Explosion-proof wall suitable for field test conditions

A field test, explosion-proof wall technology, applied to walls, building components, buildings, etc., can solve the problems of hidden safety hazards, difficult to meet, time-consuming and labor-intensive, etc., and achieve the effect of strong protective structure, simple structure, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

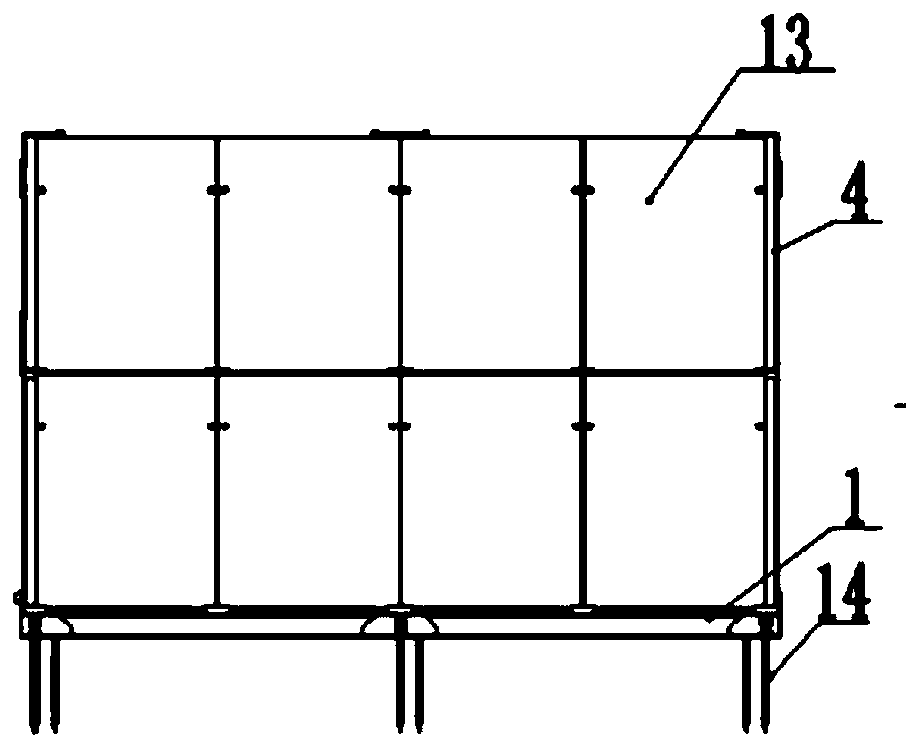

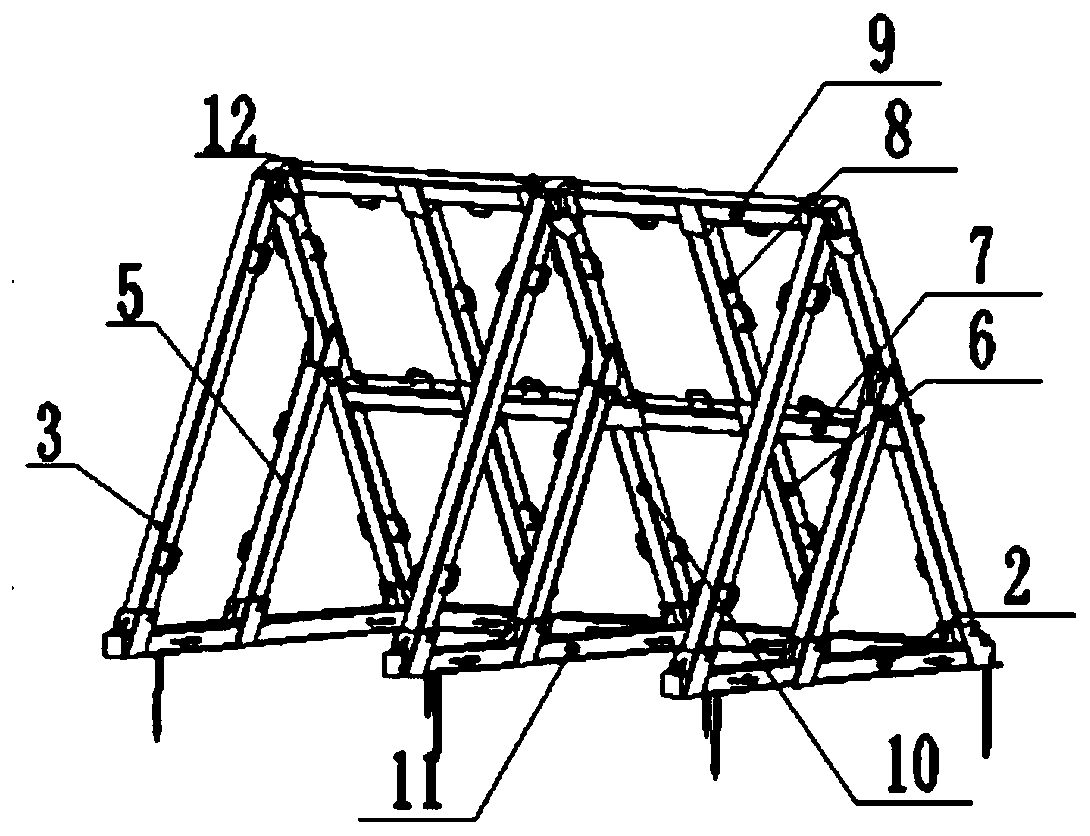

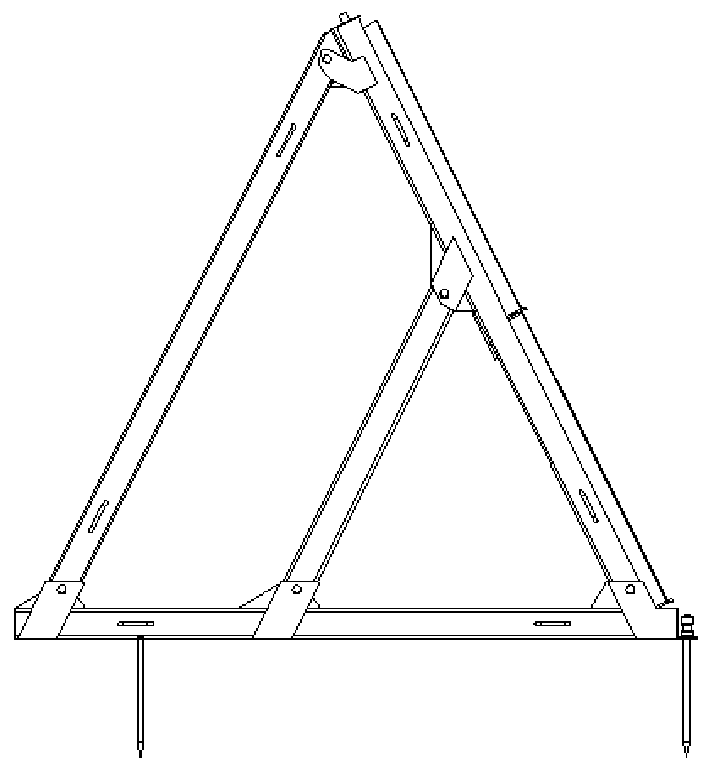

[0038] An explosion-proof wall suitable for field test conditions is characterized in that it includes a plurality of triangular units, each triangular unit includes a bottom bracket 2, a rear bracket 3 and a front bracket 4, and the bottom bracket 2, the rear bracket 3 and the front bracket 4 Both ends are connected with bolts to form a triangular triangular unit; one end of the bottom bracket 2 of each triangular unit is fixedly connected to the bottom beam 1 with bolts, and the triangular faces of each triangular unit are perpendicular to the bottom beam 1, and each There is a distance between the triangular faces of the triangular unit; similarly, the upper end of the front bracket 4 of each triangular unit is fixedly connected to the upper beam 9 with bolts, and the middle part of the front bracket 4 is fixedly connected to the middle beam 7 with bolts; the bottom beam 1 , the middle beam 7, the upper beam 9 and the front bracket 4 of each triangular unit form the wall slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com