Aluminum cutting machine capable of conveniently recovering wastes

A technology for recycling waste and cutting machines, which is applied in the field of aluminum processing, can solve the problems of inconvenient recycling of waste and inconvenient cleaning of devices, and achieve the effects of convenient waste recycling, prevention of precision, and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

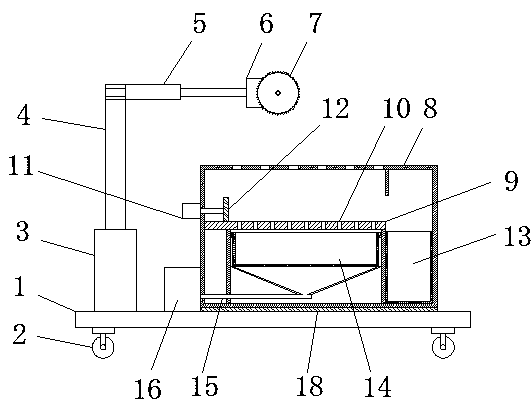

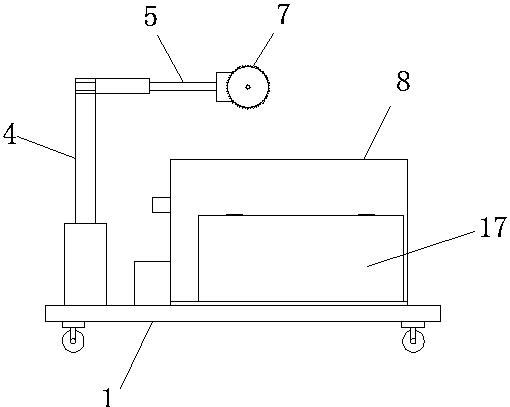

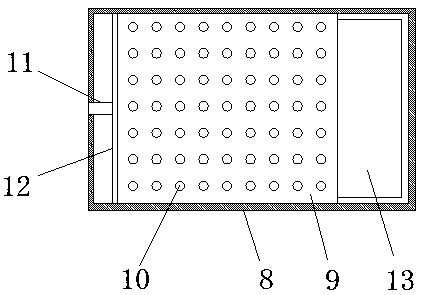

[0023] See Figure 1-3 , The present invention provides a technical solution: an aluminum cutting machine that is convenient for recycling waste, including a base 1, a universal wheel 2, a hydraulic lifting cylinder 3, a lifting rod 4, an electric telescopic rod 5, a cutting motor 6, and a cutting blade 7. , Workbench 8, baffle 9, filter hole 10, electro-hydraulic rod 11, push plate 12, waste collection box 13, net basket 14, dust suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com