Liquid ejecting head and liquid ejecting system

A liquid ejection head, liquid technology, applied in the direction of inking device, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A: The first embodiment

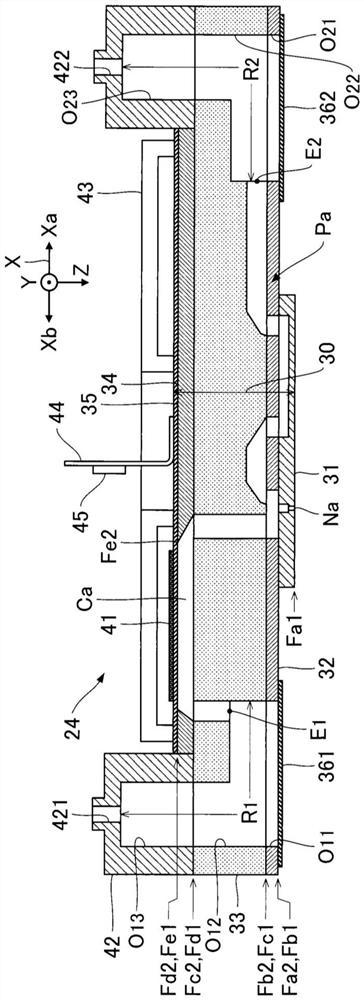

[0028] like figure 1 As illustrated, in the following description, an X-axis, a Y-axis, and a Z-axis that are perpendicular to each other are assumed. One direction along the X-axis when observed at an arbitrary point is denoted as an Xa direction, and the opposite direction to the Xa direction is denoted as an Xb direction. The X-Y plane including the X-axis and the Y-axis corresponds to a horizontal plane. The Z axis is an axis along the vertical direction, and the positive direction of the Z axis corresponds to the downward direction in the vertical direction.

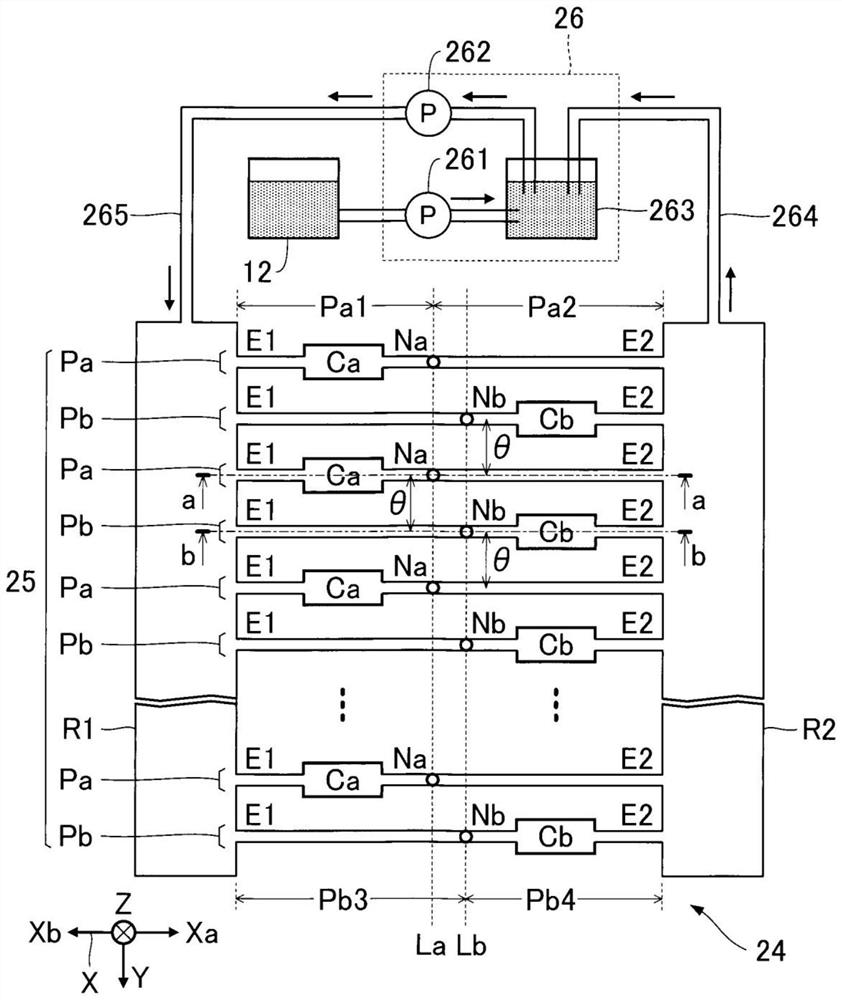

[0029] figure 1 It is a configuration diagram illustrating an exemplary configuration of a part of the liquid ejection system 100 according to the first embodiment. The liquid ejection system 100 of the first embodiment is an inkjet type printing device that ejects droplets of ink, which is an example of liquid, onto a medium 11 . The medium 11 is, for example, printing paper. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com