Cable unwinding equipment for wire and cable manufacturing

A technology of wire and cable unwinding equipment, which is applied in the direction of thin material handling, conveying filamentous materials, transportation and packaging, etc., and can solve the problem of single function of cable unwinding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

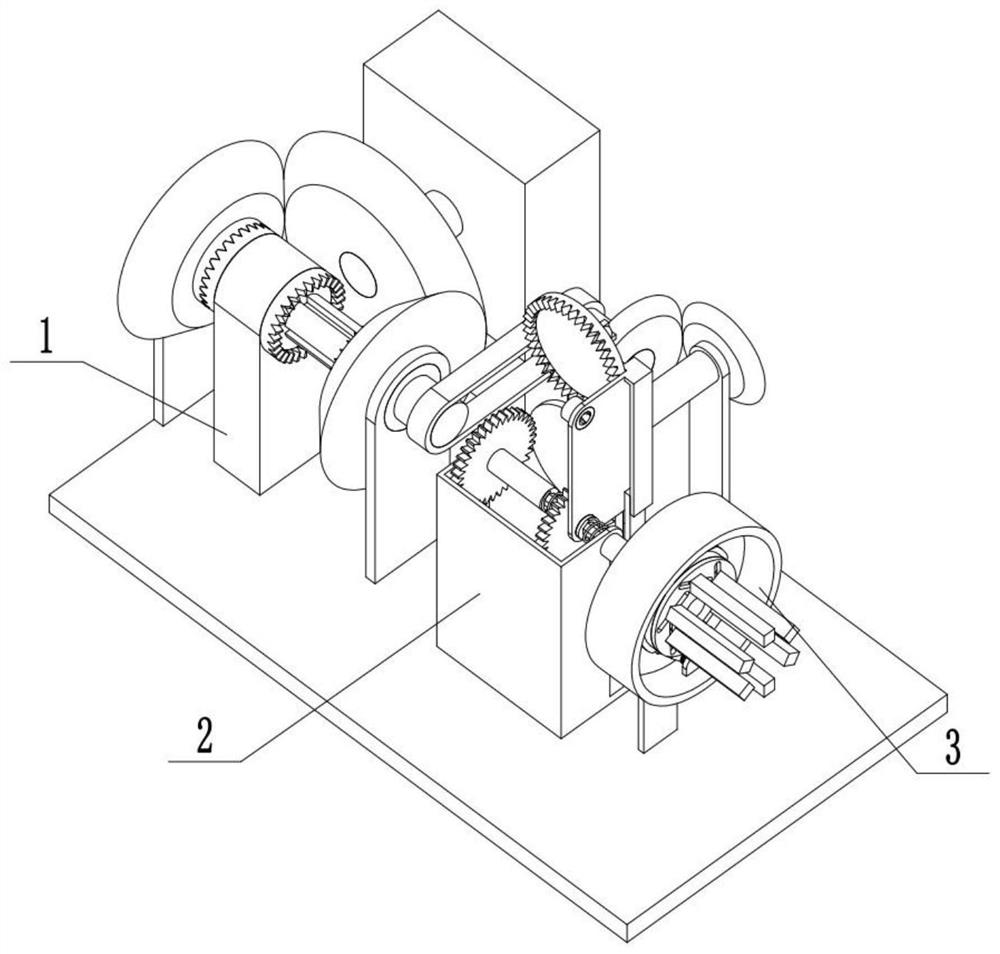

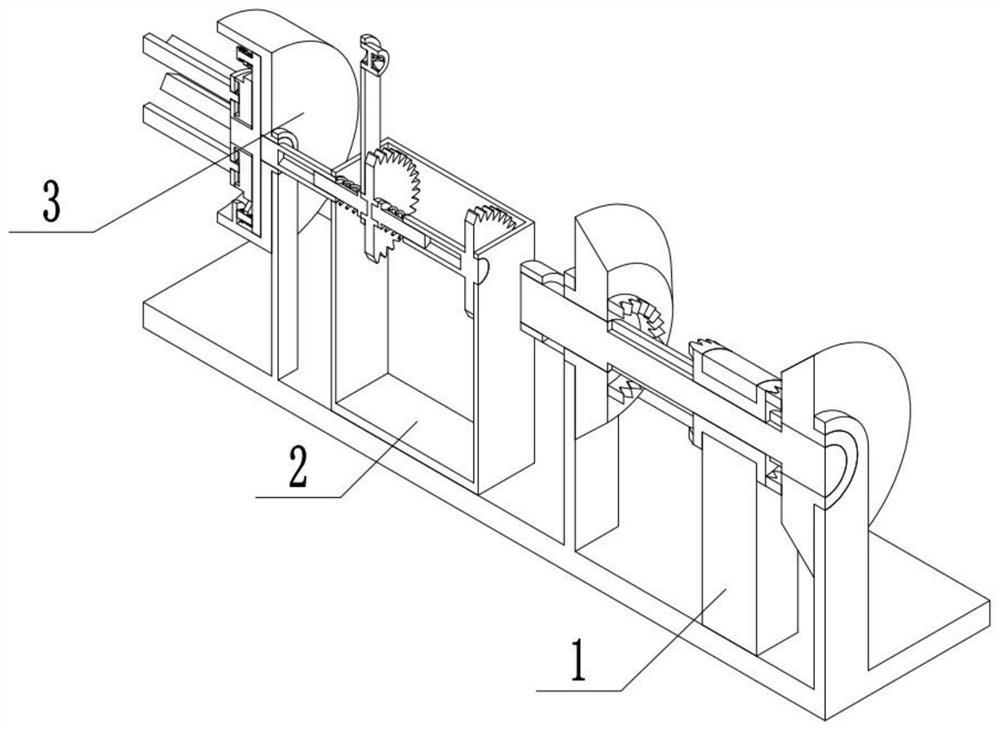

[0028] Combine below Figure 1-11 Describe this embodiment, a cable unwinding device for wire and cable manufacturing, including a drive assembly 1, a switch assembly 2, and a rope winding assembly 3, characterized in that: the drive assembly 1 is connected to the switch assembly 2, and the switch assembly 2 It is connected with the winding rope assembly 3, and the winding rope assembly 3 is connected with the driving assembly 1.

specific Embodiment approach 2

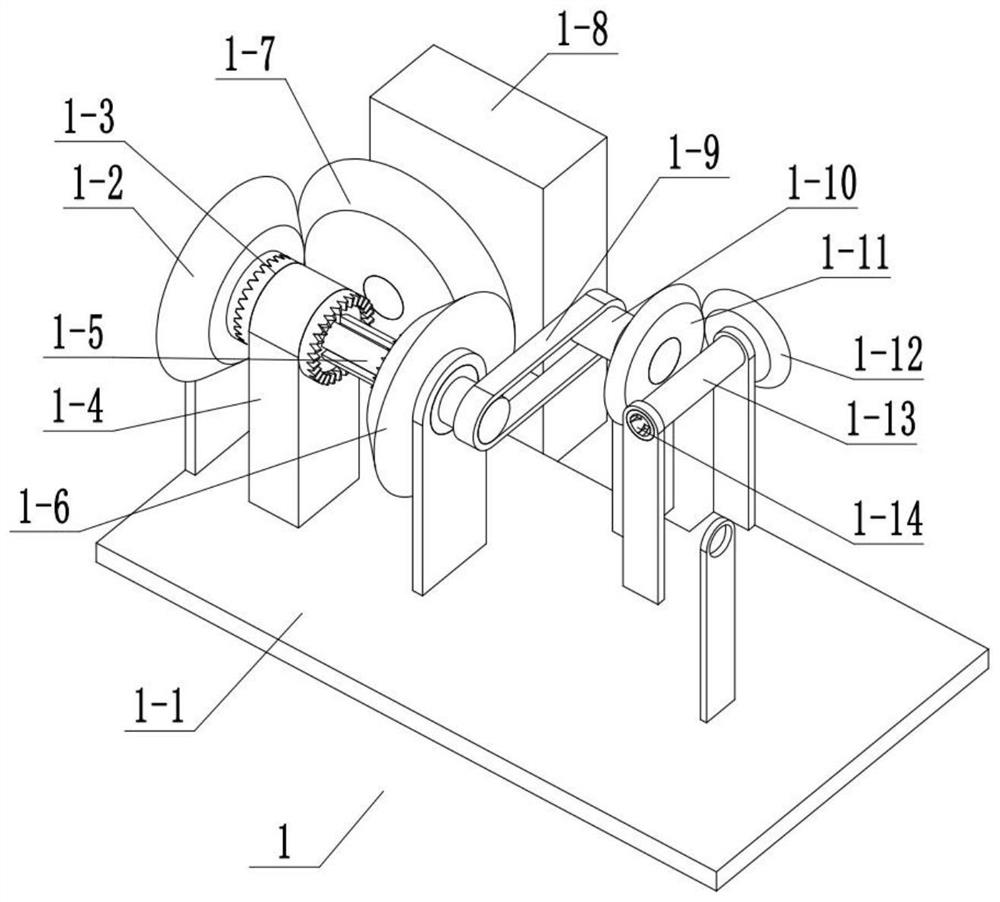

[0029] Combine below Figure 1-11Describe this embodiment, this embodiment will further explain the first embodiment, the drive assembly 1 includes a power base plate 1-1, a bevel gear 1-2, a drive sleeve 1-3, a drive bracket 1-4, and a middle shaft 1-5, bevel gear two 1-6, bevel gear three 1-7, input motor 1-8, belt one 1-9, bevel gear shaft one 1-10, bevel gear four 1-11, bevel gear five 1- 12. Bevel gear shaft 2 1-13, groove 1-14, input motor 1-8 is fixedly connected with power base plate 1-1, middle-end rotating shaft 1-5 is rotationally connected with power base plate 1-1, bevel gear one 1- 2. Bevel teeth 2 1-6 are rotatably connected to the power base plate 1-1, bevel teeth 1 1-2 and bevel 2 1-6 are all rotatably connected to the middle shaft 1-5, and the driving sleeve 1-3 is connected to the middle The end shaft 1-5 is slidingly connected, the driving sleeve 1-3 is connected with the first bevel gear 1-2 or the second bevel gear 1-6, the driving sleeve 1-3 is rotation...

specific Embodiment approach 3

[0030] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the switching assembly 2 includes a switching bracket 2-1, a limit slider 2-2, a matching bracket 2-3, and a limit slider 2 2-4 , Cooperate with lever one 2-5, cooperate with lever push spring one 2-6, half gear 2-7, straight tooth one 2-8, cooperate lever two 2-9, cooperate lever push spring two 2-10, Full gear 2-11, mid-end gear lever 2-12, matching lever three 2-13, matching lever push spring three 2-14, straight teeth two 2-15, matching lever four 2-16, matching lever Push spring four 2-17, output rod one 2-18, transmission rod one 2-19, limit slide bar one 2-2 is fixedly connected with switching bracket 2-1, limit slide bar two 2-4 and matching bracket 2 -3 is fixedly connected, and the limit slide bar one 2-2 is slidably connected between the limit slide bar two 2-4 and the matching bracket 2-3, and the half gear 2-7 and the full gear 2-11 are all conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com