Inclined type sliding supporting structure

A sliding support and tilting technology, which is applied in the direction of mobile grate, lighting and heating equipment, combustion method, etc., to achieve the effect of accurate positioning and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

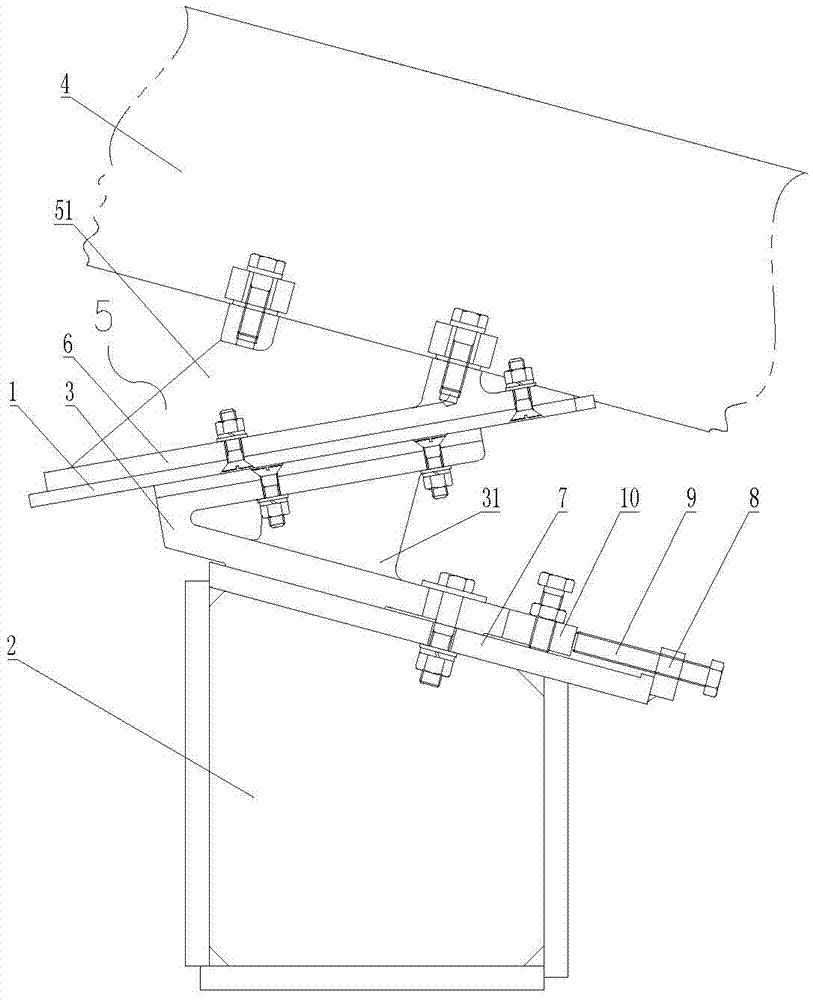

[0013] Such as figure 1 As shown, an inclined sliding support structure includes a sliding support track 1, the sliding support track 1 is installed on a base 2, a V-shaped support 3 is installed on the base 2, and the sliding support track 1 is installed on one side of the V-shaped support 3 On the side, the other side of the V-shaped bracket 3 is fixed on the top of the base 2; the grate beam 4 is installed on the grate bracket 5 through nuts, and the bottom end of the grate bracket 5 is equipped with a sliding plate 6, which is a copper plate , the sliding support track 1 is a stainless steel plate; the top of the base 2 is welded with a fixed plate 7, the fixed plate 7 is inclined downward at a certain angle with the horizontal plane, and the end of the fixed plate 7 inclined downward is welded with an adjusting nut 8, and the inside of the adjusting nut 8 An adjusting screw 9 is installed, and the nail head of the adjusting screw 9 abuts against the end of the other side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com