Prefabricated material hoisting device for expressway construction

A technology for highways and hoisting devices, applied in transportation and packaging, load hanging components, cranes, etc., can solve the problems of reduced safety in the use of hoisting devices, inconvenient prefabricated materials for sorting and lifting, and inconvenient use and retrieval, etc., to achieve The effect of improving the safety of use and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1

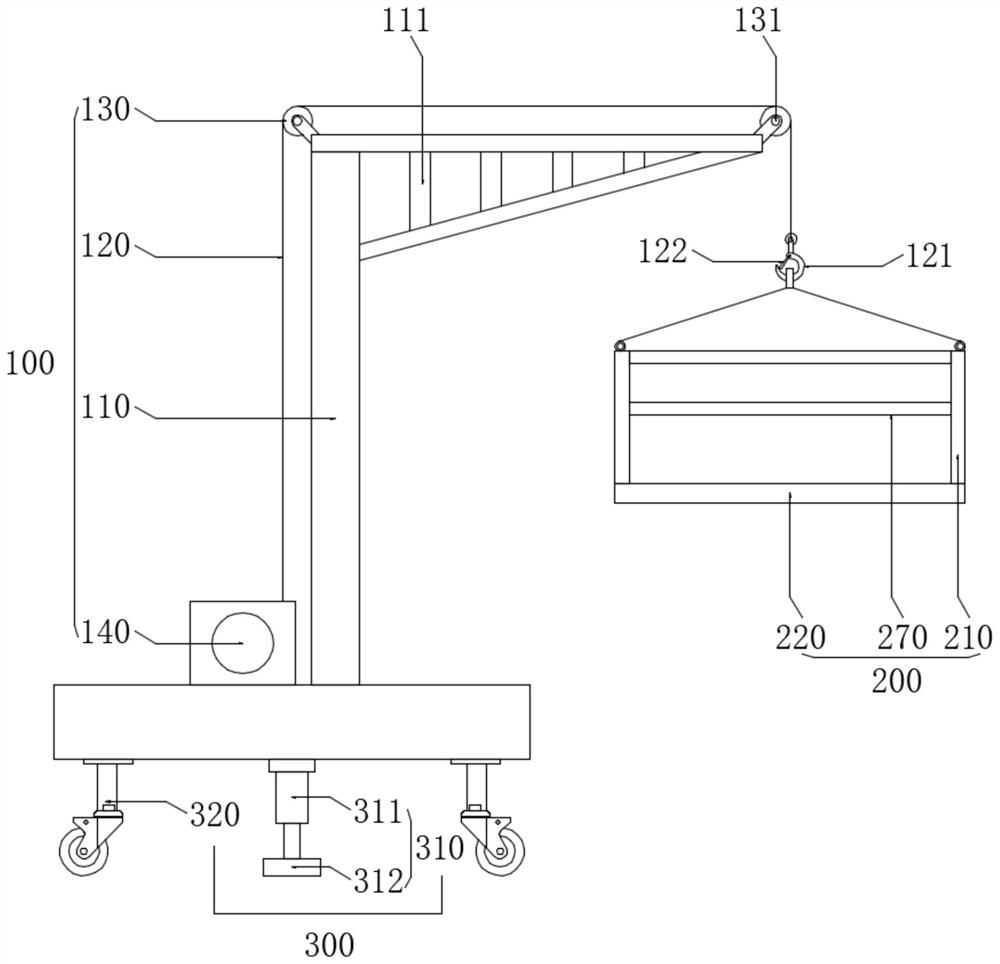

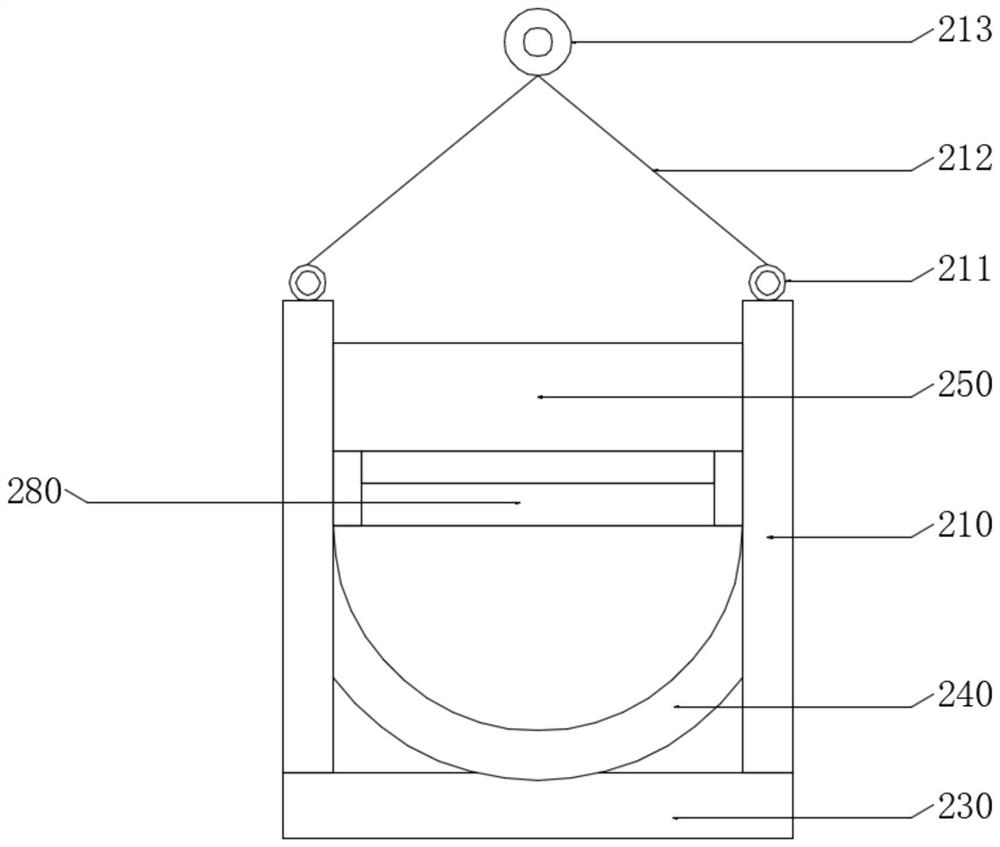

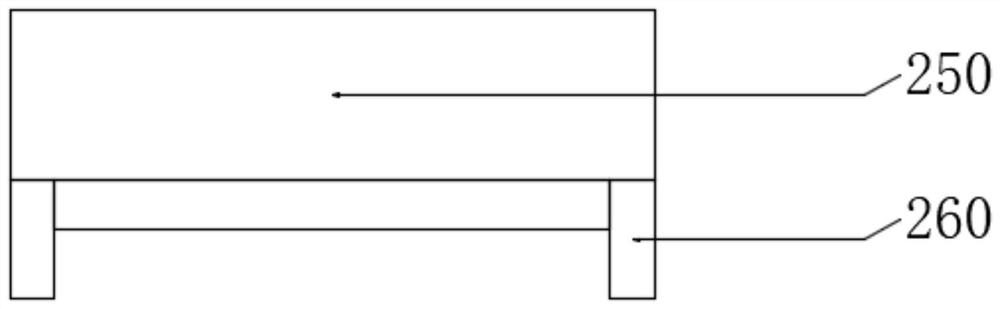

[0026] see Figure 1-4 , the present invention provides a technical solution: a hoisting device for prefabricated materials for expressway construction, including a hoisting power mechanism 100 and a sorting and packaging mechanism 200 .

[0027] see figure 1 The lifting power mechanism 100 includes a frame 110, a suspension rope 120, a pulley 130 and a hoist 140, the pulley 130 is rotatably connected to both sides of the top of the frame 110, the hoist 140 is fixedly connected to one side of the bottom of the frame 110, and the top of the frame 110 is provided with Support beam 111, support beam 111 is fixedly connected with frame 110, and support beam 111 is set to improve the stability of frame 110, and pulley 130 is connected with frame 110 rotation by rotating shaft 131, and hanging rope 120 bottom is provided with hook 121, and hook 121 and The sling 120 is fixedly connected, the inside of the hook 121 is provided with an anti-off bar 122, one end of...

Example Embodiment

[0029] Example 2

[0030] see Figure 1-4 , the present invention provides a technical solution: a hoisting device for prefabricated materials for expressway construction, including a hoisting power mechanism 100 and a sorting and packaging mechanism 200 .

[0031] see figure 1 The lifting power mechanism 100 includes a frame 110, a suspension rope 120, a pulley 130 and a hoist 140, the pulley 130 is rotatably connected to both sides of the top of the frame 110, the hoist 140 is fixedly connected to one side of the bottom of the frame 110, and the top of the frame 110 is provided with Support beam 111, support beam 111 is fixedly connected with frame 110, and support beam 111 is set to improve the stability of frame 110, and pulley 130 is connected with frame 110 rotation by rotating shaft 131, and hanging rope 120 bottom is provided with hook 121, and hook 121 and The sling 120 is fixedly connected, the inside of the hook 121 is provided with an anti-off bar 122, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com