Raw material conveying equipment for building bridge

A technology for conveying equipment and raw materials, which is applied in the direction of freight vehicles, transportation and packaging, and load fixing, etc. It can solve problems such as poor stability of steel pipe reinforcement structures, easy sliding of tubular steel materials forward, and difficulty in taking and placing steel pipes. It achieves the effect of comprehensive protection action and high strength of blocking protection structure and high strength of protection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

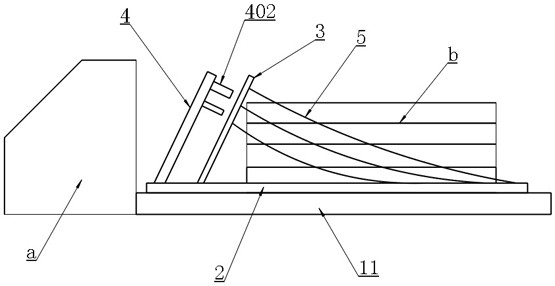

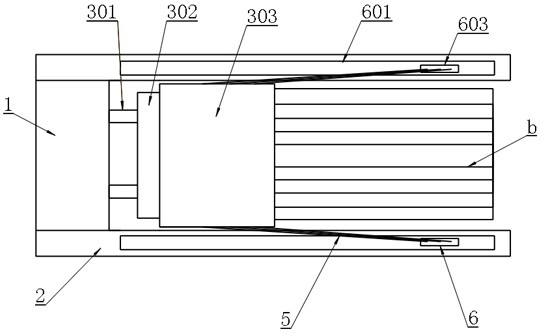

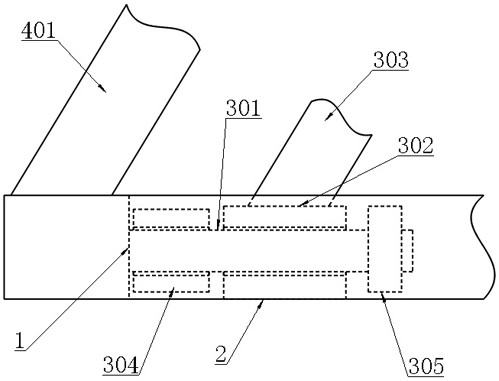

[0025] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Image 6 As shown, a raw material conveying equipment for building a bridge includes a transport vehicle bottom plate 11, and also includes an intermediate plate 1 arranged on the upper surface of the transport vehicle bottom plate 11 and at a position close to the side of the cab a, respectively arranged on The two ends of the middle plate 1 and the two side plates 2 located on both sides of the pile of steel pipes b are arranged on the side of the middle plate 1 close to the steel pipe b and are used to prevent the vehicle from sliding forward when braking suddenly The movable inclined baffle unit 3 of the steel pipe is arranged on the upper surface of the middle plate 1 and is used to block and fix the fixed inclined baffle unit 4 of the movable inclined baffle unit 3, which is respectively arranged on the two side plates 2 and between the two sides of the movable inclined baffle unit 3 and are used to pull a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com