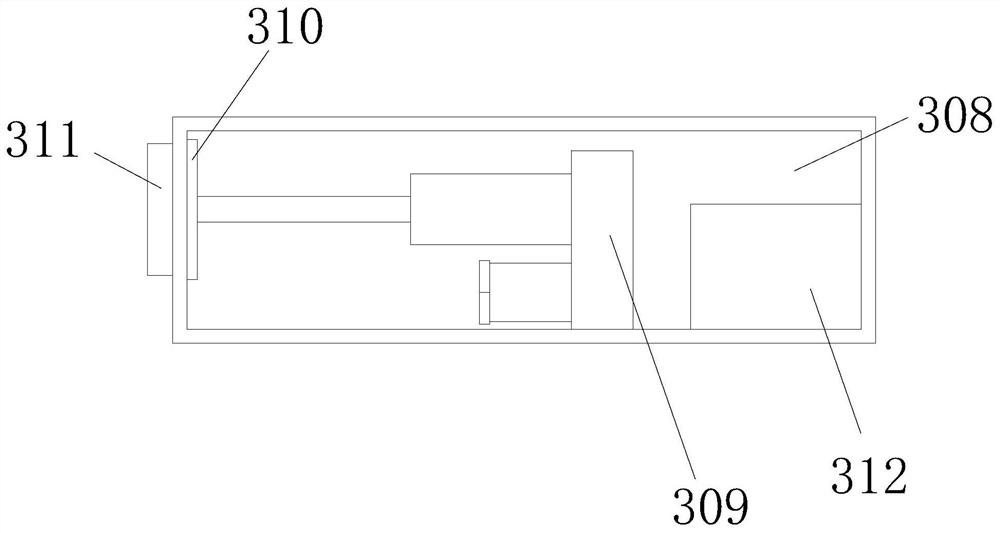

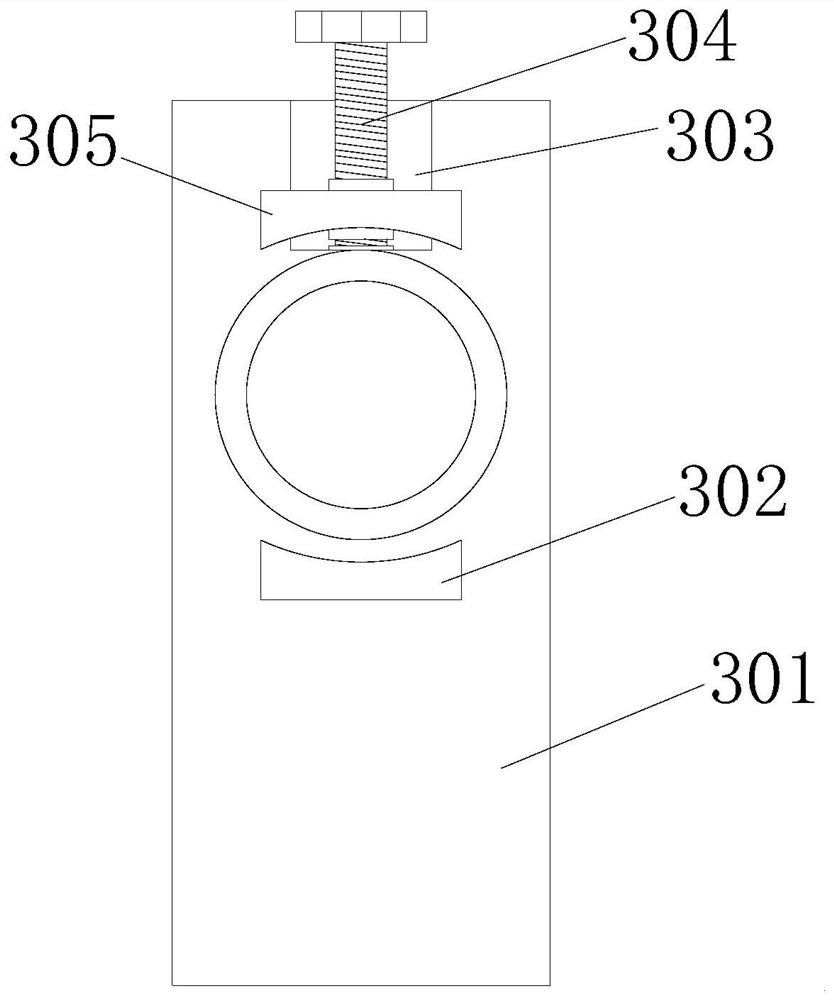

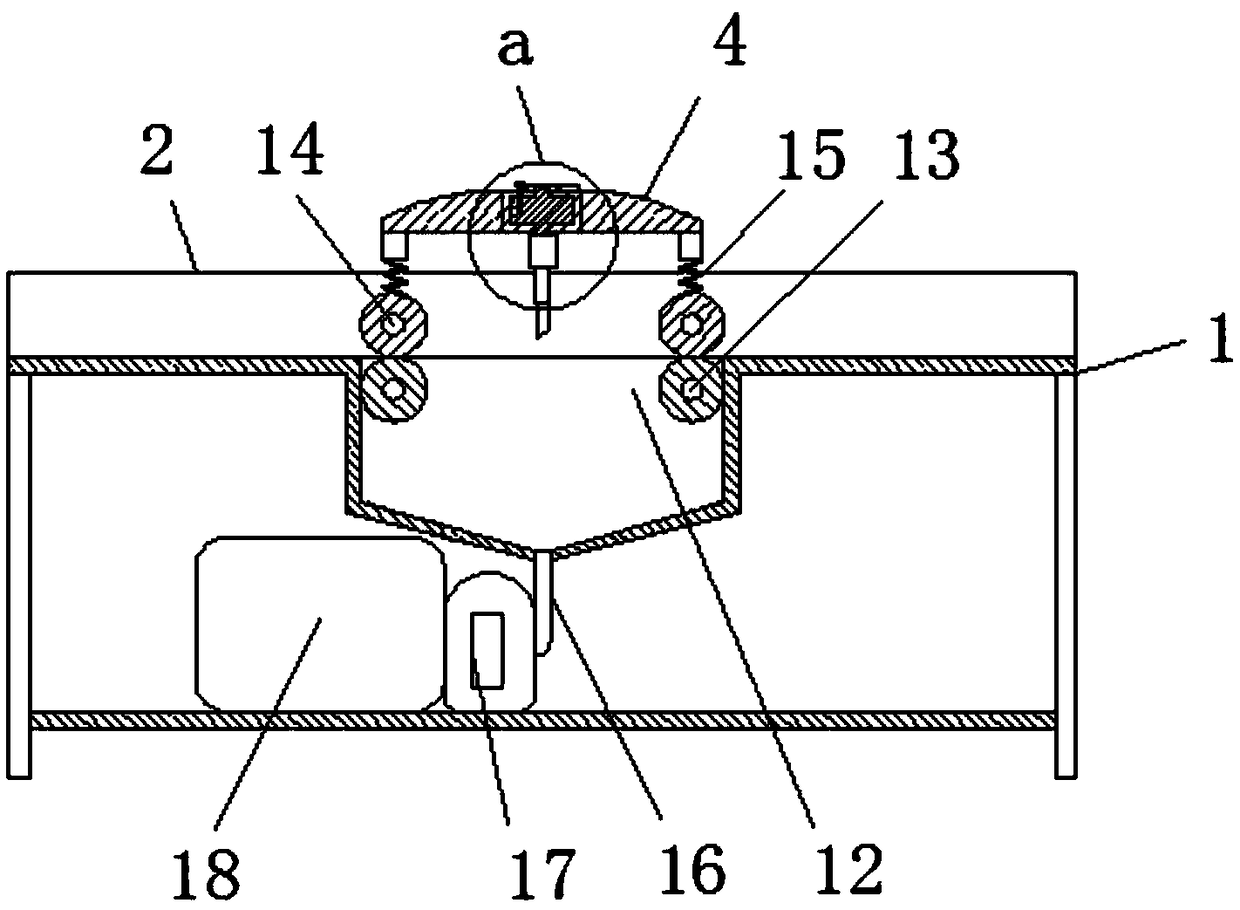

Detection equipment for detecting stability of fabricated steel and use method of detection equipment

InactiveCN113049387AAccurate measurementAccurate advance distancePreparing sample for investigationMaterial strength using tensile/compressive forcesStructural engineeringMachine

The invention discloses detection equipment for detecting the stability of fabricated steel and a using method of the detection equipment. The detection equipment comprises a workbench, a testing machine is installed at one end of the top of the workbench, an inspection device is installed at the end, away from the testing machine, of the top of the workbench, and a cutting device is installed on one side of the top of the workbench. The inspection device comprises a mounting seat, a placement plate is mounted at the bottom of one end, far from the testing machine, of the mounting seat, a placement groove is formed in the top of one end, far from the testing machine, of the mounting seat, a threaded rod is rotatably mounted in the placement groove, and a clamping block is mounted on the outer surface of the threaded rod. According to the invention, an electric cylinder is arranged in the inspection device, the advancing distance of a pressure sensor is more accurate by utilizing the characteristic of accurate transmission of the electric cylinder, and when the pressure sensor is in contact with one end of a test material, an accurate numerical value is obtained through conversion of an external computer by transmitting an electric signal, so that the situation that errors are caused by manual measurement and test evaluation is further influenced is avoided.

Owner:温州思本德建筑工程有限公司

An all-in-one fixed cutting machine dedicated to special-shaped steel for construction

ActiveCN112589645BWith tilt adaptive functionEasy cross cuttingGrinding carriagesGrinding machinesMachineRocker arm

The invention discloses a special-purpose fixed cutting integrated machine for building special-shaped steel materials, which comprises a rocker-arm type cutting machine and a bearing part. In the present invention, a bearing part is provided, and the bearing part includes a walking guide frame, a cutting machine connecting plate, a lifting arm, an oil cylinder and a combination of magnetic suction connections, wherein the lifting arm is inside the walking guide frame, and one end of the lifting arm is hinged with the magnetic connection combination, and the oil cylinder controls The lifting arm swings up and down, and the magnetic suction connection combination is used to absorb the special-shaped steel located at the lower part of the walking guide frame. During the process of adsorption and rising, it has a tilt adaptive function. At the same time, the magnetic suction connection combination is also used in conjunction with the cutting machine connection plate, specifically After the magnetic suction connection combination carries the special-shaped steel up to the limit position, the cutting piece and the special-shaped steel of the rocker cutting machine on the cutting machine connecting plate can be in a vertical distribution state, which is convenient for cross-cutting, and the entire feeding, fixing, lifting and cutting process Simple operation, convenient and high safety.

Owner:张建洁

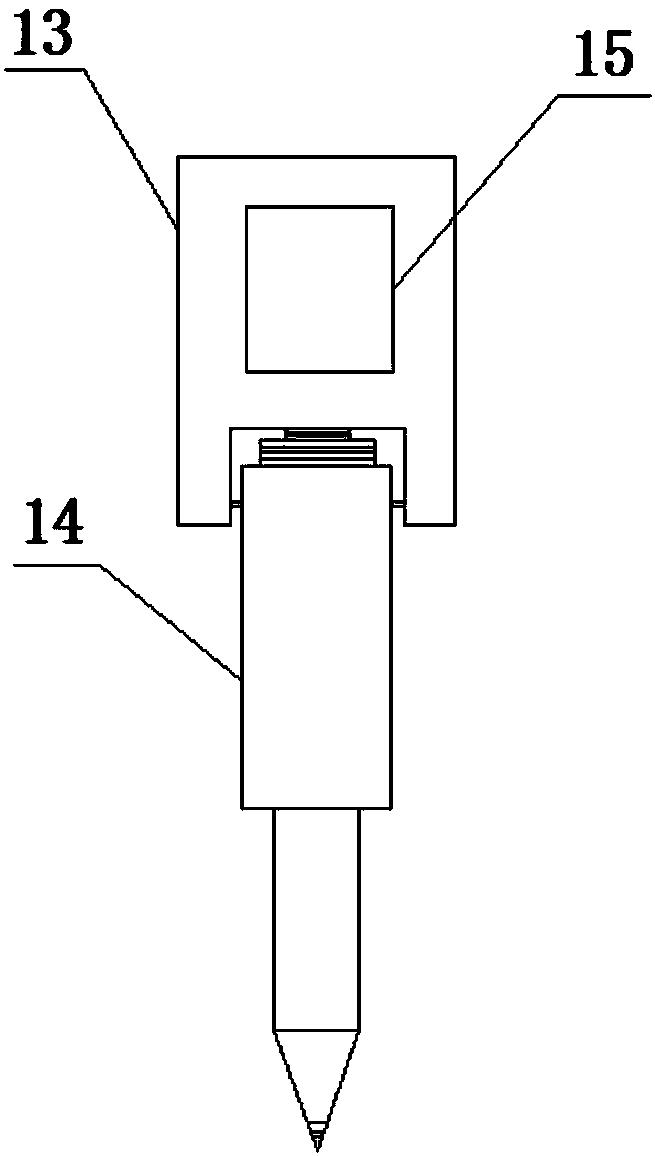

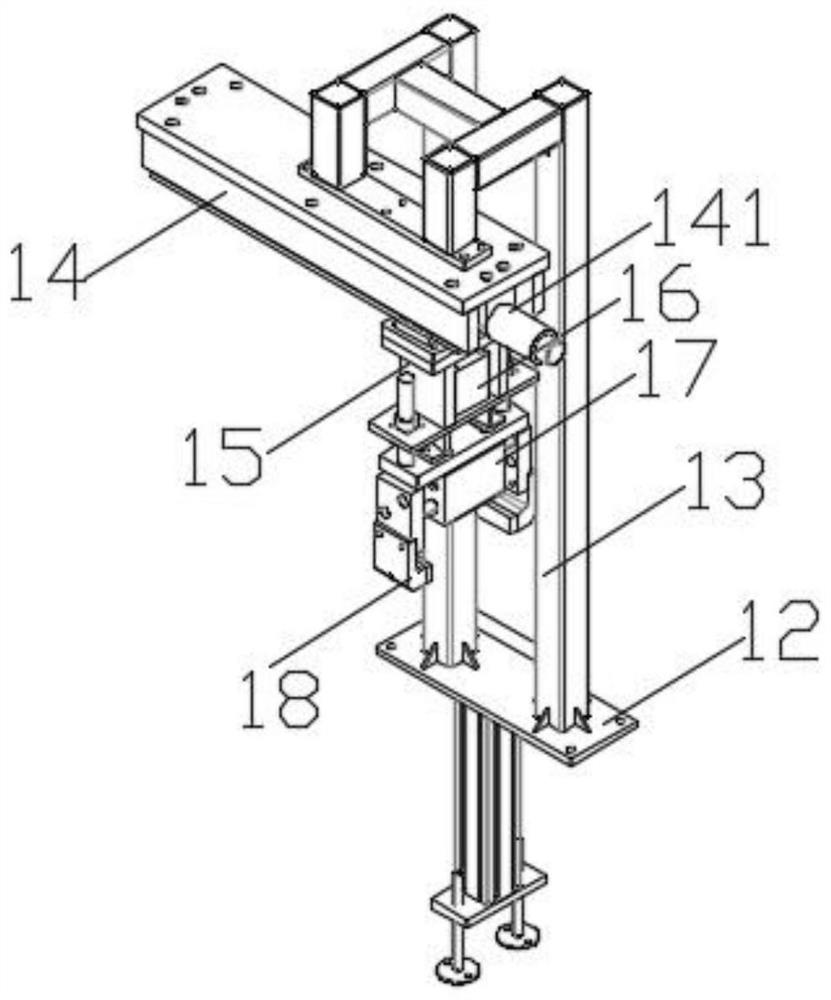

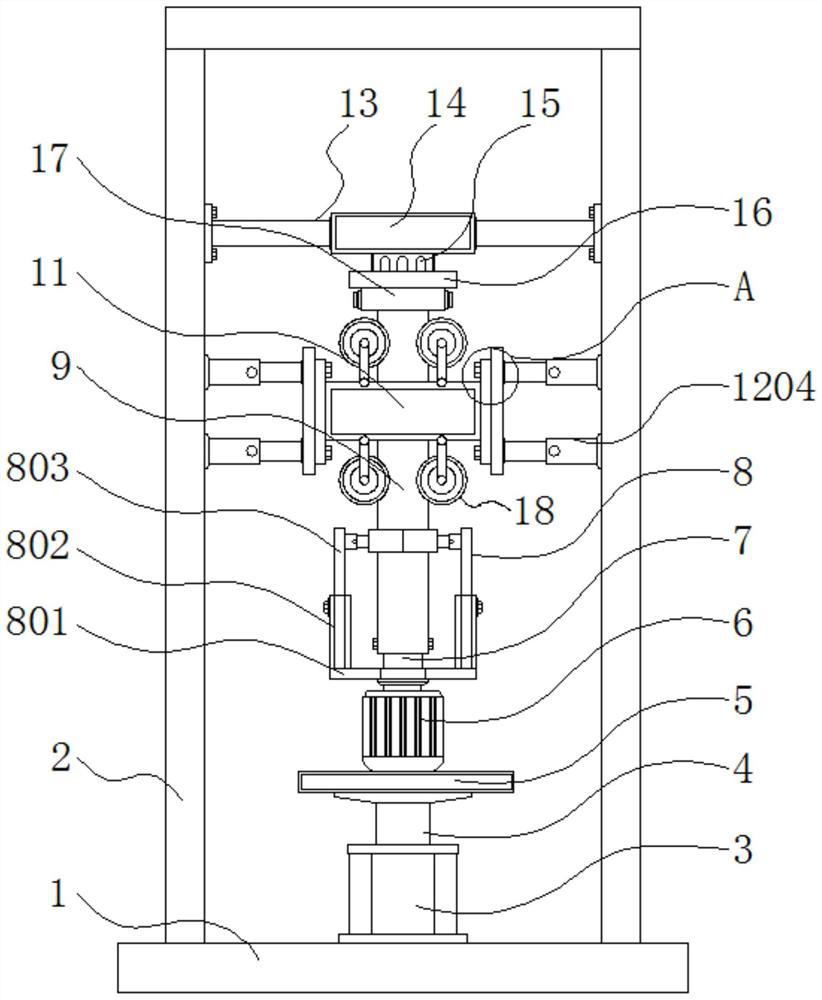

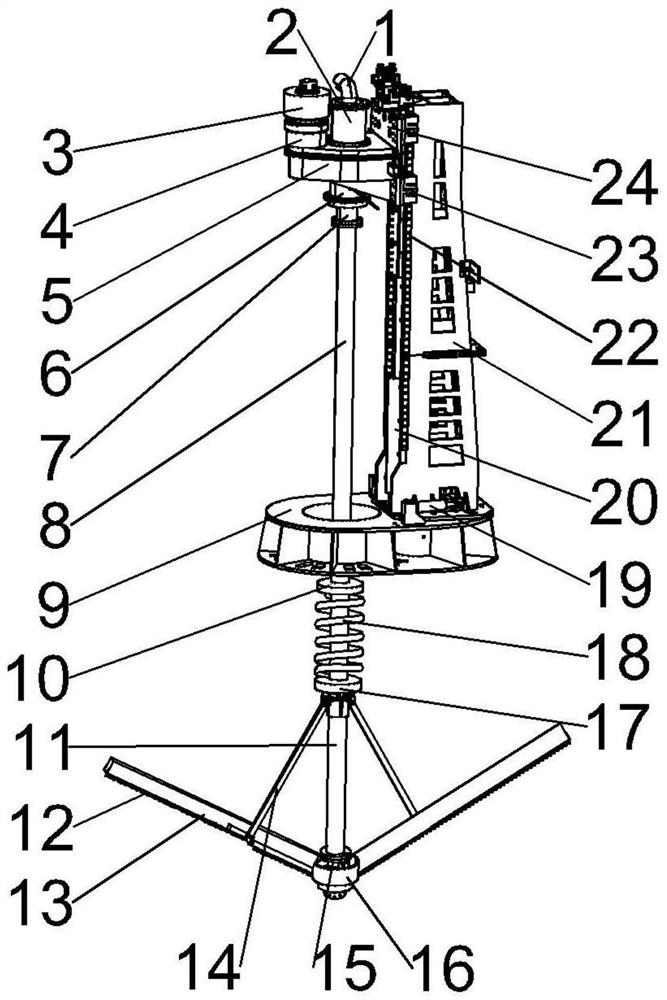

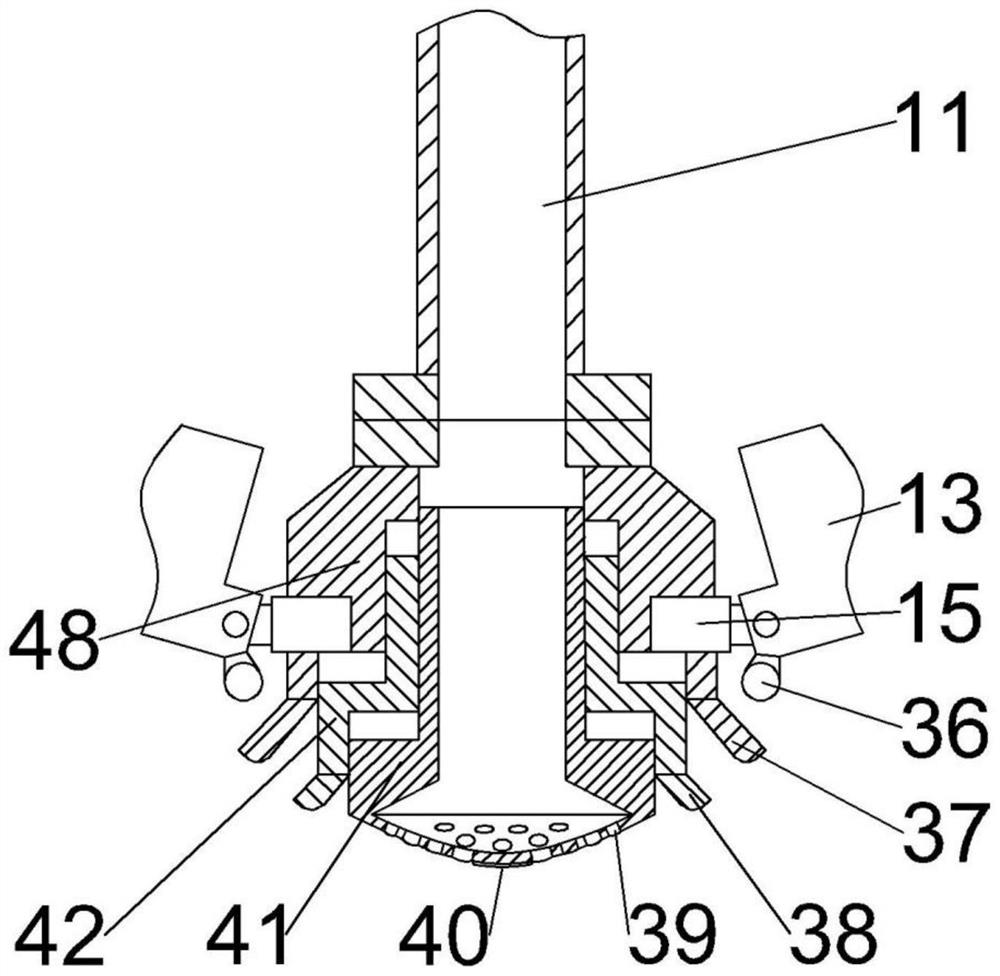

Automatic unloading equipment for reactor catalyst

ActiveCN114522627AEasy to adjust the cutting positionFlexible cutting processNuclear energy generationChemical recyclingChemical industryPtru catalyst

The invention belongs to the technical field of catalyst unloading equipment in the chemical industry, and particularly relates to reactor catalyst automatic unloading equipment which comprises a stand column platform, a stand column assembly is rotationally connected to one side of the top face of the stand column platform, and a motor reducer assembly is vertically and slidably connected to one side of the stand column assembly. A cutter row assembly used for cutting hardened catalysts is arranged below the motor speed reducer assembly, the top end of the cutter row assembly penetrates through the other side of the top face of the stand column platform and is in transmission connection with the lower portion of the motor speed reducer assembly, and a micro adjusting assembly used for finely adjusting the stand column assembly is arranged between the top face of the stand column platform and the bottom end of the stand column assembly. The bottom of the cutter row assembly is connected with a suction assembly used for collecting hardened catalysts, and an oil way brush ring used for controlling oil ways in the cutter row assembly and the micro adjusting assembly is arranged between the motor speed reducer assembly and the top end of the cutter row assembly. The device can improve the cleaning efficiency, reduce the labor intensity and uniformly crush the hardened catalyst.

Owner:JIANGSU TIANPENG PETROCHEMICAL TECH CO LTD

A double-layer fabric cutting device with adjustable cutting position

ActiveCN107696128BWrinkles won't happenGuaranteed accuracySevering textilesMetal working apparatusPulp and paper industryWoven fabric

The invention discloses a double woven fabric cutting device with adjustable cutting positions. The double woven fabric cutting device comprises a machine frame, a fixed plate, a cutting carrier and acutting mechanism. The machine frame is of a U-shaped structure, the fixed plate is installed at the bottom of the machine frame, the cutting carrier is installed on the fixed plate and comprises twosupporting blocks, two springs and multiple inserted plates, each supporting block is provided with a cut V-shaped groove, the inserted plates are inserted into inserted grooves of the supporting blocks, the lengths of the inserted plates decrease successively on the supporting blocks from top to bottom, the outer ends of the inserted plates abut together, and the outer ends of the inserted plates and the surfaces of the supporting blocks are located on the same horizontal surface. The cutting mechanism is installed above the supporting blocks. The cutting spacing of the double woven fabric cutting device is adjustable.

Owner:JIANGSU LAINADUO INTELLIGENT EQUIP CO LTD

Novel wood board cutting machine capable of recycling waste

PendingCN113352406ASolve the problem that it is not particularly convenient to adjust the position of the toolImprove cutting efficiencyProfiling/shaping machinesBark-zones/chip/dust/waste removalElectric machineryRotational axis

The invention relates to the technical field of wood board processing, and discloses a novel wood board cutting machine capable of recycling waste, which comprises a workbench, a cutting groove is formed in the top of the workbench, a rotating shaft is fixedly connected to the inner wall of the workbench, and a mounting table is movably connected to the outer wall of the rotating shaft; and a movable shaft is fixedly connected to the inner wall of the mounting table, a supporting table is movably connected to the outer wall of the movable shaft, a motor is fixedly connected to the top of the supporting table, and a rotating shaft is fixedly connected to an output shaft of the motor through a coupler. According to the novel wood board cutting machine capable of recycling the waste, the purpose that the cutting position is conveniently adjusted is achieved, the problem that the position of a cutter of a common wood board cutting machine is not very convenient to adjust is solved, people can adjust the position of the cutter according to needs, wood boards of different sizes can be conveniently cut, the cutting efficiency of the cutting machine is improved, the time spent by people for cutting wood boards is shortened, the practicability of the cutting machine is improved, and the requirements of people are met.

Owner:湖南日鑫建设工程有限公司

A cutting device with adjustable thickness for processing aluminum alloy doors and windows

ActiveCN113560642BEasy millingHighly easy to controlMilling equipment detailsMetal working apparatusMetallurgyMilling cutter

The invention discloses a thickness-adjustable cutting device for processing aluminum alloy doors and windows, relates to the technical field of aluminum alloy processing, and solves the problem that the existing device is inconvenient to mill the top of an aluminum material to adjust its thickness. A thickness-adjustable cutting device for processing aluminum alloy doors and windows, including a front and rear reciprocating lead screw fixedly connected to the top surface of a thickness control table; a horizontal reciprocating lead screw fixedly connected to the top of a front and rear reciprocating lead screw ball nut seat ; Vertical reciprocating screw, the vertical reciprocating screw is fixedly connected to the top of the ball nut seat of the horizontal reciprocating screw; Milling motor, the milling motor is fixedly connected to the front end of the ball nut seat of the vertical reciprocating screw; It is installed at the bottom of the milling motor shaft; through the control of multiple sets of reciprocating screw screws, the milling cutter disc at the bottom of the milling motor can be moved in multiple directions, which is convenient for milling aluminum materials of different widths and controlling its thickness.

Owner:广州展宏金属科技有限公司

Cutting device for corrugated carton production

InactiveCN108638574AAvoid offsetEasy to adjust horizontal positionPaper-makingBox making operationsCartonPaperboard

The invention discloses a cutting device for corrugated carton production. The cutting device for corrugated carton production comprises a cutting table and a cutting port, and the side face of the cutting table is provided with a limiting plate; an adjusting bolt is arranged behind the limiting plate; an installing frame is arranged above the cutting table, and a slide rail is arranged below theinstalling frame; a fixed bolt is arranged on the side face of the slide rail, and a dividing ruler is arranged above the fixed bolt; a sliding block is arranged below the slide rail, and a cylinder is arranged below the sliding block; a fixed rod is arranged below the cylinder, and a cutting blade is arranged below the fixed rod; the cutting port is located above the cutting table; a limiting roller is arranged above a fixed roller; and a dust sucking pipe is arranged below the cutting port. The cutting device for corrugated carton production is provided with a dust sucking machine, scraps generated when the device is used for cutting paperboards can be conveniently sucked, the scraps are collected into a dust collecting bin, and therefore scrap dust can be conveniently removed.

Owner:杨传平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com