Animal grease smelting equipment

A technology of animal fat and smelting equipment, which is applied in the direction of fat oil/fat production, fat generation, and fat material recovery, which can solve problems such as low production efficiency, inability to smelt fat, and discontinuous smelting methods, and achieve the goal of improving the smelting oil yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

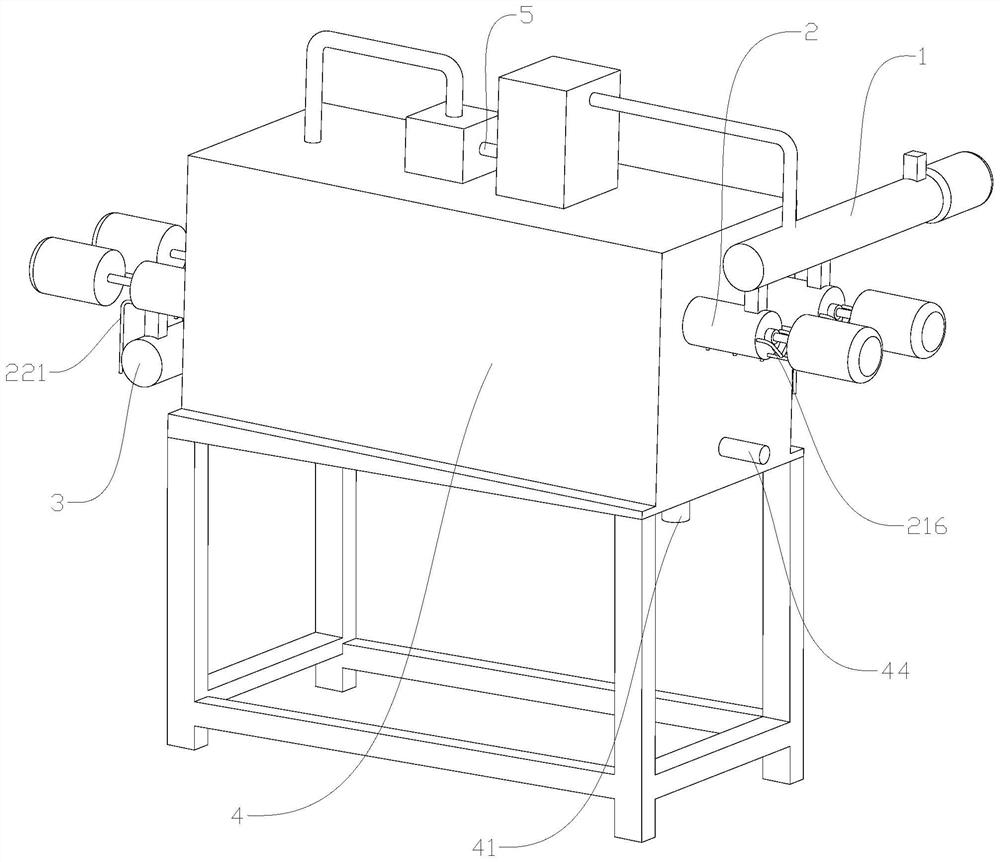

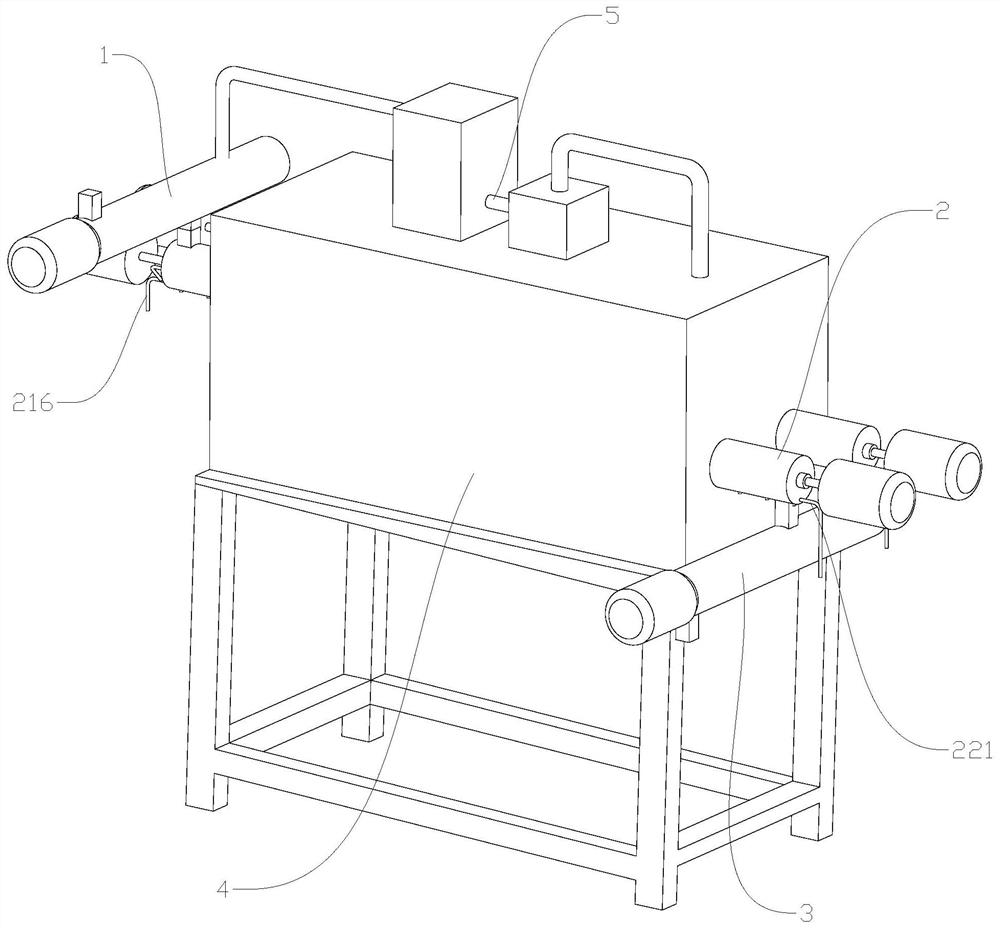

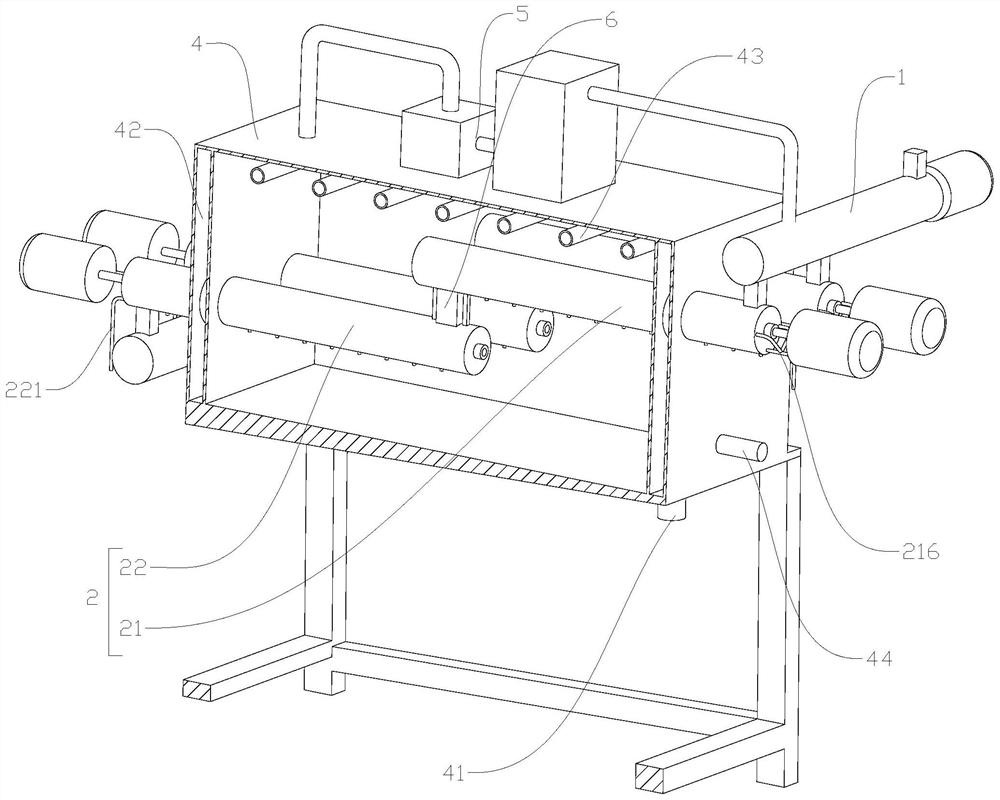

[0023] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the accompanying drawings used in the embodiments will be briefly introduced below. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

[0024] Please see Figure 1 to Figure 7, the embodiment of the present invention provides a kind of animal fat smelting equipment, including preheating conveying equipment 1, smelting and squeezing equipment 2, oil residue conveying equipment 3, smelting heating box 4, negative pressure device 5, the preheating conveying equipment 1 is set On one side of the smelting heating box 4, the preheating conveying equipment 1 can not only play the role of conveying the raw materials, but also can preheat the raw materials during the conveying process, greatly im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com