Efficient water-saving countercurrent water circulation heat exchange type condenser

A condenser and water circulation technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of water collection by water collector and unsatisfactory water collection effect, and achieve the effect of facilitating retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

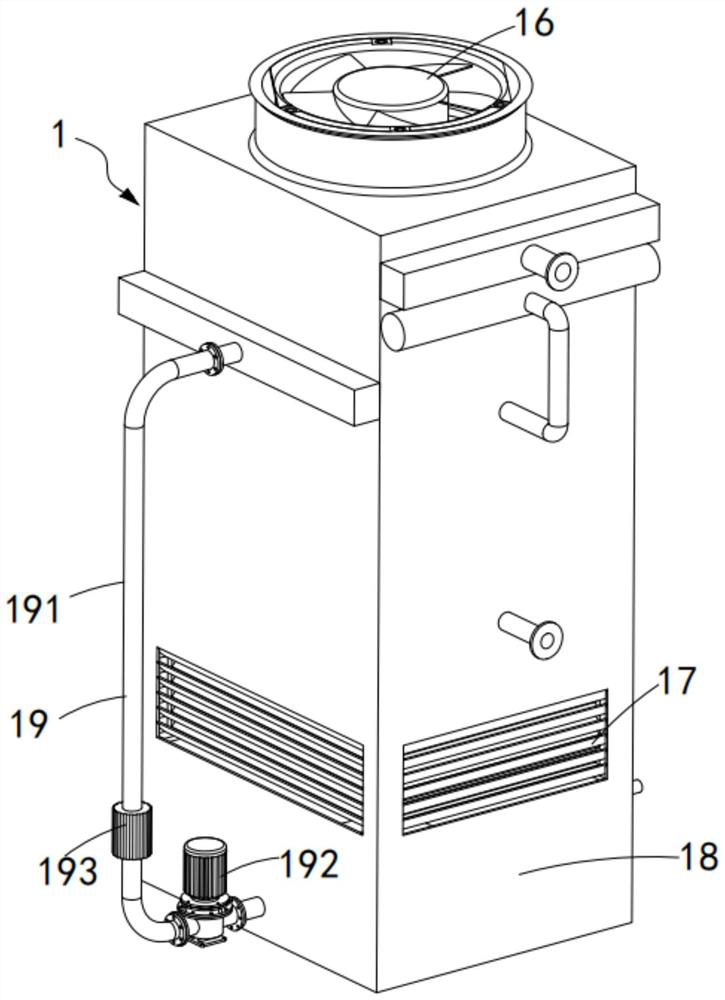

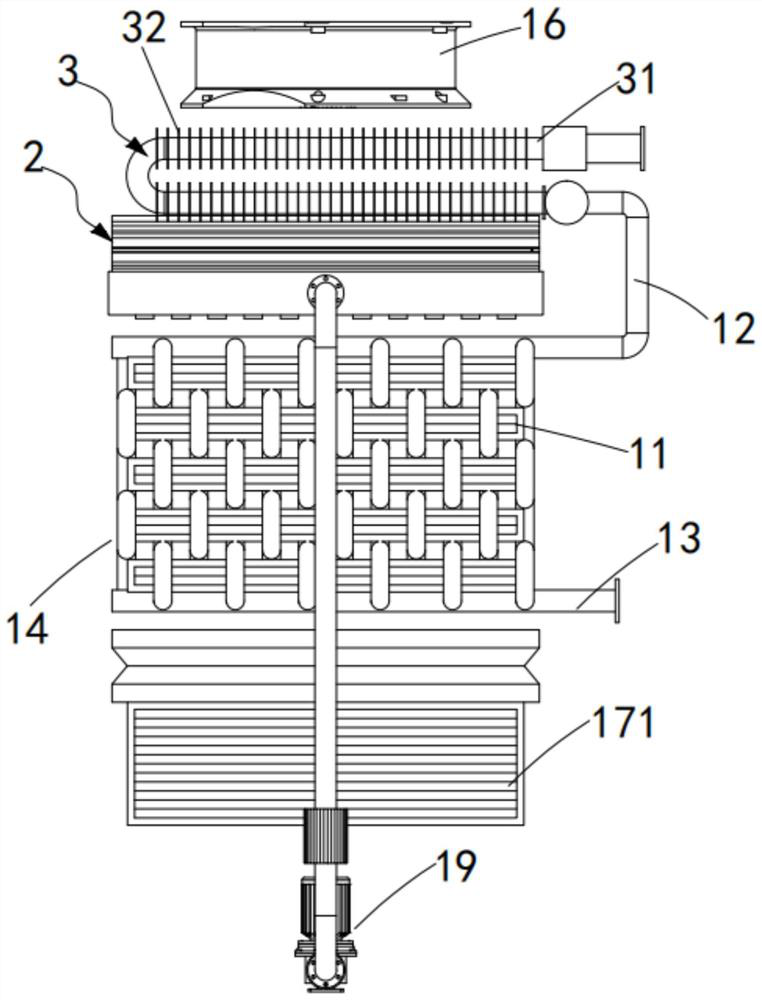

[0072] Such as Figure 1 to Figure 14 As shown, a high-efficiency water-saving countercurrent water circulation heat exchange condenser includes a condenser shell 1 and also includes:

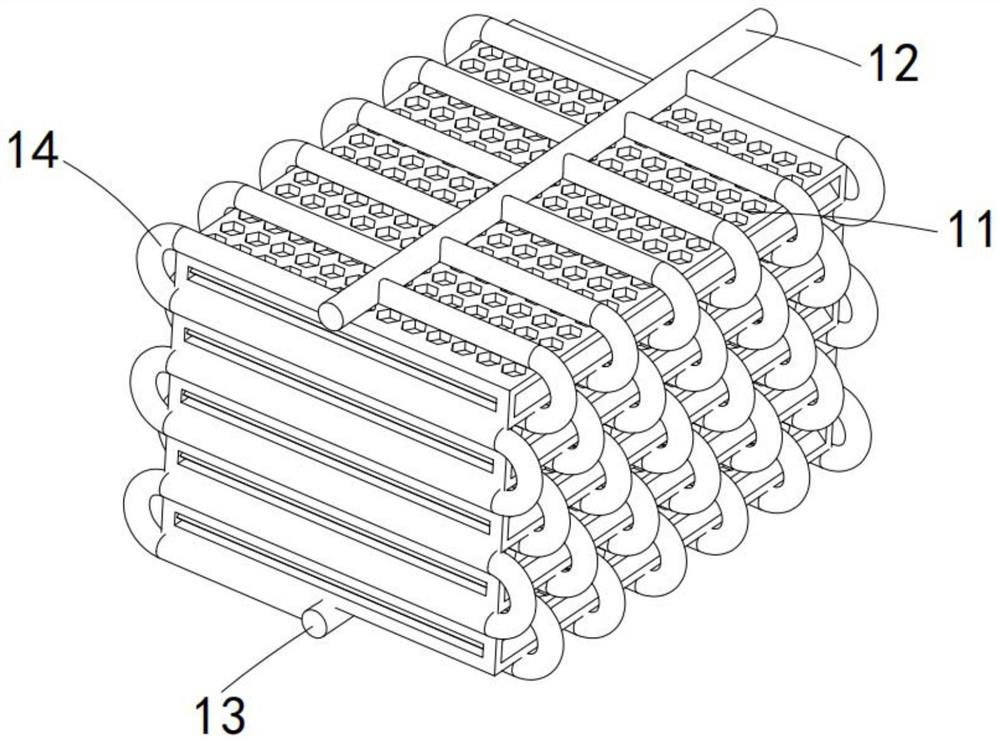

[0073] A heat exchanger 11, the heat exchanger 11 is located in the middle of the condenser shell 1 in the height direction;

[0074] A liquid inlet pipe 12, the liquid inlet pipe 12 is arranged in the condenser shell 1, and the liquid inlet pipe 12 is located above the upper end surface of the heat exchanger 11;

[0075] A liquid outlet pipe 13, the liquid outlet pipe 13 is arranged in the condenser housing 1, and the liquid outlet pipe 13 is located below the lower end surface of the heat exchanger 11, the liquid outlet pipe 13 is connected to the inlet A heat exchange tube 14 is connected between the liquid tubes 12;

[0076] The water distribution pipe 15, the water distribution pipe 15 is arranged in the condenser shell 1, and the lower side of the water distribution pipe 15 is evenly di...

Embodiment approach

[0097] As a preferred embodiment, the water collection unit 23 includes:

[0098] The water collection pipe 231, the water collection pipe 231 is integrally connected with the corrugated plate 21 along the length direction of the corrugated plate 21, the water collection pipe 231 is arranged in a circular tube shape, and the water collection pipe 231 is not connected with the corrugated plate 21 A number of through holes 232 are provided through the side wall;

[0099] A sponge column 233, the sponge column 233 is inserted in the water collection pipe 231, and the sponge column 233 absorbs water vapor through the through hole 232;

[0100] Extrusion head 234, the extrusion head 234 is symmetrically installed on both sides of the axial direction of the water collection pipe 231, the extrusion head 234 pushes and squeezes the sponge column 233 toward the water collection pipe 231, and the extrusion The head 234 is hollow inside and communicated with the flow guide unit 41 throu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap