A pipeline sealing structure capable of realizing high-temperature gas leakage safety protection, pipeline sealing and high-temperature gas leakage method

A technology of safety protection and sealing structure, which is applied in the direction of safety valves, pipes/pipe joints/fittings, pipe components, etc., can solve the problem that the impact load is difficult to control accurately, and achieve the effect of simple structure, low maintenance cost and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

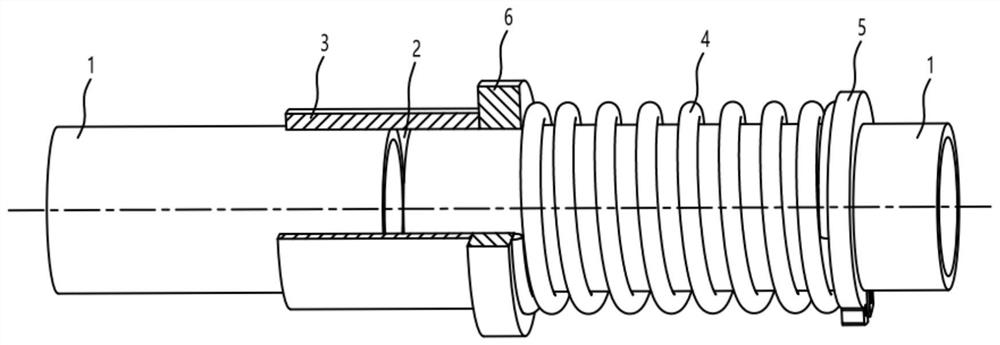

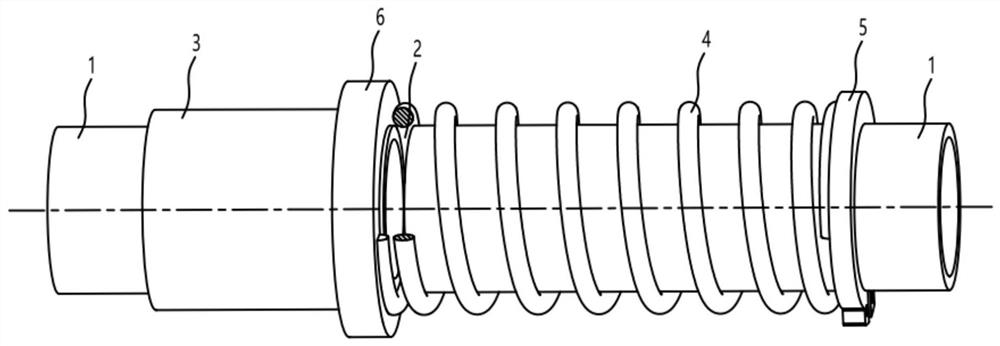

[0028] Such as figure 1 , figure 2As shown, this embodiment provides a pipeline 1 sealing structure that can realize high-temperature gas leakage safety protection, including a gas leakage channel 2 arranged on the pipeline 1, and the gas leakage channel 2 is used for gas leakage protection when the safe working temperature is exceeded. The memory pipe joint 3, the memory spring 4 and the spring retaining ring 5 are sleeved on the pipeline 1. The memory pipe joint 3 and the memory spring 4 are made of memory materials, and the memory inner diameter is the pipe inner diameter when the memory pipe joint 3 returns to the memorized shape , the memory length of the memory spring 4 is the spring length when the memory spring 4 returns to the memory shape, and the memory restoring force of the memory spring 4 is the driving force when the memory spring 4 returns to the memory shape; The memory inner diameter of the memory pipe joint 3 is slightly smaller than the outer diameter of ...

Embodiment 2

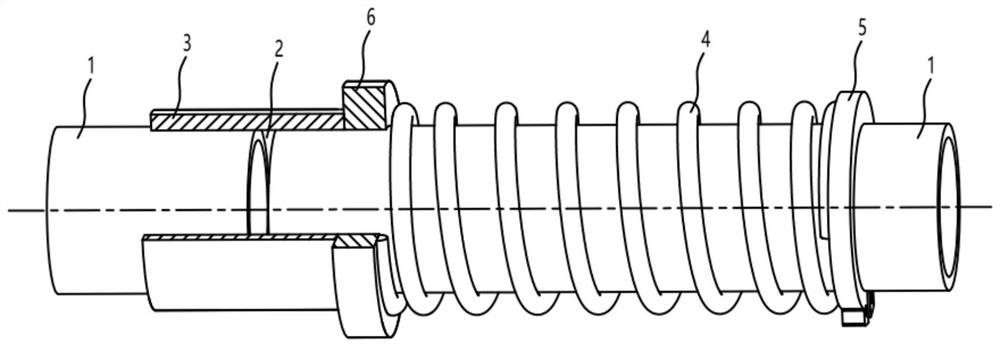

[0036] Different from Embodiment 1, this embodiment provides another sealing structure of pipeline 1 that can realize high-temperature gas leakage safety protection, that is, the memory spring 4 is transformed from a compressed state to a stretched state. Such as image 3 , Figure 4 As shown, it includes the air release channel 2 provided on the pipeline 1, and also includes the memory pipe joint 3, the memory spring 4 and the spring retaining ring 5 which are sleeved on the pipeline 1 in sequence; the memory pipe joint 3 is located at the air release channel 2, The memory inner diameter of the memory pipe joint 3 is smaller than the outer diameter of the pipeline 1 to seal the leak passage 2; the spring retaining ring 5 is fixed on the pipeline 1, and the two ends of the memory spring 4 are fixedly connected to the spring retaining ring 5 and the memory pipe joint 3 respectively, When the memory spring 4 restores the memory shape, it can provide tension. The sum of the memo...

Embodiment 3

[0038] Based on the pipeline 1 sealing structure disclosed in Embodiment 1 and Embodiment 2 that can realize high-temperature gas leakage safety protection, this embodiment provides a method for pipeline 1 sealing and high-temperature gas leakage. Expand the inner diameter of the memory pipe joint 3 to be larger than the outer diameter of the pipeline 1 under variable temperature, set the memory pipe joint 3 on the leak channel 2 on the pipeline 1, and then heat to the austenite phase transition temperature of the memory pipe joint 3 to make the memory The pipe joint 3 shrinks and fastens the pipeline 1 and closes the leak channel 2; however, the heating temperature is lower than the starting temperature of the austenite phase transformation of the memory spring 4, and the memory spring 4 will not restore the memory shape. When the ambient temperature is higher than the critical safe working temperature When the value is higher than the austenite transformation temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com