A cutting device with adjustable thickness for processing aluminum alloy doors and windows

A technology for aluminum alloy doors and windows and a cutting device, applied in the field of aluminum alloy processing, can solve the problems of not setting aluminum material milling, not setting translation transmission, and inconvenient for milling to adjust its thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

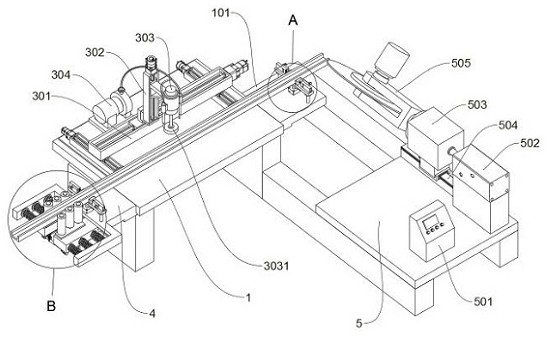

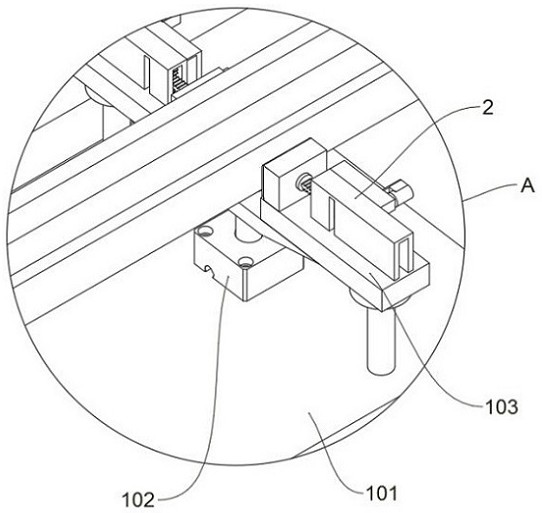

[0065] see Figure 1 to Figure 4 and Figure 9 to Figure 10 , Embodiment 1 provided by the present invention: a cutting device with adjustable thickness for processing aluminum alloy doors and windows, including a thickness control table 1; The number of fixed structures is set to two groups, which are fixedly connected to the left and right sides of the thickness control table 1; The table 101 is fixedly connected to the right end of the thickness control table 1, the top of the right extension table 101 is fixedly connected to the receiving frame 103, the vertical hydraulic cylinder 102 is fixedly connected to the bottom of the right extension table 101, and the telescopic part of the vertical hydraulic cylinder 102 is vertically installed in the middle of the receiving frame 103 Inside, the top of the telescopic part of the vertical hydraulic cylinder 102 is fixedly connected to the support plate 1021, the vertical hydraulic cylinder 102 is electrically connected to the co...

Embodiment 2

[0069] Embodiment two, such as Figure 8 As shown, the thickness control structure includes: front and rear reciprocating lead screws 3, the number of which is set to two groups, which are fixedly connected to the top surface of the thickness control platform 1, and are electrically connected to the control part 501; horizontal reciprocating lead screws 301, horizontal reciprocating The lead screw 301 is fixedly connected to the top of the ball nut seat of the front and rear reciprocating lead screw 3, and its electrical property is connected to the control part 501; the vertical reciprocating lead screw 302 is fixedly connected to the top of the ball nut seat of the horizontal reciprocating lead screw 301, It is electrically connected to the control unit 501; the milling motor 303, the milling motor 303 is fixedly connected to the front end of the ball nut seat of the vertical reciprocating screw 302, and its electrical property is connected to the control unit 501; the millin...

Embodiment 3

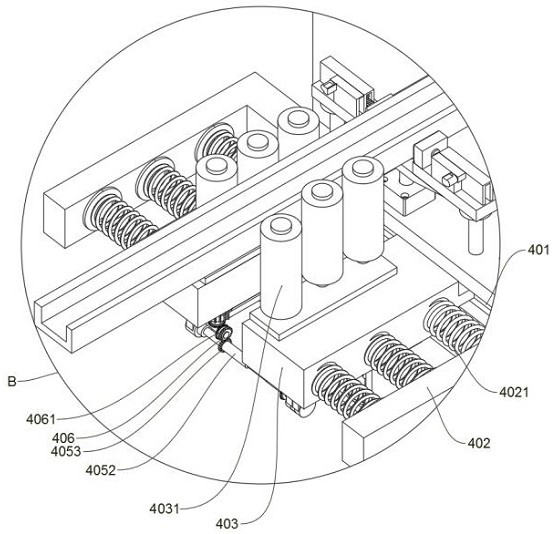

[0070] Embodiment three, such as Figure 5 to Figure 7As shown in , the bottom end of the pinch roller 4031 is coaxially connected with a bottom gear 404, and the bottom gears 404 are driven by a chain. The bottom shaft 405 is connected, the bevel gear set B4041 is coaxially connected with the right side of the bottom shaft 405, the left end of the bottom shaft 405 is connected with a square rod 4051 through a coaxial connection, and the left side of the square rod 4051 is sleeved with a square groove tube 4052 The right side of the square groove pipe 4052 is provided with a first-stage gear 4053 through coaxial connection, and the bottom of the left slide block 403 is rotationally connected with a second-stage gear 406. A bevel gear set C4061 is provided through a coaxial connection, the top of the bevel gear set C4061 is coaxially connected to the bottom of the bottom gear 404, the number of sliders 403 is set to two sets, and the number of clamping rollers 4031 on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com