Automobile seat skeleton structure

A technology of car seat frame and frame, applied in seat frame, vehicle seat, movable seat and other directions, can solve the problems of feeling uncomfortable, wasting time and manpower, affecting efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

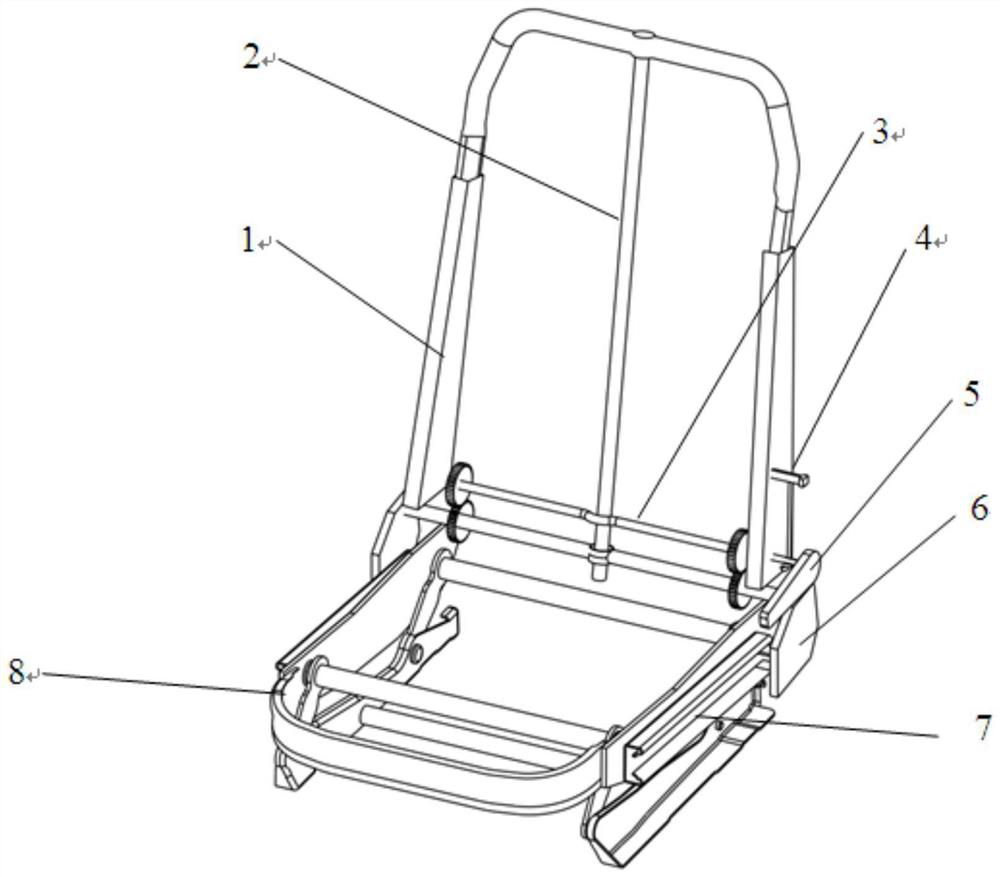

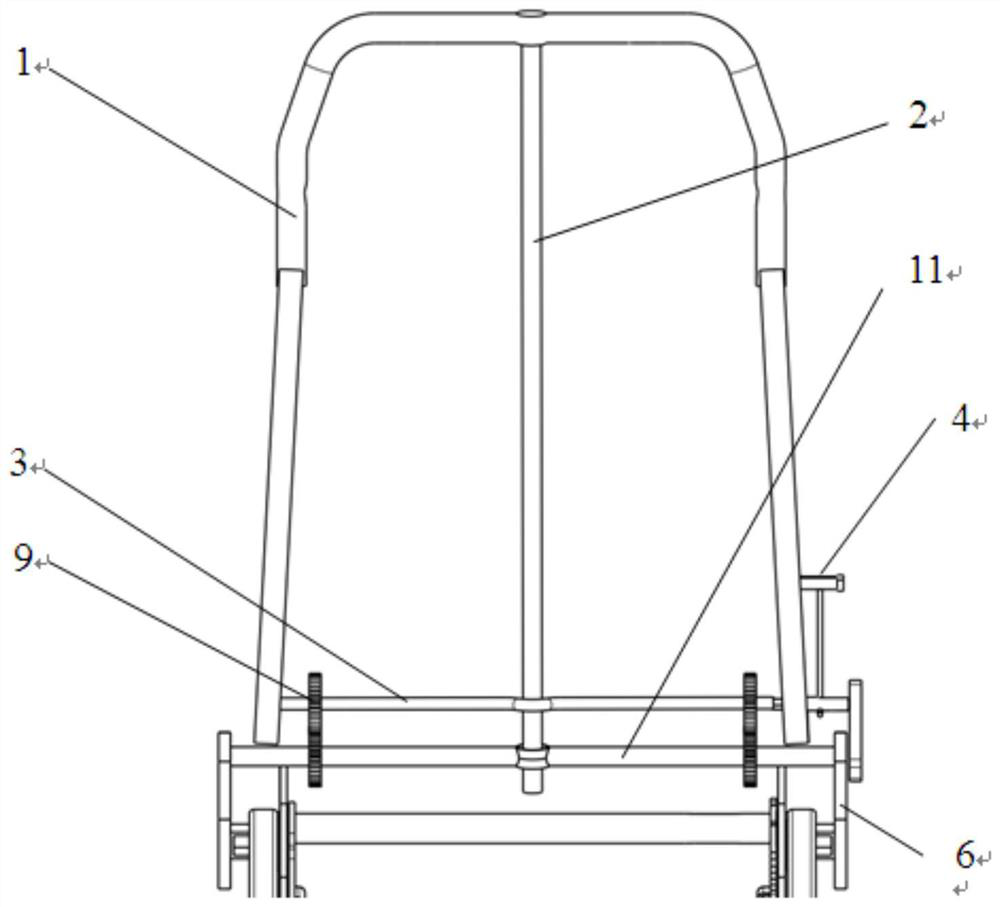

[0040] A car seat frame structure, comprising a backrest frame 1 and a seat pan frame connected under the backrest frame 1;

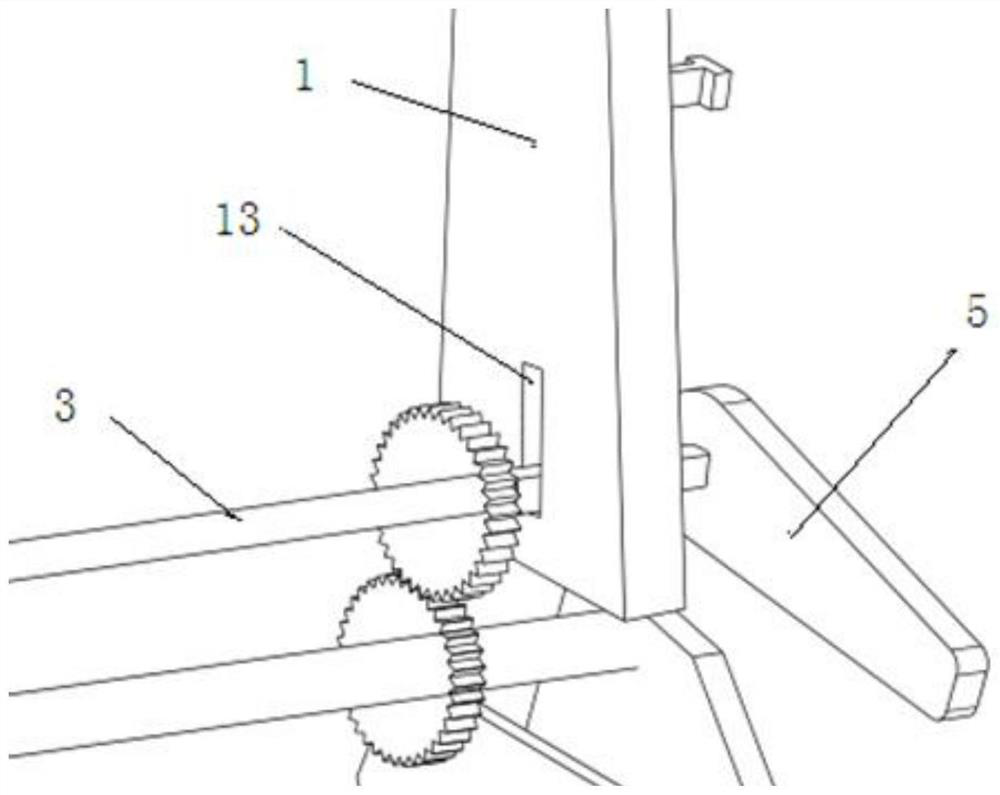

[0041] A connecting mechanism that can quickly realize the backrest moving back and forth is provided between the backrest outer frame 1 and the seat pan frame 8, and the connecting mechanism includes:

[0042] The rotating shaft 2, whose upper end passes through the upper end of the backrest frame 1, and whose lower end extends downward until passing through the second connecting rod 11 located below the backrest frame 1;

[0043] The moving seat 6 includes two moving seats 6, and the two moving seats 6 are symmetrically fixed at both ends of the second connecting rod 11;

[0044] Both sides of the pan frame 8 are symmetrically provided with two adjusting slide rails 7 , and the moving seat 6 is slidably connected to the adjusting slide rails.

[0045] The backrest outer frame 1 has a U-shaped structure, one side of the opening end of the U-shaped str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com