Cold heading die structure capable of adjusting direction of forming cavity

A forming cavity and cold heading technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problem of large randomness, inability to achieve fine-tuning, and inability to effectively solve product shape and position tolerances, etc. problem, to achieve the effect of easy operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

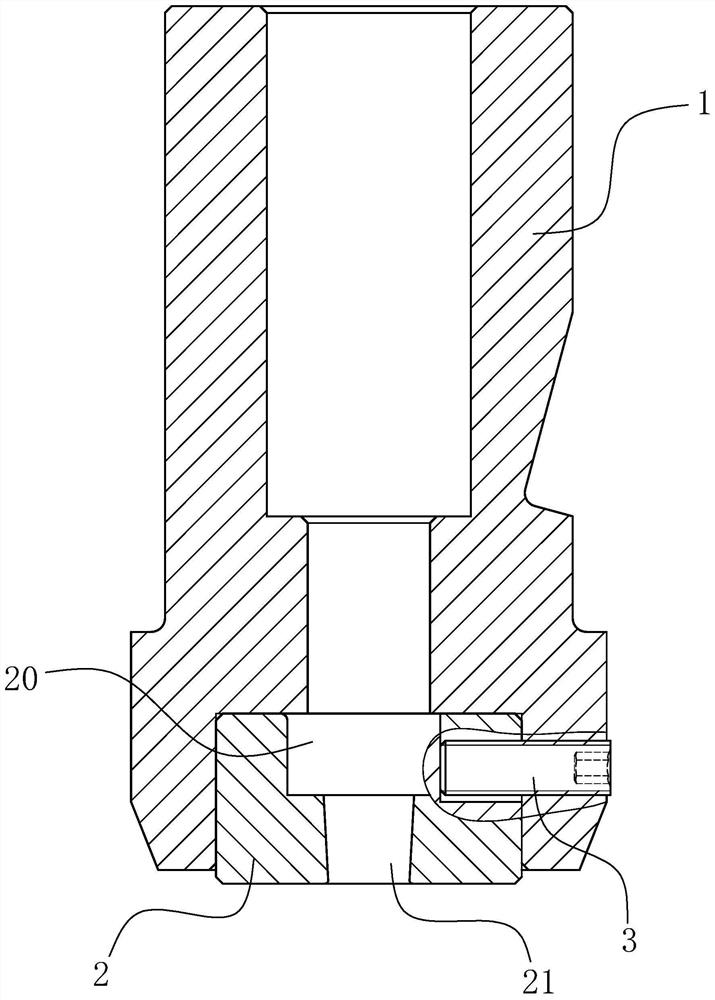

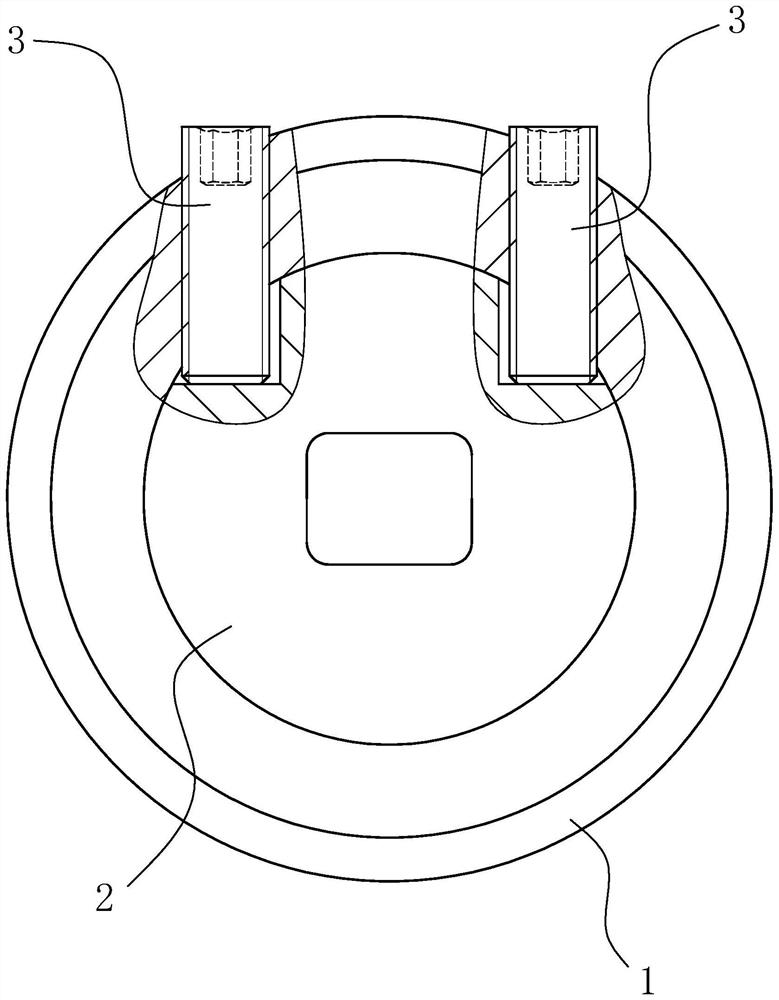

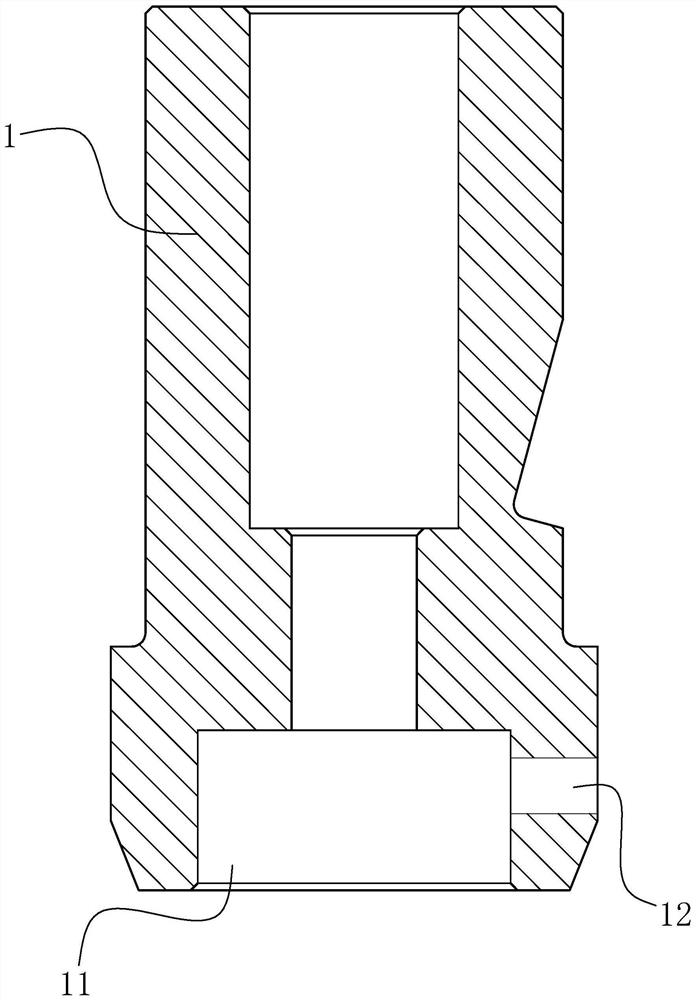

[0025] Such as Figure 1 to Figure 6 As shown, the cold heading die structure capable of adjusting the direction of the forming cavity in this embodiment includes an outer mold shell 1 and an inner mold body 2, the inner mold body 2 is detachably arranged at the bottom of the outer mold shell 1, and the bottom surface of the inner mold body 2 A molding cavity capable of cold heading parts is provided on the top, and an installation cavity 11 capable of installing the inner membrane body 2 is arranged at the bottom of the outer mold shell 1. Threaded holes 12 are distributed on the side wall at the bottom of the outer mold shell 1, and corresponding adjusting screws 3 are screwed in the threaded holes 12. Touching together, when the tail ends of the adjusting screws 3 are respectively screwed to change the length of the top of the correspondin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap