Raw stone cutting machine

A stone cutting machine and rough stone technology, applied in the field of rough stone cutting machines, can solve the problems of inconvenience of use, rough stone movement, heavy rough stone weight, etc., and achieve the effect of convenient use and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

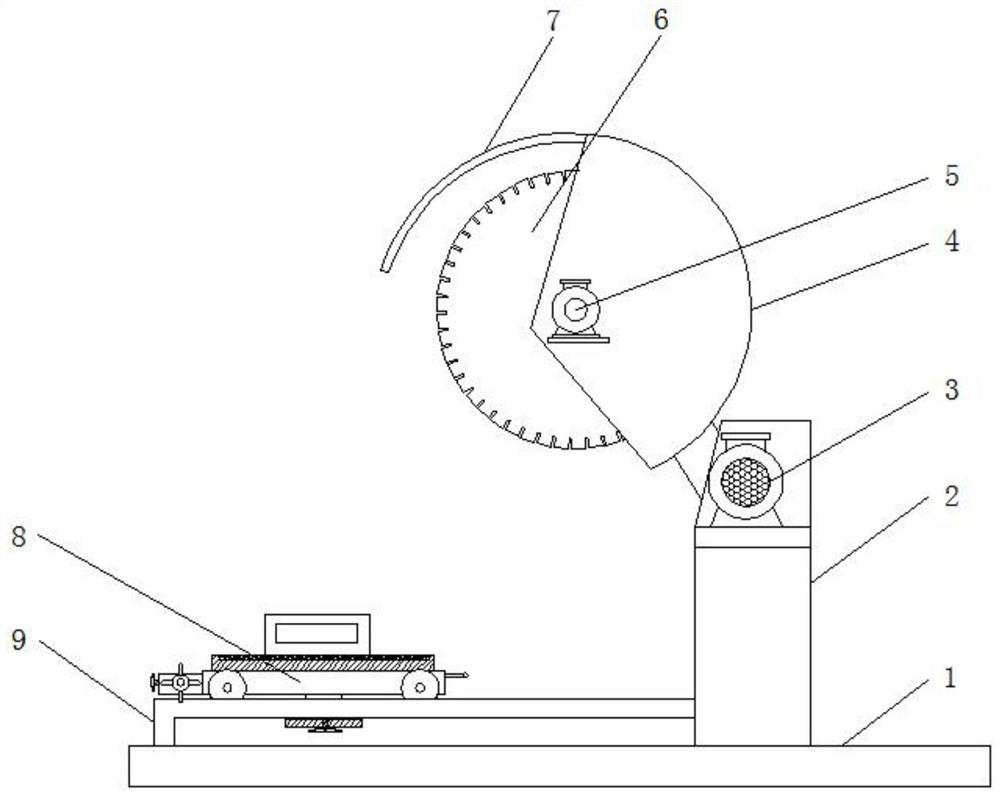

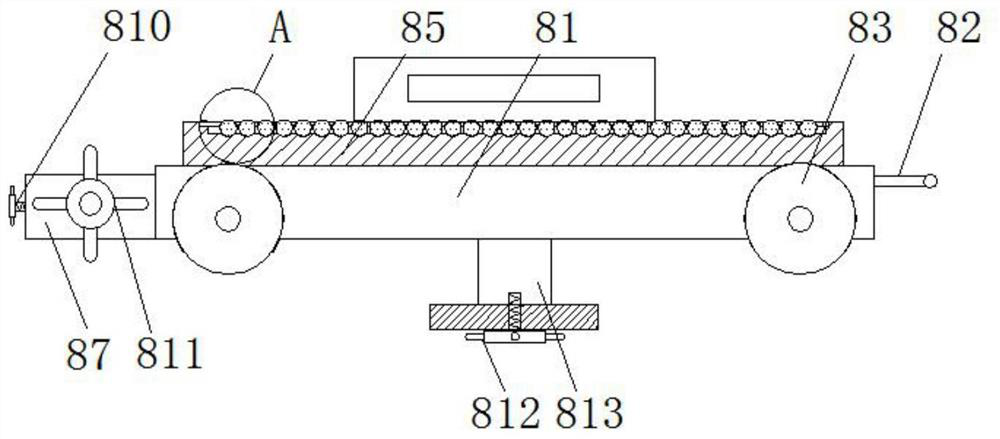

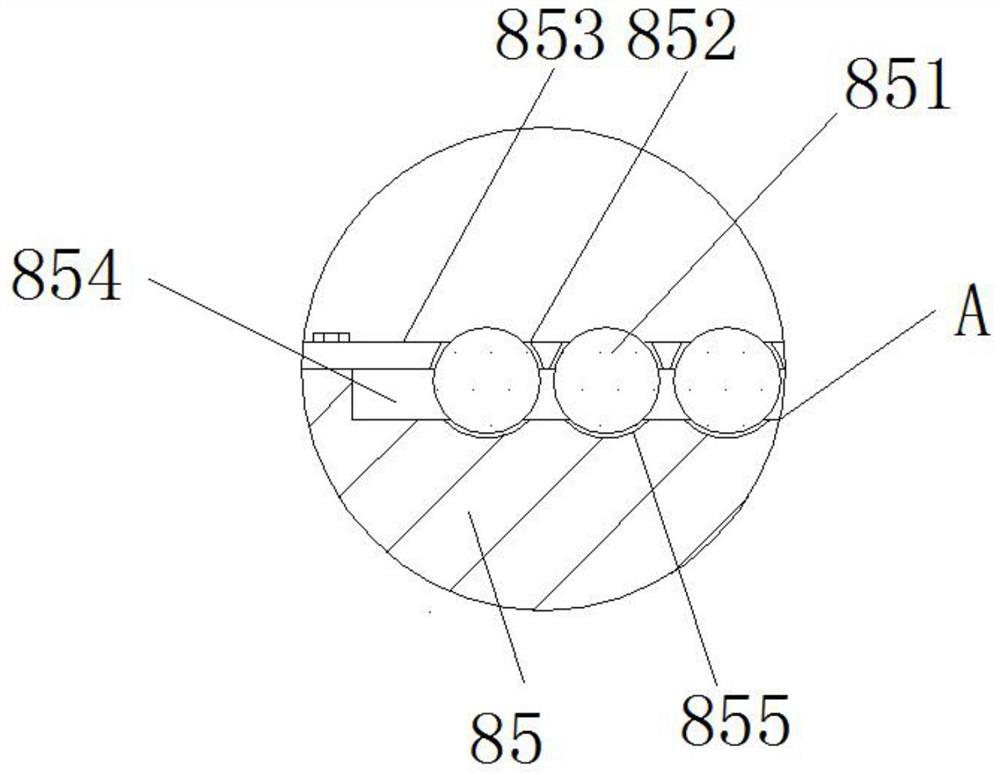

[0026] Such as Figure 1-5 The shown rough stone cutting machine comprises a bottom plate 1, a fixed table 2 arranged at one end of the top of the bottom plate 1, a cutting disc fixed shell 4 hingedly arranged on one side of the top of the fixed table 2, and a fixed shell 4 arranged on the top side of the fixed table 2 for Motor one 3 for controlling the rotation of the cutting disk fixed shell 4, a cutting disk 6 arranged inside the cutting disk fixed casing 4 for cutting rough stones, and a motor two 5 arranged on one side of the cutting disk fixed casing 4 for driving the cutting disk 6 to rotate And be arranged on the arc-shaped baffle plate 7 on the top side of the cutting disc fixed shell 4, the section of the cutting disc fixed shell 4 is set as a fan-shaped structure, and the angle between the two sides of the cutting disc fixed shell 4 is 150 °, and the arc-shaped baffle plate is away from One end of the cutting disc fixed shell exceeds the extension line on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com